MC 1,5/ 2-STF-3,5 BK AU

-

PCB connector

1714978

PCB connector, nominal cross section: 1.5 mm2, color: black, nominal current: 8 A, rated voltage (III/2): 160 V, contact surface: Au, contact connection type: Socket, number of potentials: 2, number of rows: 1, number of positions: 2, number of connections: 2, product range: MC 1,5/..-STF, pitch: 3.5 mm, connection method: Screw connection with tension sleeve, screw head form: L Slotted, conductor/PCB connection direction: 0 °, plug-in system: COMBICON MC 1,5, locking: Screw locking mechanism, mounting method: Screw flange, type of packaging: packed in cardboard

Product details

| Product type | PCB connector |

| Product family | MC 1,5/..-STF |

| Product line | COMBICON Connectors S |

| Number of positions | 2 |

| Pitch | 3.5 mm |

| Number of connections | 2 |

| Number of rows | 1 |

| Number of potentials | 2 |

| Mounting type | Screw flange |

| Properties | |

| Nominal current IN | 8 A |

| Nominal voltage UN | 160 V |

| Contact resistance | 1.4 mΩ |

| Rated voltage (III/3) | 160 V |

| Rated surge voltage (III/3) | 2.5 kV |

| Rated voltage (III/2) | 160 V |

| Rated surge voltage (III/2) | 2.5 kV |

| Rated voltage (II/2) | 320 V |

| Rated surge voltage (II/2) | 2.5 kV |

| Connection technology | |

| Connector system | COMBICON MC 1,5 |

| Nominal cross section | 1.5 mm² |

| Contact connection type | Socket |

| Interlock | |

| Locking type | Screw locking mechanism |

| Mounting type | Screw flange |

| Tightening torque | 0.3 Nm |

| Conductor connection | |

| Connection method | Screw connection with tension sleeve |

| Conductor/PCB connection direction | 0 ° |

| Conductor cross-section rigid | 0.08 mm² ... 1.5 mm² |

| Conductor cross-section flexible | 0.08 mm² ... 1.5 mm² |

| Conductor cross-section AWG | 28 ... 16 |

| Conductor cross-section flexible, with ferrule without plastic sleeve | 0.25 mm² ... 1.5 mm² |

| Conductor cross-section, flexible, with ferrule, with plastic sleeve | 0.25 mm² ... 0.5 mm² |

| 2 conductors with same cross section, solid | 0.08 mm² ... 0.5 mm² |

| 2 conductors with same cross section, flexible | 0.08 mm² ... 0.75 mm² |

| 2 conductors with same cross section, flexible, with ferrule without plastic sleeve | 0.25 mm² ... 0.34 mm² |

| 2 conductors with the same cross section, flexible, with TWIN ferrule with plastic sleeve | 0.5 mm² ... 0.5 mm² |

| Cylindrical gauge a x b / diameter | 2.4 mm x 1.5 mm / 1.6 mm |

| Stripping length | 7 mm |

| Drive form screw head | Slotted (L) |

| Tightening torque | 0.22 Nm ... 0.25 Nm |

| Specifications for ferrules without insulating collar | |

| recommended crimping tool | 1212034 CRIMPFOX 6 |

| Specifications for ferrules with insulating collar | |

| recommended crimping tool | 1212034 CRIMPFOX 6 |

| Material data - contact | |

| Note | WEEE/RoHS-compliant, free of whiskers according to IEC 60068-2-82/JEDEC JESD 201 |

