Push-X connection Push-X technology enables the easy connection of rigid and flexible conductors with or without ferrules. Even very small and flexible conductors can be clamped quickly and easily due to the pretensioned contact chamber.

Your advantages

- Highly convenient operation with the effortless and tool-free direct-connection technology

- Quick installation of all types of conductors with and without ferrules

- Clear identification of the conductor connection with the force-guided actuating push button and the acoustic click sound when wiring

- Reduced installation times with the factory-opened clamping space

- Quick and easy conductor release as well as pretensioning of the contact spring, enabled by the force-guided actuating push button

Push-X technology made simple

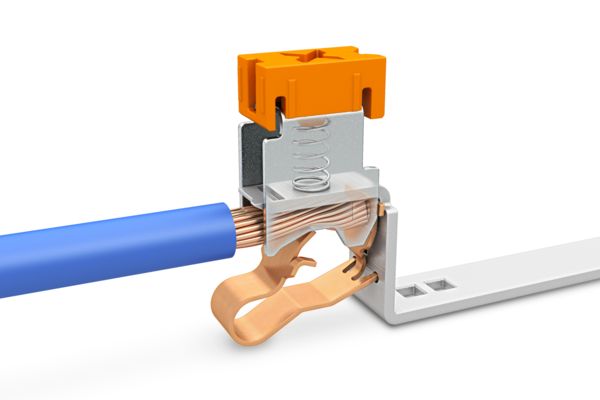

As opposed to existing Push-in connection technology, Push-X can accommodate all types of conductors with direct wiring tool-free and without significant force. A pretensioned contact spring lies at the heart of this new technology. This principle enables the connection of rigid and flexible conductors with or without ferrules. Even the smallest flexible conductors trigger the connection. Lightly tapping the release surface at the end of the clamping chamber causes the conductor to be contacted with ease. By tapping, the mechanism is released and the conductor is contacted quickly and permanently. As with Push-in, connected conductors can be released by pressing the orange push button. At the same time the conductor is released, the contact spring is preloaded for a new wiring operation.

Push-X technology

More information on Push-X

Would you like to learn more about products with Push-X technology? Click on the following link for more information, product overviews, and free samples. Click on the link below and enter the new world of Push-X technology.

Push-X in comparison with other connection technologies

Fast, faster, Push-X – see just how easy wiring with Push-X technology is compared to other connection technologies. It’s hard to imagine a faster way to connect flexible conductors. Push-X is also suitable for automatic wiring with industrial robots.

Our portfolio with Push-X technology

XT terminal blocks

Easily connect rigid and flexible conductors with or without ferrules using XT terminal blocks with Push-X technology. Even the smallest and most flexible conductors can be clamped quickly and easily with the pretensioned contact chamber. Simply insert the conductor to the end of the chamber. Pressing down the locking mechanism at the end of the chamber releases the contact spring and snaps it shut rapidly. The XT terminal blocks are available in the nominal cross-section of 2.5 mm².

XPC series PCB connectors

The XPC 1,5 and XPC 2,5 series connectors enable the secure fast connection of conductors. Rigid and flexible conductors with or without ferrules are connected directly, effortlessly, and tool-free by means of the innovative Push-X technology. The stripped conductor is inserted directly into the open connection point, and an acoustic signal provides confirmation to the users that the connection is secure. The innovative Push-X technology is also extremely reliable with its user-friendly clamping chamber that is in open state when delivered. Demanding test procedures have also ensured that the connectors remain ready for direct connection even for severe impacts.

Versions for 4 mm² conductors are planned for the XPC series.

Our portfolio with lateral Push-X connection

XTV terminal blocks

The lateral Push-X technology is simply an adaptation of the frontal connection. The operation of the technologies is the same as for the frontal connection. The main reason for this adaptation is the reduction of bending radii during wiring, because the XTV terminals are mainly used for larger conductors from 4 mm² to 25 mm². The XTV terminal blocks, combined with the PTV and PTPOWER terminal blocks, provide for cross-section wiring with lateral spring connection.

You may also be interested in

Push-X technology

Push-X technology

A new concept in tool-free conductor connection: Push-X can accommodate all types of conductors with direct wiring tool-free and without significant force. Would you like to find out more? Click on the following link to find more information about the technology and related products. You can also order free product samples that are shipped directly to your door. Just click on the link below and enter the new world of Push-X technology.