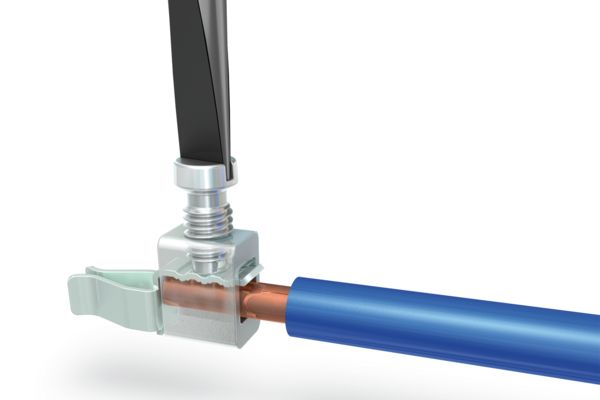

When the clamping space is tightened, the screw presses the conductor against the terminal base via a highly elastic wire guard.

The screw connection is a global standard. Screw connection technology from Phoenix Contact features maintenance-free conductor connection and offers maximum versatility with the multi-conductor connection.

With screw connections, you can achieve the highest contact forces regardless of the conductor cross-section. In conjunction with high-quality surfaces and copper alloys, the forces ensure gas-tight contact points. They ensure long-term stable connections with permanently low contact resistance, even under aggressive ambient conditions.

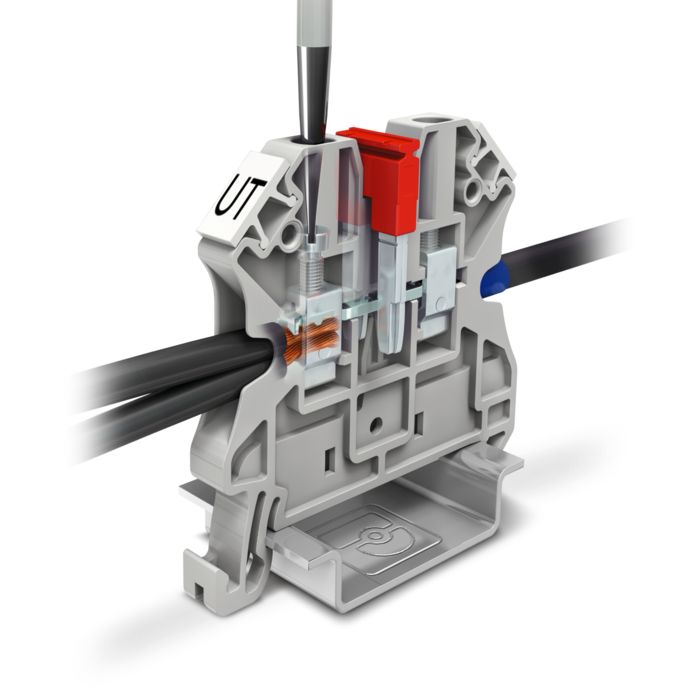

When tightening UT terminal blocks, the screwdriver remains at a constant height. The terminal sleeve is pulled upwards by way of the elevator principle. The screw braces against the current bar. The conductor is securely routed through the terminal sleeve below the current bar and is therefore protected against exposure to the radial forces of the screw.

The integrated Reakdyn principle makes re-tightening connection screws unnecessary and prevents the connection from being inadvertently disengaged. In conjunction with the Reakdyn groove, the force applied deforms the tension sleeve in the elastic area. The result is a screw locking mechanism that protects the thread.

When the clamping space is closed, the tension sleeve presses the conductor firmly against the busbar. The conductor is protected by zero rotational movement and the distribution of the high clamping force over the large contact surfaces. This ensures a permanently reliable connection.

The product range extends from compact solutions with a 2.5 mm pitch with currents up to 6 A to a 20 mm pitch with currents up to 232 A.

Screw connections from Phoenix Contact are available with flange versions, gold versions, different conductor connection directions, with TWIN connectors, screw heads, partially assembled, printed, and with different colors.

When the clamping space is tightened, the screw presses the conductor against the terminal base via a highly elastic wire guard.

As devices become smaller, the conductor cross-sections also need to be smaller. When screw termination technology is used, PRC 20 series connectors rely on a wire guard. This brings two advantages:

First, ferrules are no longer necessary. And it also prevents litz wires from being damaged or sheared off when the screw is tightened.

