In maintenance-intensive applications, such as tool changes on robots, you can easily replace wear-prone and maintenance-intensive connections with NearFi couplers, thus minimizing downtime costs.

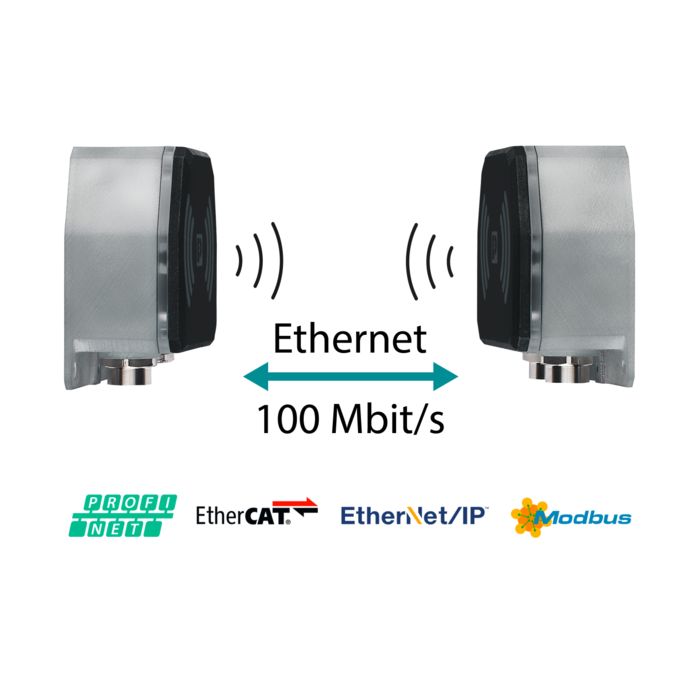

Protocol-independent near-field communication in real time

The couplers transmit Ethernet data at a speed of up to 100 Mbps (full duplex) in real time. At the same time, the couplers are fully protocol-transparent, meaning that all conventional Ethernet protocols can be used.

The fast device startup enables use in applications where application-specific functions such as “Fast Startup” are required.

Near-field communication via air gap does not require frequency planning or wireless expertise.

Constant power transmission with automatic current equalization

In addition, the couplers transmit power inductively, and can therefore supply other end devices such as I/O stations, switches, etc., with power without the need for contact. A power of 50 W can be transmitted via a NearFi path.

By combining two NearFi paths, the power can be increased to 100 W with automatic current equalization. In addition, application-specific functions such as the transmission of two electrically isolated voltages (US/UA, each 50 W) are also enabled.

Would you like to learn more about the contactless, real-time NearFi transmission technology from Phoenix Contact? Then simply watch our video on the topic.

In the demo, we’ll show you how to minimize costly outages by simply replacing wear-prone connections or slip rings in industrial applications with the NearFi coupler.

Robust and versatile in use

Where conventional connection technology reaches its limits due to space and movement restrictions, vibrations, dust, dirt, rotation, and frequent contacting, NearFi enables wear-free communication across an air gap of a few centimeters. Moreover, transmission through non-metallic materials such as glass, plastic, and wood is possible, which opens up a variety of application possibilities.

With robust IP65 housings featuring M12 connections for Ethernet and power, you can also use the NearFi couplers in demanding environments.

Your advantage: Universal in application.

NearFi coupler in use

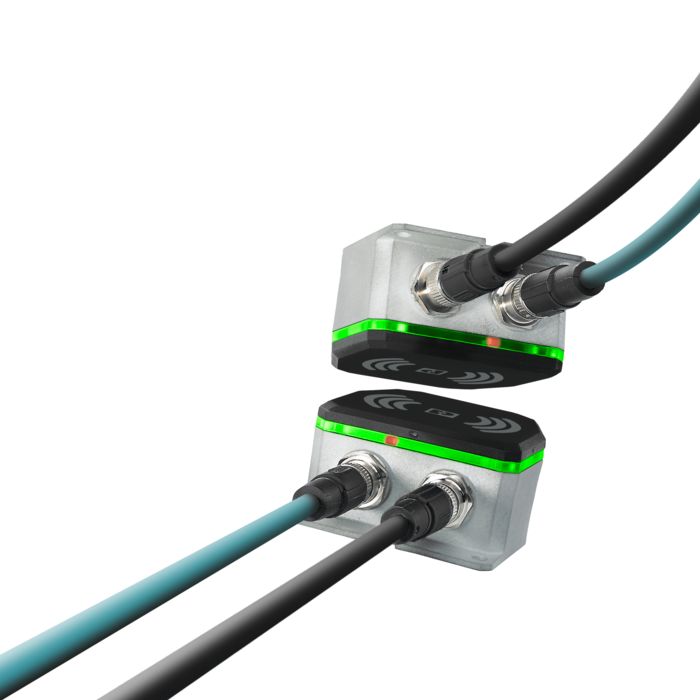

In contrast to standard connector solutions, the NearFi couplers can be positioned to face each other from any direction, and even rotating in relation to each other. Furthermore, the couplers do not need to be position precisely opposite each other, but can face each other with an offset, or at a tangential angle.

The couplers can be mounted flexibly with the universal mounting options. They can be mounted via the mounting flange using M5 screws or via the inside thread with M6 screws.

Your advantage: Reduced degree of precision required for the mechanical movement of two independent system parts.

