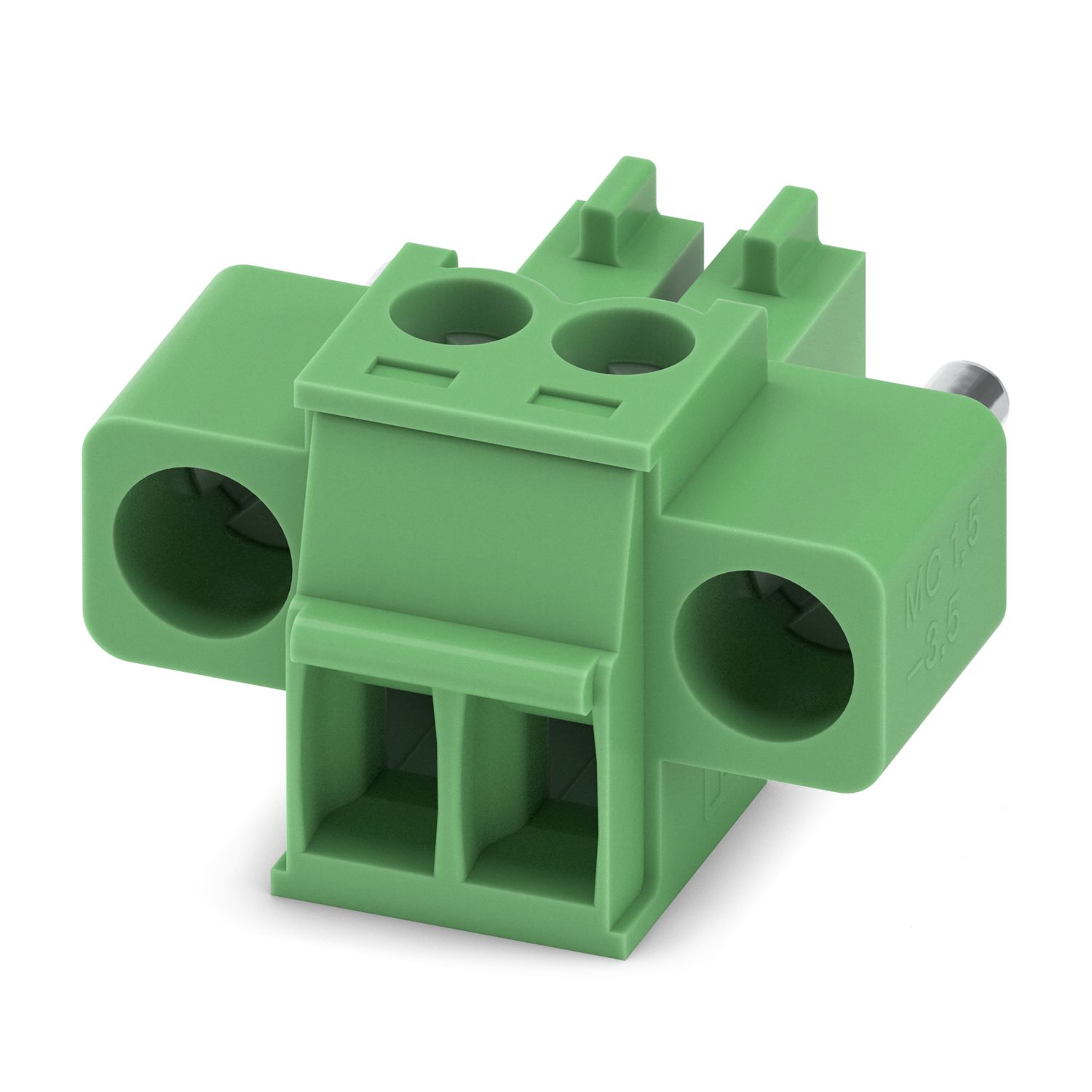

product line COMBICON