Solutions for high system availability in the process industry Production plants in the process industry must produce reliably even under extreme conditions. High safety requirements and harsh ambient conditions with some potentially explosive atmospheres place special demands on a reliable power supply. Whether your requirements are in the upstream/midstream sector, in the refinery, or in chemical processing – we offer reliable concepts for your auxiliary power supply.

Reliable power supply solutions are needed in a wide range of applications in the process industry. For the central or decentral supply of measurement and control technology, automation systems, and instrumentation, for junction boxes with remote IOs in the Ex area of chemical plants, for compressor stations on pipelines, or for the various package units. All of these applications bring different challenges.

Find out here about products and solutions for the various requirements that can be adapted in the direction of performance classes and supply system configurations.

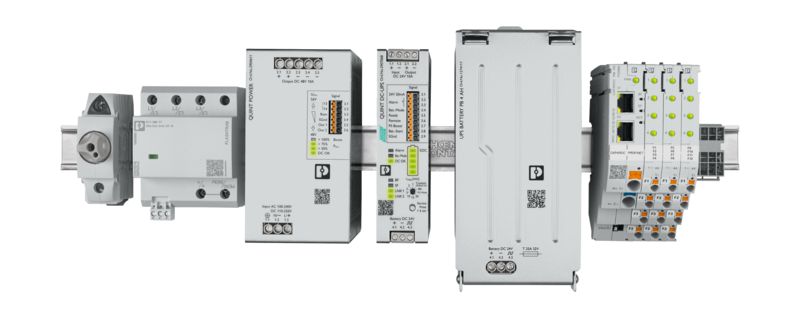

Control cabinet for central control rooms in the process industry

Reliable supply for central control rooms

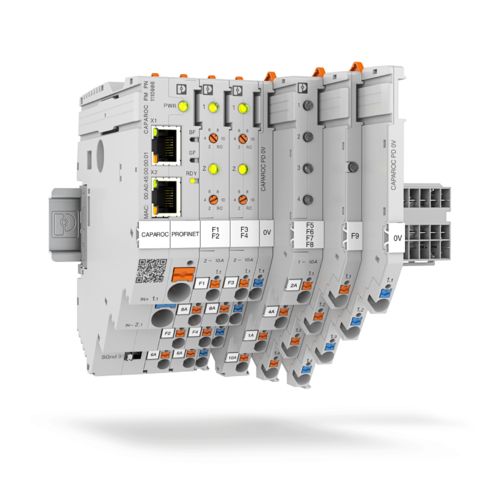

The reliable supply of central control rooms in process technology is of crucial importance for the smooth functioning of production plants. To ensure this, power supply solutions from the medium-voltage level right down to the load often have a redundant design. In combination with surge protection, device circuit breakers, and energy measuring devices, they ensure high system availability.

Redundant power supply solutions make sure that individual failures do not lead to plant downtime. Surge protection eliminates any voltage spikes in the power grid and gives your critical electronics a long service life. The energy measuring devices let you monitor and optimize plant energy consumption and help you comply with ISO 50001.

Our products for the central 24 V supply We will be happy to help you create your own individual solution.

Junction box on the pipeline

Reliable supply along the pipeline

Pipelines stretch over great distances, often through uninhabited areas, deserts, and perpetual ice.

Compressor stations are required at regular intervals for operation, and measuring systems for leakage monitoring are also required to ensure environmental protection. Maintaining these typically unmanned facilities along the pipeline also brings the challenge of harsh ambient conditions. Extreme temperatures, battery buffering in the event of mains failures, and remote condition monitoring play an important role, in particular for the power supply solution.

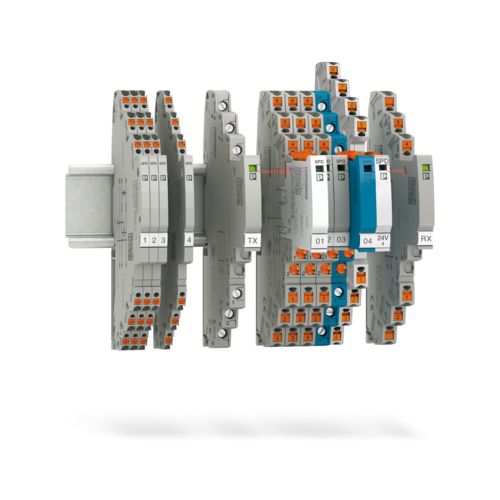

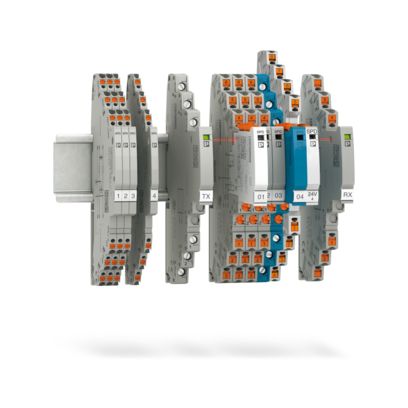

A communicative solution makes sure condition monitoring runs smoothly along the pipeline. In combination with an uninterruptible power supply, surge protection, and device circuit breaker, a reliable supply is ensured.

