Coupling of factory and building: A central energy manager creates sustainable synergy effects The Emalytics Automation building management system harmonizes data formats and intelligently networks sectors.

Brief summary

Coupling the factory automation and building technology sectors can be used to achieve the energy pilot control of production. Here, data serves as the basis for comprehensive automation and networking. Digitalization is required in order for all sectors to speak the same language. Data interfaces and harmonized data formats enable standardized communication between classic building technology and production machines. This is the only way to detect interactions in order to optimize the overall organism in further steps.

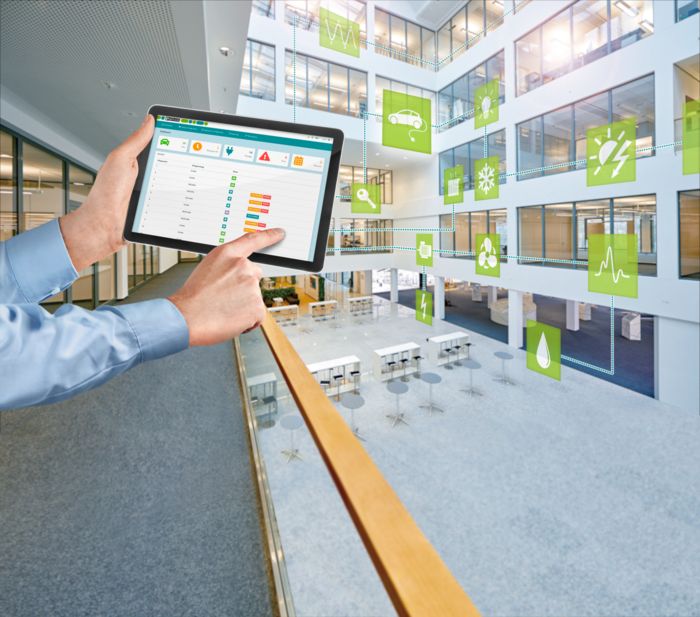

Emalytics Automation takes on this role at Phoenix Contact. Developed as a building management system, this solution can be used to improve the energy consumption of entire production locations. With the aim of enabling the data from all trades to be usable for Emalytics, the management system converts them into a uniform format and stores them in the Phoenix Contact cloud.

Energy optimization in entire locations

Generating, distributing, and consuming energy – this triad from a holistic networked energy system provides energy at the right time exactly where it is needed. This requires smart sector coupling that is based on renewable electrical energy. Such a concept forms the basis of the vision of the All Electric Society. The holistic approach of electrification, networking, and automation of the energy, industry, infrastructure, and mobility sectors works not only on a large scale, but also on a smaller scale. With components and systems from electrical engineering, electronics, and automation, Phoenix Contact provides solutions for this that create sustainable synergy effects between production and building automation. The latter has the potential to perform the task of a central energy manager in the future. As an illustration, if a larger order arrives in the scheduling department, for example, the building management system charges the internal battery storage system so that it is later able to smooth out the peak loads expected in production. To do this, it is necessary to know how high the energy consumption is per unit.

Emalytics represents a solution that can be used to centrally manage and optimize the network of different sectors

Standardized provision of all data points

Data therefore serves as the basis for comprehensive automation and networking. But what data is required and why is an open IIoT framework required? Data interfaces and harmonized data formats enable standardized communication between classic building technology and production machines. Emalytics Automation takes on this role at Phoenix Contact.

Developed as a building management system, this solution can be used to improve the energy consumption of entire production locations. With the aim of enabling the data from all trades to be usable for Emalytics, the management system converts them into a uniform format and stores them in the Phoenix Contact cloud. Once the data is prepared intelligently, nothing stands in the way of cross-sector efficient operations: the building management system connected to the production area as well as the charging network of the company’s e-fleet and a battery storage system – and everything powered by energy generated in-house. The battery can also be charged from power drawn from the local power grid, but it is ideally supplied by the in-house photovoltaic system. Another option: cooperatively financed wind parks, which, compared to purchasing green electricity, enable energy independence and in-house operation.

