Modernization of brownfield systems

In many production plants, control systems from different manufacturers and different generations are in use due to long runtimes. The modernization of process equipment is inevitable as support continues to decline due to discontinuations. Migration focuses not only on replacing outdated technology, but also on adapting the processing plant to the increased requirements of the future.

It makes no difference whether you want to perform the complete migration in one go or in several stages. With our solutions for the modernization of your processing plants, you bring the communication system up to date. This optimizes your maintenance processes. In addition, you reduce downtimes in your plants and make inspection rounds paperless.

Your advantages

- Lower marshalling costs by reducing the number of control cabinets by up to 20%

- Scalable signal marshalling concept from a single source adapted to the individual needs of your processing plant

- Increased productivity and efficiency of plants through the use of new technologies

Renovating control engineering

There is no one perfect way to achieve the fastest and most error-free refit of aging control engineering. In coordination with you, we will analyze the current status of your systems to determine the right time for migration.

Rapid conversion of control and interface technology

How old is the control system and measurement and control technology that you are using? Which I/O modules are in use? Which signals are transmitted from the field to the control system? We discuss these and other questions together with you, because every starting situation in a migration project is different. Therefore, there is no single strategy for connecting to a new I/O system.

After a careful inventory and consultation, the plan for the conversion is made. Our experts in automation technology will work out this plan together with your specialist personnel from MCR technology and maintenance. We provide special adaptation concepts for all common control systems to address all local concerns regarding your system. Thus, even a modernization in running operations is possible, error-free, and with low downtimes.

Modernization of the signal connection

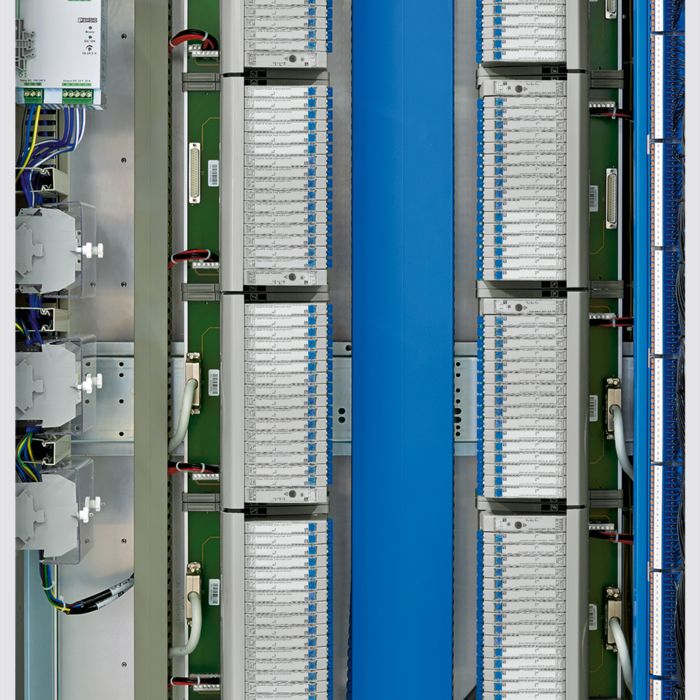

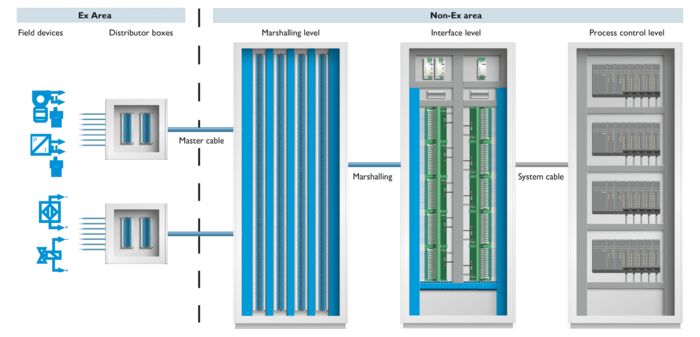

Conventional analog and binary signals continue to be the most frequently used signal types in process engineering plants. This type of signal transmission is easy to handle and diagnose, however its classic parallel wiring requires a large amount of space in the switch room. With customized signal marshalling, you can save space in your switch room.

