Feed-through terminal block, nom. voltage: 1000 V, nominal current: 125 A, number of connections: 2, connection method: Screw connection, Rated cross section: 35 mm2, cross section: 1.5 mm2 - 50 mm2, mounting type: NS 35/7,5, NS 35/15, color: gray

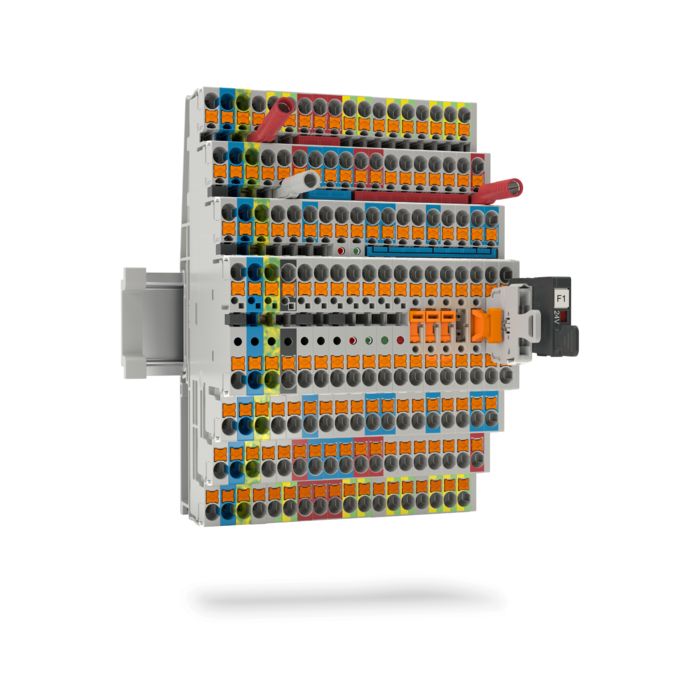

Use the feed-through terminal blocks, multi-level terminal blocks, and multi-conductor terminal blocks from Phoenix Contact for space-saving connection of two or more conductors in just one terminal block. The terminal blocks are characterized by their flexible bridgeability and optimum marking options.

Feed-through terminal block, nom. voltage: 1000 V, nominal current: 125 A, number of connections: 2, connection method: Screw connection, Rated cross section: 35 mm2, cross section: 1.5 mm2 - 50 mm2, mounting type: NS 35/7,5, NS 35/15, color: gray

Protective conductor terminal block, number of connections: 4, connection method: Push-in connection, Rated cross section: 2.5 mm2, cross section: 0.14 mm2 - 4 mm2, mounting type: NS 35/7,5, NS 35/15, color: green-yellow

Double-level terminal block, nom. voltage: 500 V, nominal current: 22 A, connection method: Push-in connection, 1st and 2nd level, Rated cross section: 2.5 mm2, cross section: 0.14 mm2 - 4 mm2, mounting type: NS 35/7,5, NS 35/15, color: gray

Feed-through terminal block, nom. voltage: 800 V, nominal current: 24 A, number of connections: 4, connection method: Spring-cage connection, Rated cross section: 2.5 mm2, cross section: 0.08 mm2 - 4 mm2, mounting type: NS 35/7,5, NS 35/15, color: gray

Feed-through terminal block, nom. voltage: 800 V, nominal current: 24 A, number of connections: 2, number of positions: 1, connection method: Push-in connection, Rated cross section: 2.5 mm2, cross section: 0.14 mm2 - 4 mm2, mounting type: NS 35/7,5, NS 35/15, color: blue

Feed-through terminal block, nom. voltage: 800 V, nominal current: 24 A, number of connections: 2, number of positions: 1, connection method: Spring-cage connection, Rated cross section: 2.5 mm2, cross section: 0.08 mm2 - 4 mm2, mounting type: NS 35/7,5, NS 35/15, color: gray

Protective conductor terminal block, number of connections: 2, connection method: Push-in connection, cross section: 0.14 mm2 - 4 mm2, mounting type: NS 35/7,5, NS 35/15, color: green-yellow

Feed-through terminal block, nom. voltage: 1000 V, nominal current: 32 A, number of connections: 2, connection method: Screw connection, Rated cross section: 4 mm2, cross section: 0.14 mm2 - 6 mm2, mounting type: NS 35/7,5, NS 35/15, color: gray

Protective conductor terminal block, number of connections: 2, connection method: Screw connection, Rated cross section: 16 mm2, cross section: 1.5 mm2 - 25 mm2, mounting type: NS 35/7,5, NS 35/15, color: green-yellow

Protective conductor terminal block, When aligning with a feed-through terminal block with the same shape, an end cover must be interposed with insulation voltages of > 690 V, number of connections: 2, connection method: Screw connection, Rated cross section: 4 mm2, cross section: 0.2 mm2 - 6 mm2, mounting method: PE foot with mounting screw, M3, mounting type: NS 35/7,5, NS 35/15, NS 32, color: green-yellow

Discover the new Push-X terminal blocks with a nominal cross-section of 1.5 mm². The terminal blocks enable the wiring of rigid and flexible conductors of between 0.34 and 2.5 mm². Push-X technology allows tool-free installation, even without ferrules.

