PTMC 1,5/32-3 /BU

-

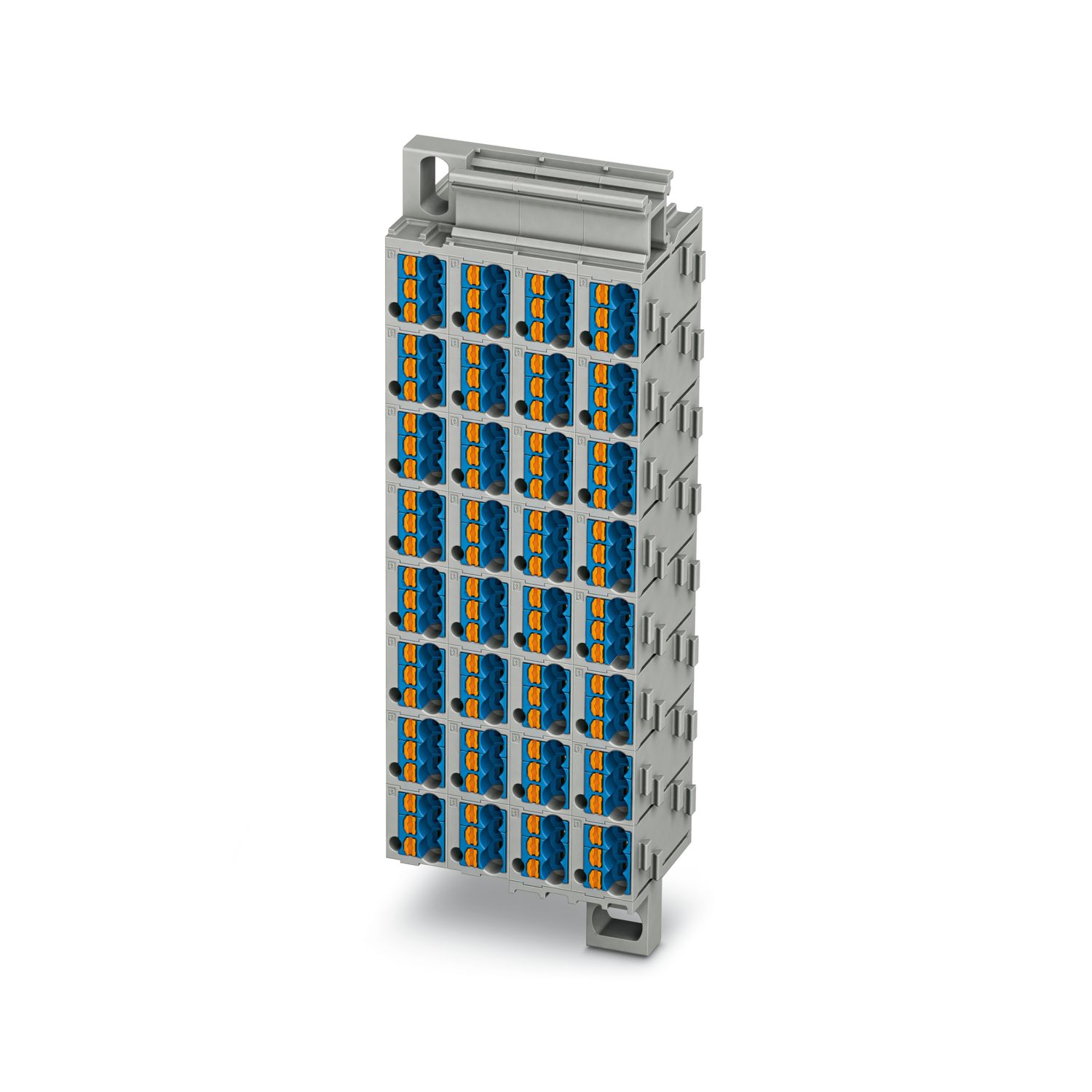

Marshalling patchboard

3270312

Marshalling patchboard, Labeled from 1 - 32, nom. voltage: 500 V, nominal current: 17.5 A, connection method: Push-in connection, cross section: 0.14 mm2 - 2.5 mm2, mounting: Panel mounting, color: gray, color of connection elements: blue

Product details

| General | Labeled from 1 - 32 |

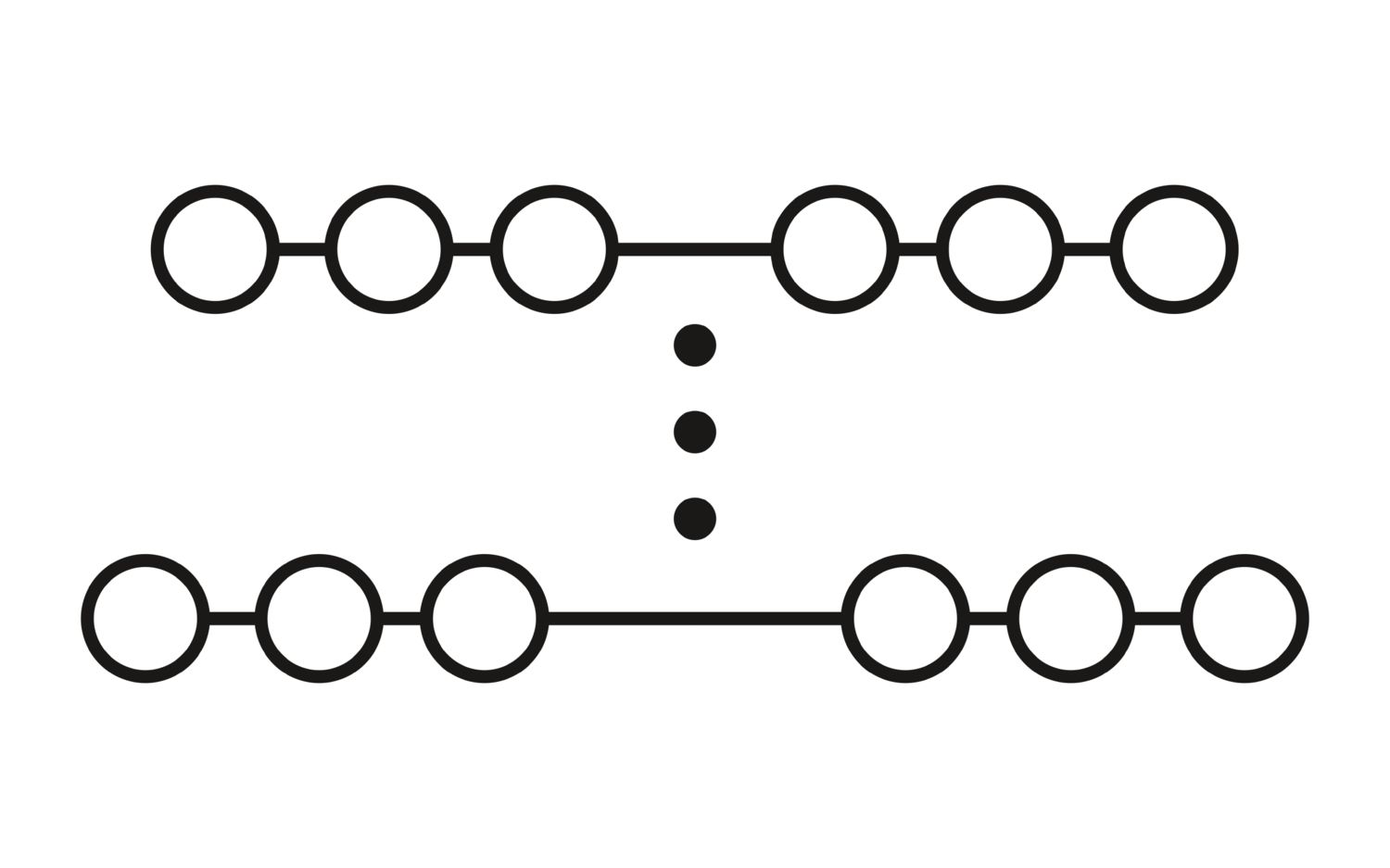

| Number of positions | 32 |

| Number of connections | 192 |

| Number of rows | 1 |

| Insulation characteristics | |

| Overvoltage category | III |

| Degree of pollution | 3 |

| Rated surge voltage | 6 kV |

| Maximum power dissipation for nominal condition | 0.56 W |

| Number of connections per level | 192 |

| Nominal cross section | 1.5 mm² |

| Rated cross section AWG | 14 |

| Connection method | Push-in connection |

| Stripping length | 8 mm ... 10 mm |

| Internal cylindrical gage | A1 |

| Connection in acc. with standard | IEC 60947-7-1 |

| Conductor cross-section rigid | 0.14 mm² ... 2.5 mm² |

| Cross section AWG | 26 ... 14 (converted acc. to IEC) |

| Conductor cross-section flexible | 0.14 mm² ... 1.5 mm² |

| Conductor cross-section, flexible [AWG] | 26 ... 16 (converted acc. to IEC) |

| Conductor cross-section flexible (ferrule without plastic sleeve) | 0.14 mm² ... 1.5 mm² |

| Flexible conductor cross-section (ferrule with plastic sleeve) | 0.14 mm² ... 1.5 mm² |

| Nominal current | 17.5 A |

| Maximum load current | 24 A (in case of a 2.5 mm² conductor cross-section, the maximum load current must not be exceeded by the total current of all connected conductors.) |

| 12 A (in case of a 2.5 mm² conductor cross-section, the maximum load current must not be exceeded by the total current of all connected conductors.) | |

| Nominal voltage | 500 V |

| Connection cross sections directly pluggable | |

| Conductor cross-section rigid | 0.34 mm² ... 2.5 mm² |

| Conductor cross-section, rigid [AWG] | 20 ... 14 (converted acc. to IEC) |

| Conductor cross-section flexible (ferrule without plastic sleeve) | 0.34 mm² ... 1.5 mm² |

| Flexible conductor cross-section (ferrule with plastic sleeve) | 0.34 mm² ... 1.5 mm² |

