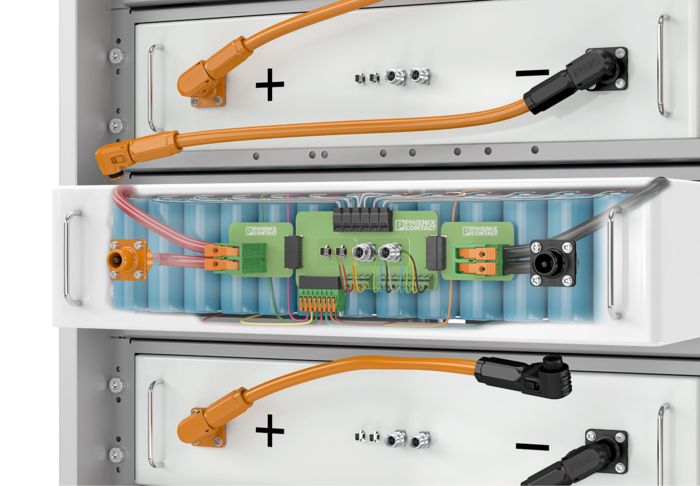

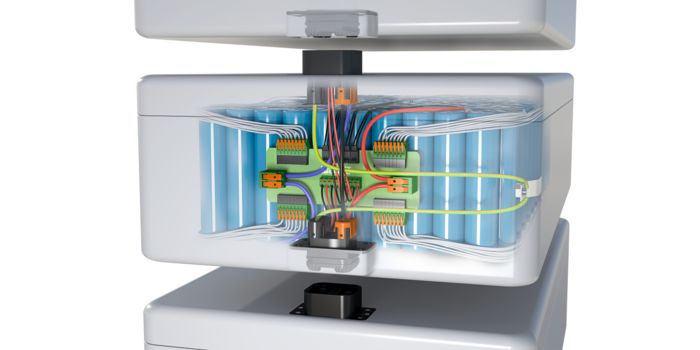

Energy storage systems are used in a huge range of applications – for example, for providing electricity in the event of grid outages. Energy storage systems have an important role to play in the energy revolution, especially with the increased use of renewable energies. This is because renewables are not available at all times to meet demand. The supply of and demand for electrical energy are quite often out of sync. Energy storage systems can bring synchronization to this equation by storing excess electricity produced by solar power and wind power systems. Whenever the demand for energy from the grid is higher than that available, the energy storage systems can make this excess electricity available again.