Temporal decoupling of energy supply and demand through energy storage

If the distribution and storage of self-generated energy is one of the core concepts of sector coupling, the early buffering of the energy generated conventionally by the energy supply companies (ESCs) is a fall-back strategy. The targeted purchasing of low-cost electricity, the coupling of properties with energy storage systems, and effective peak load management (peak shaving) ensure high availability at an acceptable cost. In this way, a large energy requirement – for example, in the context of high production capacity utilization or a considerable seasonal heating or cooling requirement – can be met with economic kWh prices. Electricity should therefore be purchased if it is clear that the energy generated in-house is not sufficient and conventional energy is available at a low price. This involves the temporal decoupling of demand and supply.

Such temporal decoupling can also be transferred over to the renewable generators – that is, the wind turbine generators and photovoltaic systems. The combination with an energy storage device creates the opportunity to use the excess energy generated during the day at night. This means that EEG (the German Renewable Energy Sources Act) systems can also remain connected to the power grid if the energy they generate is not required. In turn, the state saves costs for compensation services. In 2022, the federal German government paid around 800 million euros in compensation for EEG systems that had to drop out of the grid due to overloaded power grids or insufficient energy consumption. This may be the case on windy and sunny days during which there is only a small amount of heating or cooling requirements. In the specific implementation, the combination of wind farm/solar park and storage system is best held at the common grid connection point. This creates a reserve unit which can provide primary control power through its energy storage system. This means that older wind farms can also participate in the primary control power market.

Intelligent digitalization of secondary substations

If the energy interrelations within a self-contained factory work, it still becomes clear that a microcosm cannot be delimited from a higher-level macrocosm. This is because the sectors on a small and large scale are in a close relationship with one another. If the power supply of a manufacturing company is to be safeguarded, the requirements of the large number of decentral network devices must also be taken into consideration. The expansion of renewable energies is presenting ever-increasing challenges for power grids and, above all, for secondary substations. As already mentioned, decentral energy generation systems – such as wind turbine generators and solar parks – operate irregularly, thus burdening the high- and medium-voltage grids with fluctuating yield loads. The grid must therefore become smarter and detect critical grid points at an early stage.

In this area, too, Phoenix Contact provides solutions for the intelligent digitalization of secondary substations, thereby ensuring transparency and overview of all stations remotely. The measured values collected are used for the automatic adjustment of the voltage levels so that grid fluctuations are eliminated and faults can be rectified more quickly. The automatic compensation of voltage fluctuations ensures both the reliable power supply of the manufacturing industry as well as the population.

These few examples show the potential of sector coupling on the path to an All Electric Society. It also becomes clear that the complex relationships can only be tackled with further digitalization and the targeted use of sensors for measurement data collection. Within production, external events need to be integrated into the automation system. This includes, for example, information from production control, economic data from the energy market, and the expected use of buildings and machines. This data is incorporated directly from the Emalytics building management system. The heart of the solution is the IIoT framework. After normalization, the recorded information points are available to the entire network as a server-based database – regardless of who accesses or is connected to the network. This can therefore be a machine as well as a photovoltaic system, pump, or ventilation system. Emalytics therefore contributes to the long-term optimization of the network.

Summary

The classic building technology of the past decades is achieving significantly more results today, especially in terms of sector coupling. With Emalytics, Phoenix Contact is using a solution that can be used to couple different areas of application – the charging stations with the energy management system, the ventilation and lighting with facility management, and the energy storage system with production. The advantage of this coupling is that complete buildings, right through to entire locations, can be optimized in terms of energy efficiency. The improvements here range from the self-use of solar power, through general energy savings and predictive maintenance, right through to peak load management.

Connect with our experts

More posts

Combatting cybercrime with full wind power

With effective security solutions, Phoenix Contact protects wind turbine turbines and other renewable energy generators against cybercrime.

5G campus networks

Industrial application examples for wireless broadband communication.

Energy storage systems connect sectors

The importance of innovative connection technology for the safe operation of energy storage systems and for the realization of the All Electric Society.