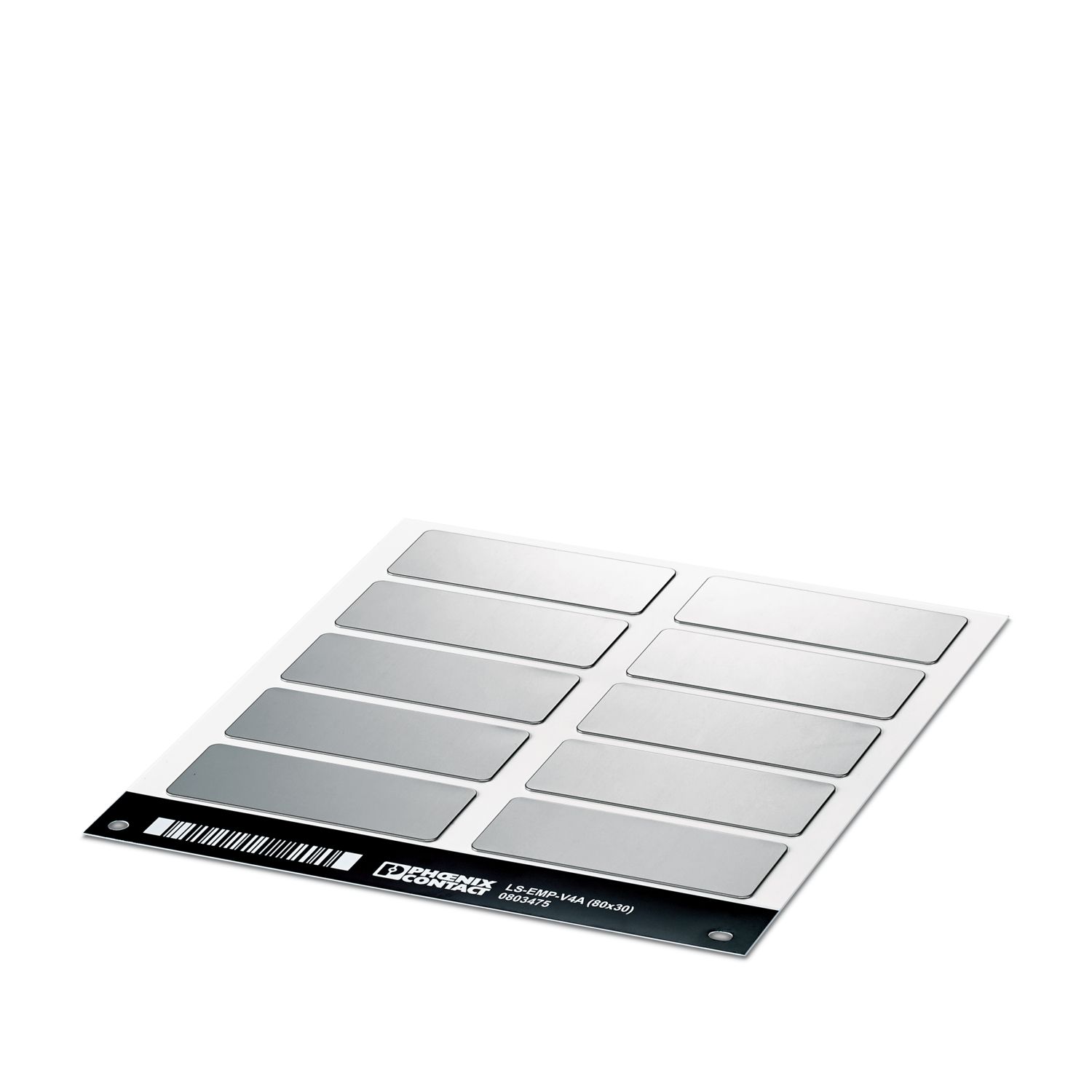

LS-EMP-V4A (80X30)

-

Equipment marking

0803475

Equipment marking, Stainless steel label, not polished, silver-colored, unmarked, can be labeled with: TOPMARK NEO, TOPMARK LASER, mounting type: snap in, Number of individual labels: 10

