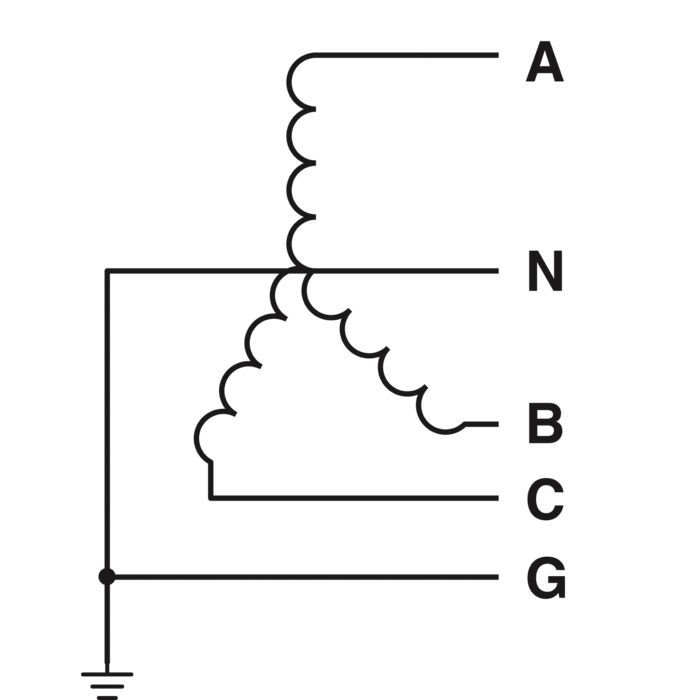

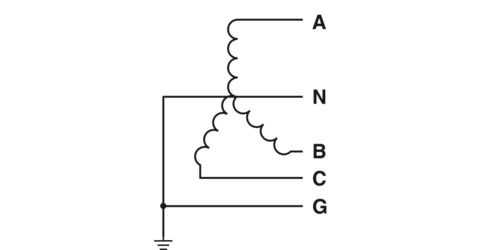

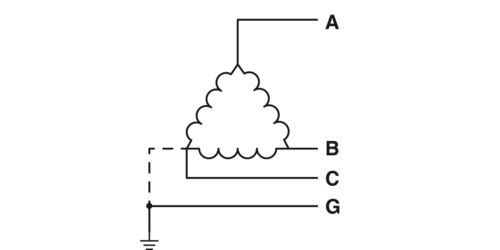

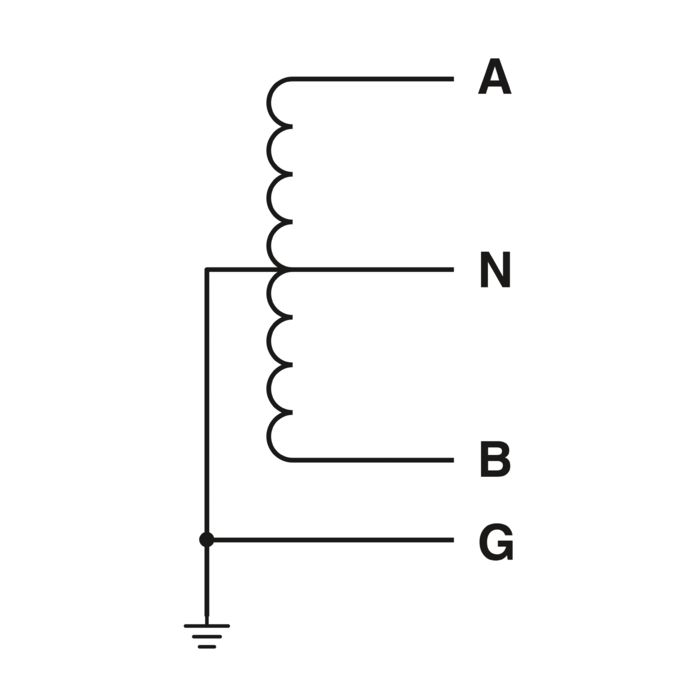

This supply system configuration is largely unknown in Europe today. It is created via a secondary-side center tap connection in a single-phase transformer. The center tap connection is grounded, so that the voltage between it and one phase is exactly half of the voltage between the phases. The voltage used is 120/240 V.

This supply system configuration is used in almost all households and small office buildings in North America. Small and low-power devices such as computers, televisions, and lighting are connected to the 120 V circuit. Devices with higher power requirements, such as air conditioning systems, are connected to the 240 V circuit.