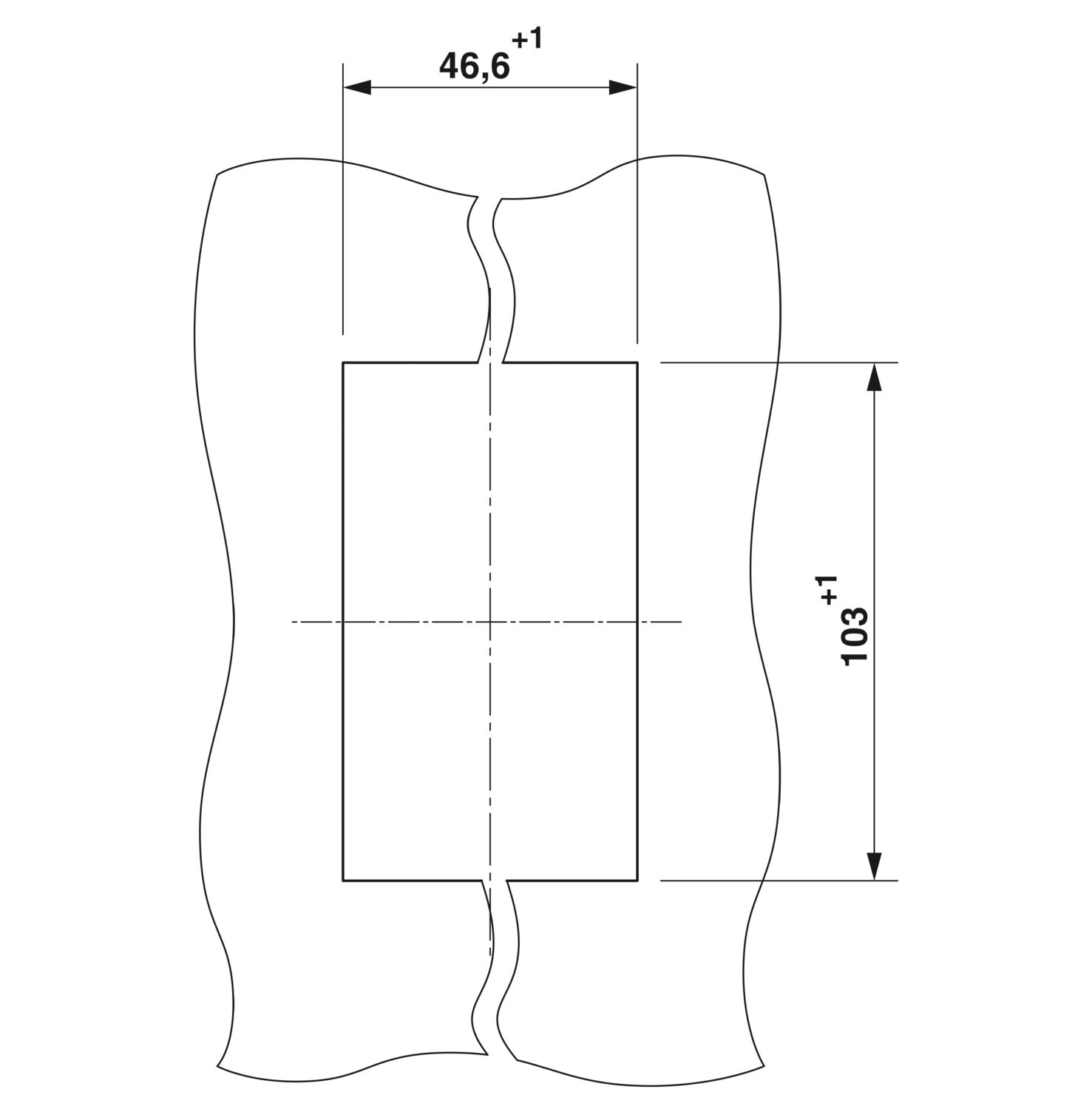

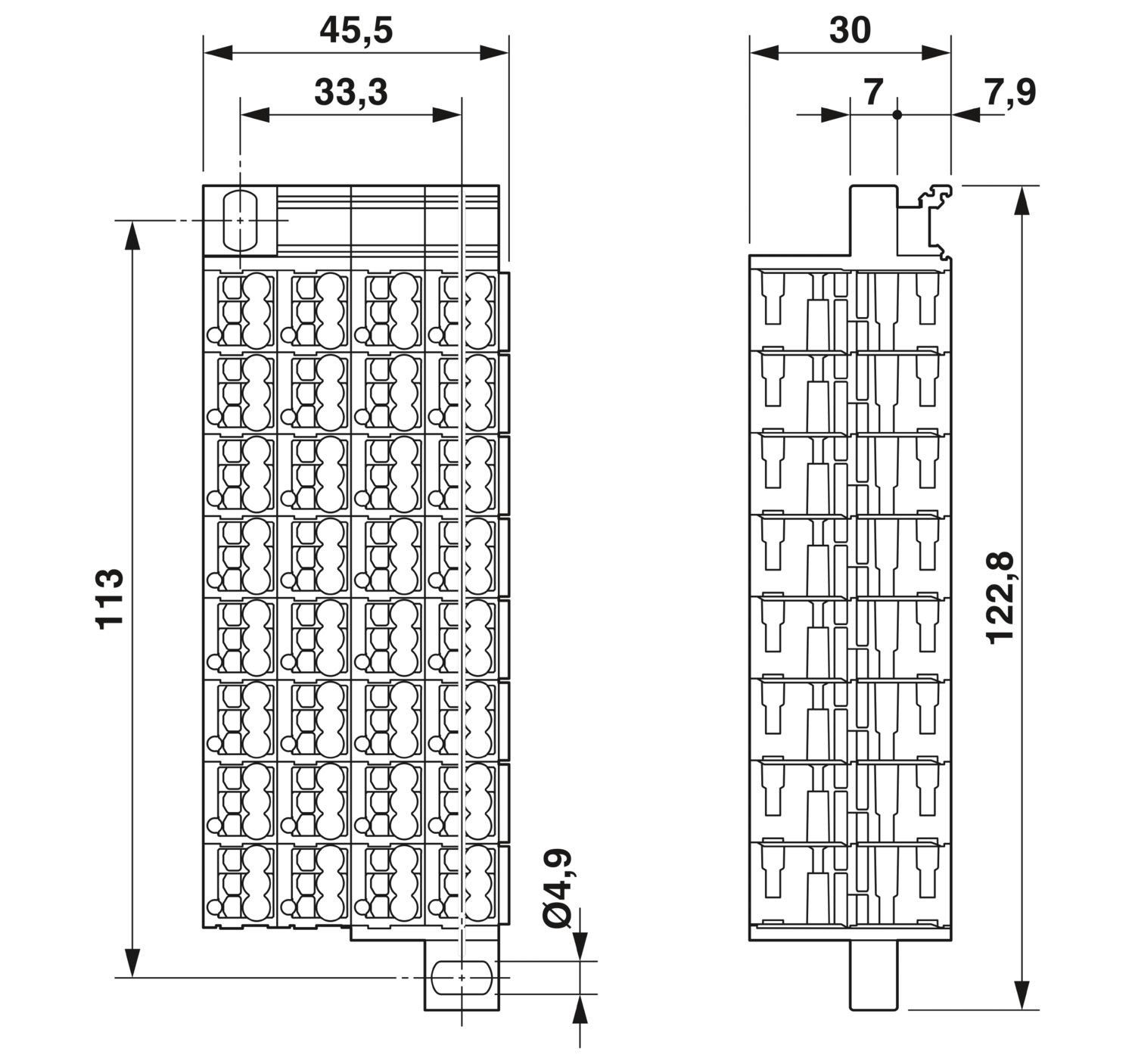

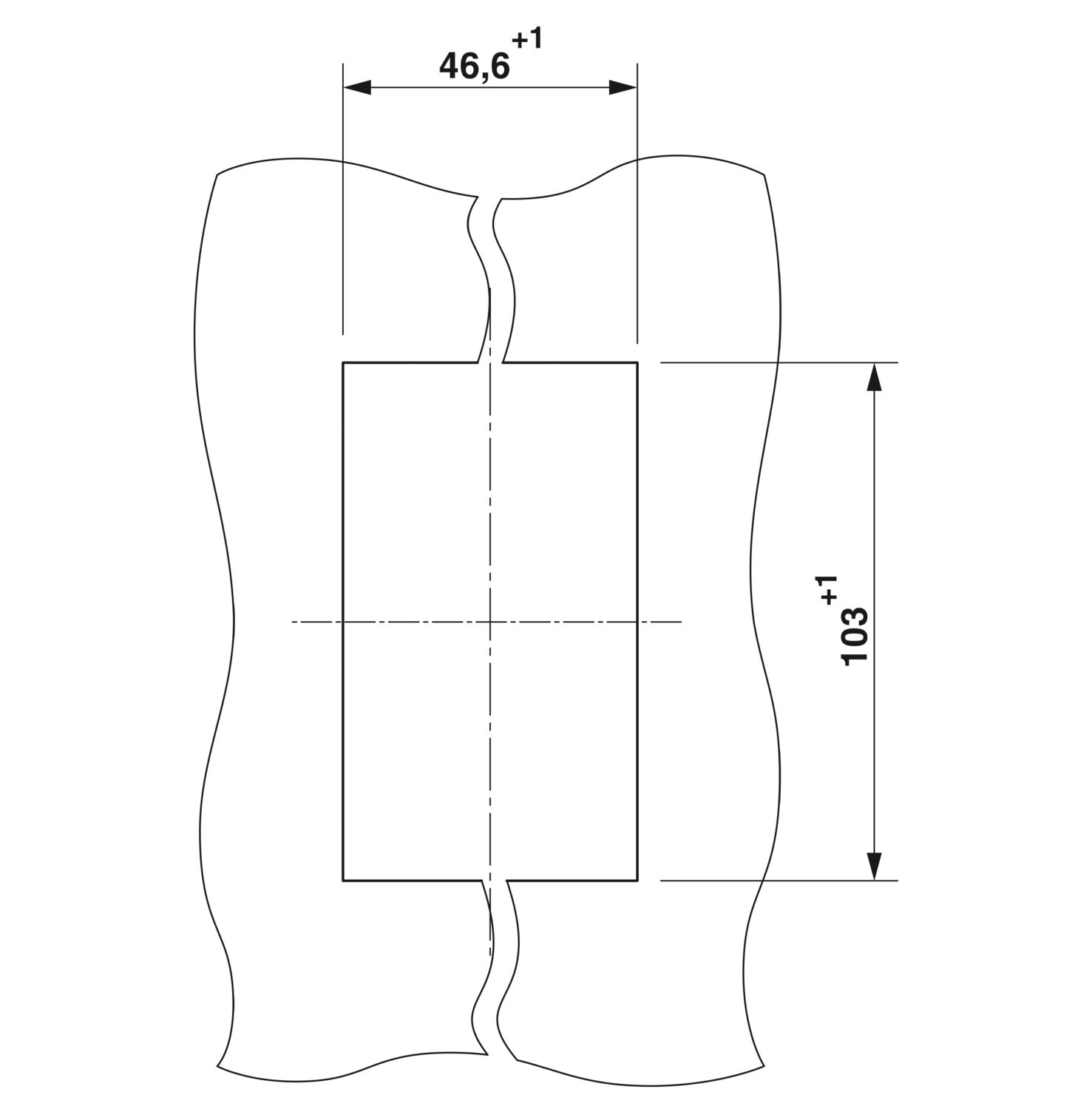

| Dimensional drawing |

|

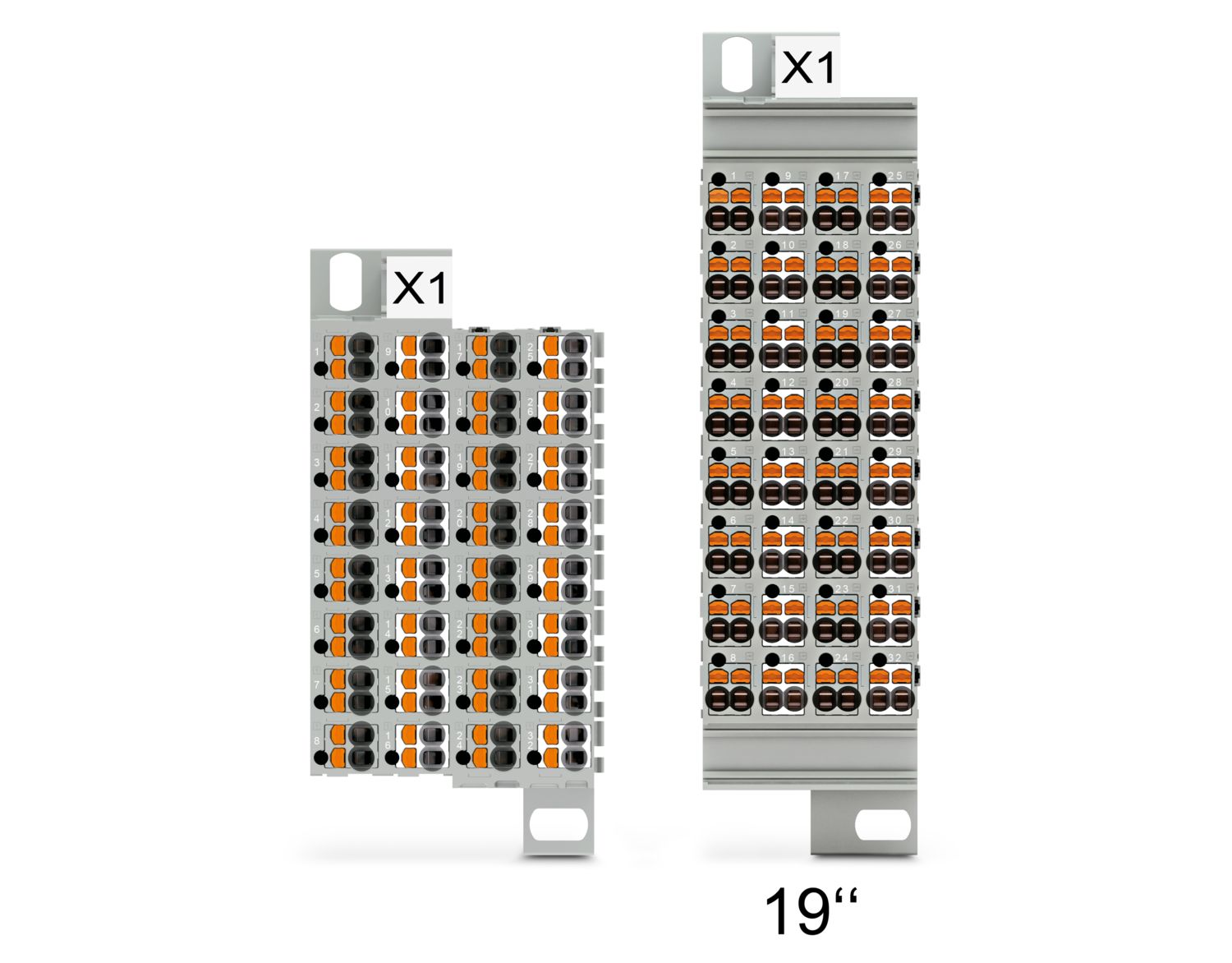

| Width | 44 mm |

| Height | 102 mm |

| Depth | 30 mm |

| Color | gray (RAL 7042) |

| Color of connection elements | blue |

| Flammability rating according to UL 94 | V0 |

| Insulating material group | I |

| Insulating material | PA |

| Static insulating material application in cold | -60 °C |

| Temperature index of insulation material (DIN EN 60216-1 (VDE 0304-21)) | 125 °C |

