UKH 50-FE-F

-

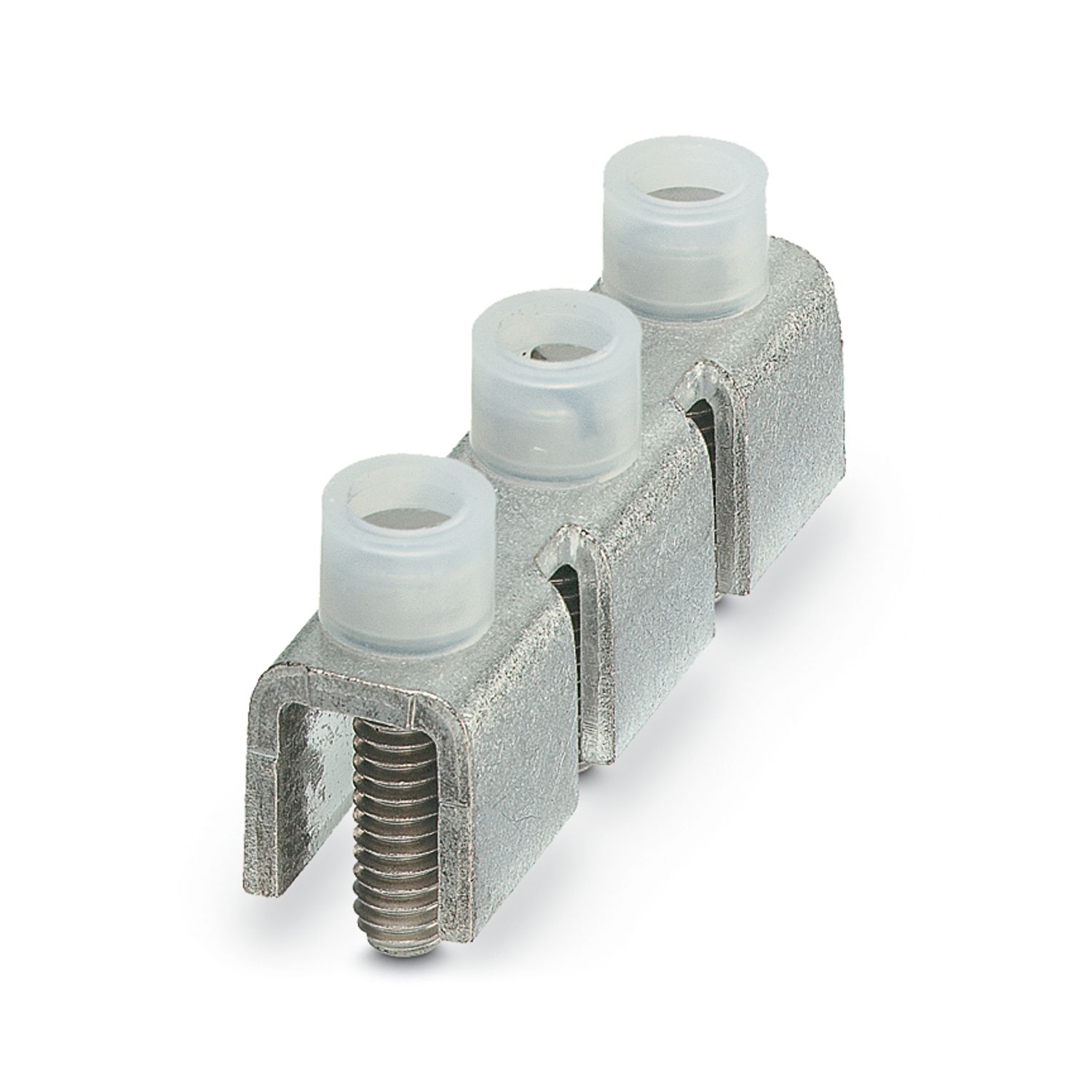

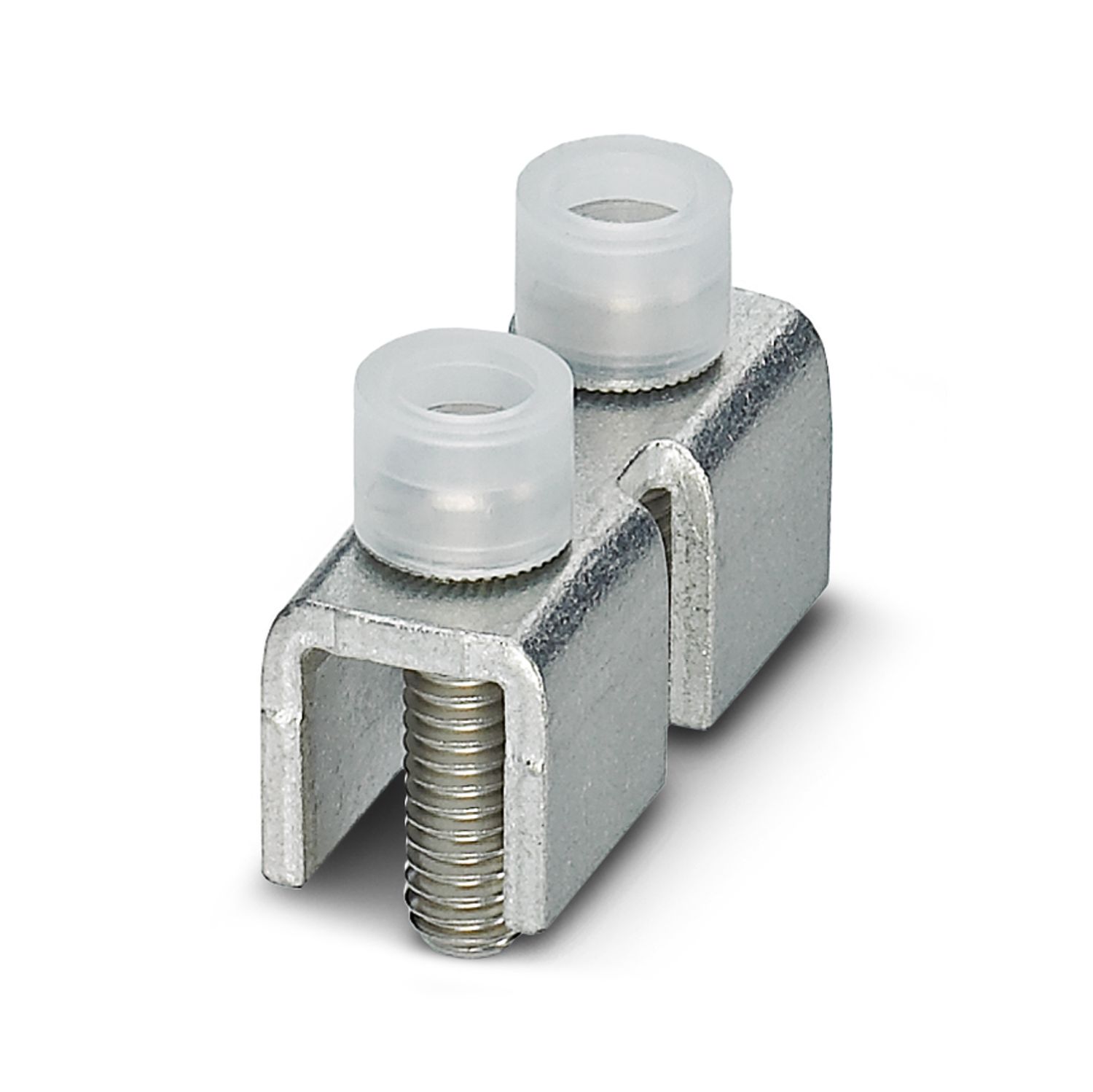

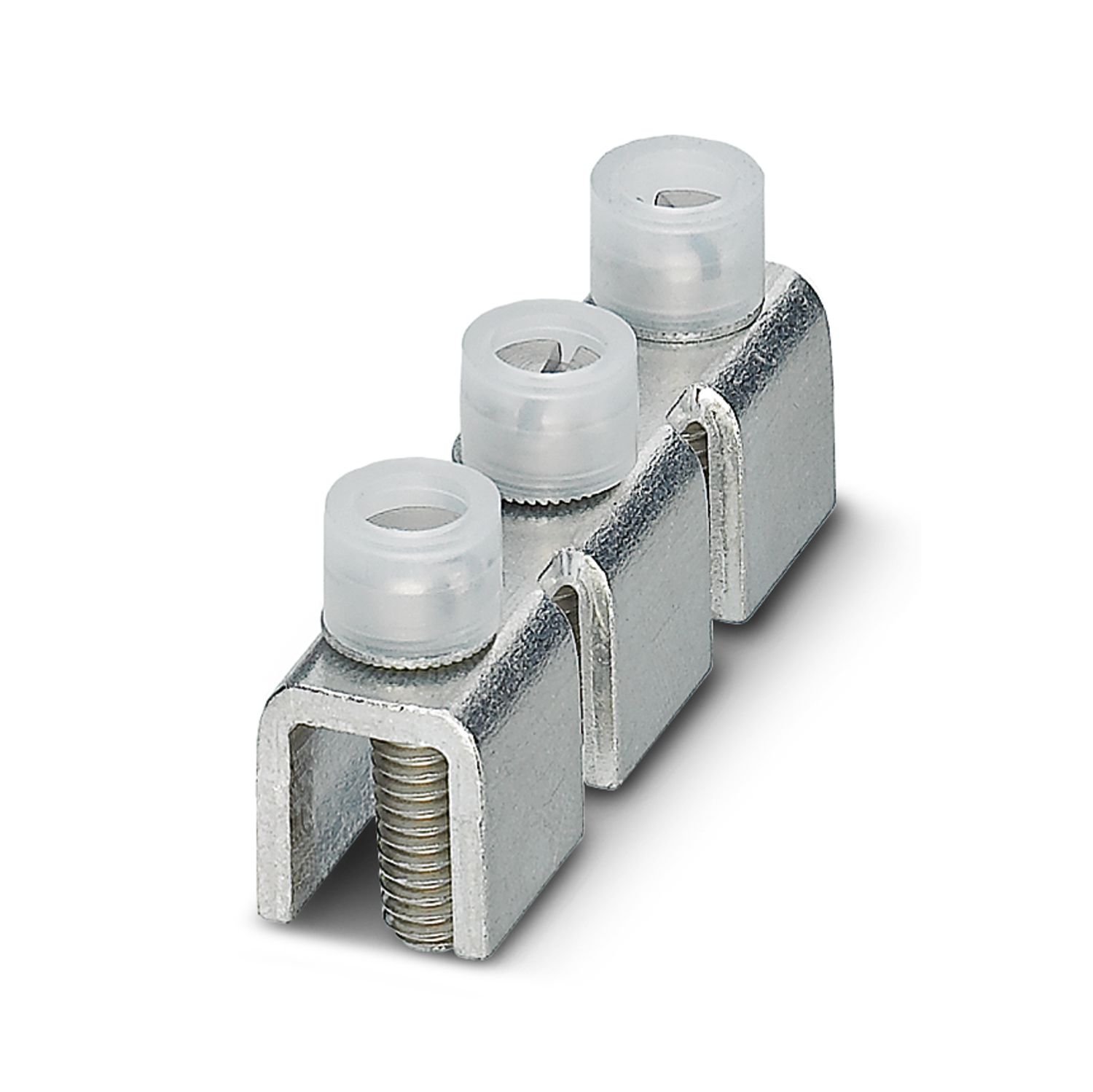

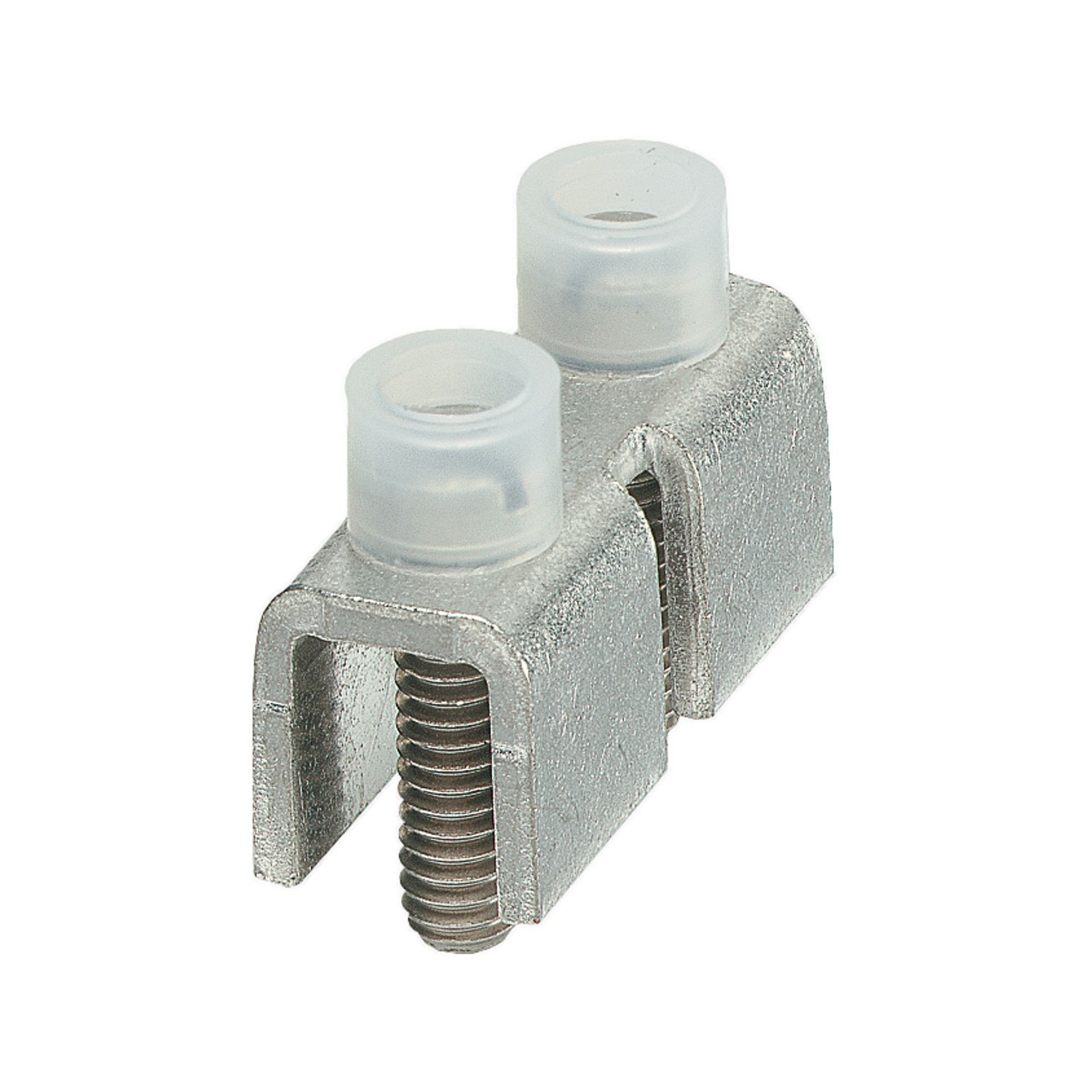

High-current terminal block

3247057

High-current terminal block, nom. voltage: 1000 V, nominal current: 150 A, number of connections: 2, number of positions: 1, connection method: Screw connection, Rated cross section: 50 mm2, cross section: 16 mm2 - 70 mm2, mounting type: direct screw connection, color: black/yellow

Product details

| General | |

| Note | For a reliable contact of multi stranded conductors it is recommended to untwist multi stranded conductors. |

