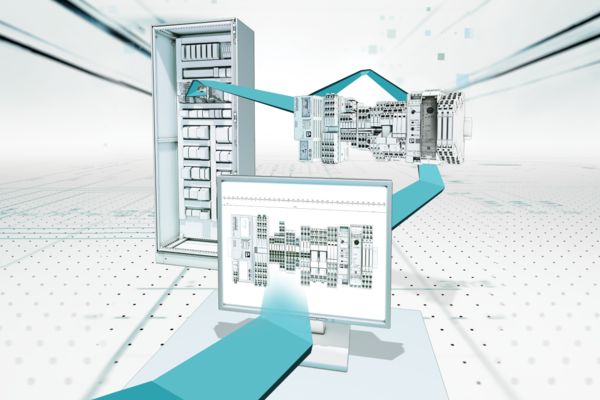

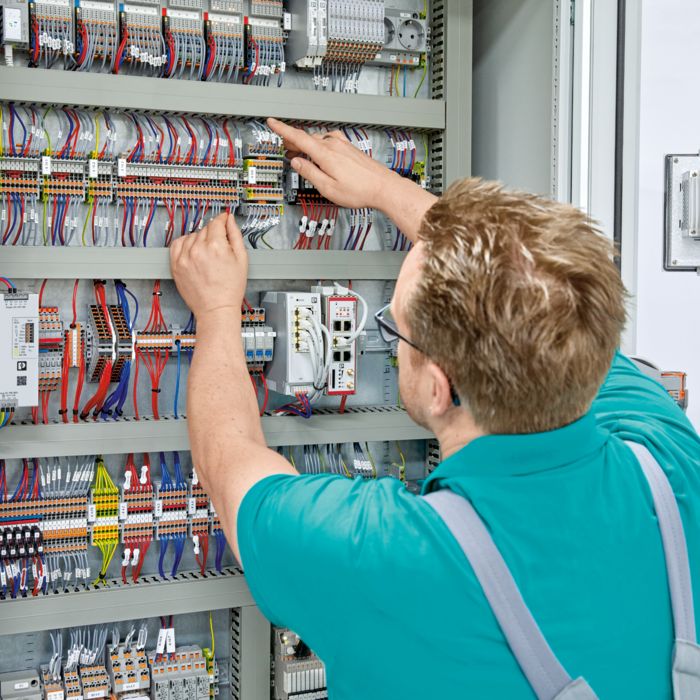

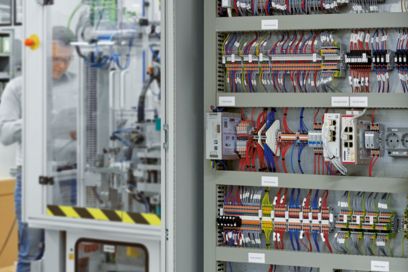

With their uniformity in function and design, the products of the COMPLETE line portfolio enable particularly easy handling throughout the entire installation process. Functional components are highlighted in color. The standardization of the accessories makes assembly particularly simple and fast.