Product details

| Marking | |

| Number of individual labels | 10 |

| Number of individual labels per row | 2 |

| Identification technology | Direct laser marking |

| Width | 80.00 mm |

| Height | 30.00 mm |

| Depth | 0.80 mm |

| Length | 30 mm |

| RoHS compliant | yes |

| Color | silver-colored |

| Material | V4A |

| Components | free from silicone, halogen, and cadmium |

| Test for substances that would hinder coating with paint or varnish | |

| Testing for paint wetting impairment substances (LABS-conformity) | VDMA 24364-A1-L:2018-05 |

| Result | Test passed |

| Scratch resistance | |

| Specification | DIN EN ISO 1518-1:2019-10 (following) |

| Tesafilm test | |

| Specification | DIN EN ISO 2409:2013 (following) |

| Result | Test passed |

| UV resistance | |

| Specification | ISO 4892-2:2013-03 (following) |

| Result | Test passed |

| Test duration | 96 h |

| Procedure | Artificial irradiation. |

| Temperature storage | |

| Specification | IEC 60068-2-2:2007-07 |

| Result | Test passed |

| Procedure | Test Bb |

| Duration | 240 h |

| Temperature for testing | 350 °C |

| Temperature resistance | |

| Specification | ANSI/UL 969-2018:03 (following) |

| Test duration | 240 h |

| Rating 225 °C (250 °C) | Test passed |

| Wipe resistance of inscriptions | |

| Specification | DIN EN 61010-1 (VDE 0411-1):2011-07 |

| DIN EN 62208 (VDE 0660-511):2012-06 (in parts) | |

| Isopropanol (99%) [67-63-0] | Test passed |

| n-Hexane [CAS No. 110-54-3] |

Test passed |

| Water + Petroleum ether [CAS No. 64742-82-1] |

Test passed |

| Sodium hydroxide 0.1 mol/l [CAS No. 1310-73-2] |

Test passed |

| Ethanol (99 %) [CAS No. 64-17-5] |

Test passed |

| Acetone (99 %) [CAS No. 67-64-1] |

Test passed |

| Immersion in chemicals, oil & fuel | |

| Specification | ISO 175:2010 (following) |

| Test duration | 168 h |

| Saltwater (saturated 350 g/l) [CAS No. - ] |

Test passed |

| Ethanol (99 %) [CAS No. 64-17-5] |

Test passed |

| Acetone (99 %) [CAS No. 67-64-1] |

Test passed |

| Methylethylketone (MEK) [CAS No. 78-93-3] |

Test passed |

| IRM 901 | Test passed |

| IRM 902 | Test passed |

| IRM 903 | Test passed |

| Testing in a condensation changing climate in the presence of sulfur dioxide | |

| Specification | DIN 50018:2013-05 (following) |

| Result | Test passed |

| Climate level | AHT 1.0 S |

| Cycles | 2 |

| Salt spray test | |

| Specification | DIN EN 60068-2-11:2000-02 |

| Result | Test passed |

| Test duration | 96 h |

| Salt spray test | |

| Specification | ISO 9227:2017-03 |

| Result | Test passed |

| Test duration | 336 h |

| Wipe resistance | DIN EN 61010-1 (VDE 0411-1) |

| Mounting type | snap in |

| Item number | 0803475 |

| Packing unit | 5 pc |

| Minimum order quantity | 5 pc |

| Sales key | BG241D |

| Product key | BG241D |

| GTIN | 4055626077918 |

| Weight per piece (including packing) | 142.3 g |

| Weight per piece (excluding packing) | 142.3 g |

| Country of origin | DE |

UNSPSC

| UNSPSC 21.0 | 39131700 |

| EU RoHS | |

| Fulfills EU RoHS substance requirements | Yes (No exemptions) |

| EU REACH SVHC | |

| REACH candidate substance (CAS No.) | No substance above 0.1 wt% |

Compatible products

PHOENIX CONTACT Ltd

Unit 15C, 906-930 Great South Road, Penrose, Auckland 1061, New Zealand