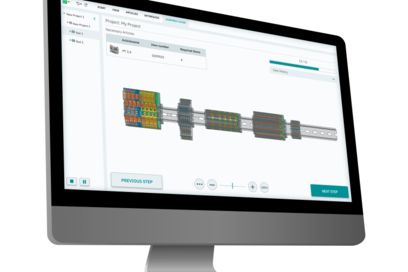

In addition to a height-adjustable workbench, the basic workstation is equipped with a bracket which can be used for attaching a terminal board or monitor, for example. With four storage areas, the upper part offers plenty of space for providing the necessary materials and components for the assembly of DIN rails. The ergonomic design of the workstation enables comfortable working with height adjustment and short reach distances.