Surge protection protects the electronics against damage caused by lightning strikes or other voltage spikes in the power grid. Device circuit breakers with signal contacts protect against overload and short circuits and issue signals when necessary. This is an important feature for ensuring the safety and functionality of the measurement systems. An uninterruptible power supply maintains a reliable supply even during power outages.

Our products for junction boxes along the pipeline We will be happy to help you create your own individual solution.

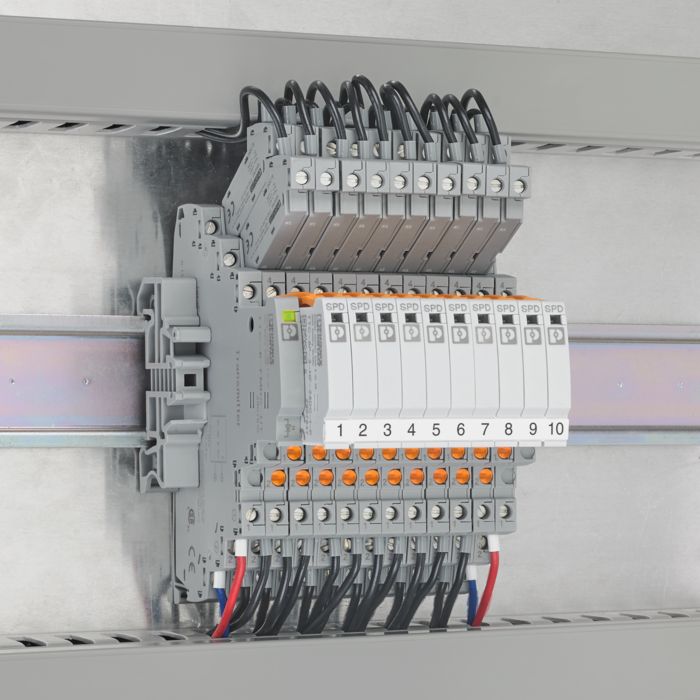

Field junction box in a chemical plant

Reliable supply of field junction boxes in the chemical park

In chemical parks, many subsystems are automated with remote IOs. These are not located in air-conditioned control rooms, but directly in the harsh environment between pipes, pipelines, and aggregates, often also in the potentially explosive area.

Depending on the availability requirements of the remote IO station, the power supply can also be designed to be redundant. If the connected instrumentation is located in an exposed position high up on tanks, pipe bridges, or distillation columns, surge protection for sensors and actuators should also be used. Device circuit breakers also protect against overloads and short circuits.

Our products for junction boxes in a chemical plant We will be happy to help you create your own individual solution.

Control cabinet for package units

Reliable supply of package units

Large-scale processing plants such as a chemical plant or a refinery are automated not only by thousands of sensors and actuators but also by a large number of so-called package units. These are independent machines or aggregates that often have a PLC and their own measurement and control technology. Examples of these include filtration, drying, or temperature control units, reactors, centrifuges, metering pumps, etc. Depending on the criticality, these units are also designed to be redundant.

The control cabinets for these machines are as different as the machines themselves. The controller of a temperature control unit is shown as an example here. Our 4th-generation QUINT POWER power supply brings enough reserves to power the PLC and a variety of electronically fused relays, contactors, and signal converters. The total consumption is monitored with an energy measuring device.

Our products for package units We will be happy to help you create your own individual solution.

