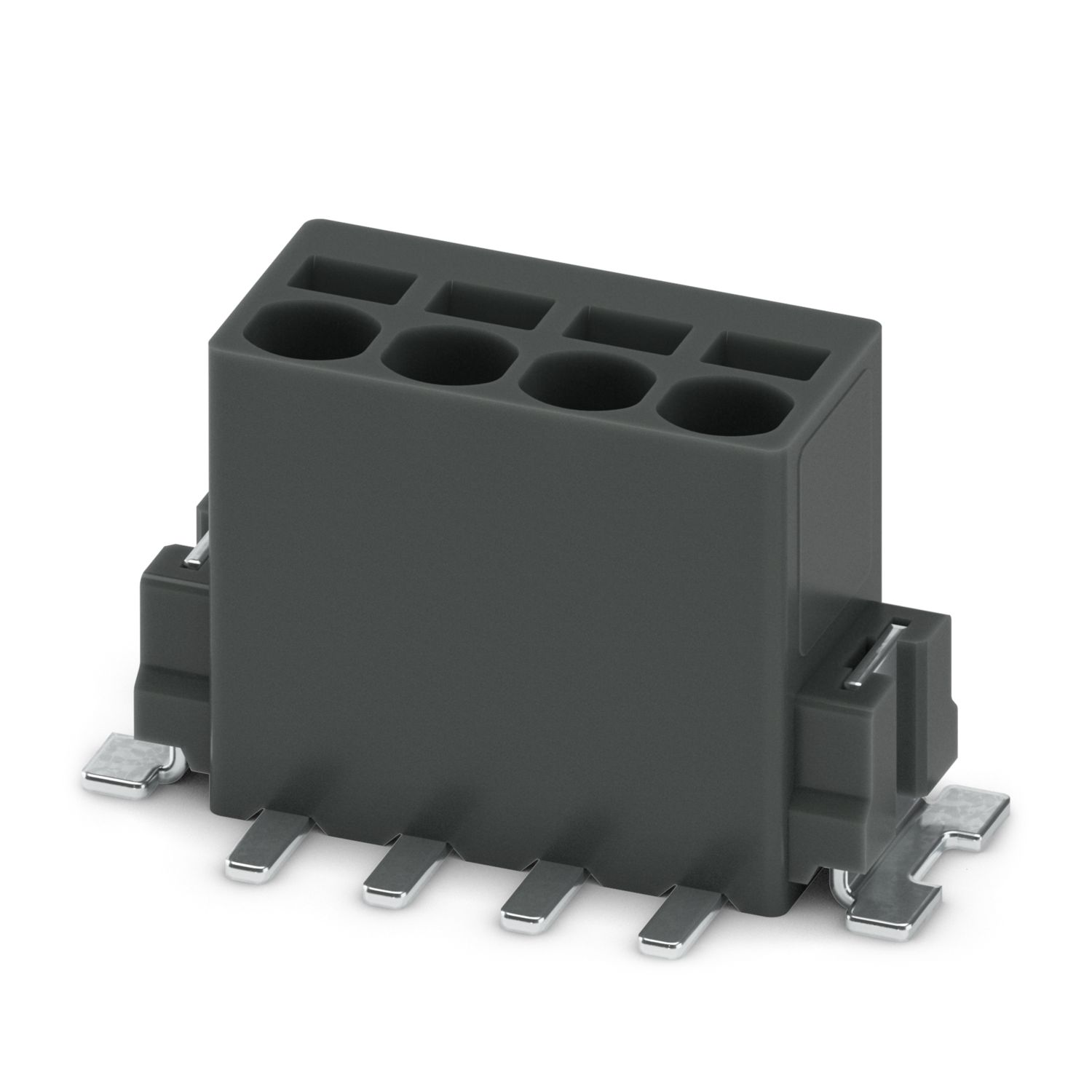

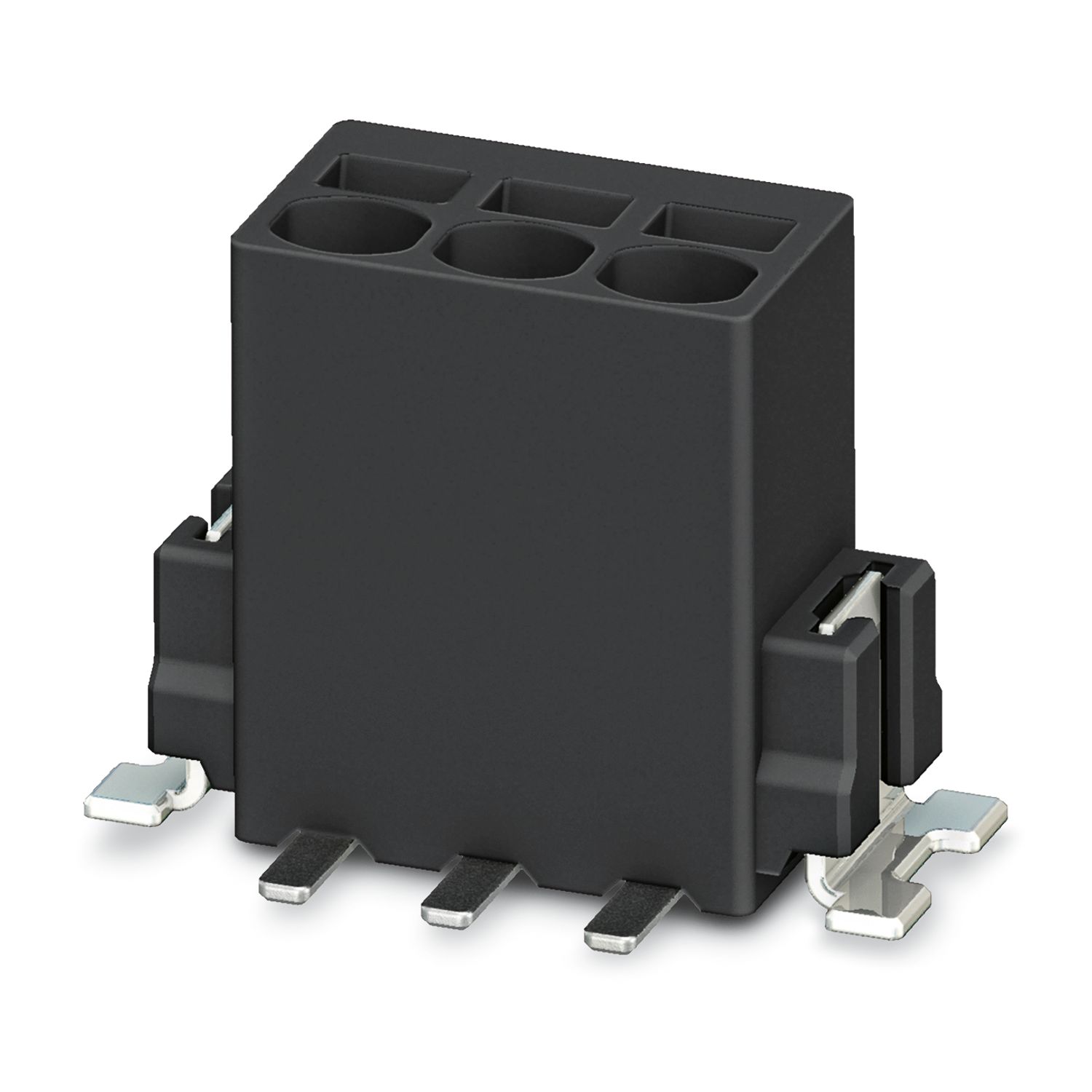

SAMPLE PTSM 0,5/ 4-2,5-V-SMD

-

PCB terminal block

1701086

Printed circuit board terminal, nominal current: 6 A, rated voltage (III/2): 160 V, nominal cross section: 0.5 mm2, number of potentials: 4, number of rows: 1, number of positions per row: 4, product range: PTSM 0,5/..-V-SMD, pitch: 2.5 mm, connection method: Push-in spring connection, mounting: SMD soldering, conductor/PCB connection direction: 90 °, color: black, Pin layout: Linear pad geometry, number of solder pins per potential: 1, type of packaging: packed in cardboard. SAMPLE set with 5 items in belt section. When used as part of soldering process, please use items without SAMPLE marking

