Marking for the Food and Beverage Industry

Particular attention is paid to the following four aspects:

1. High chemical resistance

To ensure the highest hygienic standards, the production equipment is cleaned several times a day. The use of the aggressive cleaning agents requires a high resistance of the marking materials as well as the lettering.

2. Visual identifiability

For quick recognition, the food industry is increasingly relying on blue labelling. Since the colour rarely occurs in natural form, it stands out particularly well and is instinctively perceived quickly.

3. Detectability

Food is subject to the highest quality and safety requirements, making final inspections indispensable. To ensure that even fragments of a marking material

can be detected in the metal detector in case of doubt, the use of detectable marking materials is recommended.

4. Optimum adhesion

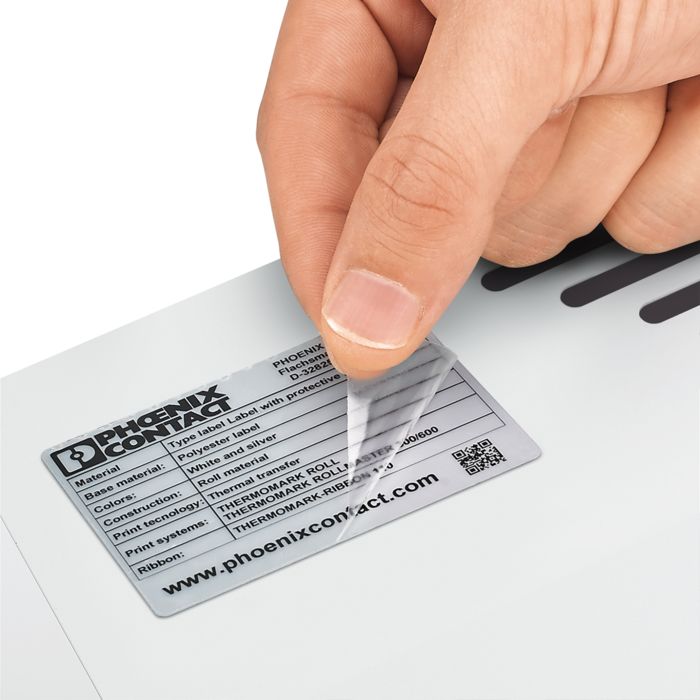

Structured surfaces of equipment and systems often make optimum label adhesion difficult. If the labels are also exposed to mechanical stresses caused by cleaning processes, an additional protective laminate is required in addition to the appropriate adhesive system.

Marking for Food and Beverage Industry

List of marking material and suitable printers

| Topmark NEO | THERMOMARK ROLL 2.0/ THERMOMARK ROLLMASTER 300/600 | Order number | |

|---|---|---|---|

| Wire marking | |||

| UC-WMTBA (24x5)/PP | x | 1199627 | |

| UC-WMTBA (29x8)/PP YE | x | 1199639 | |

| UC-WMTBA (29x8)/PP BU | x | 1199635 | |

| UC-WMTBA-D (24x5)/PP | x | 1312764 | |

| UC-WMTBA-D (29x8)/PP YE | x | 1312768 | |

| UC-WMTBA-D (29x8)/PP LBU | x | 1199650 | |

| LS-WMTB-V4A (29x8) | x | 0831516 | |

| LS-WMTB-V4A (40x15) | x | 0831517 | |

| WMTB HF-D (30x10)R BU | x | 1255591 | |

| WMTB HF-D (40x12)R BU | x | 1255595 | |

| Equipment marking | |||

| EML-LPR-D (100x73)R SR | x | 1255582 | |

| EML-LPR-D (100X73)R YE | x | 1255583 | |

| EML-LPR-D (85,6x54)R RD | x | 1255581 | |

| EML-D (20x8)R | x | 1182298 | |

| EML-D (40x15)R | x | 1054876 | |

| EML-D (60x30)R SR | x | 1054879 | |

| LS-EMLP-V4A (60X30) | x | 0803991 | |

| LS-EMSP-V4A (50X15) | x | 0831654 |