Signal marshalling in the process industry

Efficient signal marshalling requires detailed planning. To reduce the size and cost of the overall switch room, it is necessary to minimize the number of control cabinets. In addition, openness to migration plays an important role.

Whether for new installations, smaller extensions, or migrations, we will be happy to develop a customized marshalling concept for your switch room.

Space-saving design

Benefit from our extensive expertise in special interface modules and cabling solutions. Our solutions are tailored both to the different I/O components of the major control system manufacturers as well as to the local requirements of the operators.

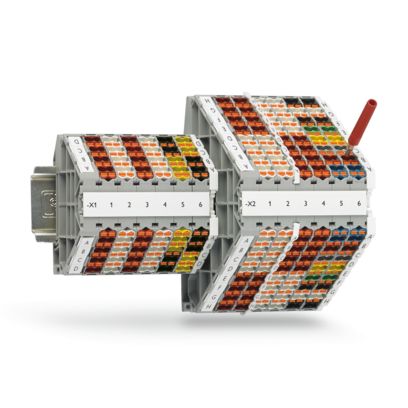

In addition to terminal blocks and marshalling terminals, passive interface modules, and relay modules, we also provide interface components. These include SIL-certified repeater power supplies, IS signal duplicators, solenoid drivers, surge protection, and safety relays. Through the use of state-of-the-art technologies, our products are developed to be temperature-optimized and are very narrow. This allows up to 1,024 analog inputs to be separated and marshalled in an 80 x 80 cm cabinet with intrinsic safety, which results in a space savings of up to 20%. These devices are mounted in the cabinet in a space-saving manner using a robust carrier system, the Termination Carrier, and connected with a turn of the wrist via a system plug.

Example of the marshalling structure for intrinsically safe signals

Paperless to Maintenance 4.0 – efficient maintenance processes

Uniform and easily readable identifications are essential for maintenance rounds. With consistent plant identification and plant-wide WLAN coverage, you can quickly identify the right component, unit, or plant part. This way, you have the appropriate documentation immediately at hand.

Smart plant identification

Take advantage of our durable, easily legibly signs, such as laser-engraved stainless steel markings.

We also provide RFID markings. These markings stay readable for a long time, even if a layer of dust forms on them. With clearly readable RFID HF or RFID UHF transponders integrated into the marking or installation material, you don’t just increase safety. You also pave the way to more advanced maintenance methods.

Industrial WLAN coverage

Make it easier to document your inspection rounds by using maintenance software on tablets. The maintenance engineer is guided to all components to be inspected based on a schedule. This scenario requires a wireless network that connects the tablets to the master MES at all times. A WLAN network is suitable for supporting maintenance processes with industrial-grade office equipment. A combination of cable and wireless is likewise possible. We can also provide you with a suitable IT security concept.

Another option is cluster management, especially for smaller networks of up to 20 access points. The commissioning process is greatly simplified. In this process, only one of the access points needs to be configured. The configuration is then transferred to the other access points in the network. With little effort, you thus fulfill all the necessary safety-related framework parameters.

Combining measurement data with artificial intelligence

By collecting measured data, you can detect potential malfunctions at an early stage, and can therefore schedule troubleshooting and the associated downtime in good time.

Preventive maintenance

Knowing today what may happen tomorrow. In the maintenance department, this is a big ask. However, it is possible to provide more data from the field today than in the past. If you link this data with web services, it is possible to prevent or reduce system shutdowns through the use of analyses.

We provide you with professional, integrated cloud solutions for your automation application – from infrastructure and platforms right through to software. This lets you utilize all the advantages and freedoms available to you during your transition into the digital age.

From RFID to mixed reality

AR applications can support operation and maintenance teams sustainably with modern marking methods and a reliable industrial-grade wireless network. The tablet, which has identified a plant part via NFC or an AR marker, then displays further information on the camera screen. This can be, for example, a data sheet, the maintenance instructions, or a video with all the work steps involved. Measured values such as tank levels or the temperature of sensors without local displays can also be displayed.

Our experts for the process industry will be happy to advise you on the possibilities of making your plants Industry 4.0-capable.

Products

Tailored solutions for the migration of your processing plants based on our reliable products.

We provide you with various products and solutions developed from connection, communication, and automation technology for typical control, monitoring, and optimization tasks. They allow you to reliably capture, transport, and process data.

Learn more about our comprehensive product portfolio in our User Manual for the Process Industry.