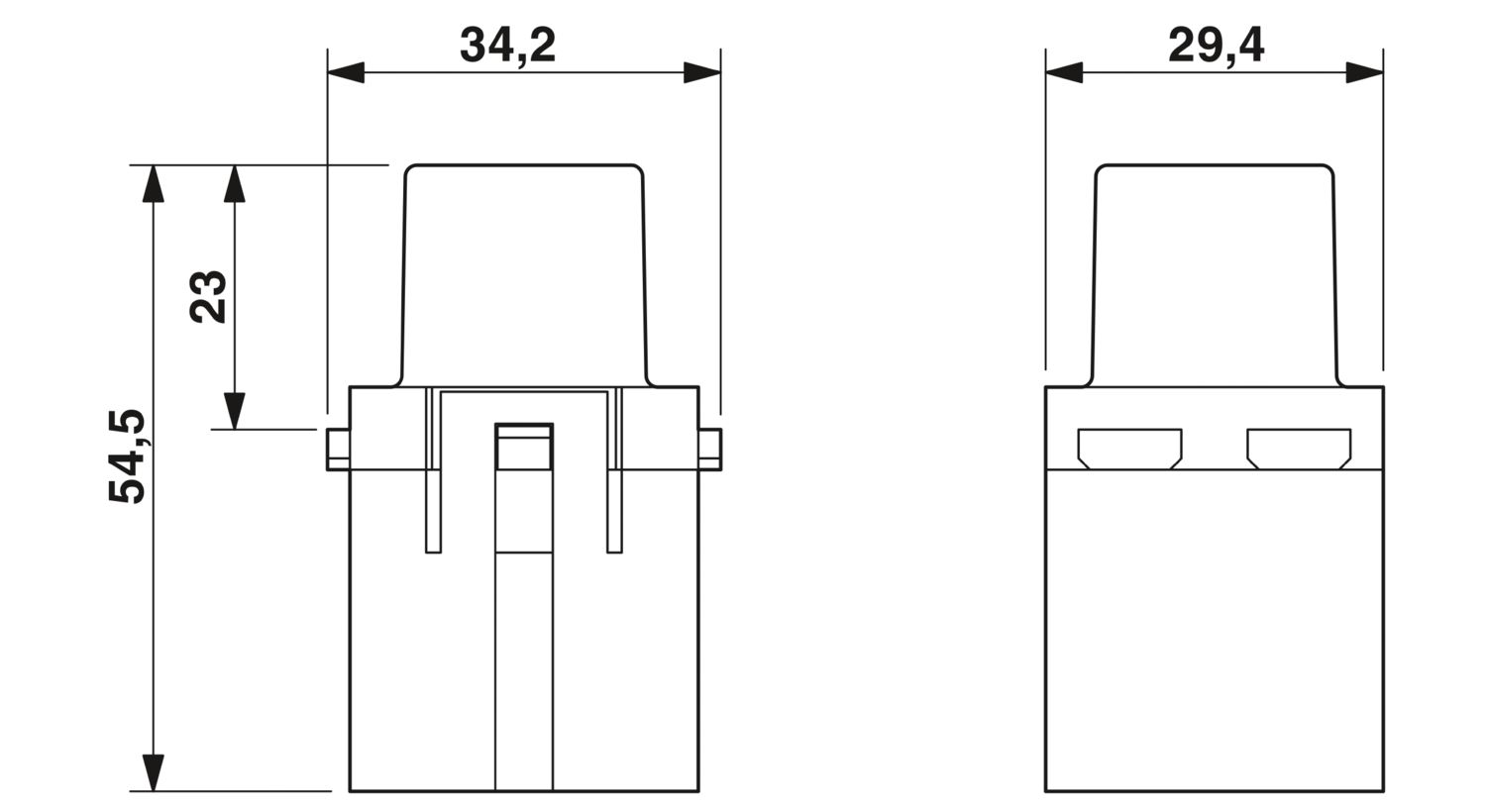

HC-M-HS 200/40-MOD-ST

-

Contact insert module

1637168