| Relative insulation material temperature index (Elec., UL 746 B) | 130 °C |

| Fire protection for rail vehicles (DIN EN 45545-2) R22 | HL 1 - HL 3 |

| Fire protection for rail vehicles (DIN EN 45545-2) R23 | HL 1 - HL 3 |

| Fire protection for rail vehicles (DIN EN 45545-2) R24 | HL 1 - HL 3 |

| Fire protection for rail vehicles (DIN EN 45545-2) R26 | HL 1 - HL 3 |

| Calorimetric heat release NFPA 130 (ASTM E 1354) | 27,5 MJ/kg |

| Surface flammability NFPA 130 (ASTM E 162) | passed |

| Specific optical density of smoke NFPA 130 (ASTM E 662) | passed |

| Smoke gas toxicity NFPA 130 (SMP 800C) | passed |

| Surge voltage test | |

| Test voltage setpoint | 7.3 kV |

| Result | Test passed |

| Temperature-rise test | |

| Requirement temperature-rise test | Increase in temperature ≤ 45 K |

| Result | Test passed |

| Short-time withstand current 1.5 mm² | 0.18 kA |

| Short-time withstand current 2.5 mm² | 0.3 kA |

| Result | Test passed |

| Power-frequency withstand voltage | |

| Test voltage setpoint | 1.89 kV |

| Result | Test passed |

| Mechanical data | |

| Open side panel | No |

| Mechanical strength | |

| Result | Test passed |

| Attachment on the carrier | |

| DIN rail/fixing support | NS 35 |

| Test force setpoint | 1 N |

| Result | Test passed |

| Test for conductor damage and slackening | |

| Rotation speed | 10 rpm |

| Revolutions | 135 |

| Conductor cross-section/weight | 0.14 mm² / 0.2 kg |

| 1.5 mm² / 0.4 kg | |

| 2.5 mm² / 0.7 kg | |

| Result | Test passed |

| Aging | |

| Temperature cycles | 192 |

| Result | Test passed |

| Needle-flame test | |

| Time of exposure | 30 s |

| Result | Test passed |

| Oscillation/broadband noise | |

| Specification | DIN EN 50155 (VDE 0115-200):2008-03 |

| Spectrum | Long life test category 1, class B, body mounted |

| Frequency | f1 = 5 Hz to f2 = 150 Hz |

| ASD level | 0.964 (m/s²)²/Hz |

| Acceleration | 0.58g |

| Test duration per axis | 5 h |

| Test directions | X-, Y- and Z-axis |

| Result | Test passed |

| Shocks | |

| Specification | DIN EN 50155 (VDE 0115-200):2008-03 |

| Pulse shape | Half-sine |

| Acceleration | 5g |

| Shock duration | 30 ms |

| Number of shocks per direction | 3 |

| Test directions | X-, Y- and Z-axis (pos. and neg.) |

| Result | Test passed |

| Ambient conditions | |

| Ambient temperature (operation) | -60 °C ... 105 °C (max. short-term operating temperature RTI Elec.) |

| Ambient temperature (storage/transport) | -25 °C ... 60 °C (for a short time, not exceeding 24 h, -60 °C to +70 °C) |

| Ambient temperature (assembly) | -5 °C ... 70 °C |

| Ambient temperature (actuation) | -5 °C ... 70 °C |

| Permissible humidity (storage/transport) | 30 % ... 70 % |

| Connection in acc. with standard | IEC 60947-7-1 |

| Mounting type | Panel mounting |

| Item number | 3270312 |

| Packing unit | 18 pc |

| Minimum order quantity | 1 pc |

| Note | Made to order (non-returnable) |

| Sales key | BE6212 |

| Product key | BE6212 |

| GTIN | 4055626058344 |

| Weight per piece (including packing) | 99.99 g |

| Weight per piece (excluding packing) | 99.99 g |

| Customs tariff number | 85369010 |

| Country of origin | PL |

ECLASS

| ECLASS-13.0 | 27250106 |

ETIM

| ETIM 9.0 | EC000897 |

UNSPSC

| UNSPSC 21.0 | 39121400 |

| EU RoHS | |

| Fulfills EU RoHS substance requirements | Yes (No exemptions) |

| China RoHS | |

| Environment friendly use period (EFUP) |

EFUP-E

No hazardous substances above the limits

|

| EU REACH SVHC | |

| REACH candidate substance (CAS No.) | No substance above 0.1 wt% |

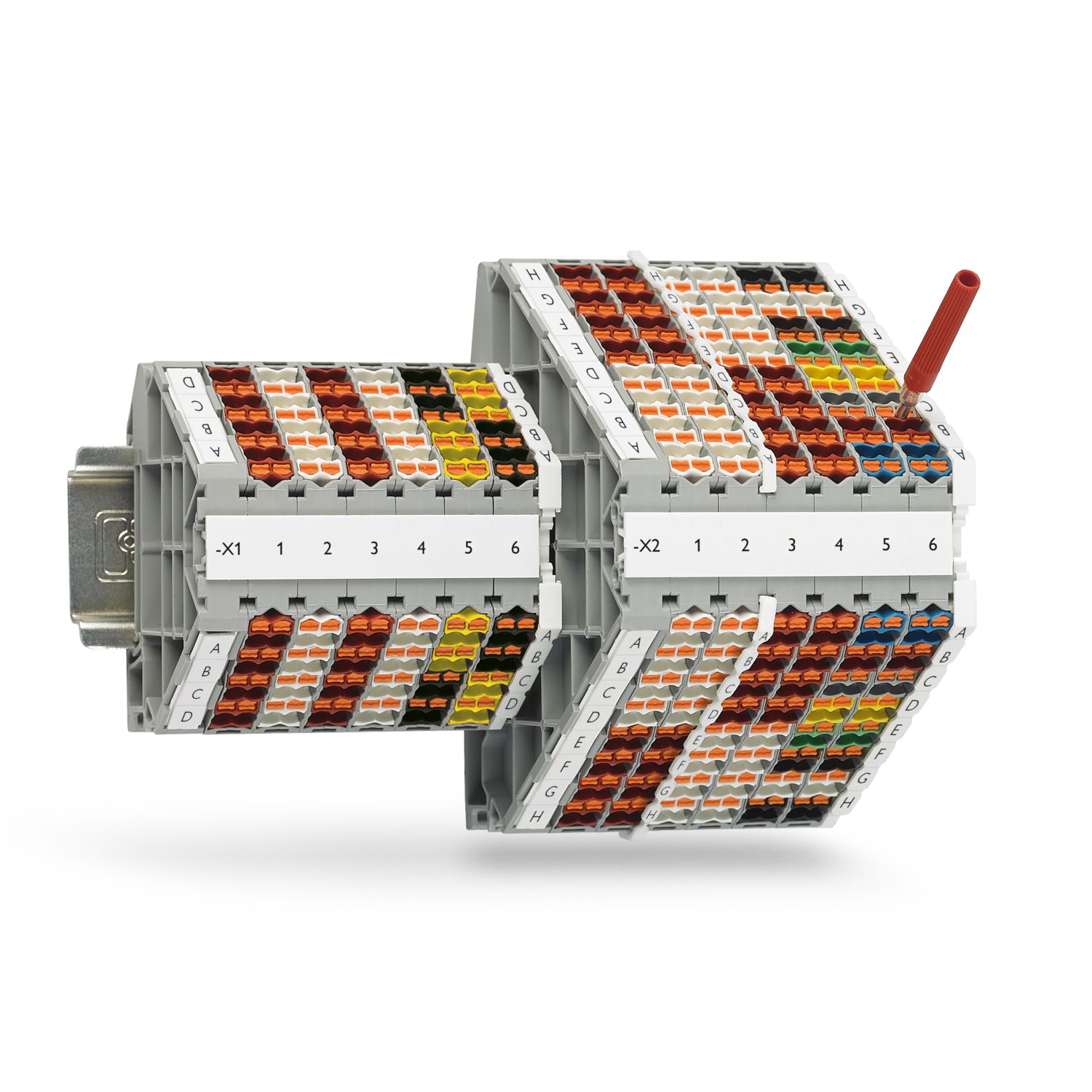

Compatible products

Note: Applying some accessories below might limit this product.