Product details

| Product type | Printed circuit board terminal |

| Product family | PTSM 0,5/..-V-SMD |

| Product line | COMBICON Terminals XS |

| Number of positions | 4 |

| Pitch | 2.5 mm |

| Number of connections | 4 |

| Number of rows | 1 |

| Number of potentials | 4 |

| Pin layout | Linear pad geometry |

| Solder pins per potential | 1 |

| Properties | |

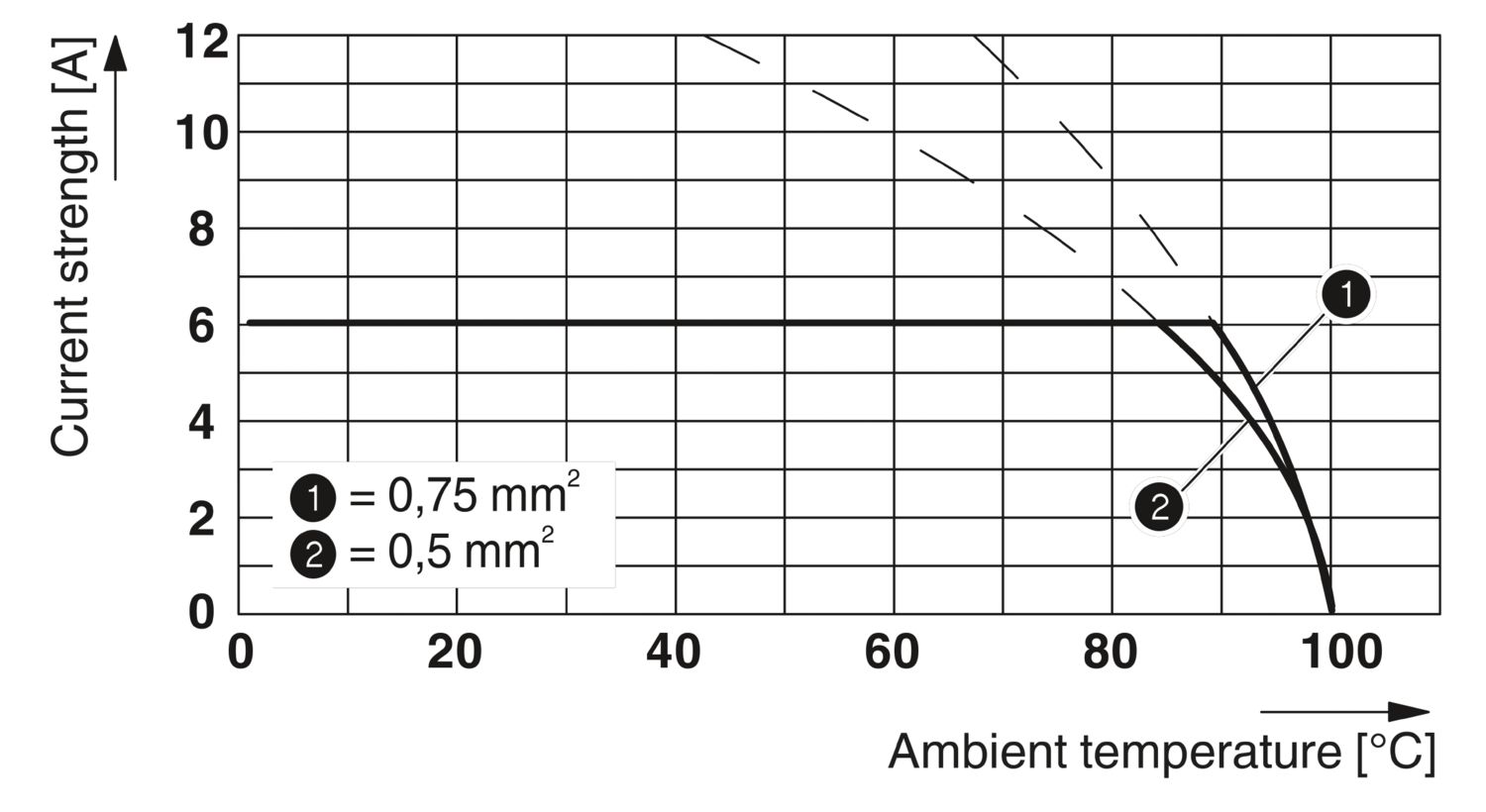

| Nominal current IN | 6 A |

| Nominal voltage UN | 160 V |

| Rated voltage (III/3) | 32 V |

| Rated surge voltage (III/3) | 2.5 kV |

| Rated voltage (III/2) | 160 V |

| Rated surge voltage (III/2) | 2.5 kV |

| Rated voltage (II/2) | 160 V |

| Rated surge voltage (II/2) | 2.5 kV |

| Connection technology | |

| Nominal cross section | 0.5 mm² |

| Conductor connection | |

| Connection method | Push-in spring connection |

| Conductor cross-section rigid | 0.14 mm² ... 0.5 mm² |

| Conductor cross-section flexible | 0.2 mm² ... 0.5 mm² (up to 0.75 mm² supported, with a stripping length of 7.5 mm and a rated insulation voltage of 32 V at III/2) |

| Conductor cross-section AWG | 26 ... 20 |

| Conductor cross-section flexible, with ferrule without plastic sleeve | 0.25 mm² ... 0.5 mm² |

