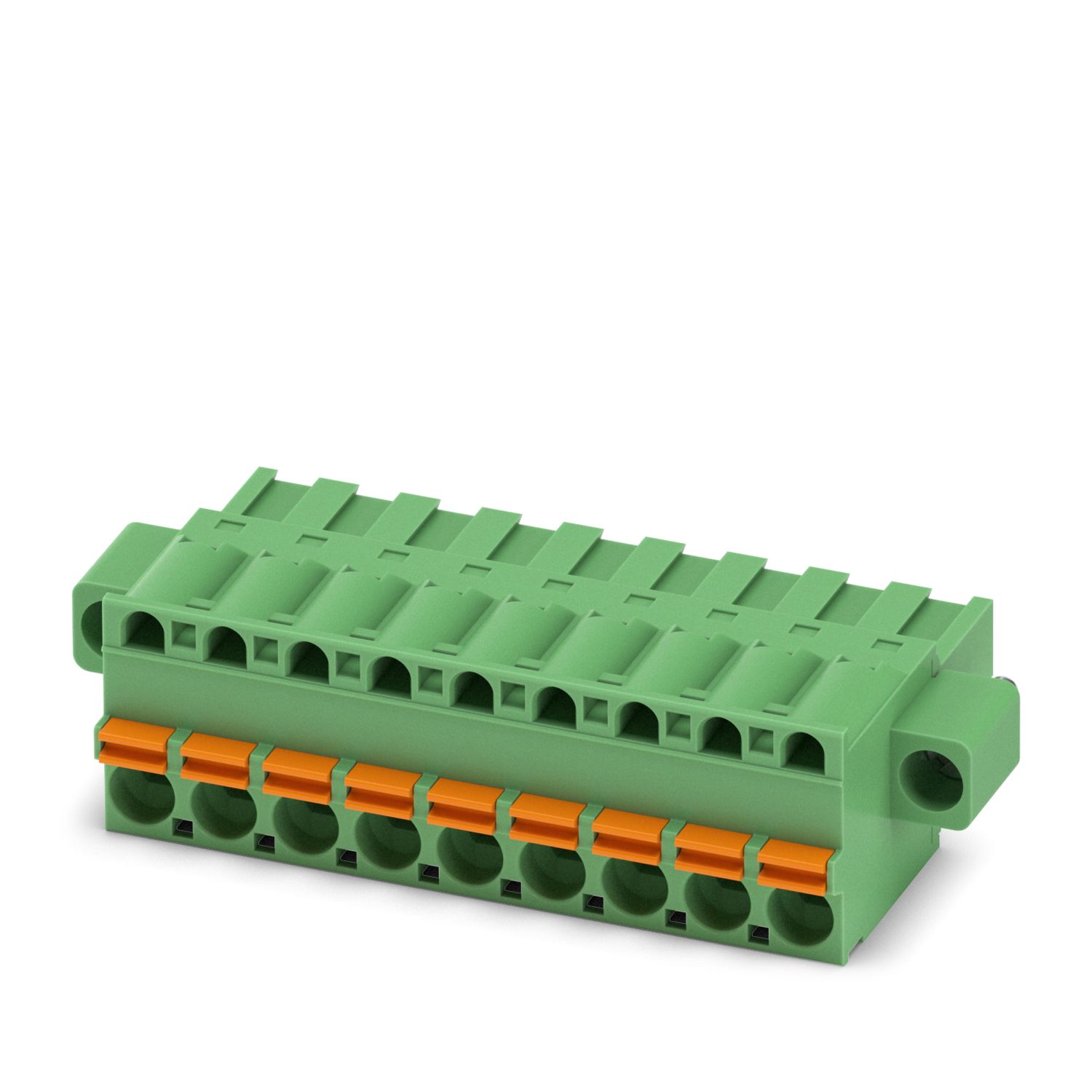

product line COMBICON Connectors M

cross section 2.5 mm2

type of packaging packed in cardboard

