CSA

Approval ID: 13631cULus Recognized

Approval ID: E60425DNV

Approval ID: TAE00002TT-05| Nominal voltage UN | Nominal current IN | Cross section AWG | Cross section mm2 | |

|---|---|---|---|---|

| keine | ||||

| 500 V | 24 A | |||

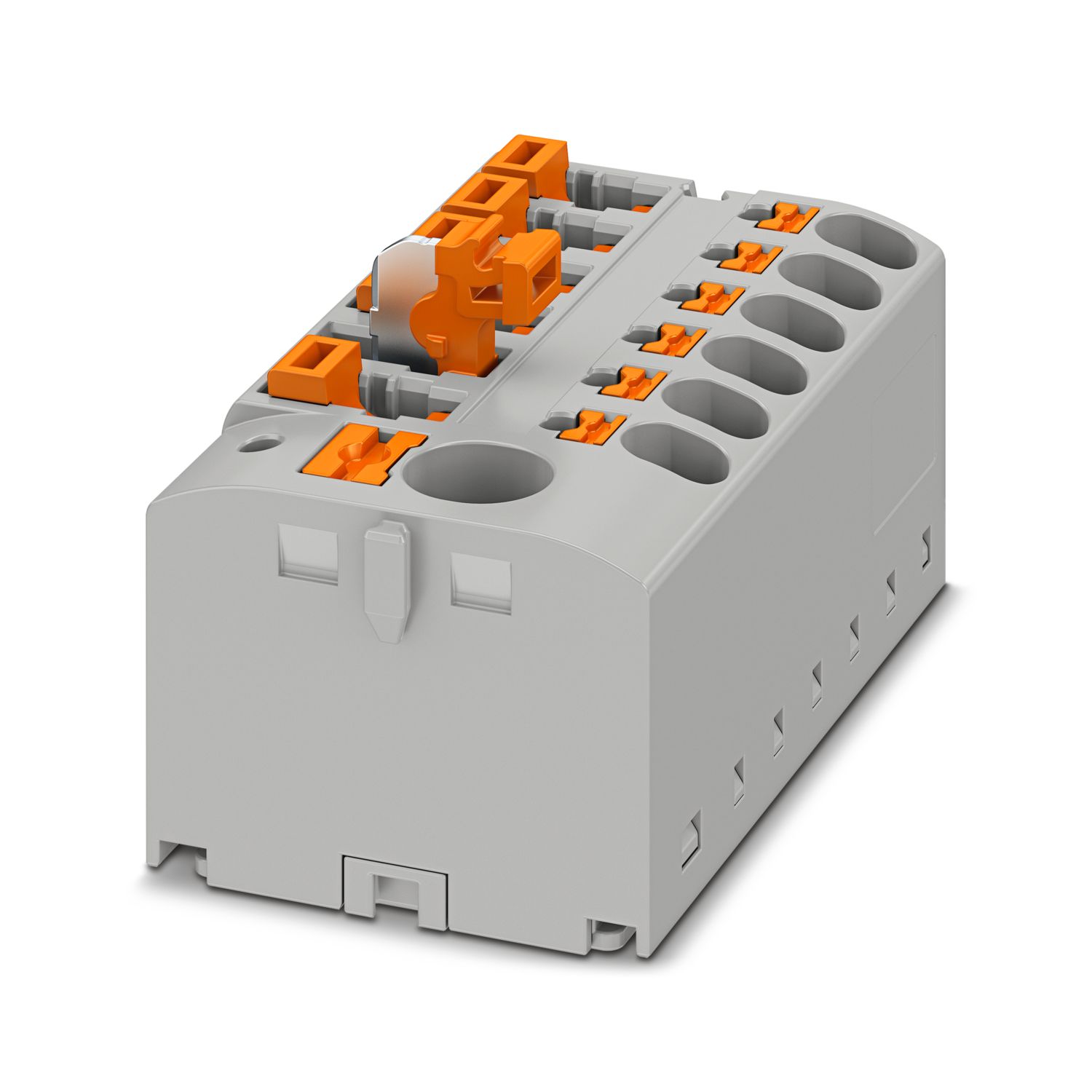

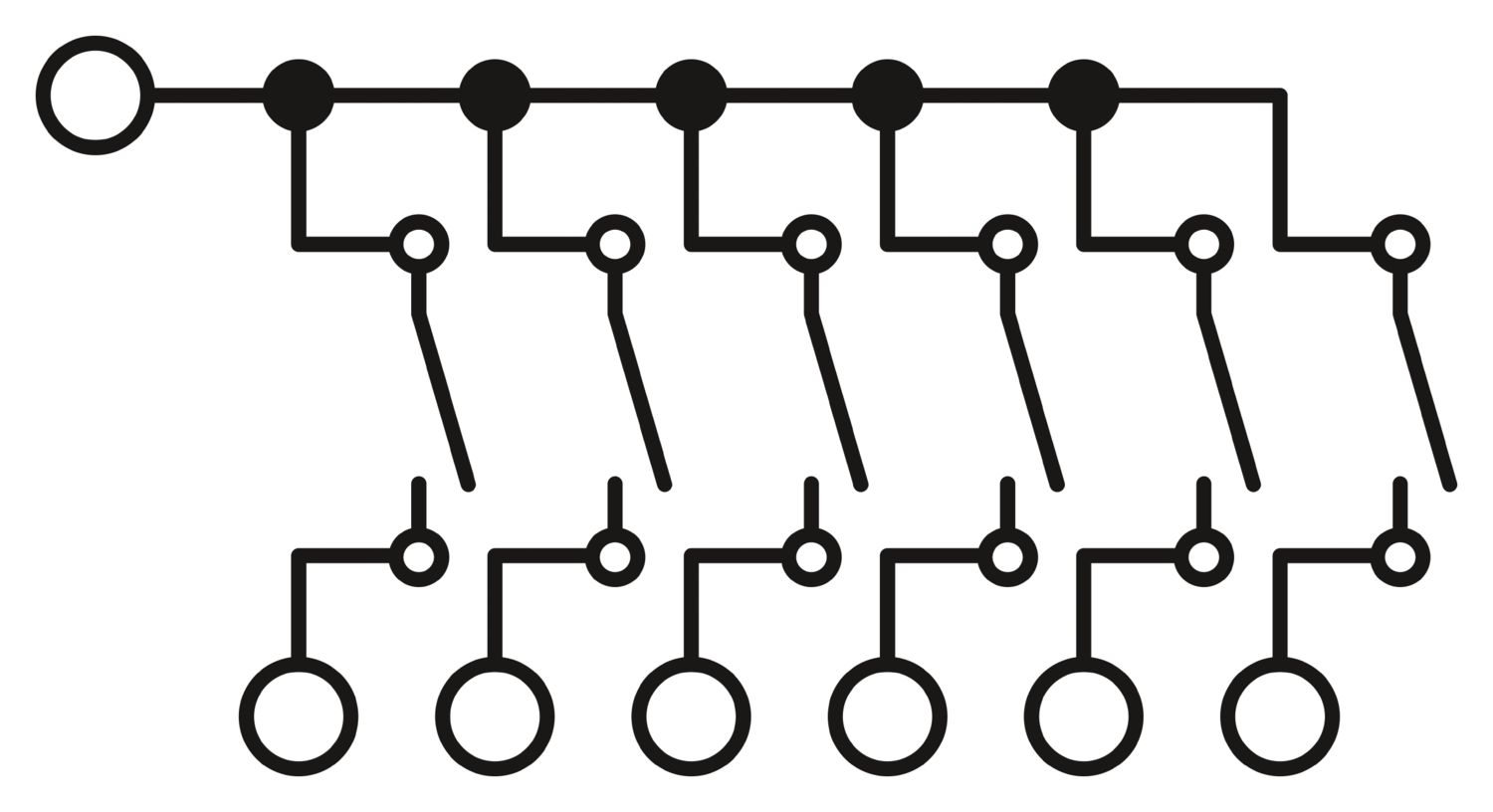

Function distribution block, Basic terminal block with feed-in and disconnect knife in the branches, disconnection via screwdriver, nom. voltage: 400 V, nominal current: 20 A, Load contact, connection method: Push-in connection, Rated cross section: 2.5 mm2, cross section: 0.14 mm2 - 4 mm2, Line contact, connection method: Push-in connection, Rated cross section: 6 mm2, cross section: 0.5 mm2 - 10 mm2, mounting: for snapping onto a DIN rail adapter, Direct mounting with flange, Free-hanging, color: gray