-

-

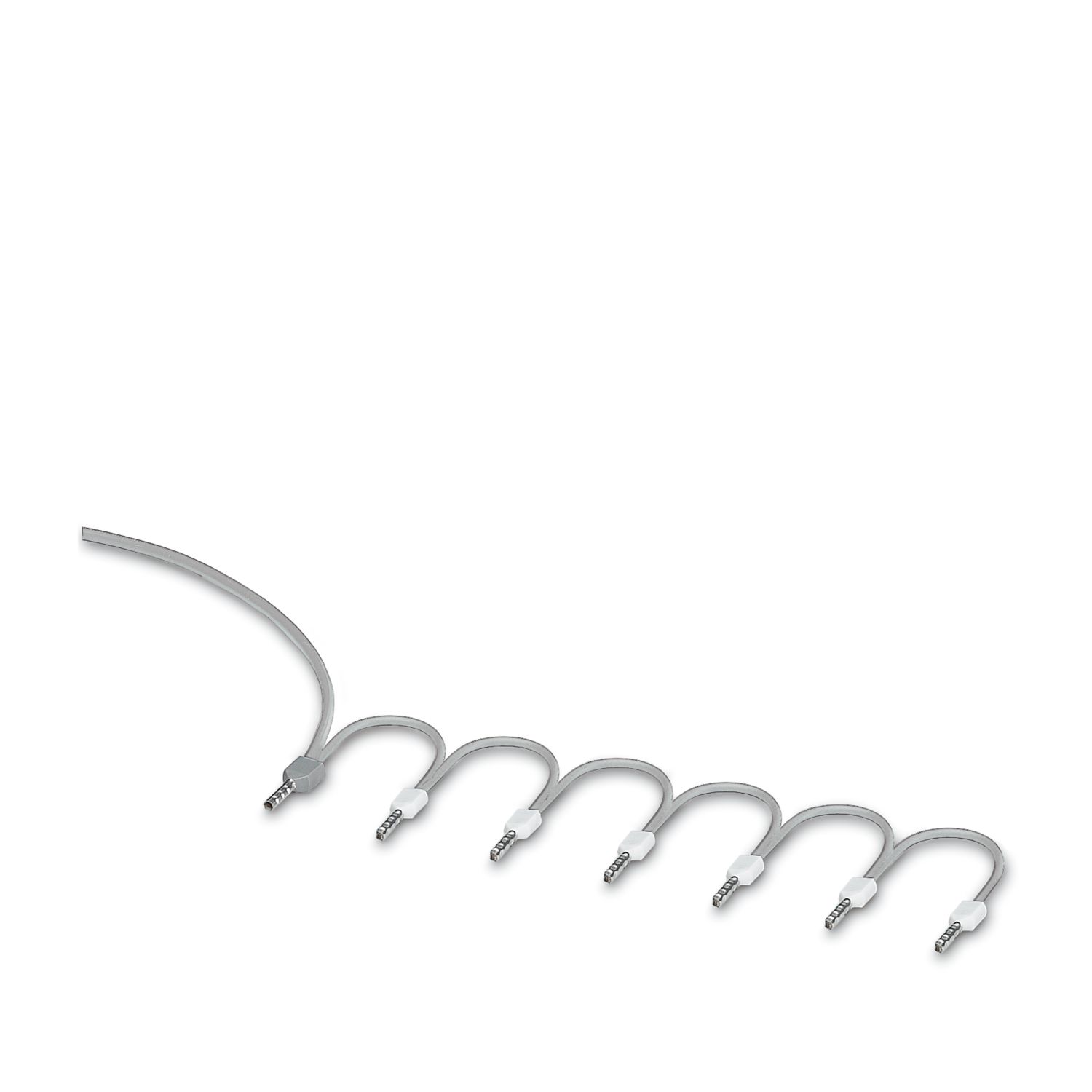

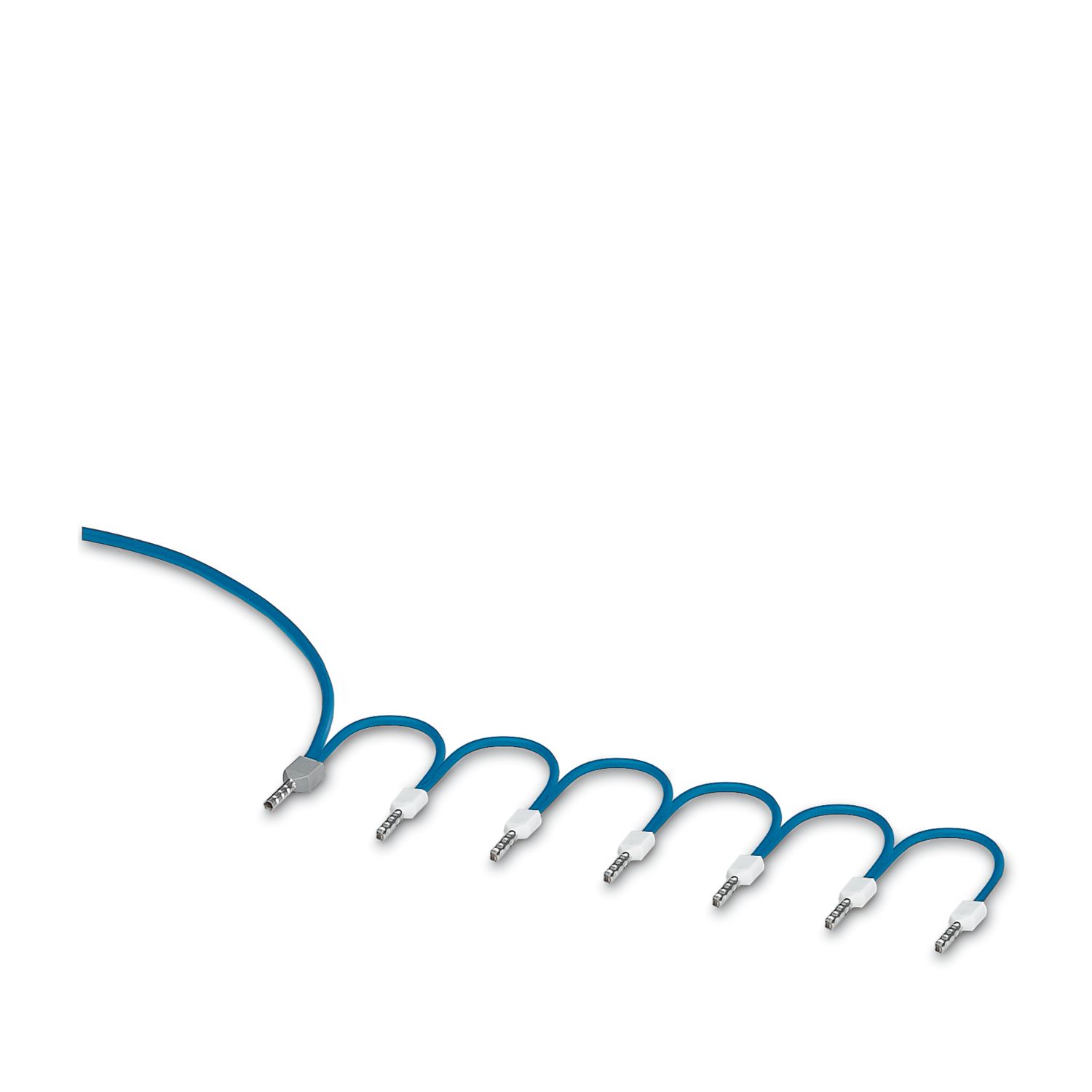

DB 50- 90 BK - Wire bridge 2820916

-

DB 50- 90 GY - Wire bridge 2820929

-

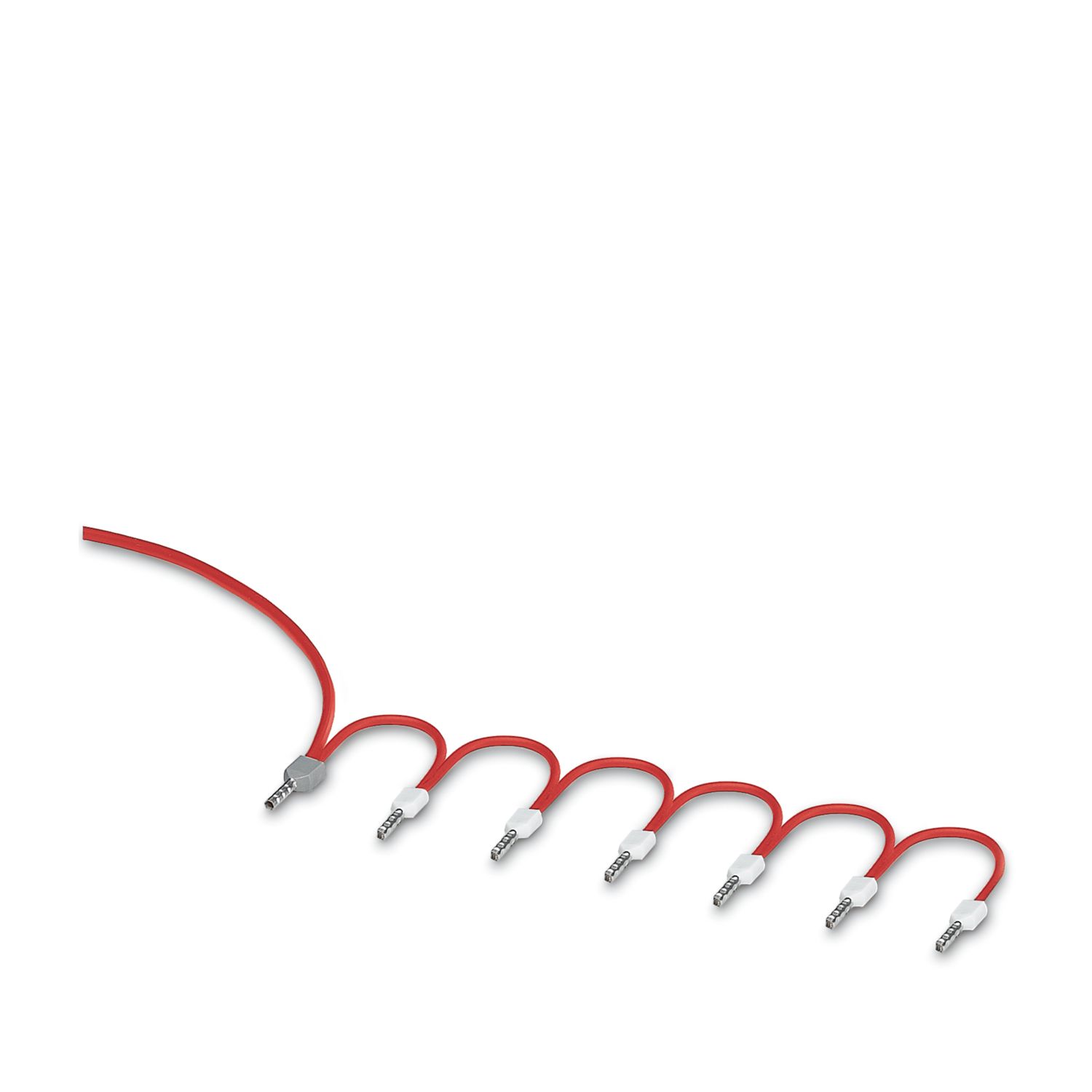

DB 50- 90 RD - Wire bridge 2864639

-

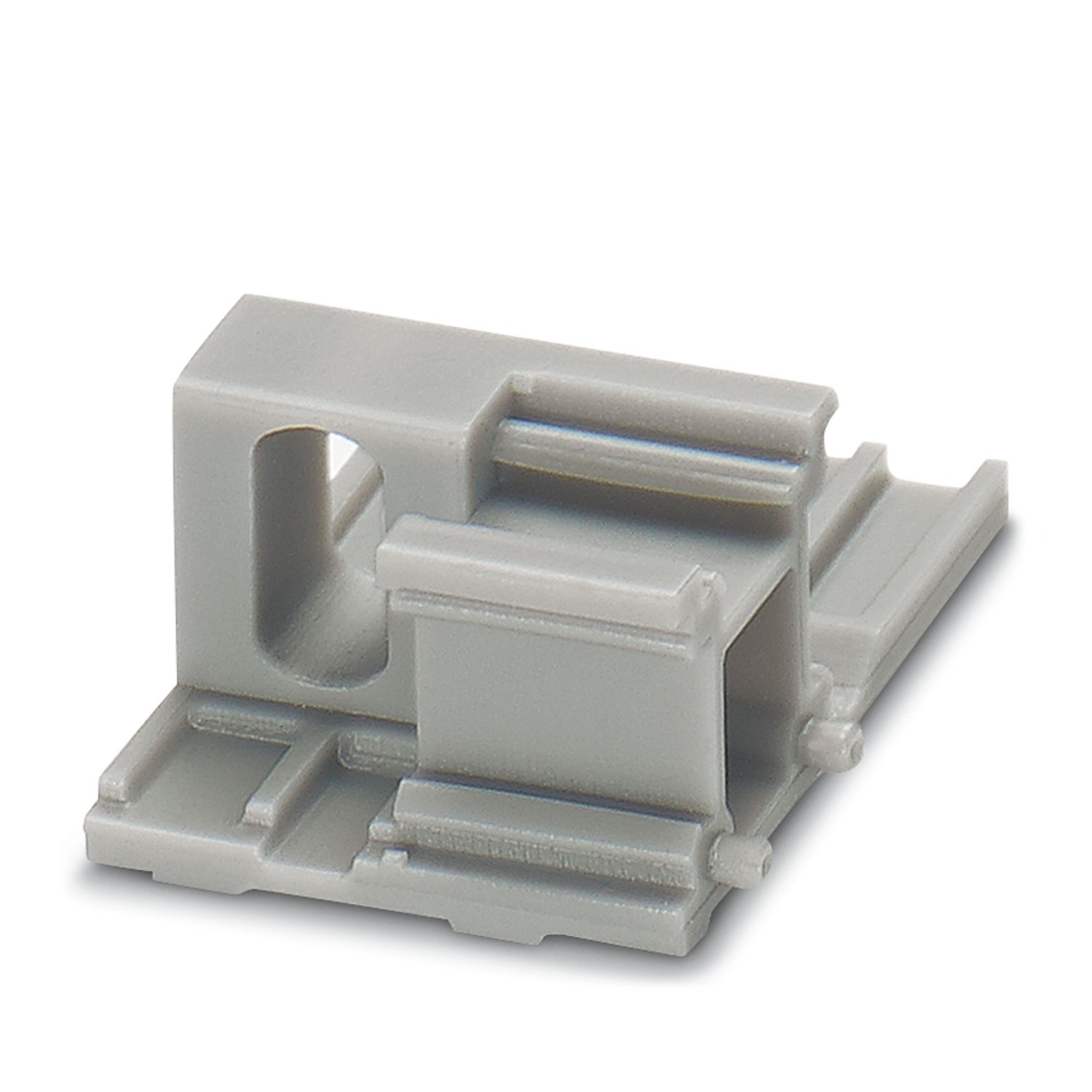

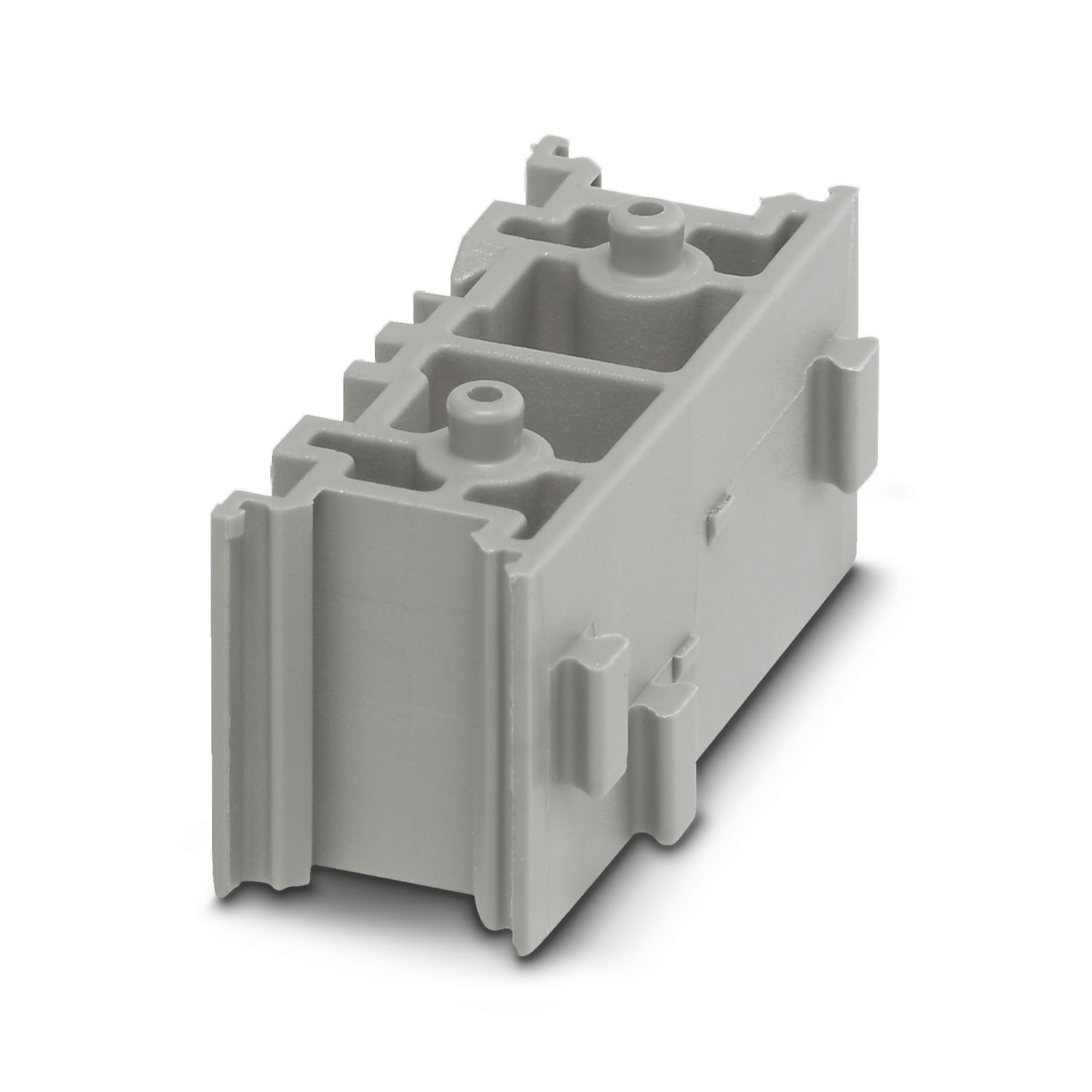

DF-PTMC-O - Flange cover 3270400

-

DF-PTMC-U - Flange cover 3270401