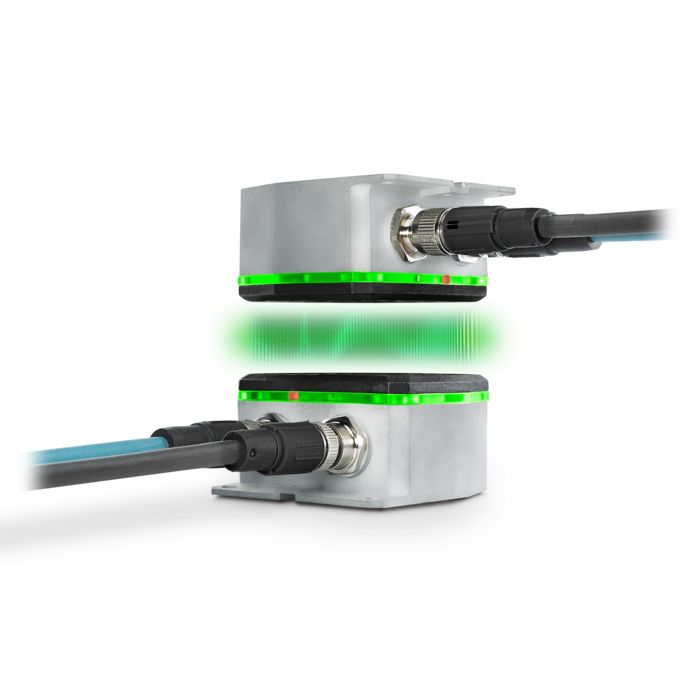

Primary and secondary couplers with all-around LED ring for rapid diagnostics

In principle, two devices are always necessary for transmission: a base coupler and a remote coupler. The couplers do not need to be configured and are as easy to use as a connector. A signal is issued via an integrated alignment aid once the devices are optimally coupled.

The all-around visual signaling with bright LEDs indicates the operational readiness of the coupling link in all spatial directions.

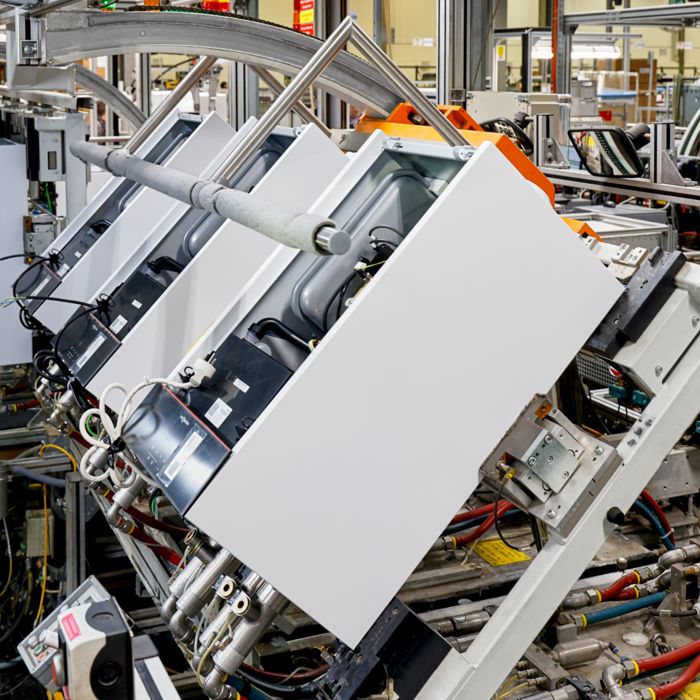

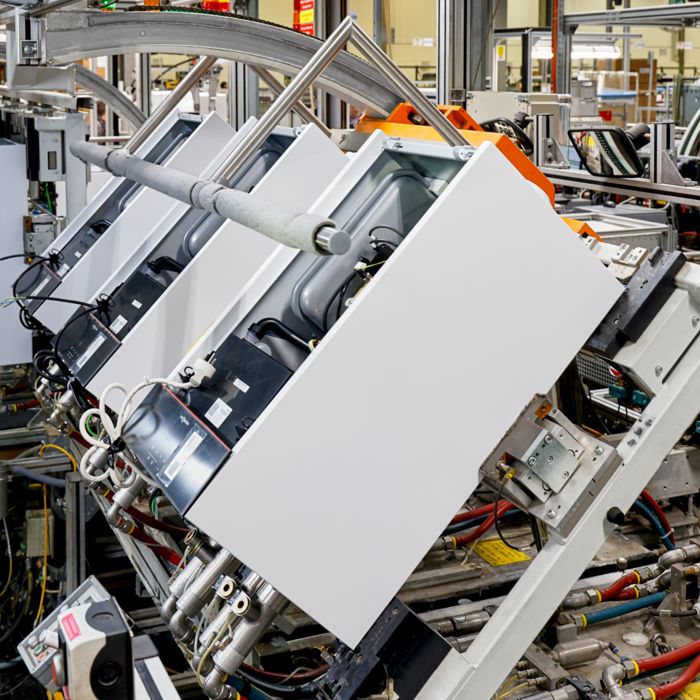

In maintenance-intensive applications, such as tool changes on robots, you can easily replace wear-prone and maintenance-intensive connections with NearFi couplers, thus minimizing downtime costs.

Communicate contactlessly with movable or rotating system parts using NearFi couplers and avoid production downtimes due to defective connectors or slip rings that are susceptible to interference.

Use NearFi couplers for contactless transmission between the workpiece carrier and the production station and replace wear-prone and maintenance-intensive connectors.

Install NearFi couplers quickly and easily on your automated guided vehicle system (AGVS) and transmit safety-related data contactlessly between the AGVS and production station.