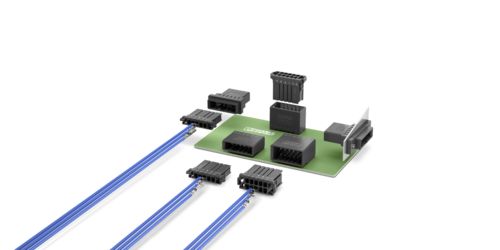

PCB connectors with crimp contacts for easy assembly

CONNEXIS reduces time and labor costs

Middletown, Pa. – The new CONNEXIS PCB connectors from Phoenix Contact use crimp contacts and spring wire termination to help manufacturers reduce time and labor costs. The preassembled wire-to-board connectors simplify connection and accelerate automated production.

The connectors and headers have integrated coding to prevent mismatching. Phoenix Contact can also provide customer-specific printing options for easier wiring. This precision and connection speed are valuable in robotics, energy storage systems, and building automation applications.

The CONNEXIS portfolio includes numerous options for design flexibility. Users can select from horizontal, vertical, and feedthrough orientations, one or two levels, and a range of positions. Three different pitches are available: 2.5 mm (D21), 3.81 mm (D31), and 5.08 mm (D32).

Phoenix Contact offers design-in support with M-CAD/E-CAD data during device development. The connectors are made with halogen-free plastics to support environmental sustainability. Learn more at www.phoenixcontact.com/connexis.

Press Contact