-

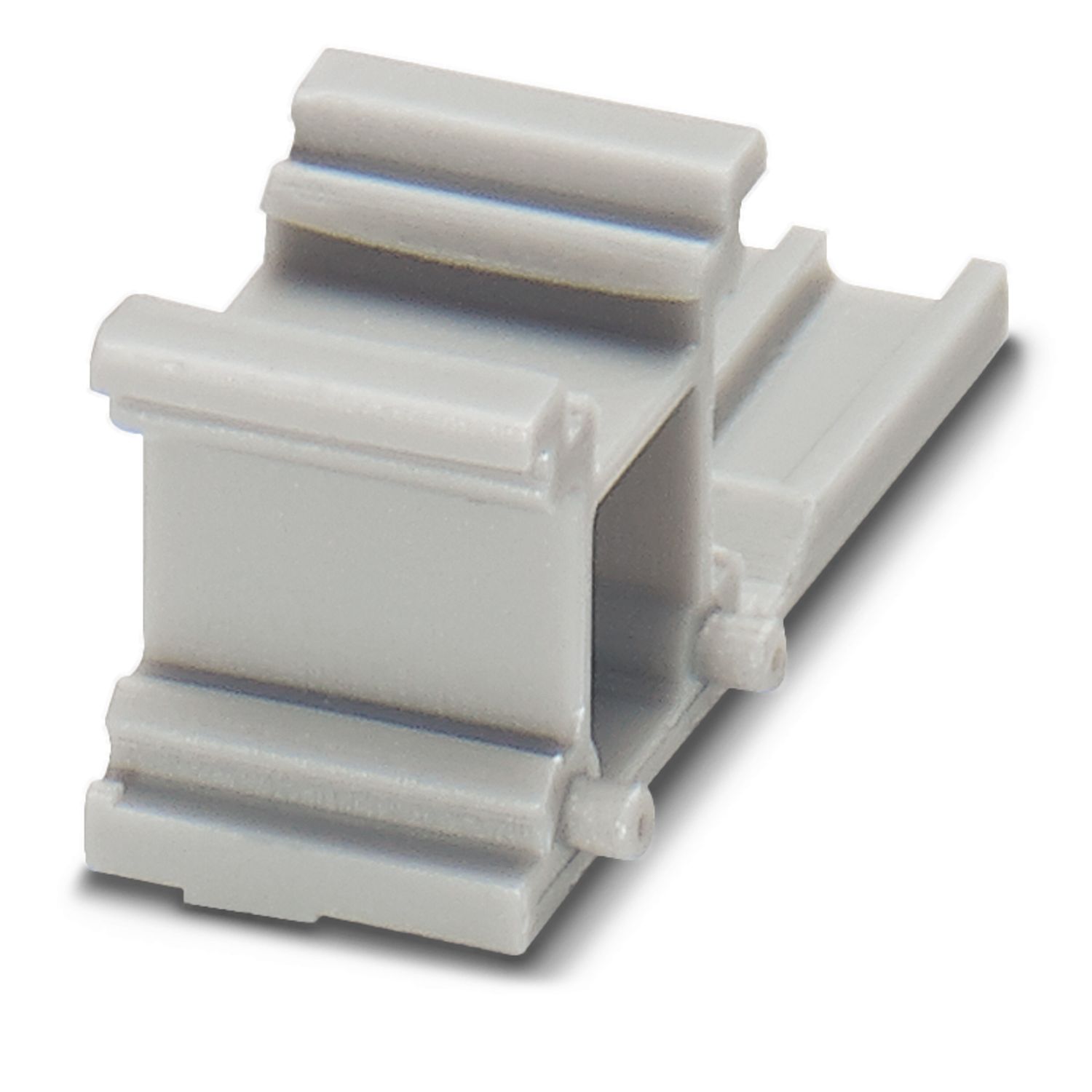

DF-PTMC-NS - Adapter 3270403

-

DF-PTMC-ZB - Marker adapter 3270410

-

RPS - Reducing plug 0201647

-

DF-PTMC-3-ZB - Marker adapter 3270405

-

MPS-MT - Test plug 0201744

-

MPS-IH WH - Insulating sleeve 0201663

-

MPS-IH RD - Insulating sleeve 0201676

-

MPS-IH BU - Insulating sleeve 0201689

-

MPS-IH YE - Insulating sleeve 0201692

-