| Number of positions | 1 |

| Number of connections | 2 |

| Number of rows | 1 |

| Potentials | 1 |

| Insulation characteristics | |

| Overvoltage category | III |

| Degree of pollution | 3 |

| Rated surge voltage | 8 kV |

| Maximum power dissipation for nominal condition | 4.73 W |

| Number of connections per level | 2 |

| Nominal cross section | 50 mm² |

| Level 1 above 1 below 1 | |

| Connection method | Screw connection |

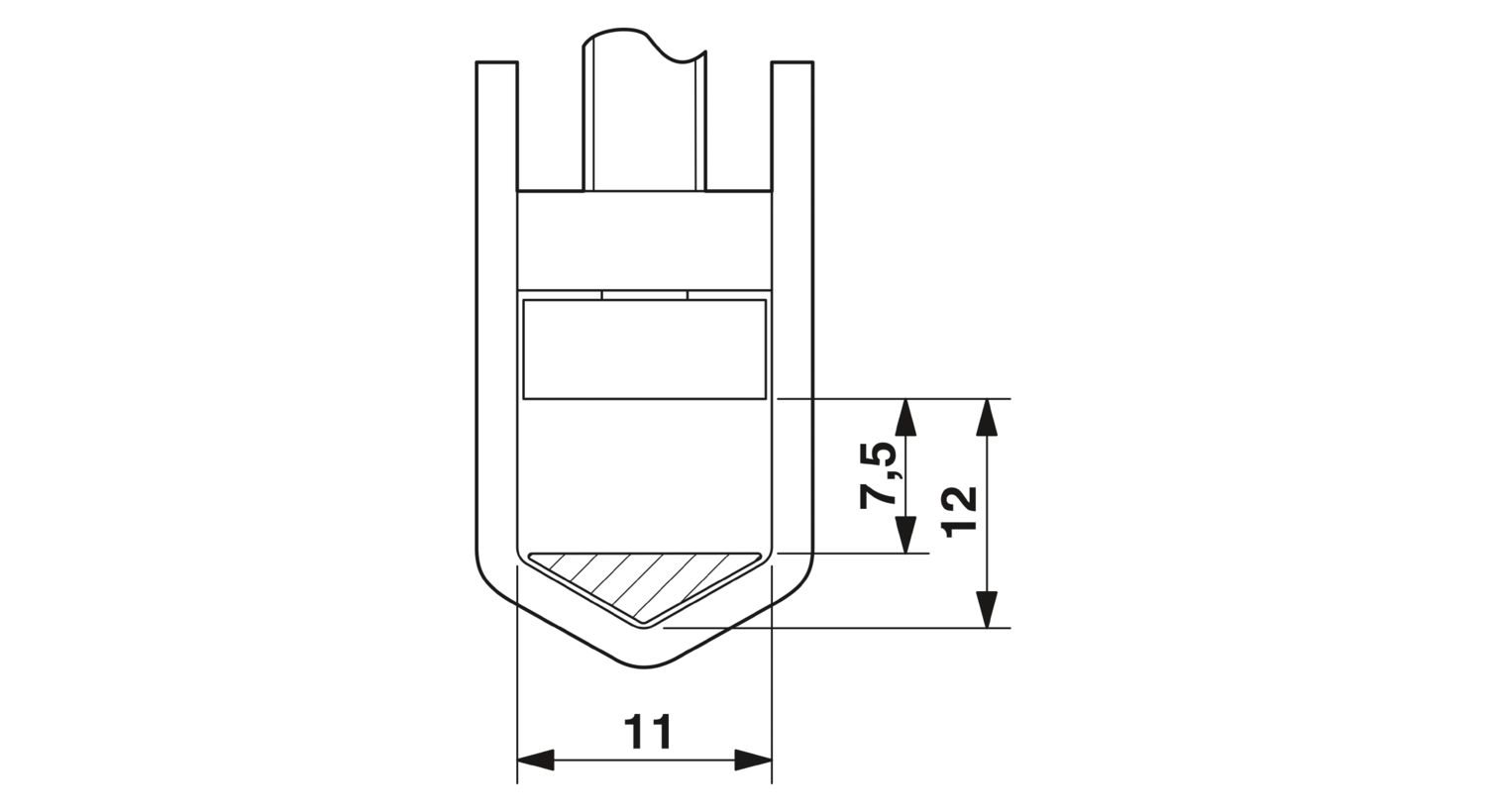

| Screw thread | M6 |

| Tightening torque | 6 ... 8 Nm |

| Stripping length | 24 mm |

| Internal cylindrical gage | B10 |

| Connection in acc. with standard | IEC 60947-7-1 |

| Conductor cross-section rigid | 16 mm² ... 70 mm² |

| Cross section AWG | 6 ... 2/0 (converted acc. to IEC) |

| Conductor cross-section flexible | 25 mm² ... 70 mm² |

| Conductor cross-section, flexible [AWG] | 3 ... 2/0 (converted acc. to IEC) |

| Conductor cross-section flexible (ferrule without plastic sleeve) | 25 mm² ... 50 mm² |

| Flexible conductor cross-section (ferrule with plastic sleeve) | 25 mm² ... 50 mm² |

| 2 conductors with same cross section, solid | 10 mm² ... 16 mm² |

| 2 conductors with same cross section, flexible | 10 mm² ... 16 mm² |

| 2 conductors with same cross section, flexible, with ferrule without plastic sleeve | 10 mm² ... 16 mm² |

| Nominal current | 150 A |

| Maximum load current | 150 A (with 50 mm² conductor cross-section) |

| Nominal voltage | 1000 V |

| Note | Note: Product releases, connection cross sections and notes on connecting aluminum cables can be found in the download area. |