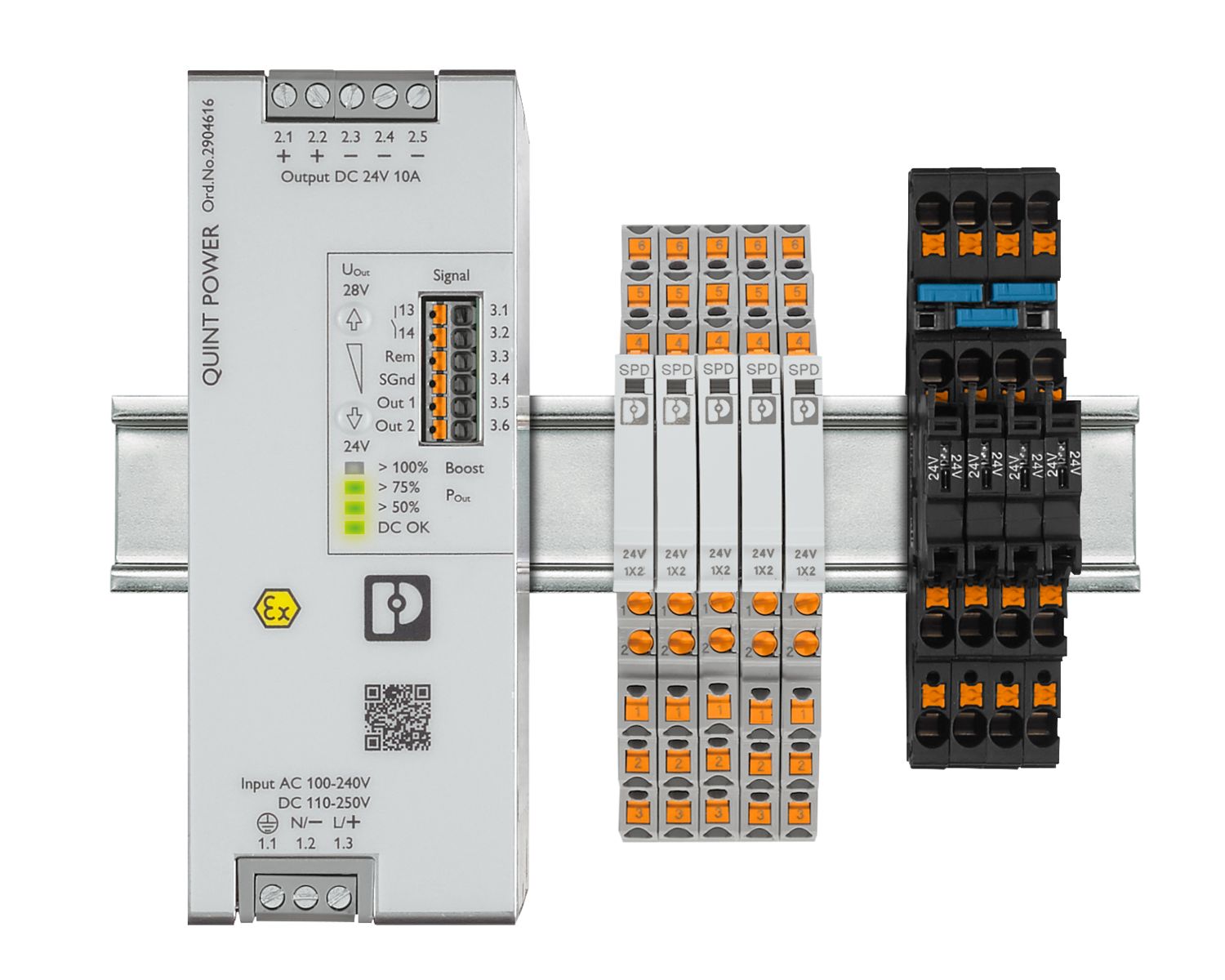

Surge protection with fuse protection for signal lines

Protection and fuse protection of sensors and actuators

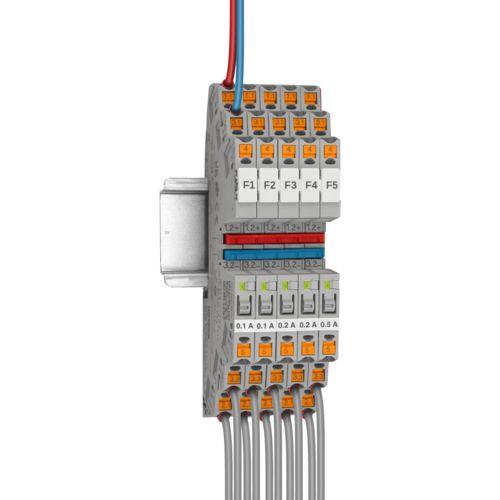

To ensure that sensors, actuators, and controllers are optimally supplied with voltage, we offer coordinated combinations of selective fuse and surge protection.

Whether lines lead from a central or decentralized switch room, a junction box, or a package unit – surge voltages, short circuits, or overloads can also occur on the 24 V side.

With an overall width of just 6 mm, TERMITRAB complete provides space-saving surge protection for sensors and actuators. The matching fuse holder for standard 5 x 20 mm micro fuses provides selective short-circuit and overload protection while simultaneously ensuring maximum space savings.

If a status indicator and remote reset option are required for overcurrent protection, then the PTCB eFuse electronic circuit breakers for currents less than 1 A are the ideal choice.

With our solutions for high system availability, a reliable power supply can be implemented quickly and easily from feed-in right through to the sensor or controller.

Our products for reliable operation of sensors and actuators