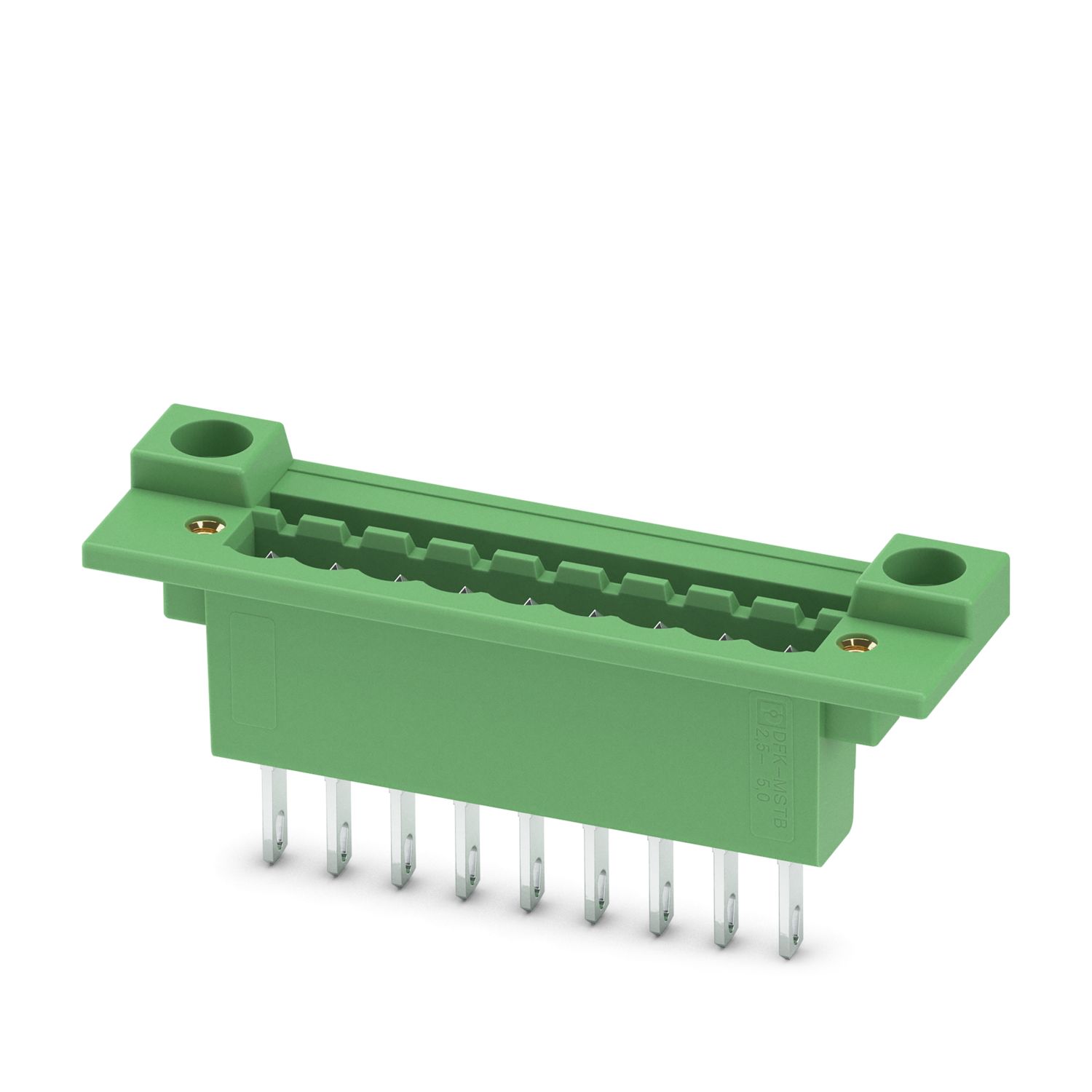

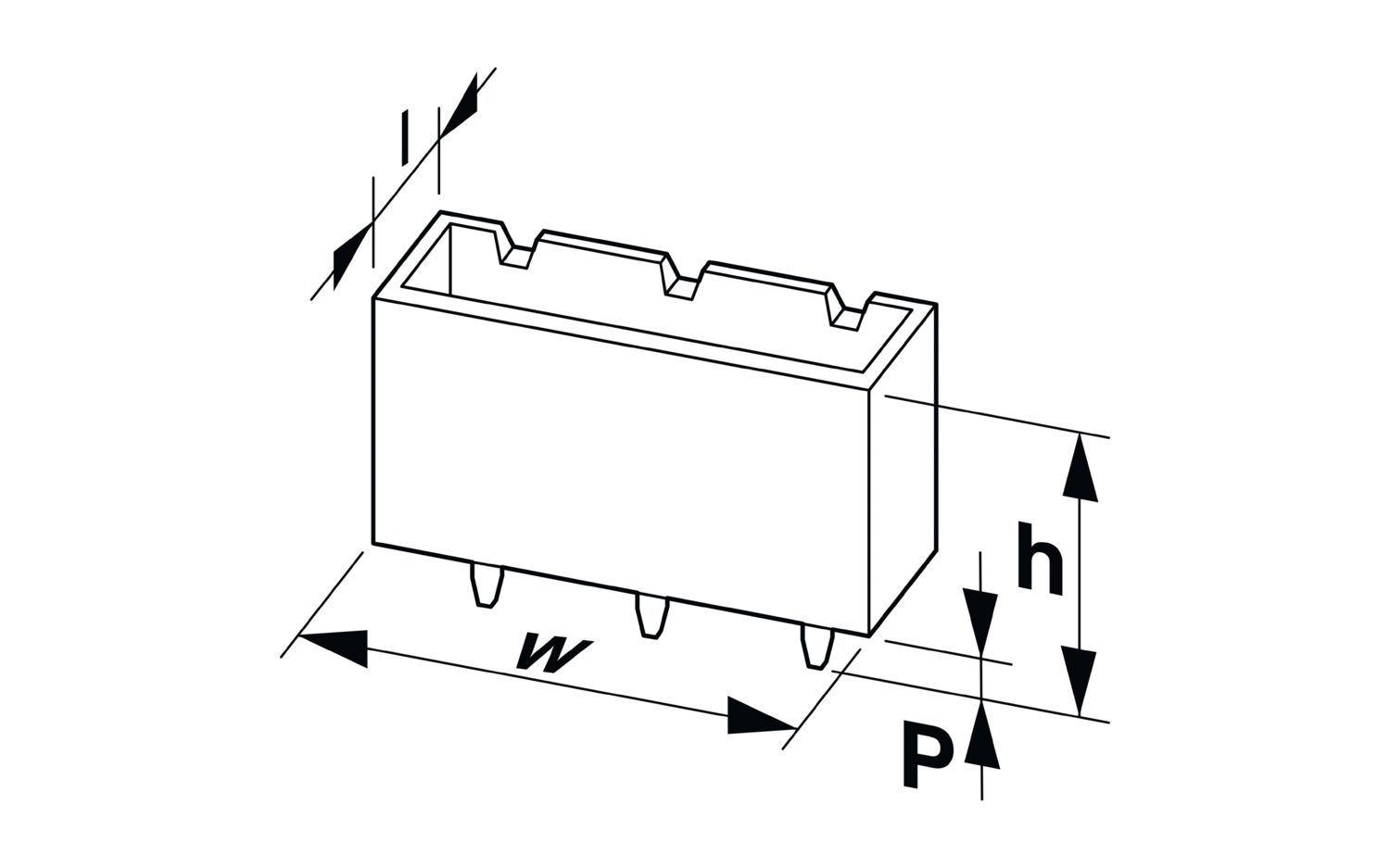

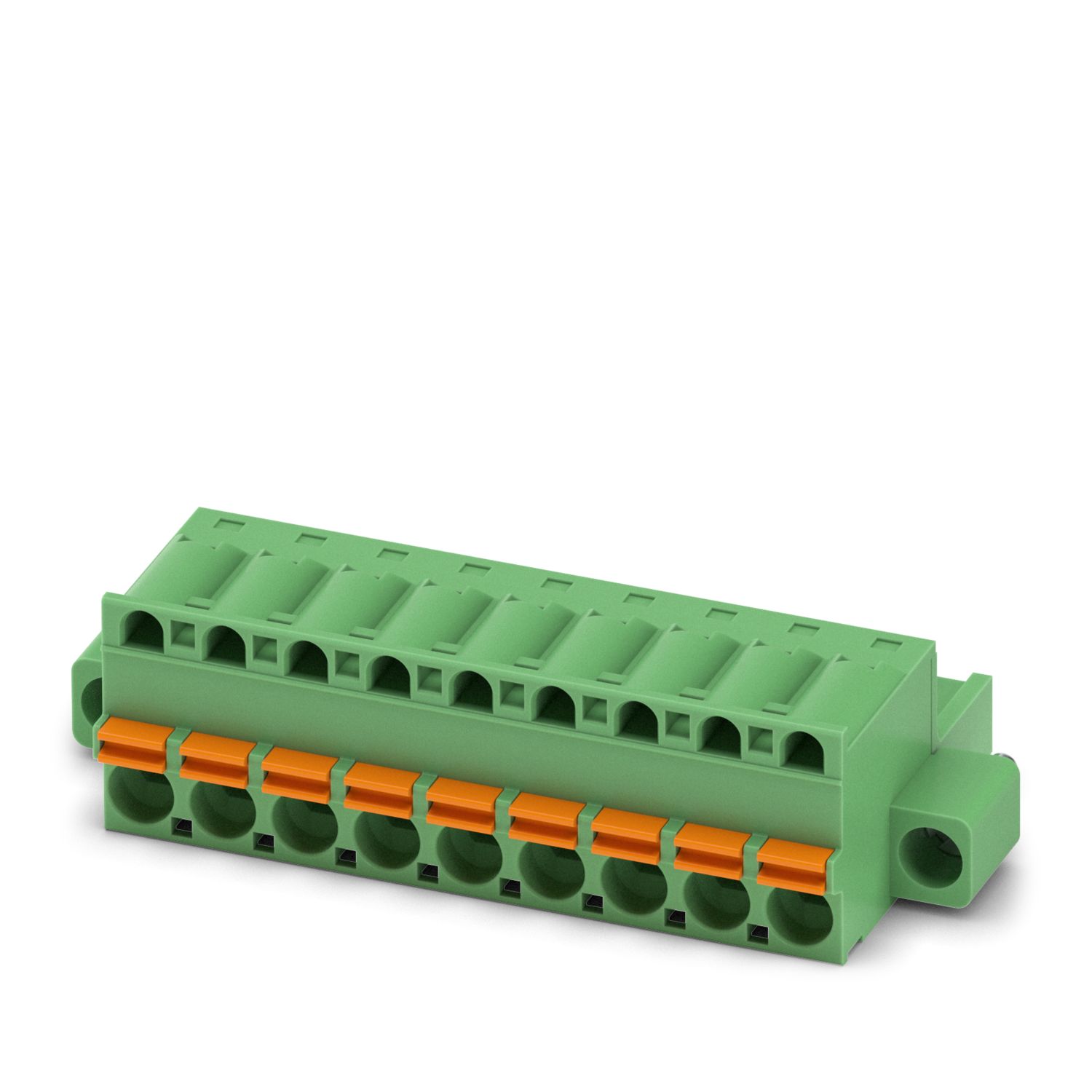