| Nominal cross section | 50 mm² |

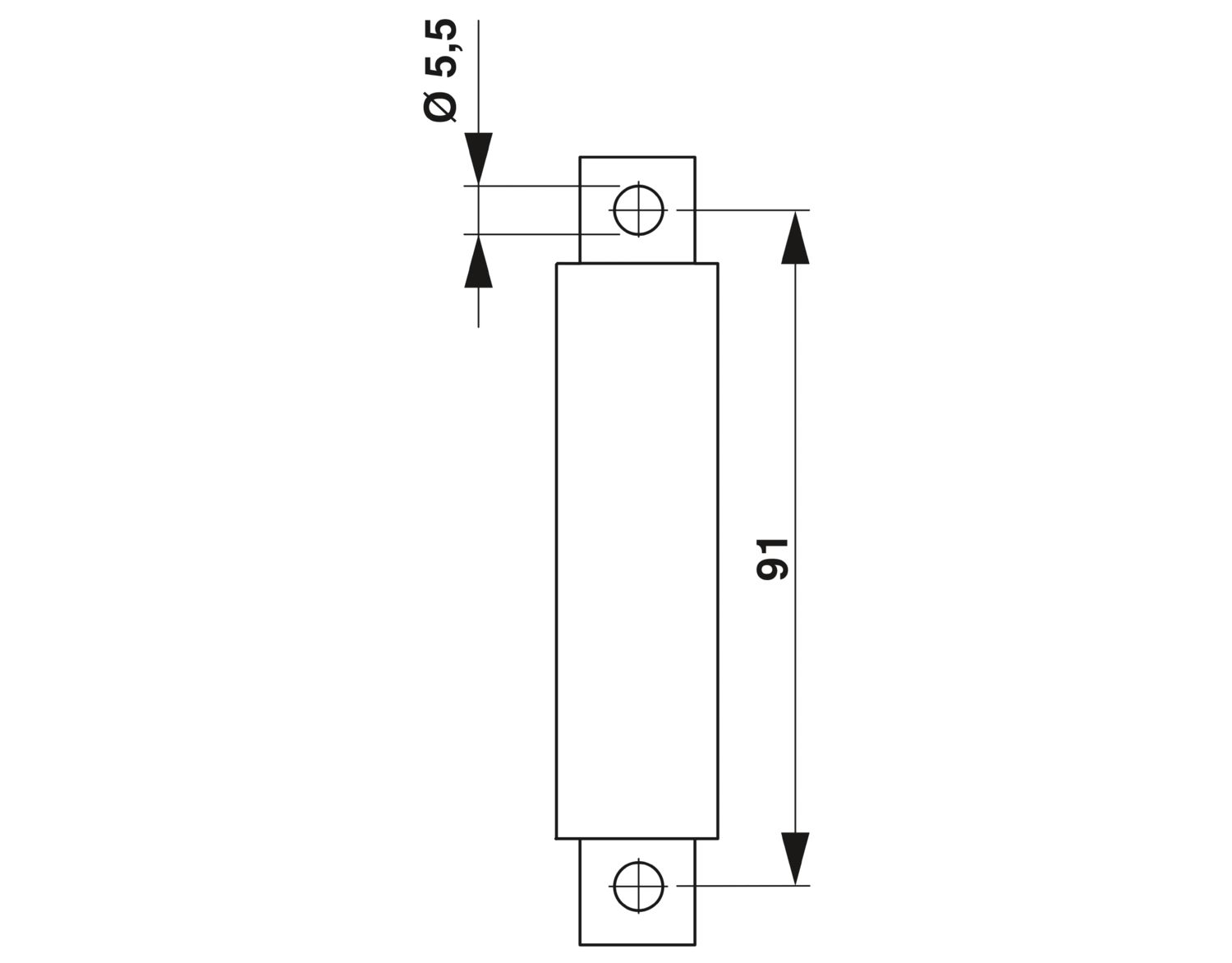

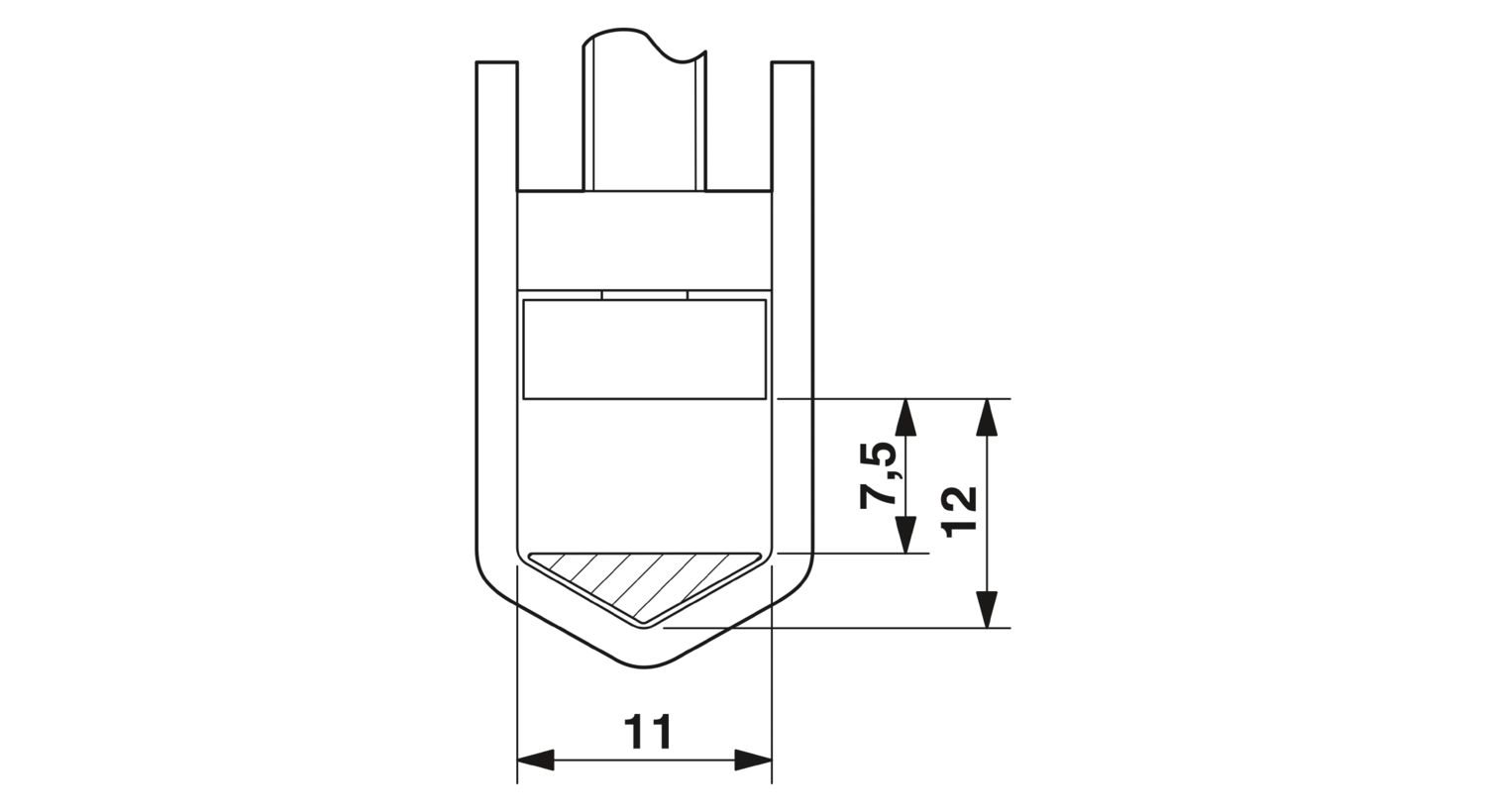

| Dimensional drawing |

|

| Width | 20 mm |

| Height | 76 mm |

| Color | black/yellow |

| Flammability rating according to UL 94 | V0 |

| Insulating material group | I |

| Insulating material | PA |

| Static insulating material application in cold | -60 °C |

| Relative insulation material temperature index (Elec., UL 746 B) | 130 °C |

| Fire protection for rail vehicles (DIN EN 45545-2) R22 | HL 1 - HL 3 |

| Fire protection for rail vehicles (DIN EN 45545-2) R23 | HL 1 - HL 3 |

| Fire protection for rail vehicles (DIN EN 45545-2) R24 | HL 1 - HL 3 |

| Fire protection for rail vehicles (DIN EN 45545-2) R26 | HL 1 - HL 3 |

| Surface flammability NFPA 130 (ASTM E 162) | passed |

| Specific optical density of smoke NFPA 130 (ASTM E 662) | passed |

| Smoke gas toxicity NFPA 130 (SMP 800C) | passed |

| Surge voltage test | |