Second, the use of the wire guard ensures the compact design of the screw terminal point. In particular, this enables multi-position, round connectors to be used in an even more flexibly.

Fixed-position contact inserts for heavy-duty connectors with classic screw connection ensure maintenance-free conductor contact. It is not necessary to retighten the connection screw. Copper conductors from 0.2 mm² to 16 mm² are reliably contacted with a gas-tight seal without pretreatment or with splice protection in the form of ferrules. It is possible to use several conductors under one screw. The wire protection that protects the individual litz wires against damage is located between the screw and the conductor. At the same time, the wire protection acts as a screw locking mechanism to prevent release due to vibrations and temperature fluctuations. The conductive parts of the screw connections are made from high-grade copper alloys that are resistant to stress cracking and corrosion.

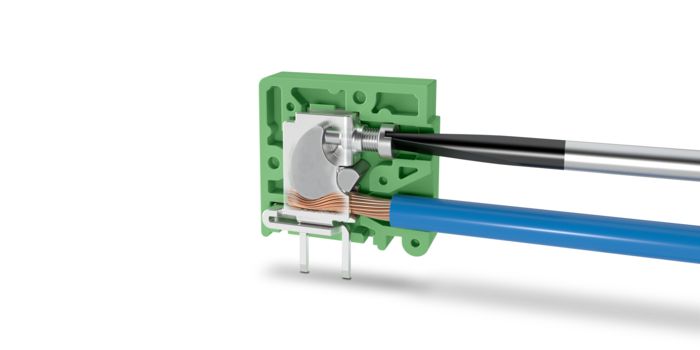

With the front screw connection, the screw actuation and the conductor connection are on the same side of the product. The angled pressure plate redirects and amplifies the contact forces on the conductor. The front screw connection is also suitable for narrow device fronts.

Fixed-position or modular contact inserts for heavy-duty connectors with axial screw connection combine the advantages of screw and crimp connection. The axial screw connection features a low space requirement, is easy to use, and it only requires a standard Allen key.

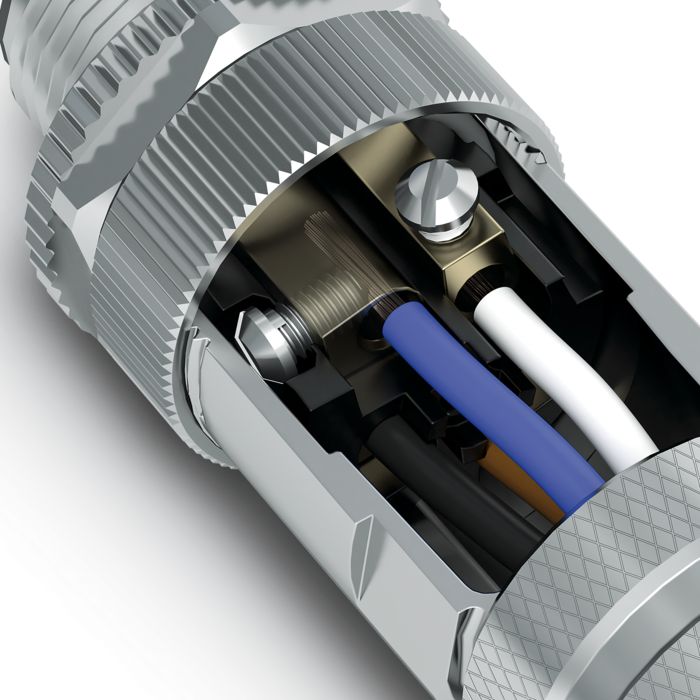

With this technology, the wire end to be contacted is guided into the connection area of the male or female contact. A tapered mandrel (part of the contact) is then screwed into the stranded wire from the front. Radial pressure is applied to the strands of the litz wire, pressing them against the contact wall. This results in a gas-tight connection with long-term stability between the wire and contact. It is important to observe the specified tightening torque. The mandrel is pressed in using an Allen key, which is applied to the front of the contact.

You can wire different cable lengths flexibly on site with M8 and M12 connectors designed for assembly. The screw connection is among the classic connection technology solutions. All types of copper conductors can be connected reliably without any pretreatment. Shielded and unshielded connectors are available in straight and angled versions for reliable signal and power transmission.