| General | |

| Note | The maximum load current of a single clamping unit must not be exceeded. |

| For power distribution applications, IEC 60364-4-43.2008; modified + corrigendum Okt. 2008 (DIN VDE 0100-430:2010-10) section 433.2 ff must be observed! | |

| Product type | Distributor terminal block |

| Number of connections | 7 |

| Number of rows | 1 |

| Insulation characteristics | |

| Overvoltage category | III |

| Degree of pollution | 3 |

| Rated surge voltage | 6 kV |

| Maximum power dissipation for nominal condition | 0.77 W |

| Service Entrance | yes |

| Number of connections per level | 7 |

| Nominal cross section | 2.5 mm² |

| Load contact | |

| Connection method | Push-in connection |

| Stripping length | 8 mm ... 10 mm |

| Internal cylindrical gage | A3 |

| B3 | |

| Connection in acc. with standard | IEC 60947-7-1 |

| Conductor cross-section rigid | 0.14 mm² ... 4 mm² |

| Cross section AWG | 26 ... 12 (converted acc. to IEC) |

| Conductor cross-section flexible | 0.14 mm² ... 4 mm² |

| Conductor cross-section, flexible [AWG] | 26 ... 12 (converted acc. to IEC) |

| Conductor cross-section flexible (ferrule without plastic sleeve) | 0.14 mm² ... 2.5 mm² |

| Flexible conductor cross-section (ferrule with plastic sleeve) | 0.14 mm² ... 2.5 mm² |

| Nominal current | 20 A |

| Maximum load current | 20 A (with 4 mm² conductor cross-section) |

| Maximum total current | 57 A (with 10 mm² conductor cross-section) |

| Nominal voltage | 400 V |

| Note | The IEC 60947-7-1 standard applies for the use of mounting accessories. |

| Nominal cross section | 2.5 mm² |

| Line contact | |

| Connection method | Push-in connection |

| Stripping length | 10 mm ... 12 mm |

| Internal cylindrical gage | A5 |

| B4 | |

| Conductor cross-section rigid | 0.5 mm² ... 10 mm² |

| Cross section AWG | 20 ... 8 (converted acc. to IEC) |

| Conductor cross-section flexible | 0.5 mm² ... 10 mm² |

| Conductor cross-section, flexible [AWG] | 20 ... 8 (converted acc. to IEC) |

| Conductor cross-section flexible (ferrule without plastic sleeve) | 0.5 mm² ... 6 mm² |

| Flexible conductor cross-section (ferrule with plastic sleeve) | 0.5 mm² ... 6 mm² |

| Nominal cross section | 6 mm² |

| Connection in acc. with standard | IEC 60998-2-2 |

| Nominal voltage | 450 V (in accordance with IEC 60998-2-2) |

| Load contact Connection cross sections directly pluggable | |

| Conductor cross-section rigid | 0.34 mm² ... 4 mm² |

| Conductor cross-section, rigid [AWG] | 22 ... 18 (converted acc. to IEC) |

| Conductor cross-section flexible (ferrule without plastic sleeve) | 0.75 mm² ... 2.5 mm² |

| Flexible conductor cross-section (ferrule with plastic sleeve) | 0.5 mm² ... 2.5 mm² |

| Line contact Connection cross sections directly pluggable | |

| Conductor cross-section rigid | 1 mm² ... 10 mm² |

| Conductor cross-section, rigid [AWG] | 18 ... 8 (converted acc. to IEC) |

| Conductor cross-section flexible (ferrule without plastic sleeve) | 1.5 mm² ... 6 mm² |

| Flexible conductor cross-section (ferrule with plastic sleeve) | 1 mm² ... 6 mm² |

| Width | 47.6 mm |

| Height | 28.6 mm |

| Depth | 23.3 mm |

| Color | gray (RAL 7042) |

| Flammability rating according to UL 94 | V0 |

| Insulating material group | I |

| Insulating material | PA |

| Static insulating material application in cold | -60 °C |

| Temperature index of insulation material (DIN EN 60216-1 (VDE 0304-21)) | 125 °C |