| Test voltage setpoint | 9.8 kV |

| Result | Test passed |

| Short-time withstand current 50 mm² | 6 kA |

| Result | Test passed |

| Power-frequency withstand voltage | |

| Test voltage setpoint | 2.2 kV |

| Result | Test passed |

| Mechanical data | |

| Open side panel | No |

| Mechanical strength | |

| Result | Test passed |

| Attachment on the carrier | |

| DIN rail/fixing support | NS 32/NS 35 |

| Test force setpoint | 10 N |

| Result | Test passed |

| Test for conductor damage and slackening | |

| Rotation speed | 10 rpm |

| Revolutions | 135 |

| Conductor cross-section/weight | 16 mm² / 2.9 kg |

| 50 mm² / 9.5 kg | |

| 70 mm²/10.4 kg | |

| Result | Test passed |

| Needle-flame test | |

| Time of exposure | 30 s |

| Result | Test passed |

| Ambient conditions | |

| Ambient temperature (storage/transport) | -25 °C ... 60 °C (for a short time, not exceeding 24 h, -60 °C to +70 °C) |

| Ambient temperature (assembly) | -5 °C ... 70 °C |

| Ambient temperature (actuation) | -5 °C ... 70 °C |

| Permissible humidity (storage/transport) | 30 % ... 70 % |

| Connection in acc. with standard | IEC 60947-7-1 |

| Mounting type | direct screw connection |

| Item number | 3247057 |

| Packing unit | 10 pc |

| Minimum order quantity | 1 pc |

| Sales key | BE1311 |

| Product key | BE1311 |

| GTIN | 4046356707237 |

| Weight per piece (including packing) | 126.54 g |

| Weight per piece (excluding packing) | 99.99 g |

| Customs tariff number | 85369010 |

| Country of origin | IN |

ETIM

| ETIM 8.0 | EC000897 |

UNSPSC

| UNSPSC 21.0 | 39121400 |

| EU RoHS | |

| Fulfills EU RoHS substance requirements | Yes (No exemptions) |

| China RoHS | |

| Environment friendly use period (EFUP) |

EFUP-E

No hazardous substances above the limits

|

| EU REACH SVHC | |

| REACH candidate substance (CAS No.) | No substance above 0.1 wt% |

Compatible products

Note: Applying some accessories below might limit this product.