| Contact material | Cu alloy |

| Surface characteristics | partially gold-plated |

| Metal surface terminal point (top layer) | Tin (4 - 8 µm Sn) |

| Metal surface terminal point (middle layer) | Nickel (2 - 3 µm Ni) |

| Metal surface contact area (top layer) | Gold (0.8 - 1 µm Au) |

| Metal surface contact area (middle layer) | Nickel (2 - 3 µm Ni) |

| Material data - housing | |

| Color (Housing) | black (9005) |

| Insulating material | PA |

| Insulating material group | I |

| CTI according to IEC 60112 | 600 |

| Flammability rating according to UL 94 | V0 |

| Glow wire flammability index GWFI according to EN 60695-2-12 | 850 |

| Glow wire ignition temperature GWIT according to EN 60695-2-13 | 775 |

| Temperature for the ball pressure test according to EN 60695-10-2 | 125 °C |

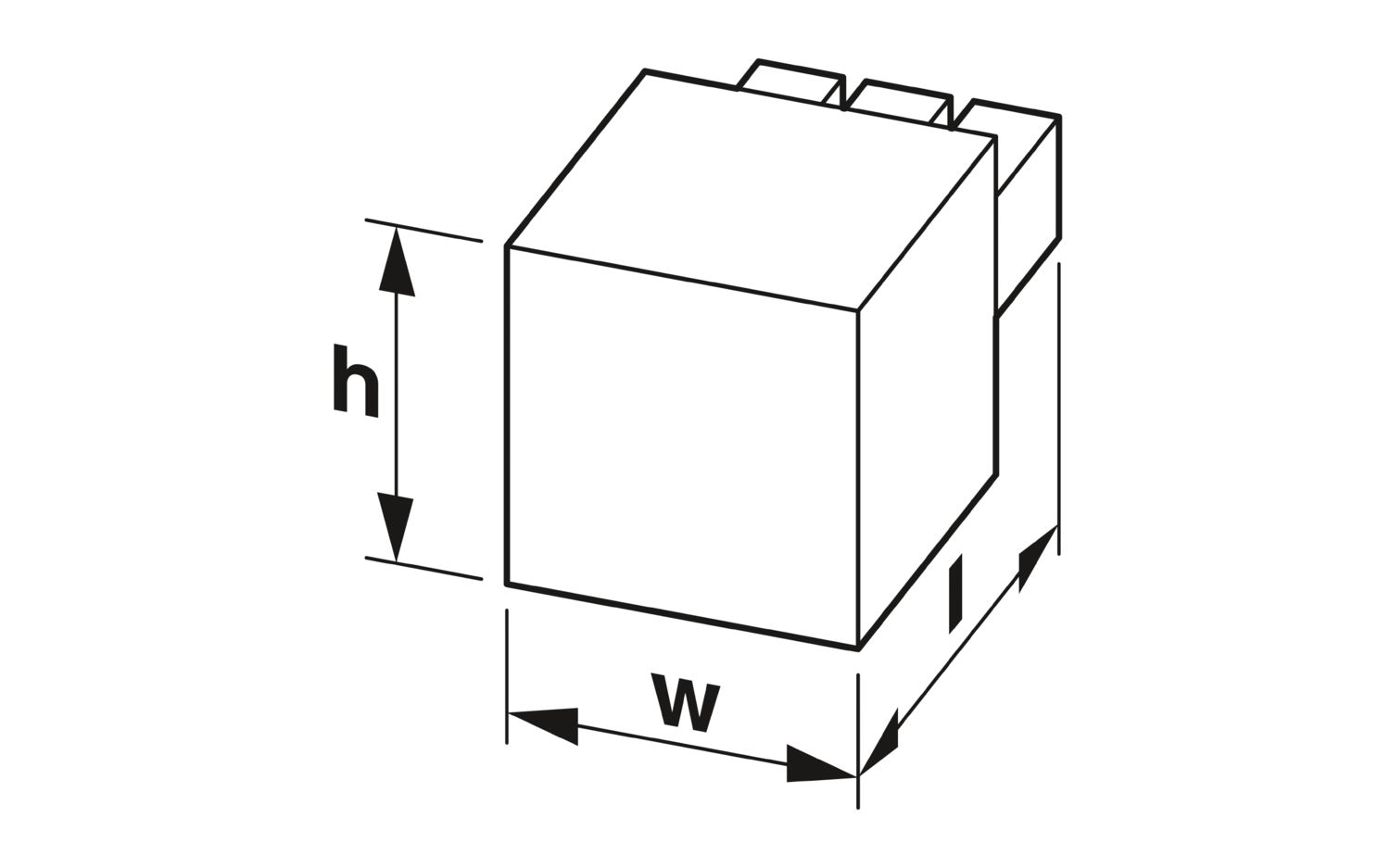

| Dimensional drawing |

|

| Pitch | 3.5 mm |

| Width [w] | 17.3 mm |

| Height [h] | 11.1 mm |

| Length [l] | 16.1 mm |

| Flange | |

| Tightening torque | 0.3 Nm |

| Note on application | The 0.08 mm² conductors must be placed in the center of the clamping space when installing them. This must be checked after installation. |

| Test for conductor damage and slackening | |

| Specification | IEC 60999-1:1999-11 |

| Result | Test passed |

| Pull-out test | |

| Specification | IEC 60999-1:1999-11 |

| Conductor cross-section/conductor type/tractive force setpoint/actual value | 0.14 mm² / solid / > 10 N |