| Relative insulation material temperature index (Elec., UL 746 B) | 130 °C |

| Fire protection for rail vehicles (DIN EN 45545-2) R22 | HL 1 - HL 3 |

| Fire protection for rail vehicles (DIN EN 45545-2) R23 | HL 1 - HL 3 |

| Fire protection for rail vehicles (DIN EN 45545-2) R24 | HL 1 - HL 3 |

| Fire protection for rail vehicles (DIN EN 45545-2) R26 | HL 1 - HL 3 |

| Calorimetric heat release NFPA 130 (ASTM E 1354) | 27,5 MJ/kg |

| Surface flammability NFPA 130 (ASTM E 162) | passed |

| Specific optical density of smoke NFPA 130 (ASTM E 662) | passed |

| Smoke gas toxicity NFPA 130 (SMP 800C) | passed |

| Surge voltage test | |

| Result | Test passed |

| Temperature-rise test | |

| Requirement temperature-rise test | Increase in temperature ≤ 45 K |

| Result | Test passed |

| Short-time withstand current 6 mm² | 0.72 kA |

| Short-time withstand current 2.5 mm² | 0.3 kA |

| Result | Test passed |

| Power-frequency withstand voltage | |

| Test voltage setpoint | 1.89 kV |

| Result | Test passed |

| Mechanical data | |

| Open side panel | No |

| Mechanical strength | |

| Result | Test passed |

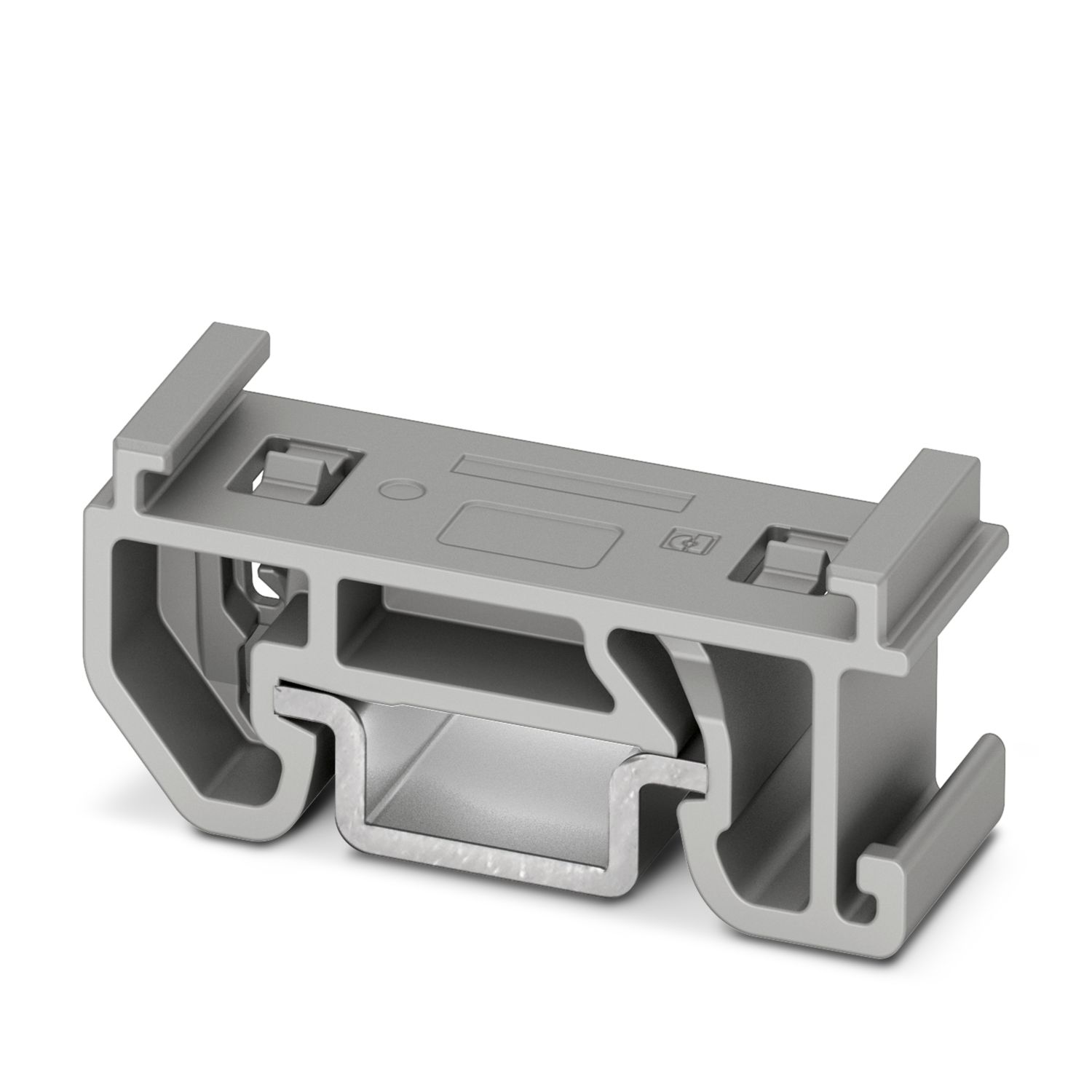

| Attachment on the carrier | |

| DIN rail/fixing support | NS 35/NS 15 |

| Result | Test passed |

| Note | When aligning several blocks, it is recommended to either place a DIN rail adapter underneath the connection point or a flange element between the blocks. |

| Depending on the application case and mechanical load, other arrangements of the mounting accessory can also be chosen. | |