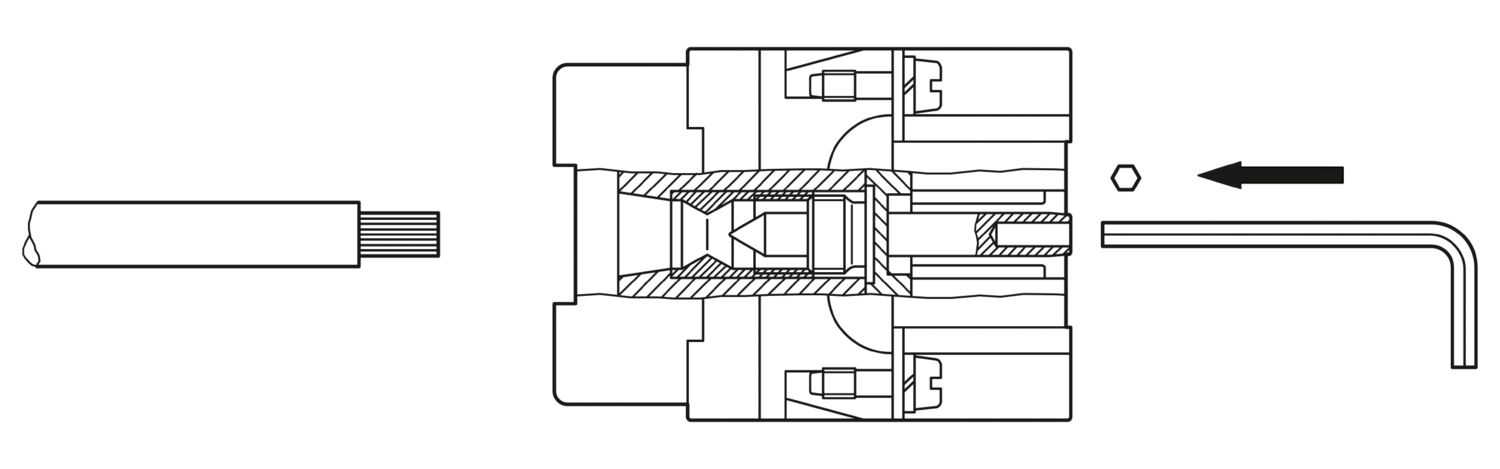

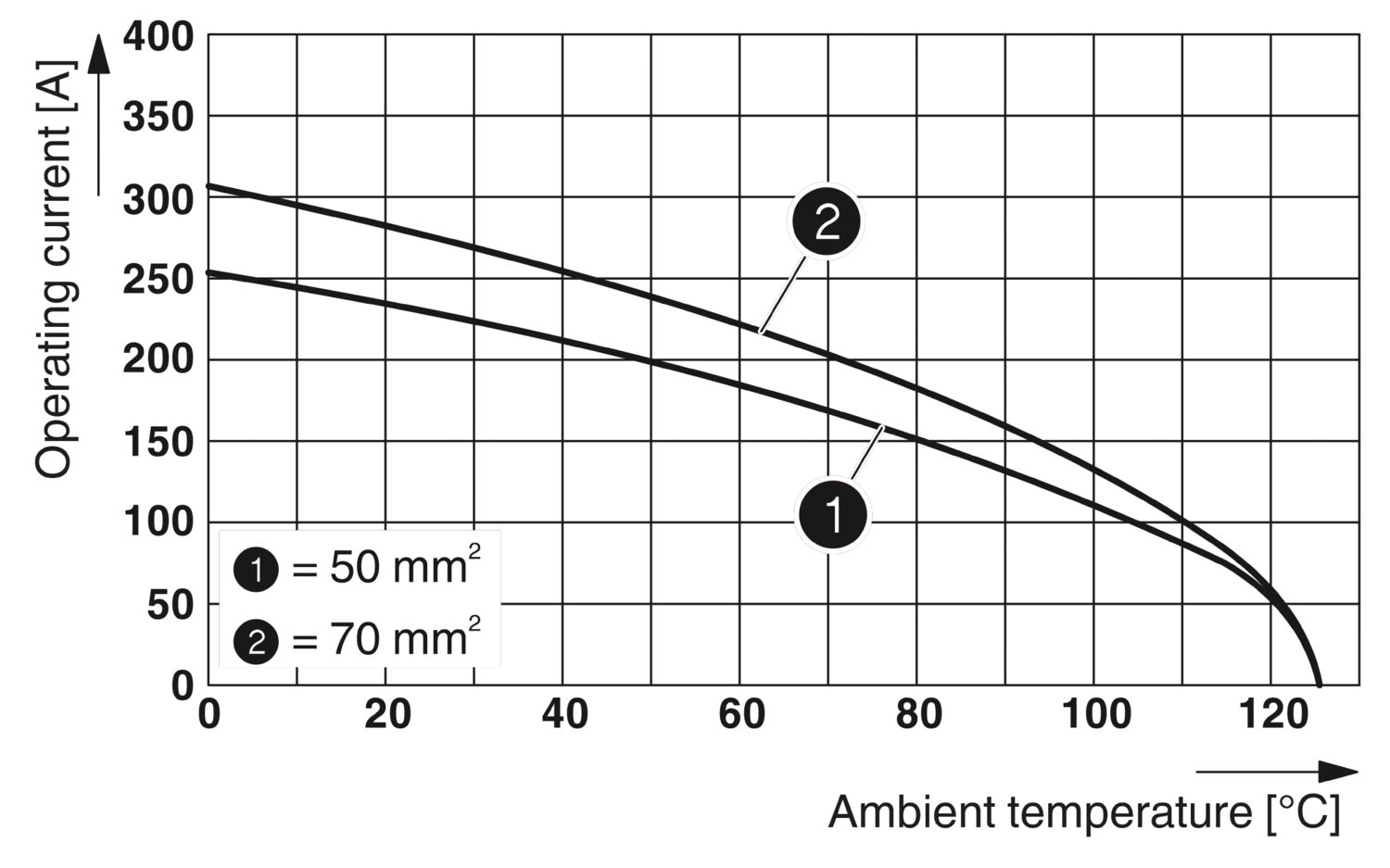

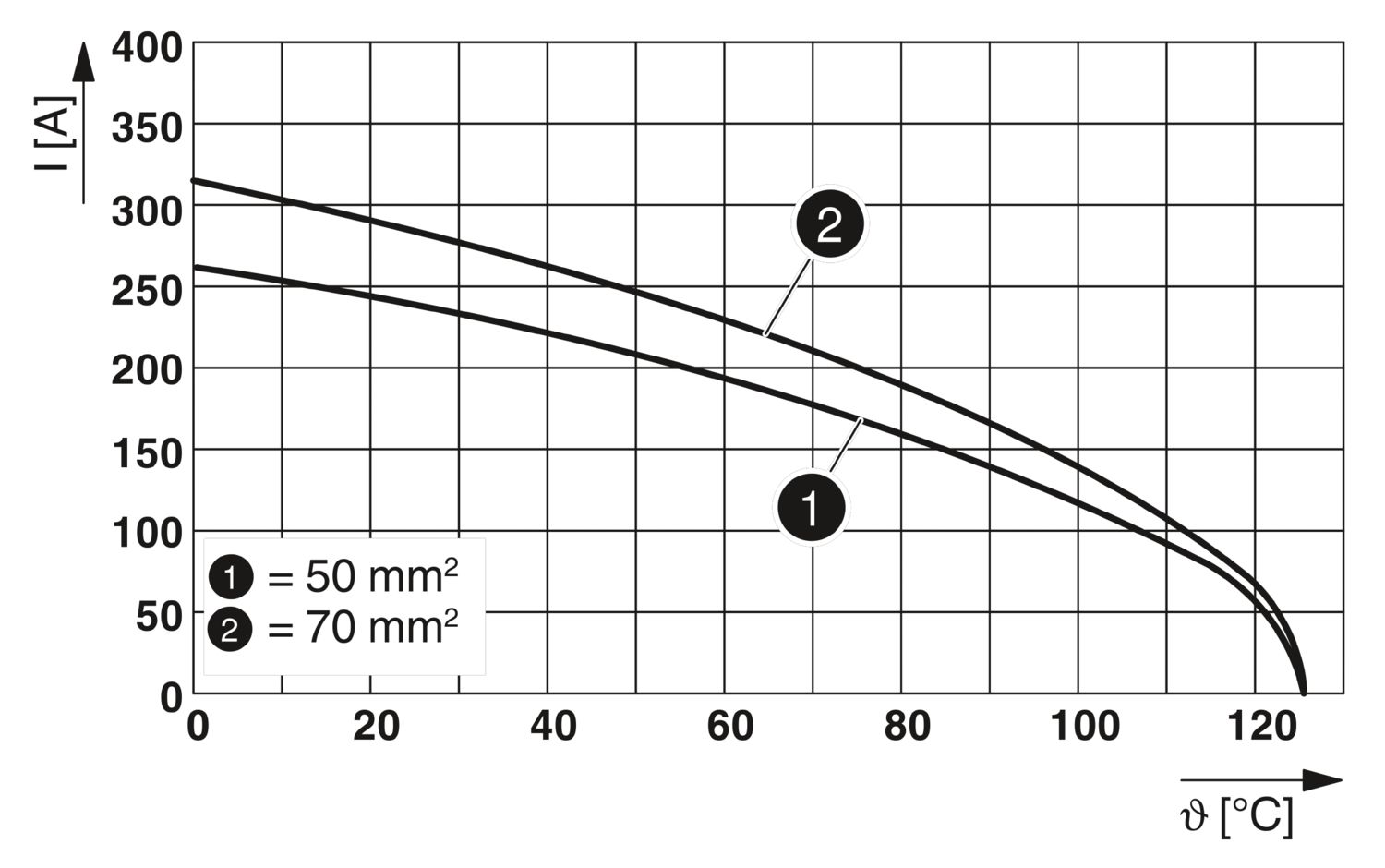

HEAVYCON contact insert module, connector, 1-pos., for axial screw connection, 200 A, 25 mm2 ... 40 mm2