| 0.14 mm² / flexible / > 10 N | |

| 1.5 mm² / solid / > 40 N | |

| 1.5 mm² / flexible / > 40 N | |

| Insertion and withdrawal forces | |

| Specification | IEC 60512-13-2:2006-02 |

| Result | Test passed |

| No. of cycles | 100 |

| Insertion strength per pos. approx. | 5 N |

| Withdraw strength per pos. approx. | 3 N |

| Torque test | |

| Specification | IEC 60999-1:1999-11 |

| Resistance of inscriptions | |

| Specification | IEC 60068-2-70:1995-12 |

| Result | Test passed |

| Polarization and coding | |

| Specification | IEC 60512-13-5:2006-02 |

| Result | Test passed |

| Visual inspection | |

| Specification | IEC 60512-1-1:2002-02 |

| Result | Test passed |

| Dimension check | |

| Specification | IEC 60512-1-2:2002-02 |

| Result | Test passed |

| Vibration test | |

| Specification | IEC 60068-2-6:2007-12 |

| Frequency | 10 - 500 - 10 Hz |

| Sweep speed | 1 octave/min |

| Amplitude | 0.35 mm (10 Hz ... 60.1 Hz) |

| Acceleration | 5g (60.1 Hz ... 500 Hz) |

| Test duration per axis | 2 h |

| Test directions | X-, Y- and Z-axis |

| Durability test | |

| Specification | IEC 60512-9-1:2010-03 |

| Impulse withstand voltage at sea level | 2.95 kV |

| Contact resistance R1 | 1.4 mΩ |

| Contact resistance R2 | 1.5 mΩ |

| Insertion/withdrawal cycles | 100 |

| Insulation resistance, neighboring positions | > 5 MΩ |

| Climatic test | |

| Specification | ISO 6988:1985-02 |

| Corrosive stress | 1.0 dm3 SO2 on 300 dm3/40 °C/3 cycles |