| Conductor cross-section, flexible, with ferrule, with plastic sleeve | 0.25 mm² ... 0.34 mm² (possible from 0.14 mm², when using ferrule AI 0.14- 6 GY in combination with crimping pliers CRIMPFOX 10T-F) |

| Cylindrical gauge a x b / diameter | - / 1.2 mm |

| Stripping length | 6 mm |

| Mounting type | SMD soldering |

| Pin layout | Linear pad geometry |

| Processing notes | |

| Process | Reflow soldering |

| Moisture Sensitive Level | MSL 1 |

| Classification temperature Tc | 260 °C |

| Solder cycles in the reflow | 3 |

| Material data - contact | |

| Note | WEEE/RoHS-compliant, free of whiskers according to IEC 60068-2-82/JEDEC JESD 201 |

| Contact material | Cu alloy |

| Surface characteristics | hot-dip tin-plated |

| Metal surface terminal point (top layer) | Tin (4 - 8 µm Sn) |

| Metal surface soldering area (top layer) | Tin (4 - 8 µm Sn) |

| Material data - housing | |

| Color (Housing) | black (9005) |

| Insulating material | LCP |

| Insulating material group | IIIa |

| CTI according to IEC 60112 | 175 |

| Flammability rating according to UL 94 | V0 |

| Note on application | Pick and place pads may protrude beyond the components. The PCB layout must ensure that collisions are avoided when components are assembled. |

