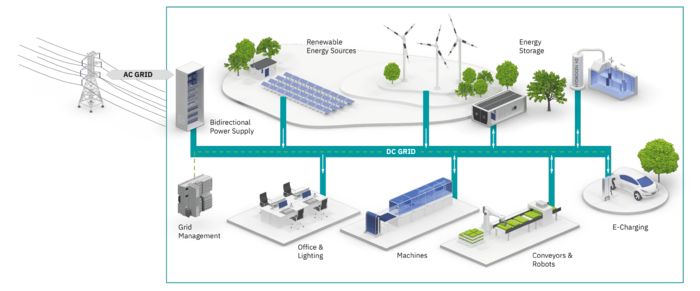

The industrial sector in particular is looking for suitable solutions to achieve climate targets. In times of climate change, the world is dealing with rising energy costs, scarce resources, and an increasing demand for energy. One approach to solving this problem is to switch from an AC power grid to a DC grid in factories. Renewable power generation, energy storage, and energy recovery are keywords of climate change that can be implemented in a DC microgrid. This reduces energy consumption and cuts peak loads (peak shaving). The effect relieves and stabilizes the supply network. The design of a DC grid for industry is one approach for a future with sustainable industrial production.