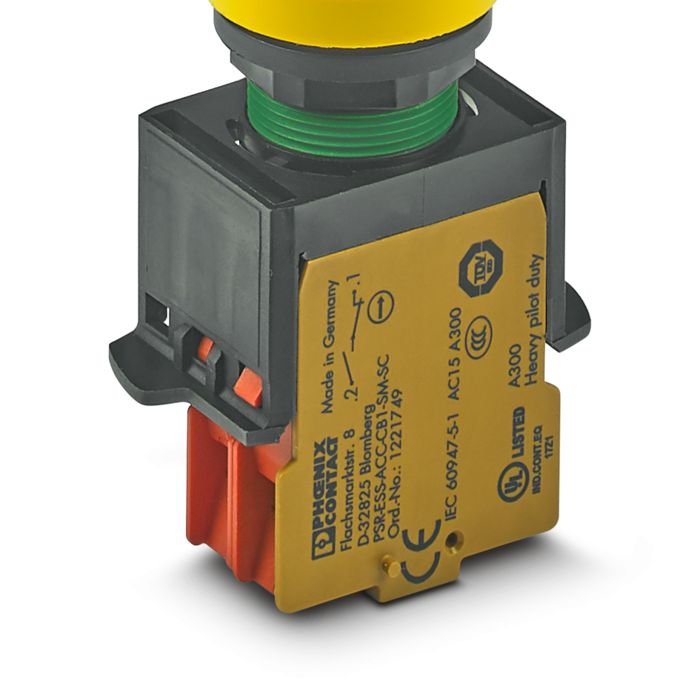

Contact module for modular emergency stop switches with force-guided N/C contact for safety-related shutdown, in conjunction with appropriate evaluation unit suitable for use up to PL e (EN ISO 13849-1), SIL 3 (EN IEC 62061)

Our TÜV-certified emergency stop switches allow you to switch your machines or system over to a safe state immediately in the event of an emergency. Our control devices with emergency stop or emergency switching off function are suitable for applications in accordance with EN ISO 13850 and EN 60204-1. Choose from our ready-to-use solutions for your standard application or configure your own emergency stop solution tailored to your requirements.

Contact module for modular emergency stop switches with force-guided N/C contact for safety-related shutdown, in conjunction with appropriate evaluation unit suitable for use up to PL e (EN ISO 13849-1), SIL 3 (EN IEC 62061)

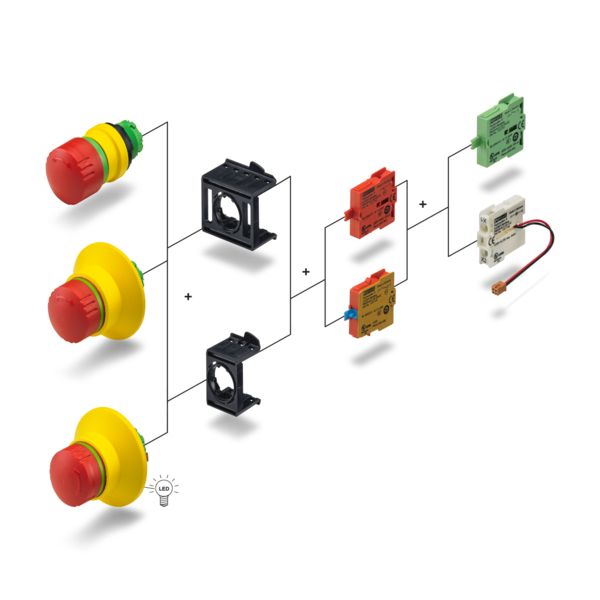

Module holder for modular emergency stop switches, connects the contact block and actuator with bayonet lock, suitable for 3 elements

Actuator with anti-lock collar for modular emergency stop switches, for combination with module holder and contact module as a functional unit, panel installation, bayonet lock

Contact module for modular emergency stop switches with N/O contact for feedback function through actuation of the emergency stop switch

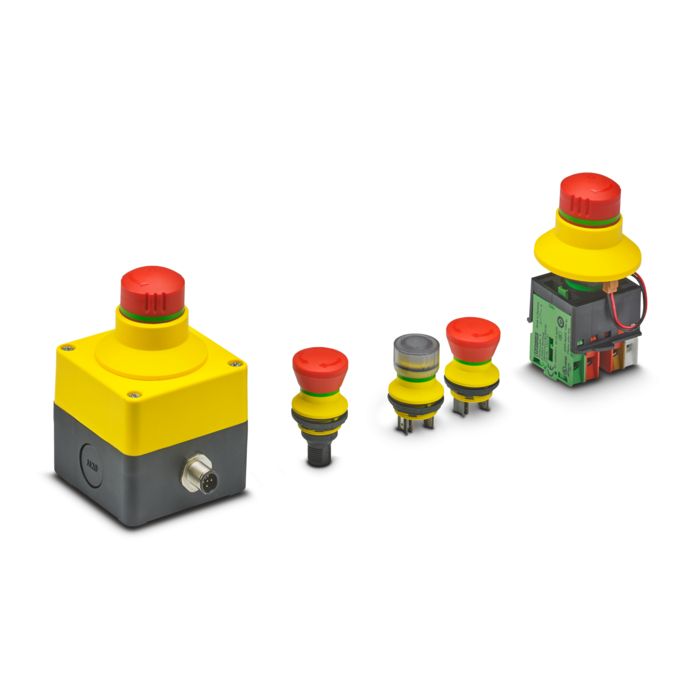

Emergency stop switch in IP65 housing, in conjunction with appropriate evaluation unit suitable for use up to PL e (EN ISO 13849-1), SIL 3 (EN IEC 62061), surface installation, 5-pos. M12 connection