| When using the DIN rail adapter PTFIX-NS35, an aligned block must not protrude by more than a half. | |

| Test for conductor damage and slackening | |

| Rotation speed | 10 rpm |

| Revolutions | 135 |

| Conductor cross-section/weight | 0.5 mm² / 0.3 kg |

| 6 mm² / 1.4 kg | |

| 10 mm² / 2 kg | |

| Result | Test passed |

| Test for conductor damage and slackening | |

| Rotation speed | 10 rpm |

| Revolutions | 135 |

| Conductor cross-section/weight | 0.14 mm² / 0.2 kg |

| 2.5 mm² / 0.7 kg | |

| 4 mm² / 0.9 kg | |

| Result | Test passed |

| Aging | |

| Temperature cycles | 192 |

| Result | Test passed |

| Needle-flame test | |

| Time of exposure | 30 s |

| Result | Test passed |

| Oscillation/broadband noise | |

| Specification | DIN EN 50155 (VDE 0115-200):2018-05 |

| Spectrum | Long life test category 2, bogie-mounted |

| Frequency | f1 = 5 Hz to f2 = 250 Hz |

| ASD level | 6.12 (m/s²)²/Hz |

| Acceleration | 3.12g |

| Test duration per axis | 5 h |

| Test directions | X-, Y- and Z-axis |

| Result | Test passed |

| Shocks | |

| Specification | DIN EN 50155 (VDE 0115-200):2018-05 |

| Pulse shape | Half-sine |

| Acceleration | 30g |

| Shock duration | 18 ms |

| Number of shocks per direction | 3 |

| Test directions | X-, Y- and Z-axis (pos. and neg.) |

| Result | Test passed |

| Ambient conditions | |

| Ambient temperature (operation) | -60 °C ... 110 °C (Operating temperature range incl. self-heating; for max. short-term operating temperature, see RTI Elec.) |

| Ambient temperature (storage/transport) | -25 °C ... 60 °C (for a short time, not exceeding 24 h, -60 °C to +70 °C) |