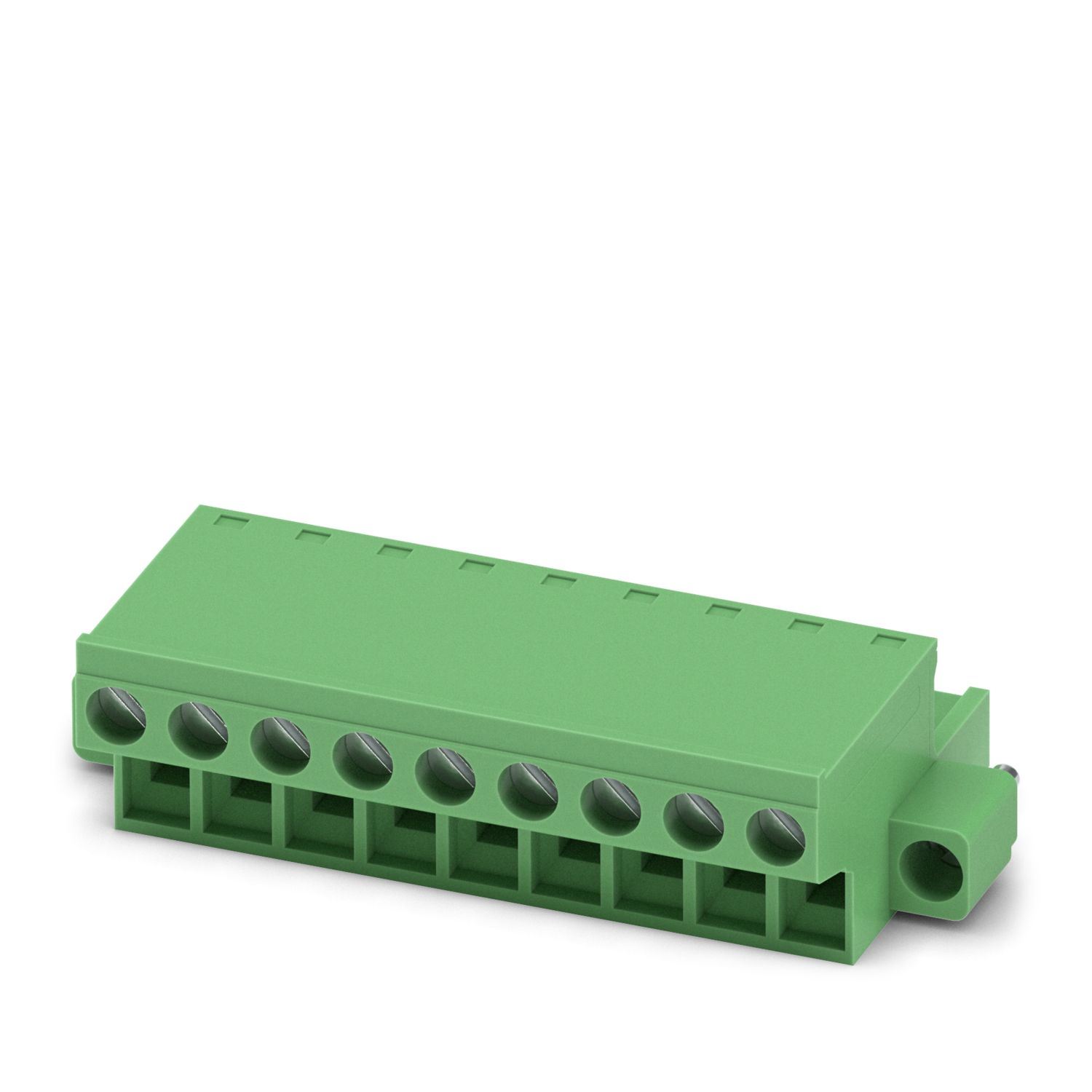

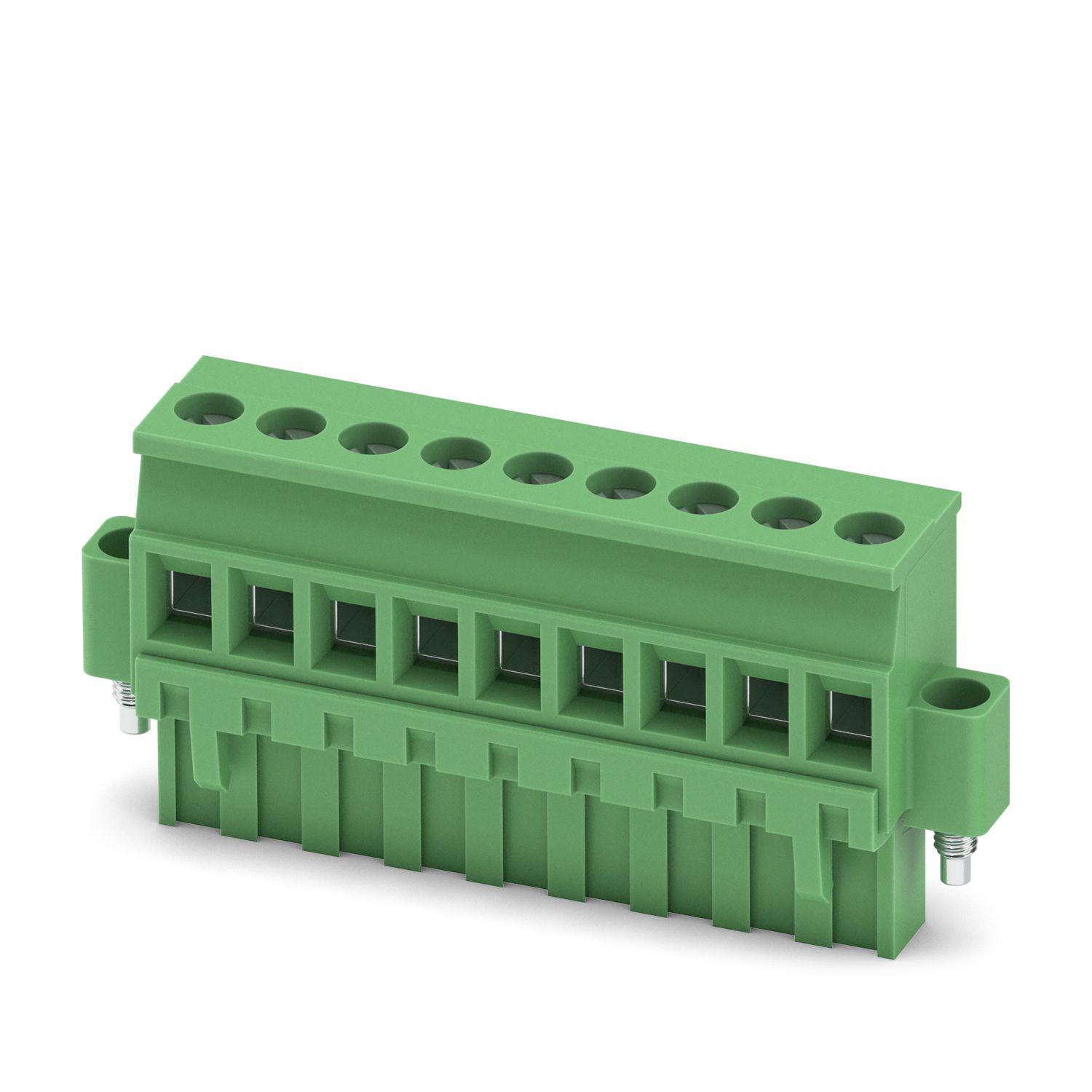

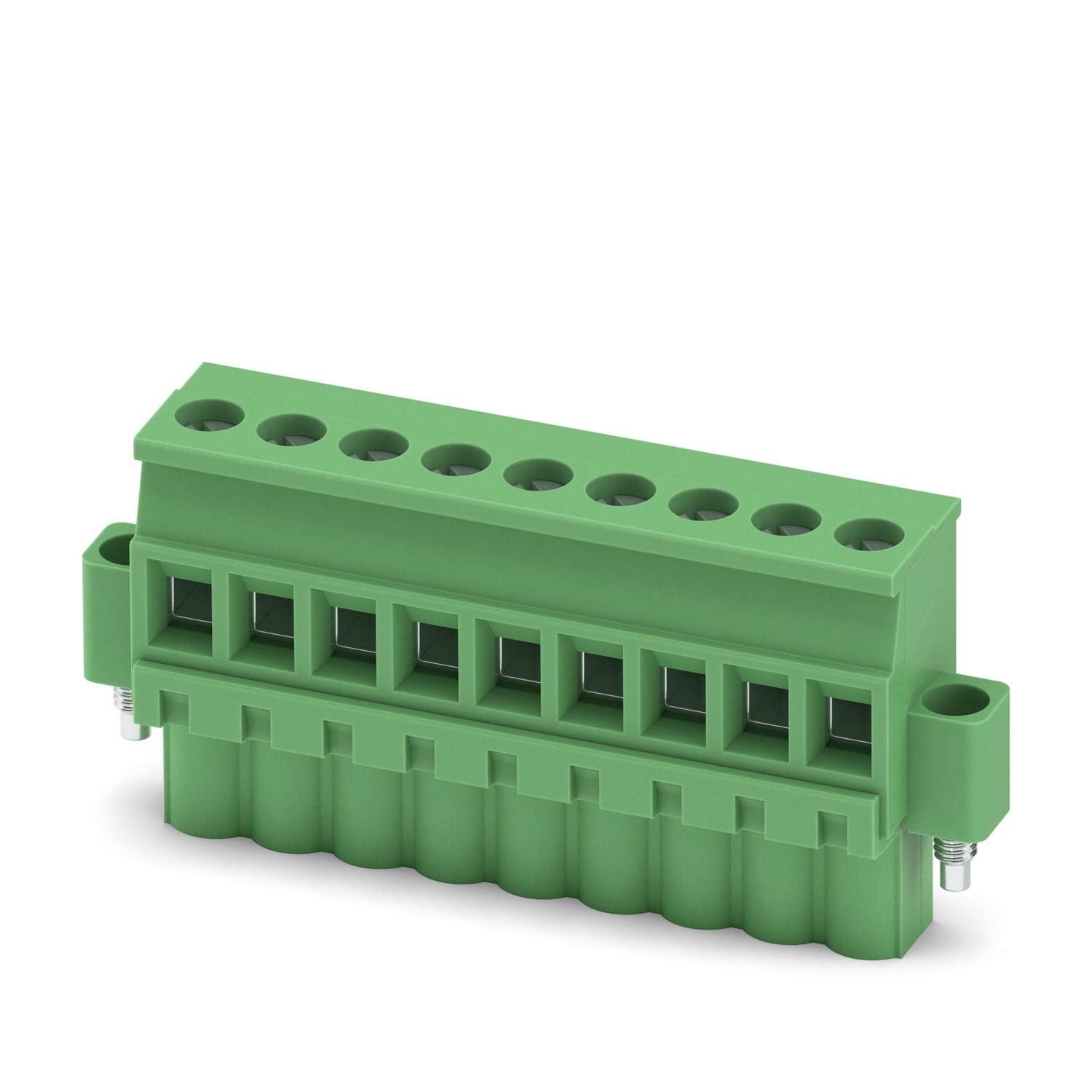

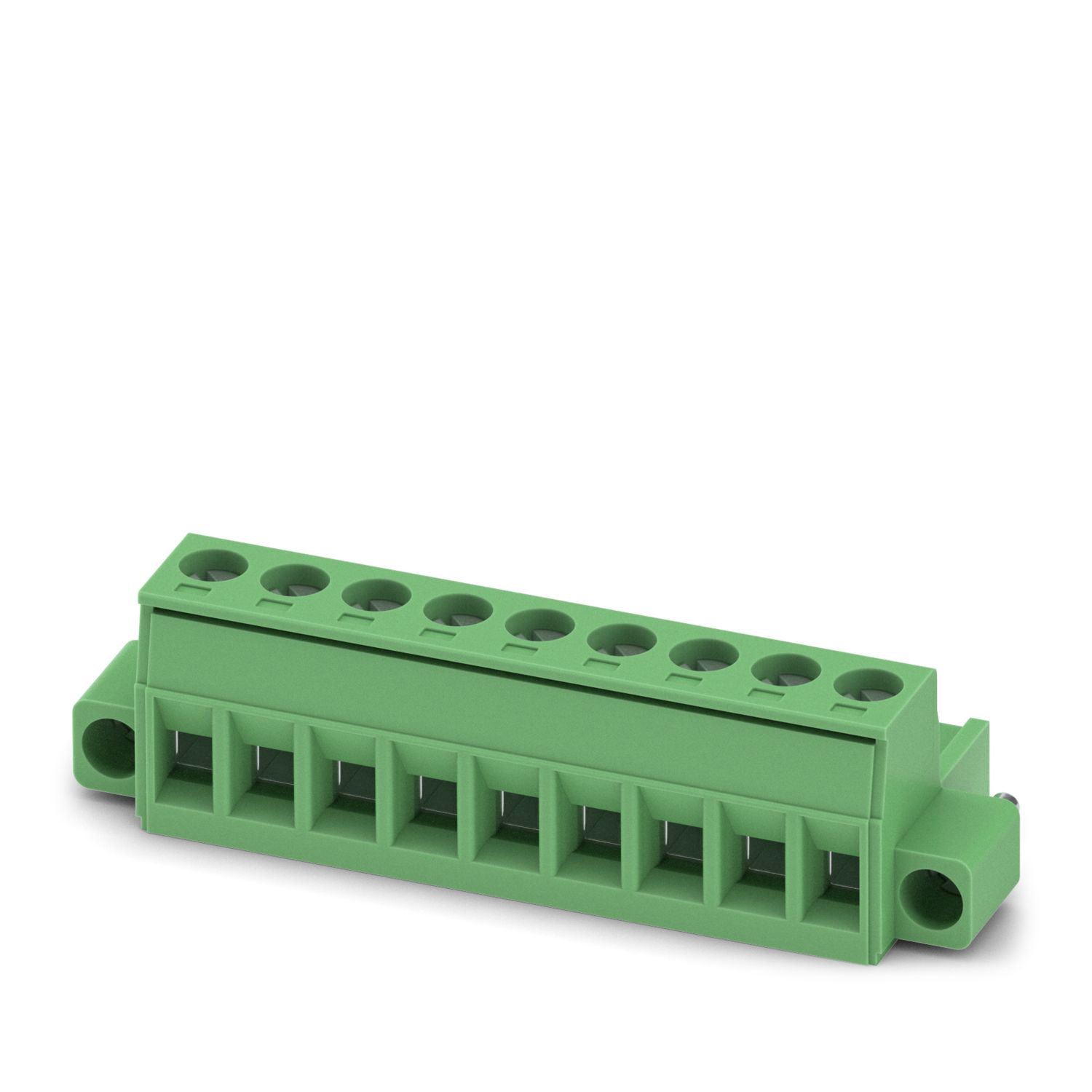