Contact module for modular emergency stop switches with force-guided N/C contact for safety-related shutdown, N/O contact for assembly monitoring, in conjunction with appropriate evaluation unit suitable for use up to PL e (EN ISO 13849-1), SIL 3 (EN IEC 62061)

Emergency stop switch, in conjunction with appropriate evaluation unit suitable for use up to PL e (EN ISO 13849-1), SIL 3 (EN IEC 62061), panel installation, 5-pos. M12 connection

Lighting module for modular emergency stop switches, suitable for PSR-ESS-M0-H120 actuator

Actuator for modular emergency stop switches, for combination with module holder and contact module as a functional unit, panel installation, bayonet lock

Emergency stop switch, in conjunction with appropriate evaluation unit suitable for use up to PL e (EN ISO 13849-1), SIL 3 (EN IEC 62061), panel installation, spade connection

Illuminated status indicator active/inactive

Increased occupational safety

Machines and systems are becoming increasingly modular in design. Not all machines and system parts are in operation permanently. To be able to reliably differentiate between active and inactive emergency stop devices in the event of danger, illuminated buttons can be used in accordance with the EN ISO 13850 standard.

If the machine part is currently in operation, the active emergency stop button is illuminated. If the machine part is not currently connected, the emergency stop button is not illuminated. Accordingly, the button is inactive and not visually recognizable as an active emergency stop or emergency switch-off.

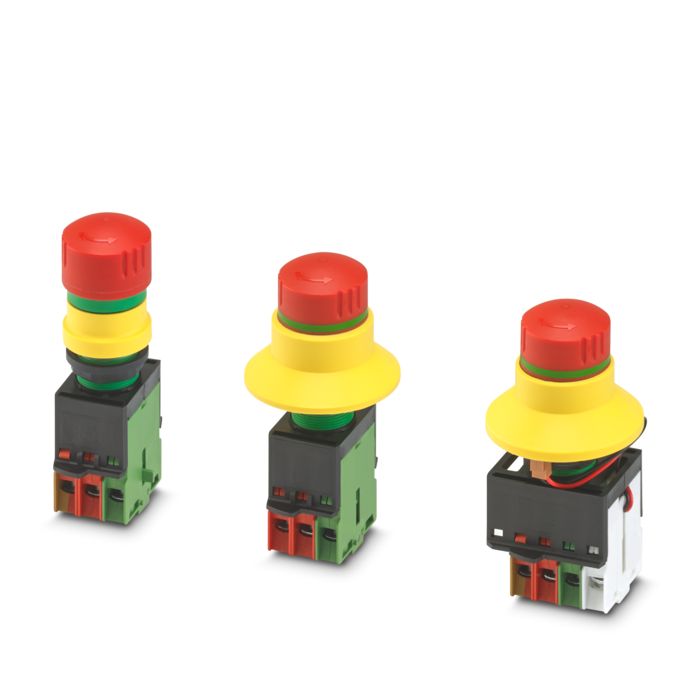

Colored switching position indicator on an unactuated switch

Rapid on-site diagnostics

Finding an active emergency stop switch is sometimes very time-consuming, especially in large systems. For time-saving on-site diagnostics, all of our emergency stop control devices are equipped with a colored switching position indicator. Upon actuation, the switches can be distinguished from unactuated switches at a glance.

Modular emergency stop switch with self-monitoring contact module

Protection against installation errors

Equip our modular emergency stop devices with self-monitoring emergency stop contact modules. These modules automatically set the machine to the safe state if errors or damage occur between the contact module and actuator when the emergency stop switches are being installed. Once the installation is correct, you can commission the machine as usual.

Self-monitoring contact modules thus ensure that your system is reliably shut down or switched off whenever necessary.

Portfolio of ready-to-use emergency stop solutions

Set up your emergency stop unit quickly and easily by using our pre-assembled switches.

Our portfolios enable quick and easy installation, whatever the demand: Install the solution directly in the field, in the operator panel, or in the machine control cabinet. As an option, our emergency stop buttons are available with 5-position M12 connection and installation via Plug and Play.

Possible combinations of modular emergency stop systems

Our modular emergency stop control devices provide cost-efficient safety solutions tailored to your requirements.

Combine actuators, module holders, and contact modules to meet your needs. Upon request, integrate additional functions such as illuminated anti-lock collars, for a particularly high level of safety.

Modular emergency stop system

What is the difference between an emergency stop and emergency switching off?

The emergency stop function is used to shut a machine down as quickly as possible in the event of imminent hazards for the operator. The emergency stop command stops the machine from performing a dangerous movement, such as mechanical rotation.

The emergency switching off function is also important in terms of electrical energy. Emergency switching off equipment immediately de-energizes a system to protect the operator from hazards such as an electric shock.

How does an emergency stop and emergency switching off work?

An emergency stop or emergency switching off is pressed manually. The red button locks in place upon actuation, and can only be released again manually. This ensures that the system remains in a safe state until the hazard is eliminated.