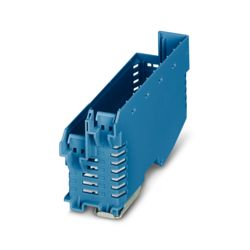

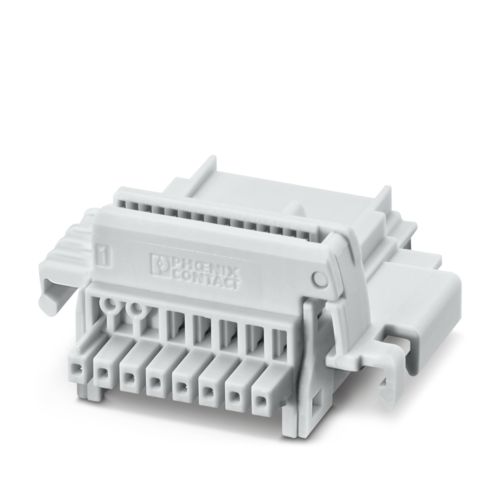

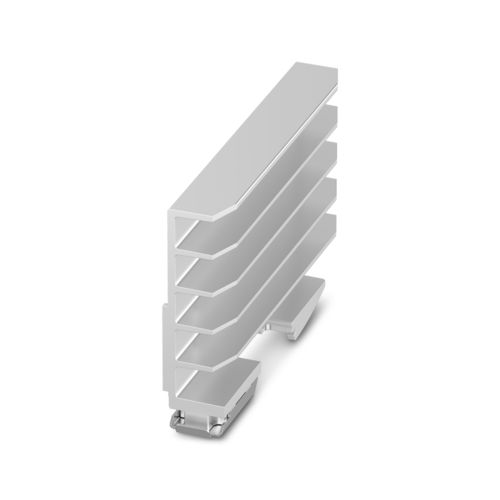

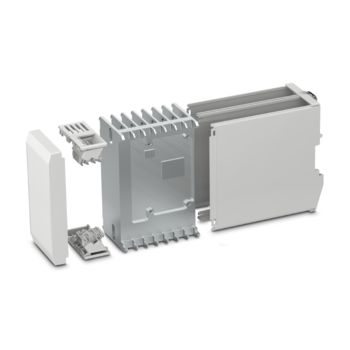

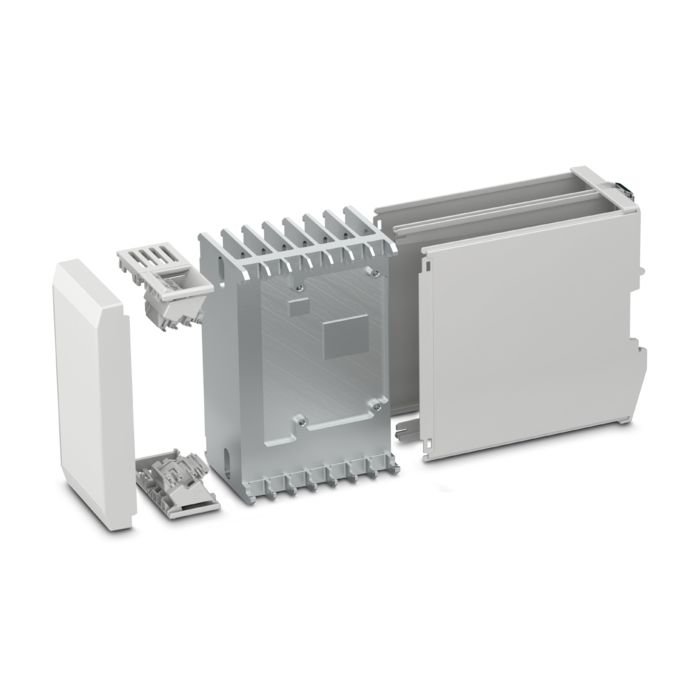

Up to four overall module widths of 18.8 mm, 37.6 mm, 56.4 mm, and 75.2 mm enable device manufacturers to realize a wide range of applications. In addition, there are housing versions with a module depth for a PCB area up to a maximum of 6,580 mm² and up to 8,510 mm² per 18.8 mm module width. Printed circuit boards can be installed vertically and horizontally to the DIN rail.