MPS-IH GN - Insulating sleeve 0201702

-

MPS-IH GY - Insulating sleeve 0201728

-

MPS-IH BK - Insulating sleeve 0201731

-

SZF 0-0,4X2,5 - Screwdriver 1204504

-

ST-BW 0 - Actuation tool 1200135

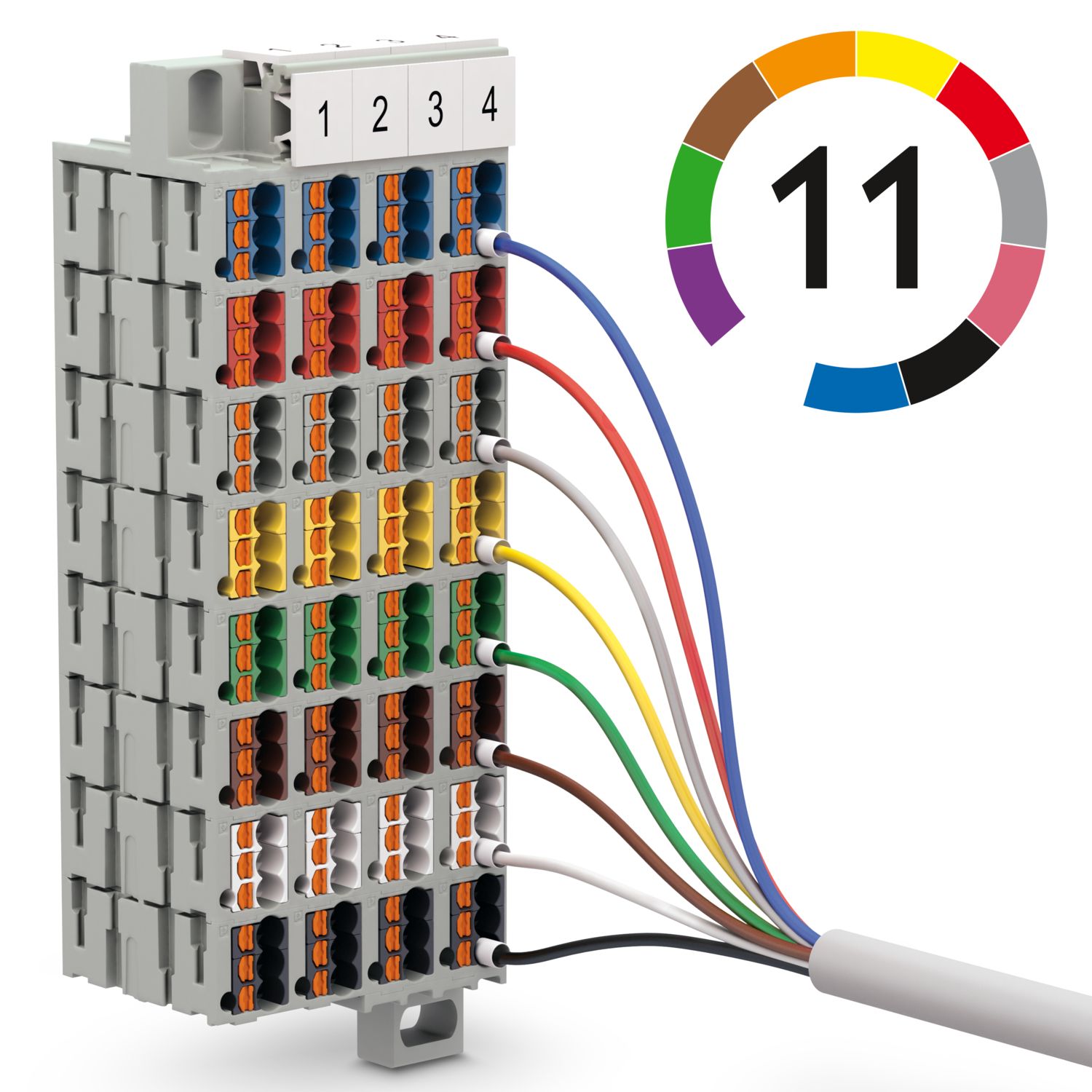

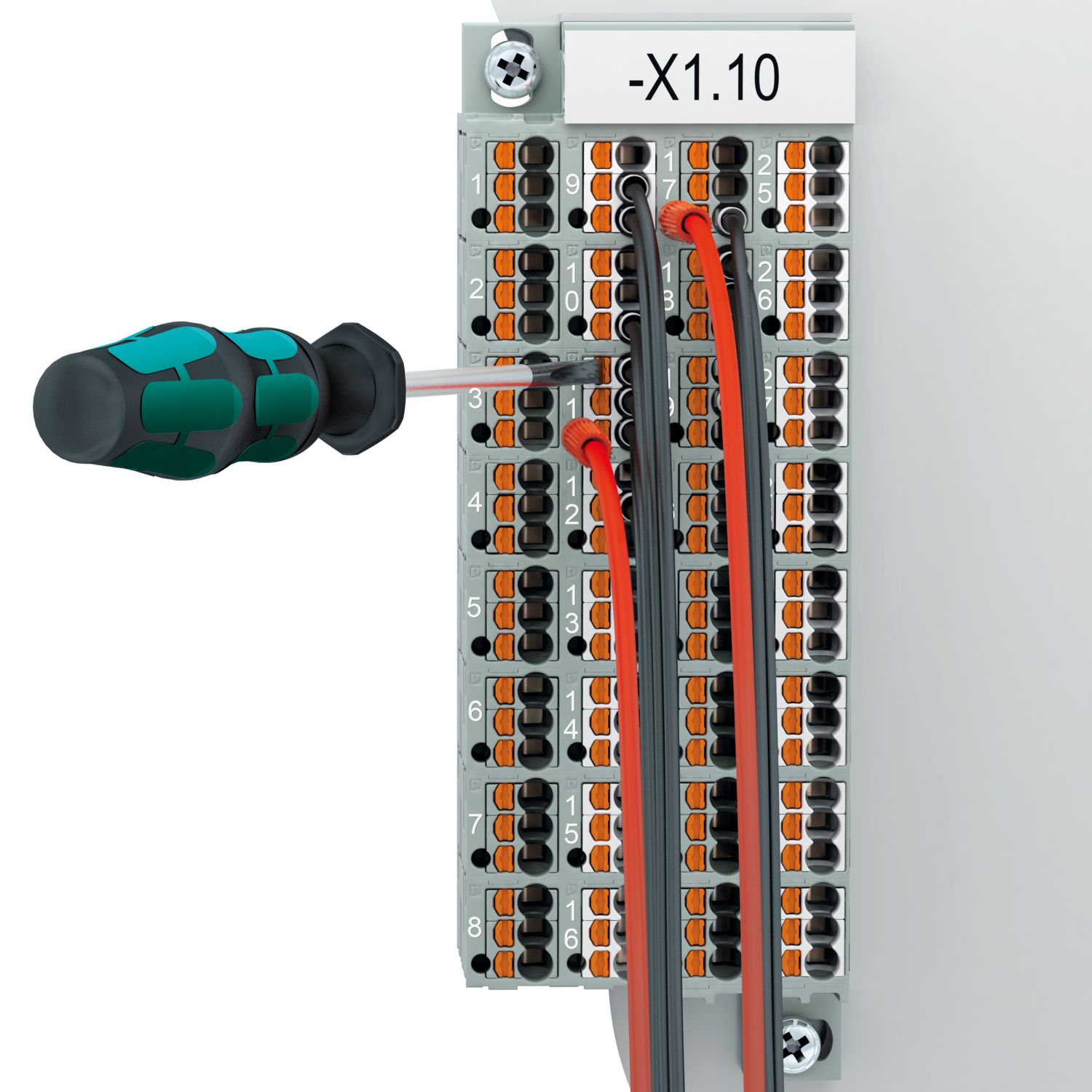

Your advantages

Blue version for using in intrinsically safe circuits in potentially explosive areas (type of protection Ex i)