| Thermal stress | 100 °C/168 h |

| Power-frequency withstand voltage | 1.39 kV |

| Shocks | |

| Specification | IEC 60068-2-6:2007-12 |

| Pulse shape | Semi-sinusoidal |

| Acceleration | 30g |

| Shock duration | 18 ms |

| Test directions | X-, Y- and Z-axis (pos. and neg.) |

| Ambient conditions | |

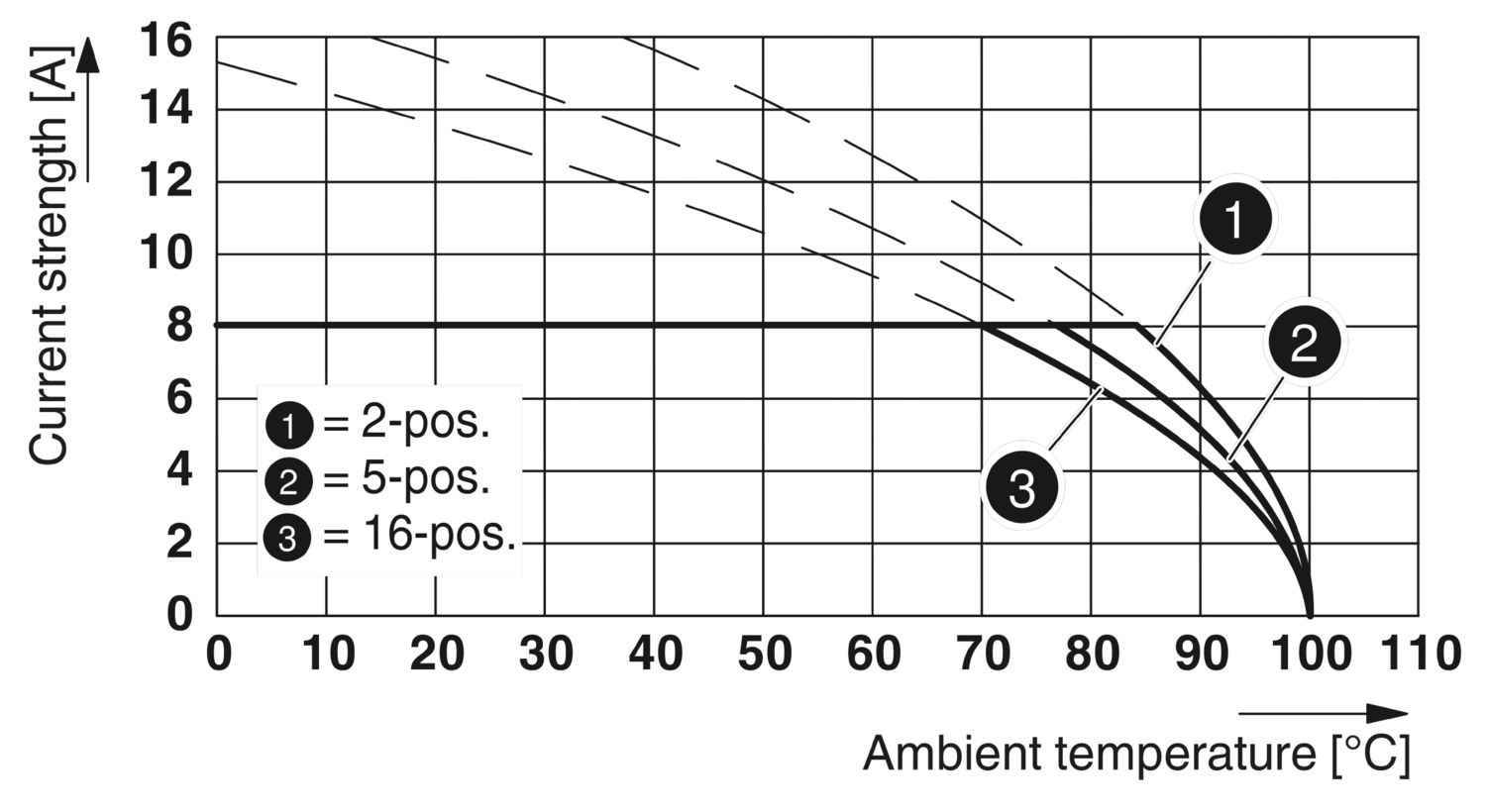

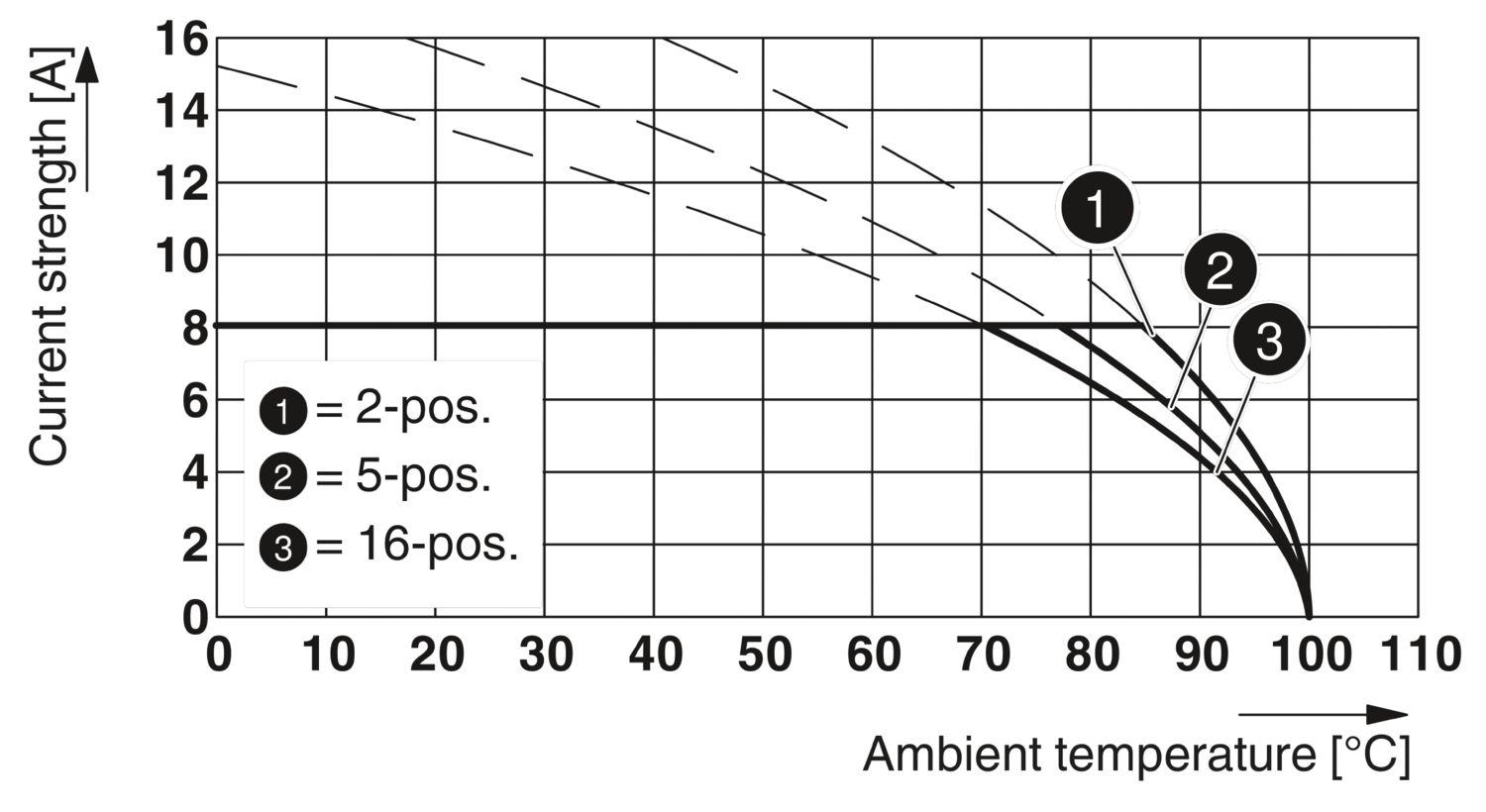

| Ambient temperature (operation) | -40 °C ... 100 °C (dependent on the derating curve) |

| Ambient temperature (storage/transport) | -40 °C ... 70 °C |

| Relative humidity (storage/transport) | 30 % ... 70 % |

| Ambient temperature (assembly) | -5 °C ... 100 °C |

| Thermal test | Test group C | |

| Specification | IEC 60512-5-1:2002-02 |

| Tested number of positions | 16 |

| Insulation resistance | |

| Specification | IEC 60512-3-1:2002-02 |

| Insulation resistance, neighboring positions | > 5 MΩ |

| Air clearances and creepage distances | | |

| Specification | IEC 60664-1:2007-04 |

| Insulating material group | I |

| Comparative tracking index (IEC 60112) | CTI 600 |

| Rated insulation voltage (III/3) | 160 V |

| Rated surge voltage (III/3) | 2.5 kV |

| minimum clearance value - non-homogenous field (III/3) | 1.5 mm |

| minimum creepage distance (III/3) | 2 mm |

| Rated insulation voltage (III/2) | 160 V |

| Rated surge voltage (III/2) | 2.5 kV |

| minimum clearance value - non-homogenous field (III/2) | 1.5 mm |