| Ambient temperature (assembly) | -5 °C ... 70 °C |

| Ambient temperature (actuation) | -5 °C ... 70 °C |

| Permissible humidity (operation) | 20 % ... 90 % |

| Permissible humidity (storage/transport) | 30 % ... 70 % |

| Connection in acc. with standard | IEC 60947-7-1 |

| IEC 60998-2-2 |

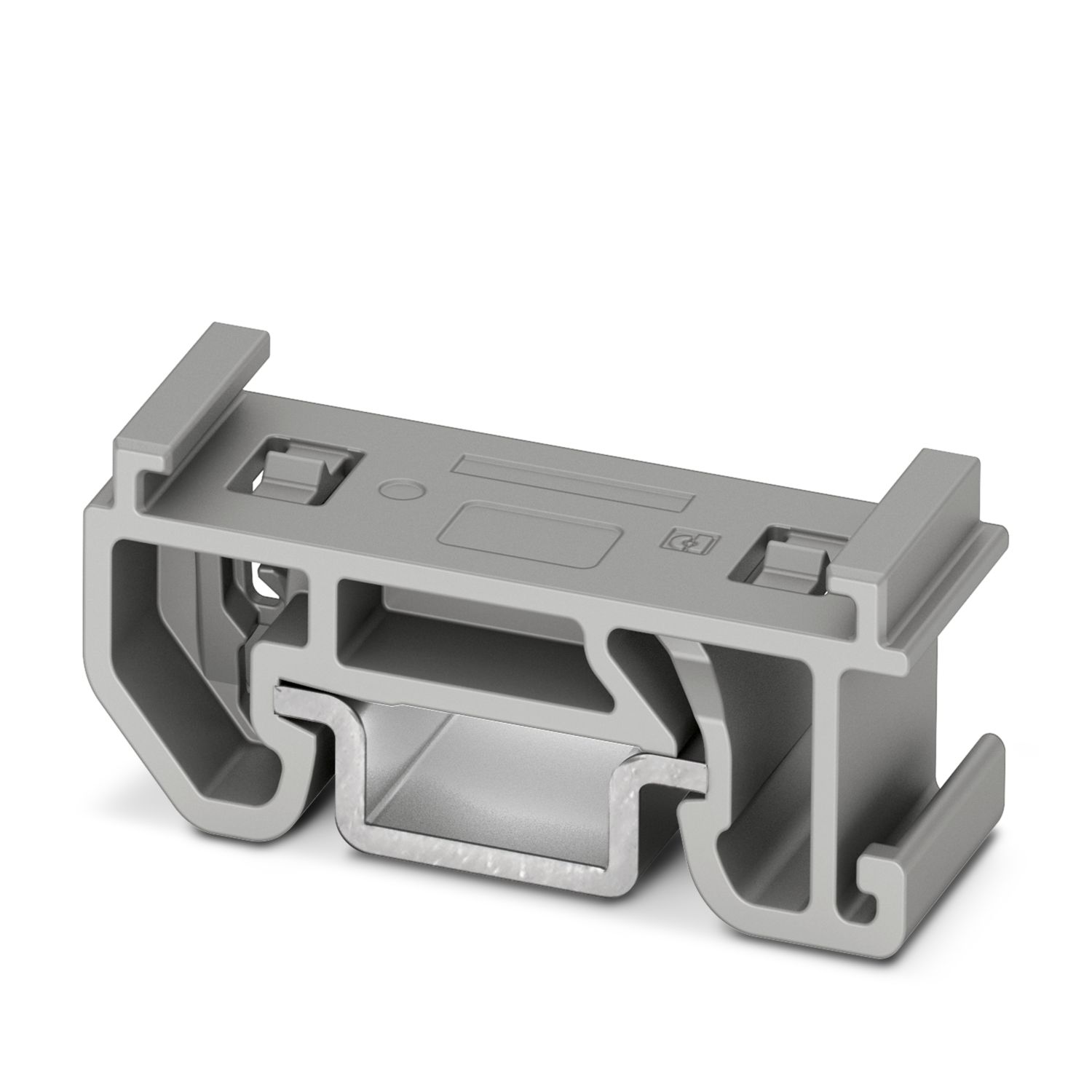

| Mounting type | for snapping onto a DIN rail adapter |

| Direct mounting with flange | |

| Free-hanging |

| Item number | 1130757 |

| Packing unit | 8 pc |

| Minimum order quantity | 8 pc |

| Sales key | BEA |

| Product key | BEA131 |

| GTIN | 4063151058364 |

| Weight per piece (including packing) | 33.94 g |

| Weight per piece (excluding packing) | 33 g |

| Customs tariff number | 85369010 |

| Country of origin | PL |

| ECLASS-13.0 | 27250118 |

| ECLASS-15.0 | 27250118 |

| ETIM 9.0 | EC000897 |

| UNSPSC 21.0 | 39121400 |

| EU RoHS | |

| Fulfills EU RoHS substance requirements | Yes (No exemptions) |

| China RoHS | |

| Environment friendly use period (EFUP) |

EFUP-E

No hazardous substances above the limits

|

| EU REACH SVHC | |

| REACH candidate substance (CAS No.) | No substance above 0.1 wt% |