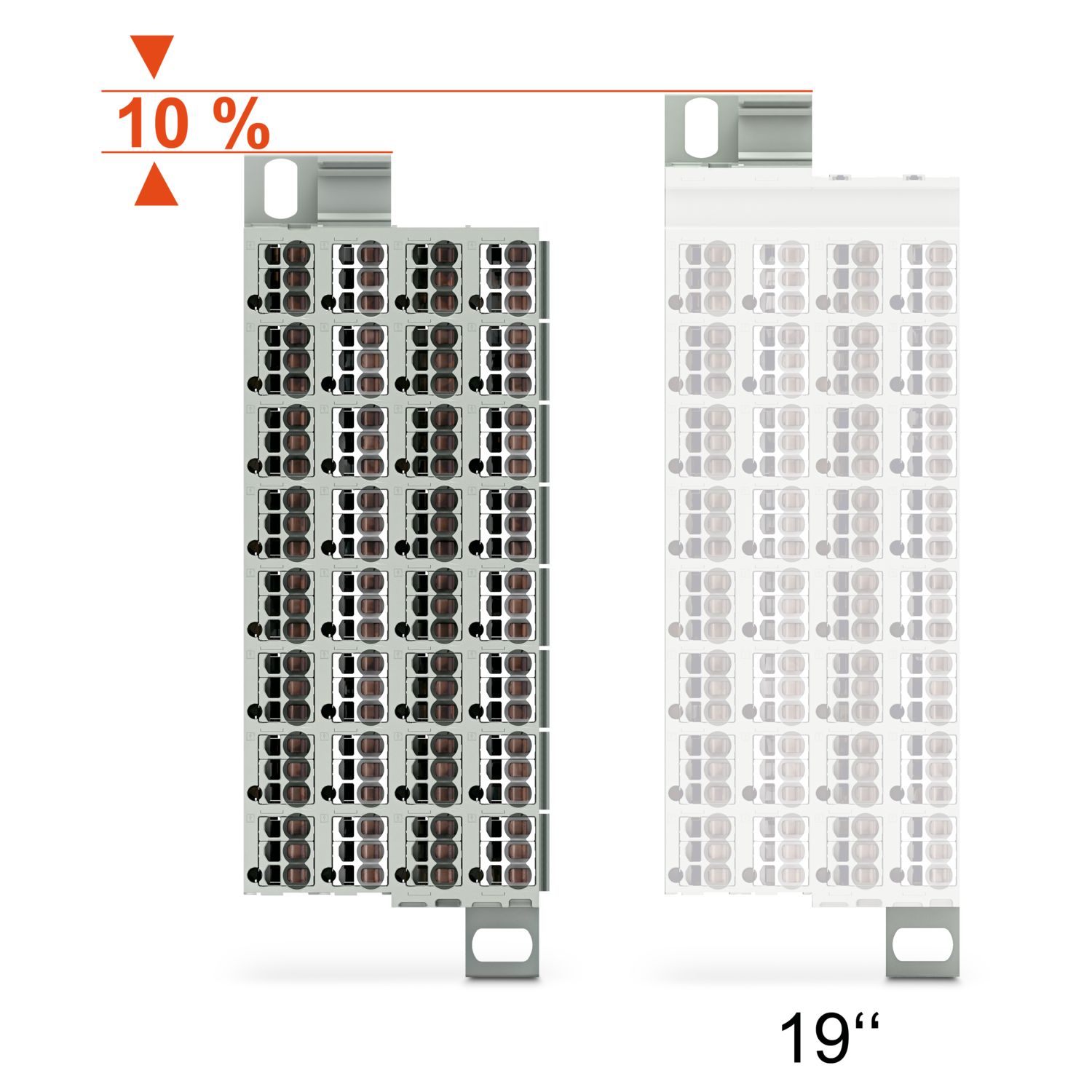

For mounting in a panel cutout

Clear representation of actuation and terminal points through vertical conductor routing

High contact quality thanks to push-in technology as a replacement for Wire-Wrap®, TERMI-POINT®, etc.

Tool-free wiring in a confined space thanks to compact size

PHOENIX CONTACT Ltd

Halesfield 13, Telford, Shropshire, TF7 4PG