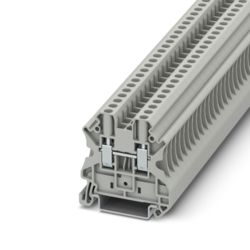

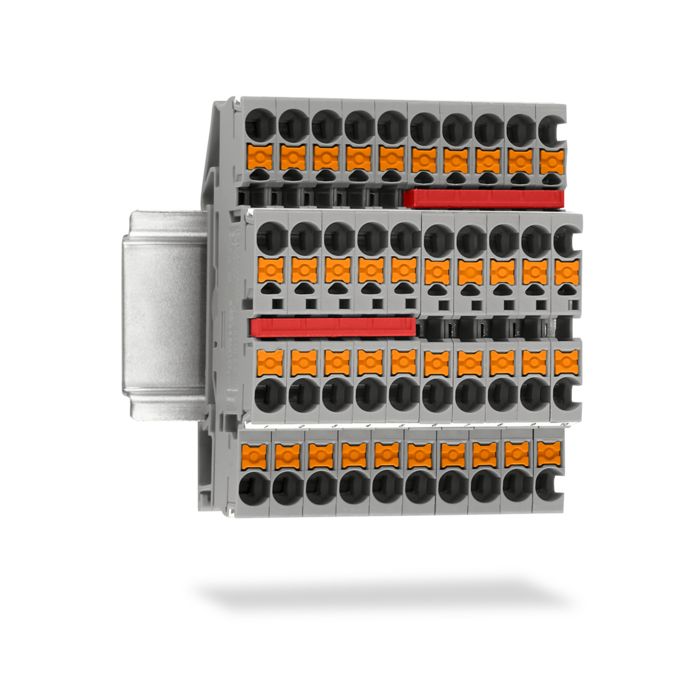

Feed-through terminal blocks

Feed-through terminal blocks are characterized by two terminal points and a compact design. The large cross-section range of the feed-through terminal blocks allows universal use in every application. Along with the standard feed-through terminal blocks for wiring with copper litz wires, for example, Phoenix Contact also provides Al/Cu terminal blocks. The universal terminal blocks enable the connection of aluminum and copper conductors in just one terminal block.