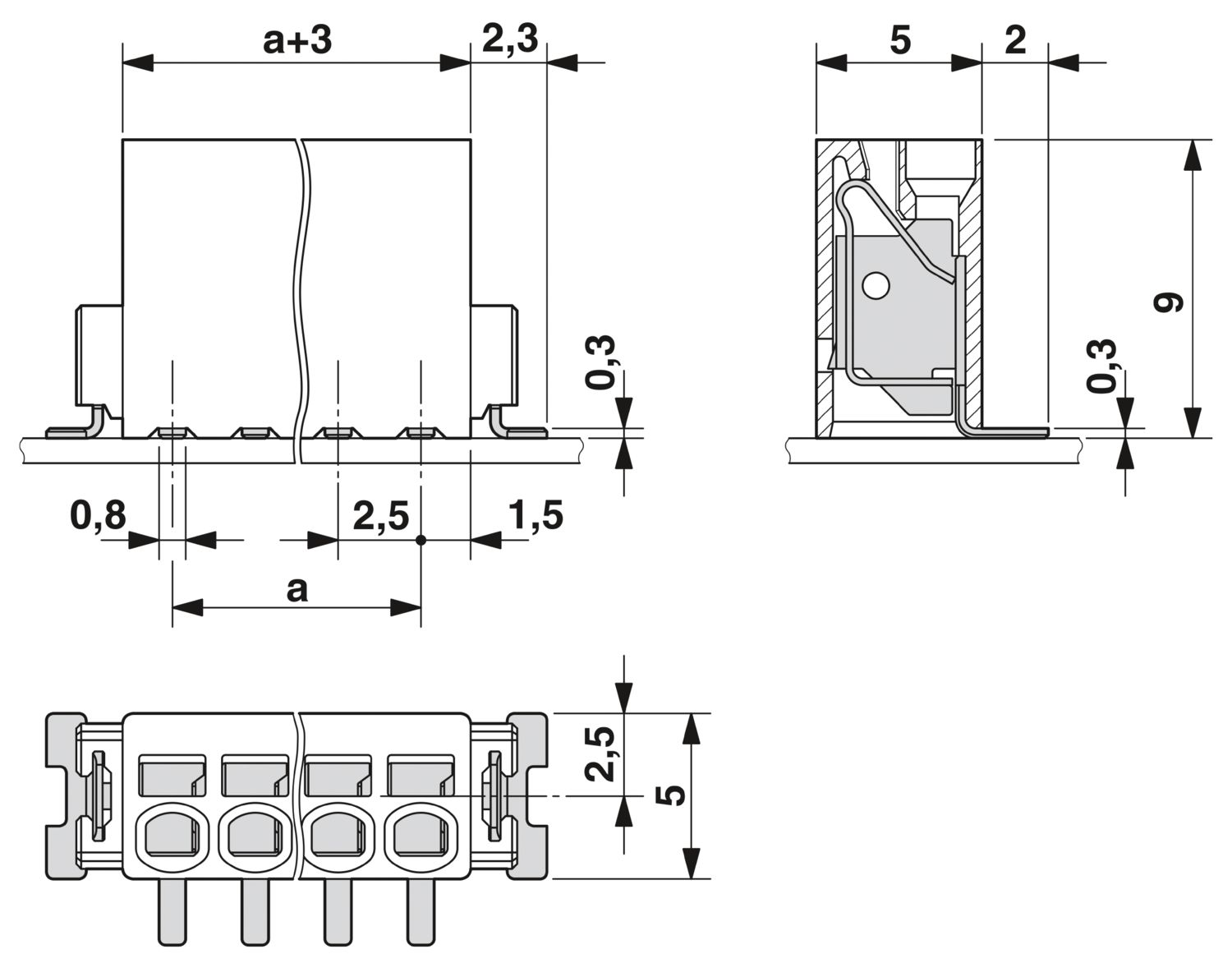

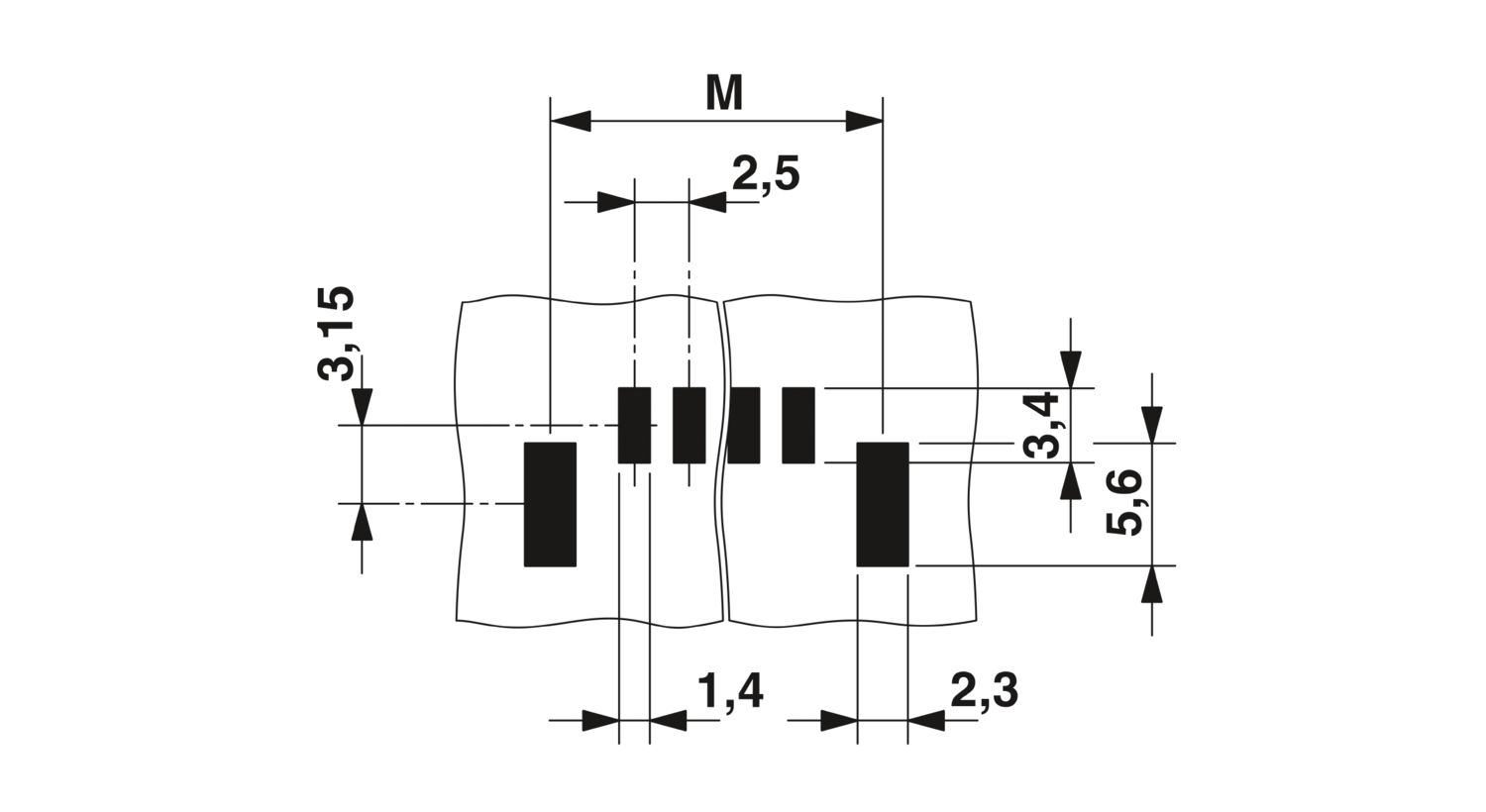

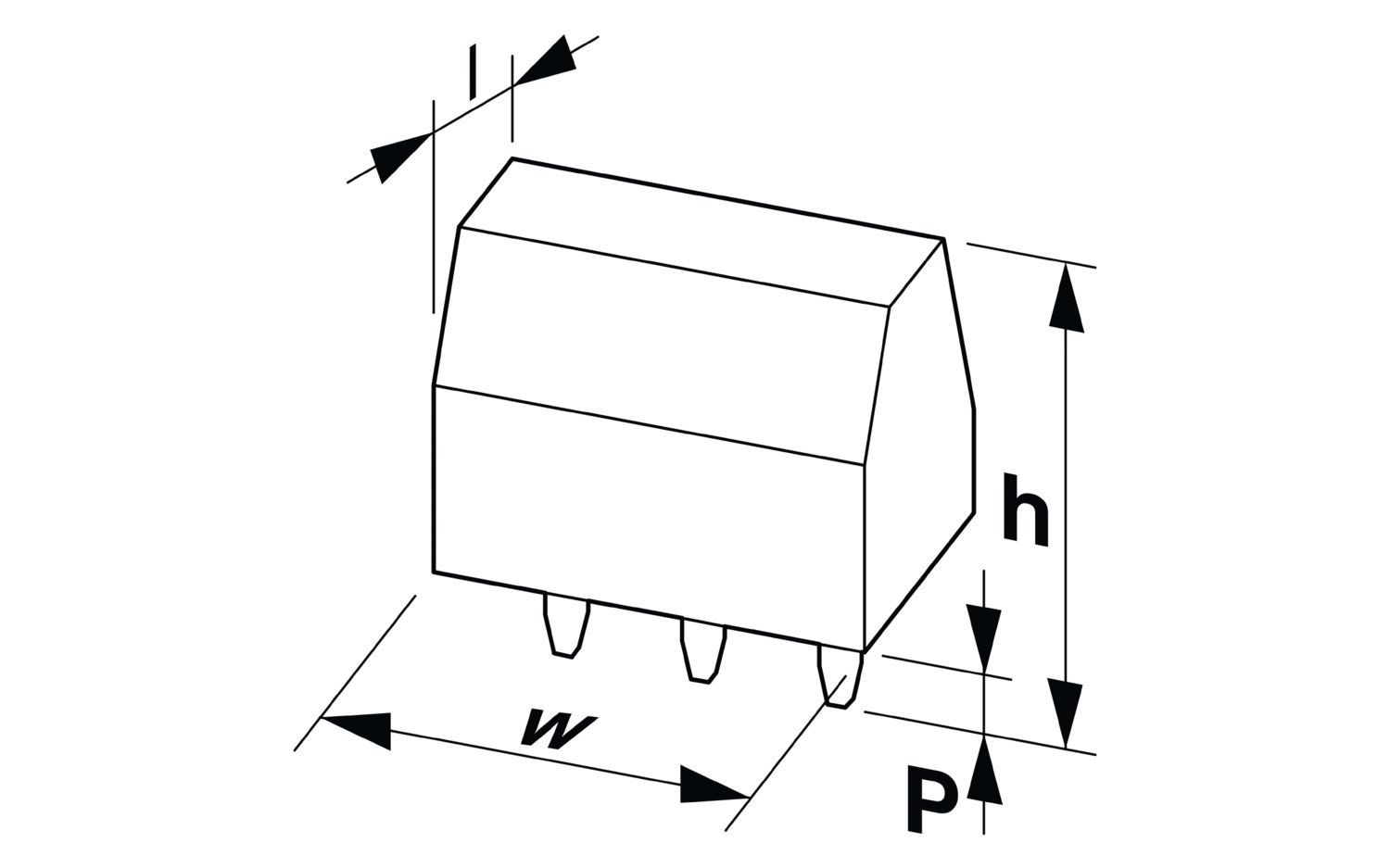

| Dimensional drawing |

|

| Pitch | 2.5 mm |

| Width [w] | 15.1 mm |

| Height [h] | 9 mm |

| Length [l] | 7 mm |

| PCB design | |

| Pad geometry | 1.4 x 3.4 mm |

| Pin spacing | 2.5 mm |

| Connection test | |

| Specification | IEC 60998-2-2:2002-12 |

| Result | Test passed |

| Test for conductor damage and slackening | |

| Specification | IEC 60998-2-2:2002-12 |

| Result | Test passed |

| Pull-out test | |

| Specification | IEC 60998-2-2:2002-12 |

| Conductor cross-section/conductor type/tractive force setpoint/actual value | 0.14 mm² / solid / > 10 N |