| minimum creepage distance (III/2) | 1.5 mm |

| Rated insulation voltage (II/2) | 320 V |

| Rated surge voltage (II/2) | 2.5 kV |

| minimum clearance value - non-homogenous field (II/2) | 1.5 mm |

| minimum creepage distance (II/2) | 1.6 mm |

| Type of packaging | packed in cardboard |

| Item number | 1714978 |

| Packing unit | 50 pc |

| Minimum order quantity | 1,000 pc |

| Note | Made to order (non-returnable) |

| Product key | AABAAB |

| GTIN | 4046356914284 |

| Weight per piece (including packing) | 2.582 g |

| Weight per piece (excluding packing) | 2.236 g |

| Customs tariff number | 85366990 |

| Country of origin | DE |

ECLASS

| ECLASS-13.0 | 27460202 |

| ECLASS-15.0 | 27460202 |

ETIM

| ETIM 9.0 | EC002638 |

UNSPSC

| UNSPSC 21.0 | 39121400 |

| EU RoHS | |

| Fulfills EU RoHS substance requirements | Yes (No exemptions) |

| China RoHS | |

| Environment friendly use period (EFUP) |

EFUP-E

No hazardous substances above the limits

|

| EU REACH SVHC | |

| REACH candidate substance (CAS No.) | No substance above 0.1 wt% |

Compatible products

Your advantages

Gold-plated contacts ensure transfer quality remains stable over the long term

Well-known connection principle allows worldwide use

Low temperature rise, thanks to maximum contact force

Allows connection of two conductors

Screwable flange for superior mechanical stability

PHOENIX CONTACT Israel Ltd.

P.O.B. 1799 Industrial Park Hasharon

Kadima 60920