-

-

FBI 3-20 - Fixed bridge 0201317

-

FBI 2-20-EX - Fixed bridge 0201113

-

FBI 3-20-EX - Fixed bridge 0201812

-

UKH 50 EP - Insertion profile 3009228

-

AGK 10-UKH 50 - Pick-off terminal block 3001763

-

SZS 1,2X8,0 VDE - Screwdriver 1205082

-

X-PEN 0,35 - Marker pen 0811228

-

WS-2K - Warning label 1004513

-

WS-4K - Warning label 1004584

-

ZB 10:UNBEDRUCKT - Zack marker strip 1053001

-

ZB 10 CUS - Zack marker strip 0824941

-

ZB10,LGS:L1-N,PE - Marker for terminal blocks 1053412

-

ZB10,LGS:U-N - Marker for terminal blocks 1053438

-

UC-TM 10 - Marker for terminal blocks 0818069

-

UC-TM 10 CUS - Marker for terminal blocks 0824605

-

UCT-TM 10 - Marker for terminal blocks 0829142

-

UCT-TM 10 CUS - Marker for terminal blocks 0829623

-

TMT 10 R - Marker for terminal blocks 0816210

-

TMT 10 R CUS - Marker for terminal blocks 0824500

Your advantages

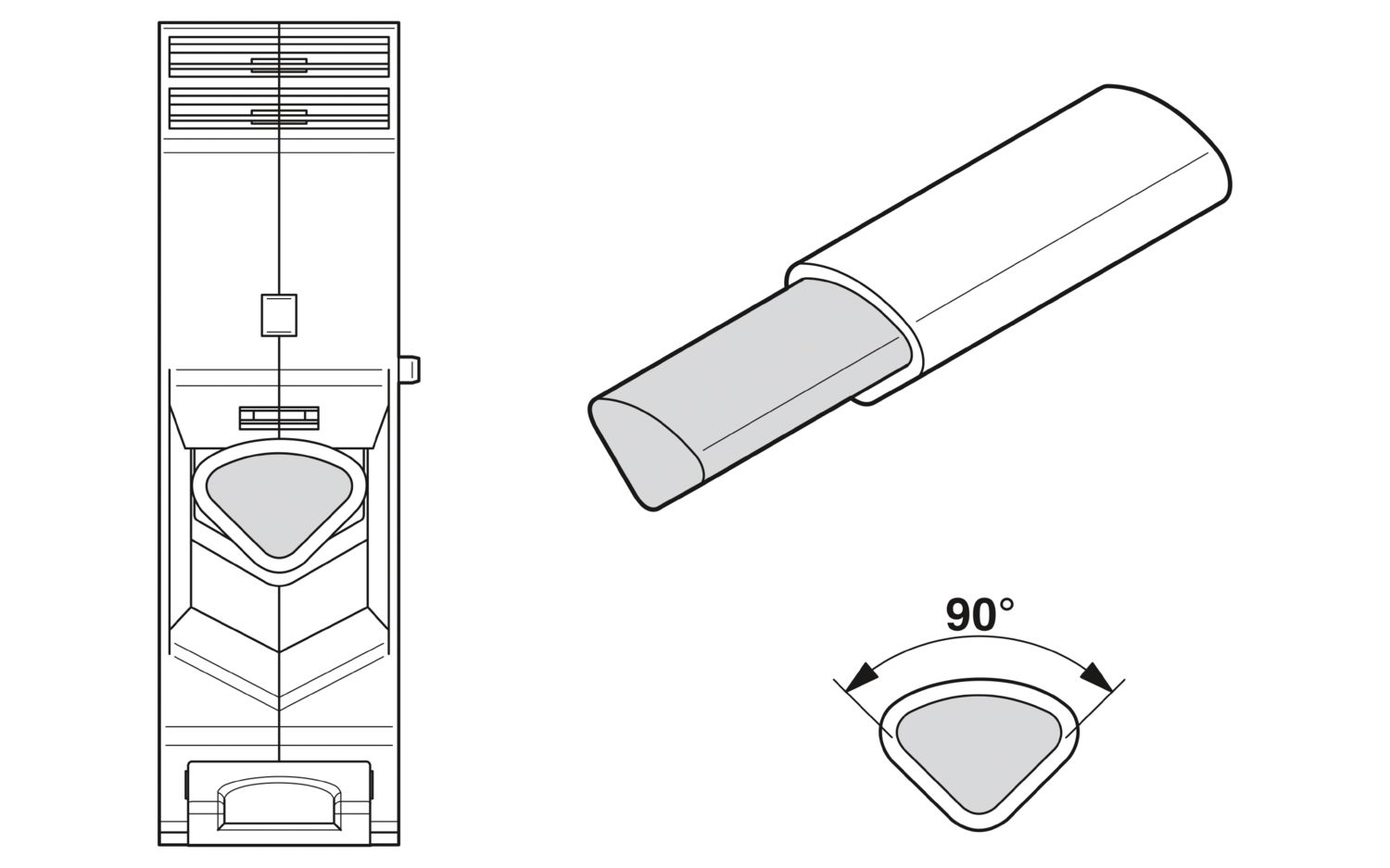

Reliable cable connection is ensured by three-point centering of the conductor in the prismatic sleeve base

Low contact resistance of the contact surface due to ribbing

Screw locking by means of spring-loaded elements in the clamping part

PHOENIX CONTACT Ltd

Halesfield 13, Telford, Shropshire, TF7 4PG