| 0.2 mm² / flexible / > 10 N | |

| 0.5 mm² / solid / > 20 N | |

| 0.75 mm² / flexible / > 30 N | |

| Flexion test | |

| Specification | IEC 60998-2-2:2002-12 |

| Result | Test passed |

| Temperature-rise test | |

| Specification | IEC 60998-2-1:2002-12 |

| Requirement temperature-rise test | Increase in temperature ≤ 45 K |

| Insulation resistance | |

| Specification | IEC 60998-1:2002-12 |

| Insulation resistance, neighboring positions | > 5 MΩ |

| Air clearances and creepage distances | | |

| Specification | IEC 60664-1:2007-04 |

| Insulating material group | IIIa |

| Comparative tracking index (IEC 60112) | CTI ≥175 to <400 |

| Rated insulation voltage (III/3) | 32 V |

| Rated surge voltage (III/3) | 2.5 kV |

| minimum clearance value - non-homogenous field (III/3) | 1.5 mm |

| minimum creepage distance (III/3) | 1.3 mm |

| Rated insulation voltage (III/2) | 160 V |

| Rated surge voltage (III/2) | 2.5 kV |

| minimum clearance value - non-homogenous field (III/2) | 1.5 mm |

| minimum creepage distance (III/2) | 1.6 mm |

| Rated insulation voltage (II/2) | 160 V |

| Rated surge voltage (II/2) | 2.5 kV |

| minimum clearance value - non-homogenous field (II/2) | 1.5 mm |

| minimum creepage distance (II/2) | 1.6 mm |

| Vibration test | |

| Specification | IEC 60068-2-6:2007-12 |

| Frequency | 10 - 150 - 10 Hz |

| Sweep speed | 1 octave/min |

| Amplitude | 0.35 mm (10 Hz ... 60.1 Hz) |

| Acceleration | 5g (60.1 Hz ... 150 Hz) |

| Test duration per axis | 2.5 h |

| Test directions | X-, Y- and Z-axis |

| Glow-wire test | |

| Specification | IEC 60998-1:2002-12 |

| Temperature | 850 °C |

| Time of exposure | 5 s |

| Ambient conditions | |

| Ambient temperature (operation) | -40 °C ... 100 °C (Depending on the current carrying capacity/derating curve) |

| Ambient temperature (storage/transport) | -40 °C ... 70 °C |

| Relative humidity (storage/transport) | 30 % ... 70 % |

| Ambient temperature (assembly) | -5 °C ... 100 °C |

| Type of packaging | packed in cardboard |

| Item number | 1701086 |

| Packing unit | 5 pc |

| Minimum order quantity | 5 pc |

| Sales key | AACBBA |

| Product key | AAKDAC |

| GTIN | 4046356515061 |

| Weight per piece (including packing) | 1.89 g |

| Weight per piece (excluding packing) | 1.71 g |

| Country of origin | IN |

ECLASS

| ECLASS-13.0 | 27460101 |

| ECLASS-15.0 | 27460101 |

ETIM

| ETIM 9.0 | EC002643 |

UNSPSC

| UNSPSC 21.0 | 39121400 |

| EU RoHS | |

| Fulfills EU RoHS substance requirements | Yes (No exemptions) |

| China RoHS | |

| Environment friendly use period (EFUP) |

EFUP-E

No hazardous substances above the limits

|

| EU REACH SVHC | |

| REACH candidate substance (CAS No.) | No substance above 0.1 wt% |

Compatible products

Your advantages

Time saving push-in connection, tools not required

Defined contact force ensures that contact remains stable over the long term

High current carrying capacity of 6 A in very compact dimensions

Designed for integration into the SMT soldering process

Vertical connection enables multi-row arrangement on the PCB

Additional solder anchors reduce the mechanical strain on the soldering spots

PHOENIX CONTACT Ltd

Unit 15C, 906-930 Great South Road, Penrose, Auckland 1061, New Zealand