Modular housing concept with DIN rail connector Modular electronics housings from the BC series are ideal for future-oriented applications in building automation. Scheidl GmbH uses the BC housing system for its Energy Controller.

Customer profile Scheidl GmbH

A relatively new company based in Nuremberg, Germany, Scheidl GmbH specializes in innovative measurement and control technology in heating system installation, with a particular focus on renewable energy and energy efficiency. The Energy Controller is also available as a stand-alone product, a measurement data logger, for monitoring systems by measuring the temperature, detecting the state, and recording meter readings.

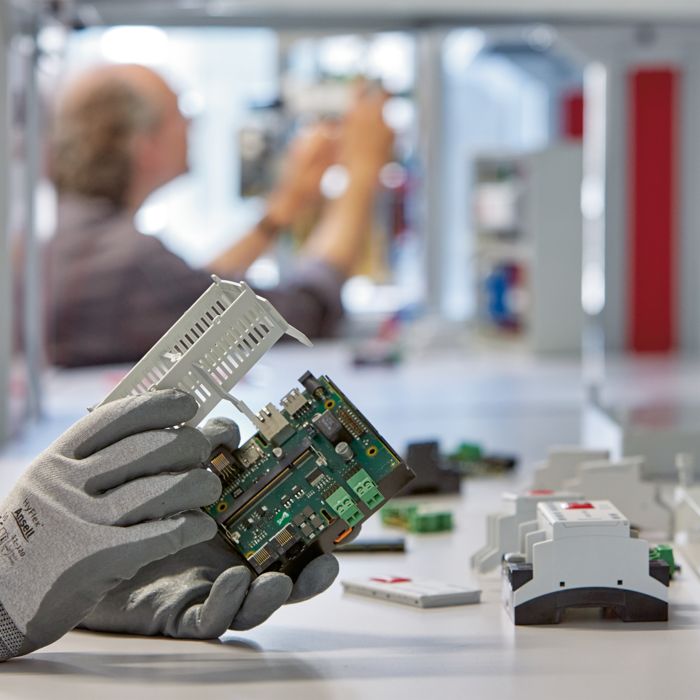

Achim Scheidl and Arno Friedrich use housings from Phoenix Contact for their solutions

The challenge

“A measurement data logger – a device for recording temperatures and energy – makes the functions of complex heating systems transparent”, explains General Manager Achim Scheidl. “Up to now, detailed measured values didn’t really matter, the systems were simple and energy costs weren’t relevant”. New heating systems, especially for the use of renewable forms of energy, are more complex. As Scheidl explains, “You can only get a true understanding of the systems when the electrical and thermal data is evaluated over a long period”.

A great deal of development work went into getting the Energy Controller to the point where it could offer the wide range of functions now available. “With our first generation, we didn’t even look at the housing, we just focused on the functions”, recalls Scheidl. “We had a real mish-mash of parts in different housings, which were connected together by cable.” When it then came time to redesign, Scheidl looked for a suitable housing system for all the device components.

The base module of the Energy Controller is the BC 107 housing from Phoenix Contact

The solution

“With the BC electronics housings from Phoenix Contact, we found a flexible system for basic and extension modules which could be adapted to our design specifications”, states Scheidl. The housing widths from 17.8 mm to 161.6 mm enable the easy setup of different modules with the same housing design.

The generous PCB assembly area simplifies configuration in the layout and development process. Internal PCB guides in all three spatial directions ensure the electronics are installed so that their functions are not impaired – the PCBs are snapped on in different positions, both parallel and orthogonal to the DIN rail.

“The 16-pos. bus connector is the key to our device design”, explains Scheidl. “Data and power are transmitted conveniently in series or in parallel. The wiring effort remains low”.

With the BC electronics housings from Phoenix Contact, we found a flexible system for basic and extension modules which could be adapted to our design specifications.

The combined heat and power plant is accessed via the Internet – the measured data is stored in the Energy Manager

The DIN rail connector also plays an important role on the long journey to the end application – such as a combined heat and power plant.

“With self-establishing, device-to-device contacting without additional wiring, it is easier to configure our Energy Manager”, explains Arno Friedrich, General Manager of Optimus Meine Energie GmbH. “Even fast installation on site and subsequent module replacement without breaking up the topology can be done easily by hand”.

As a customer and cooperation partner of Scheidl GmbH, Optimus Meine Energie GmbH uses the Energy Controller as a central component for its Energy Manager. The Energy Manager is used, for example, in the combined heat and power plants of the regional energy supplier Rewag in Regensburg, Germany. The heating systems with combined heat and power are thereby controlled according to demand and in a coordinated manner. All relevant operating data can be read by means of remote access, and in the event of malfunctions, the operator is immediately informed automatically. This eliminates the need for time-consuming on-site appointments to check the system, thereby increasing availability.

Easy module replacement with DIN rail connectors

Optimus not only handles the installation, the company also offers energy monitoring as a complete package and as a service for the operator – the modular DIN rail housing concept also plays an important role here.

“With this modular concept, we’re able to precisely configure our Energy Manager for every system and easily make modifications during the course of operation”, explains Friedrich. “If at any time the operator would like an additional unit, it’s just a case of adding another module from Scheidl”. Hot-plugging is supported – the device does not have to be shut down and there is no additional software to install either.

Products BC modular electronics housings

Modular electronics housings from the BC series are ideal for future-oriented applications in building automation. The DIN rail housings for the control cabinet impress with their contemporary design, optional touch displays and membrane keypads, versatile PCB connection technology, and 8- or 16-pos. DIN rail connectors.

Conclusion

A measurement data logger makes the functions of complex heating systems transparent by recording detailed measured values. This is particularly important for modern heating systems that use renewable energy.

Scheidl GmbH developed the Energy Controller and opted for the flexible BC housing system from Phoenix Contact. This housing enables the easy setup and replacement of modules and reduces wiring effort.

Optimus Meine Energie GmbH uses this Energy Controller for its Energy Managers, which are used in combined heat and power plants, for example. The modular concept enables the Energy Managers to be easily adapted for every system.