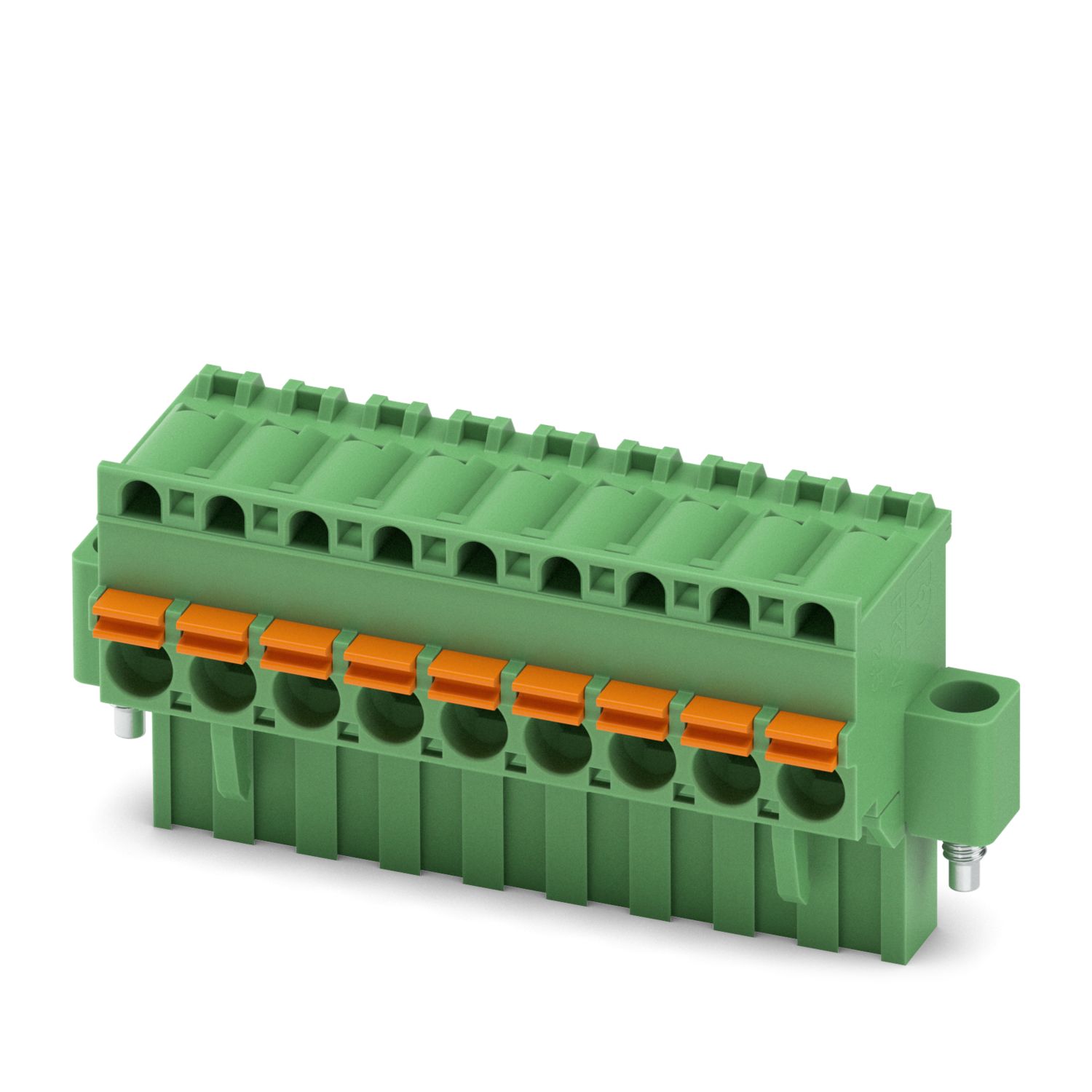

Feed-through header, nominal cross section: 2.5 mm2, color: green, nominal current: 12 A, rated voltage (III/2): 320 V, contact surface: Sn, contact connection type: Pin, number of potentials: 9, number of rows: 1, number of positions: 9, number of connections: 9, product range: DFK-MSTB 2,5/..-GF, pitch: 5 mm, connection method: Solder/Slip-on connection, mounting: Direct mounting, pin layout: Linear pinning, solder pin [P]: 9.3 mm, number of solder pins per potential: 1, plug-in system: COMBICON MSTB 2,5, Pin connector pattern alignment: Standard, locking: Screw locking mechanism, mounting method: Threaded flange, type of packaging: packed in cardboard