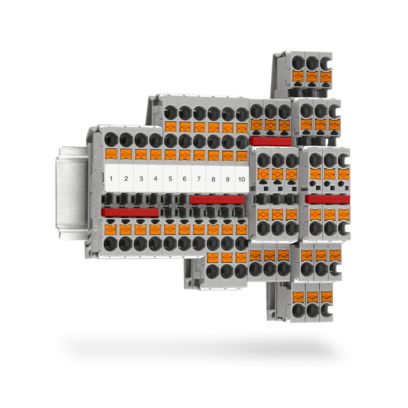

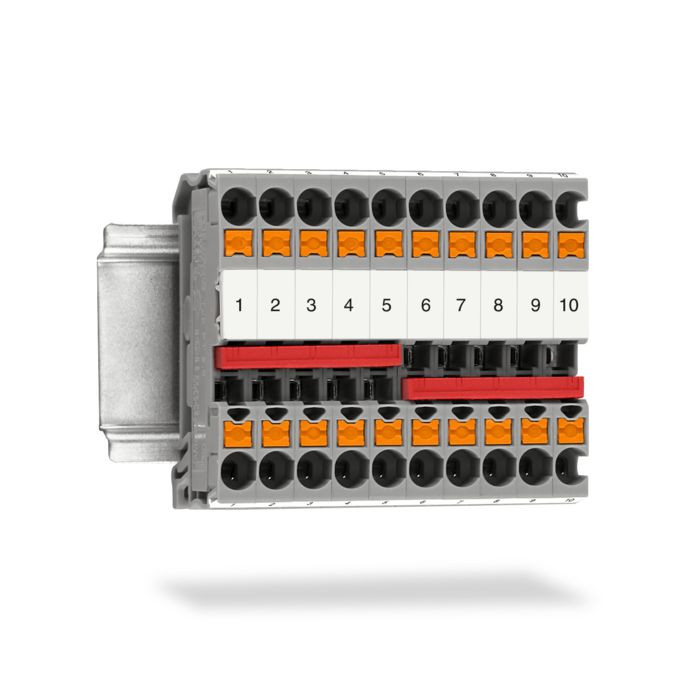

Multi-conductor terminal blocks

Even more compact wiring is possible with the multi-conductor terminal blocks from Phoenix Contact. Multi-conductor terminal blocks are feed-through terminal blocks with three or four connections that are all routed via the same current bar. This allows you to connect up to four conductors with individual wiring per terminal block. The design of the terminal blocks means that fewer terminal blocks and supply lines are required for wiring. Along with an improved overview, this also enables wiring or potential distribution in tight spaces.

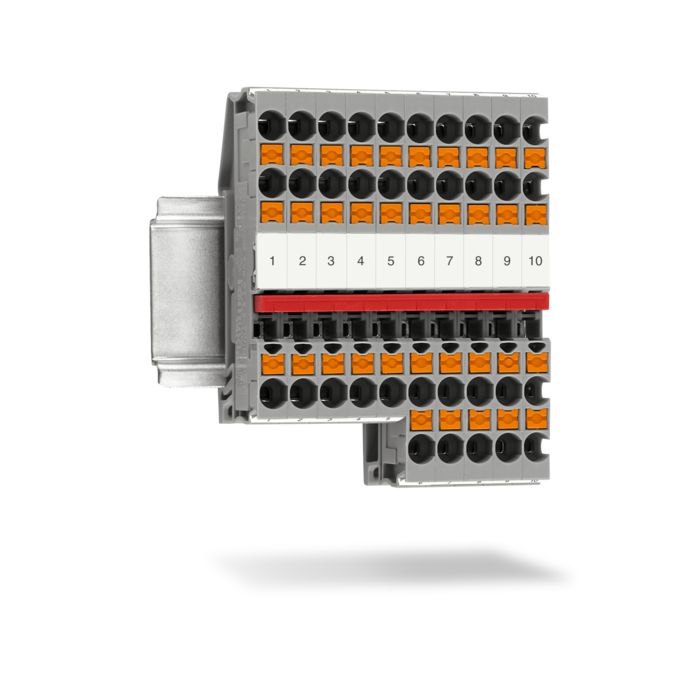

Double-level terminal blocks

Compared to the feed-through terminal blocks, the double-level terminal blocks enable even higher wiring density and greater flexibility than the multi-conductor terminal blocks. To put it simply, double-level terminal blocks are two feed-through terminal blocks in one terminal block. To make this possible, the terminal blocks have two levels, each of which carries a potential. If necessary, these levels can be quickly and easily connected with vertical PV bridges, which means that the double-level terminal blocks can also be used as multi-conductor terminal blocks. To reduce manual bridging effort, the portfolio also includes terminal blocks with permanently integrated bridging. These versions have “PV” in the product name. The double-level terminal blocks with lateral conductor connection feature offset levels. The offset enables unhindered access to the lower connection level and its push button or screw, even when fully wired.

Multi-level terminal blocks

Multi-level terminal blocks are terminal blocks that have multiple levels. Unlike double-level terminal blocks, they usually have three or four levels, but are similar in design to double-level terminal blocks. Each of the levels carries its own potential. Depending on the terminal block version, either just the top two levels or all levels can be connected easily with vertical bridging. In addition to the normal versions, those with integrated PV bridging are also available. With those, manual bridging is not necessary because all levels are connected at the factory. In addition to the simple feed-through versions, the range of four-level terminal blocks and three-level terminal blocks also include versions with one or more functional levels. The function level usually has a disconnect zone in which either a knife disconnection or a universal disconnect zone for various function connectors is installed. The portfolio also includes special motor terminals for the space-saving connection of three-phase motors. The bridging option for simple phase bridging on each level reduces the wiring time.

Efficient planning with clipx ENGINEER

The clipx ENGINEER engineering software makes it possible to plan and procure terminal strips, assembled mounting plates, and junction boxes more efficiently than ever, and to seamlessly transfer the data to production – at every workplace. Accelerate your planning process with smart interfaces to your CAE program and to Phoenix Contact applications and configurators.

Terminal blocks product brochure

Would you like to get printed materials about our terminal blocks? Below you will find various brochures on the subject of terminal blocks. In addition to the product brochure, you will find a brochure about the CLIPLINE complete terminal block system and about the quality tests for the terminal blocks.