Connectors S

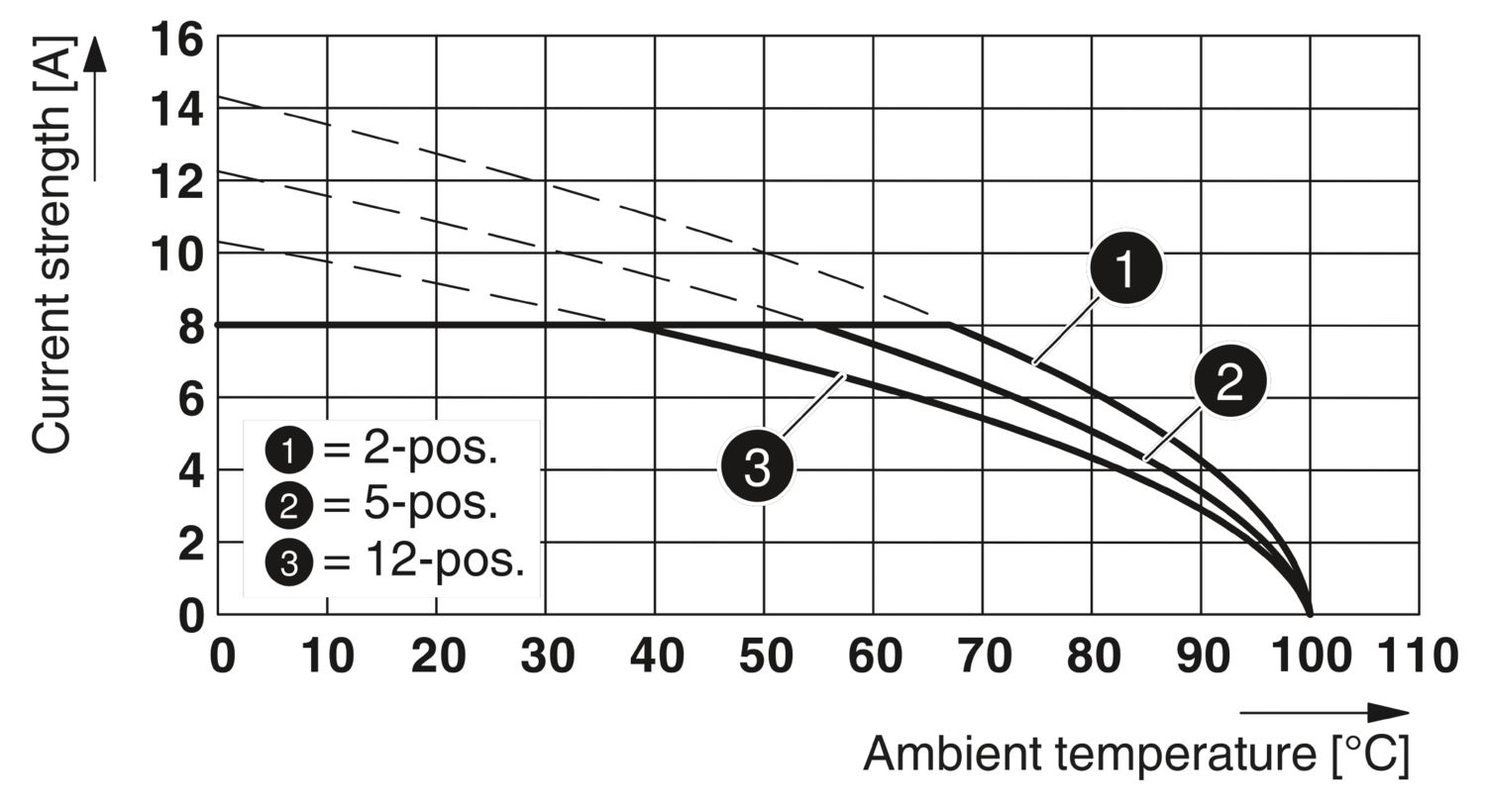

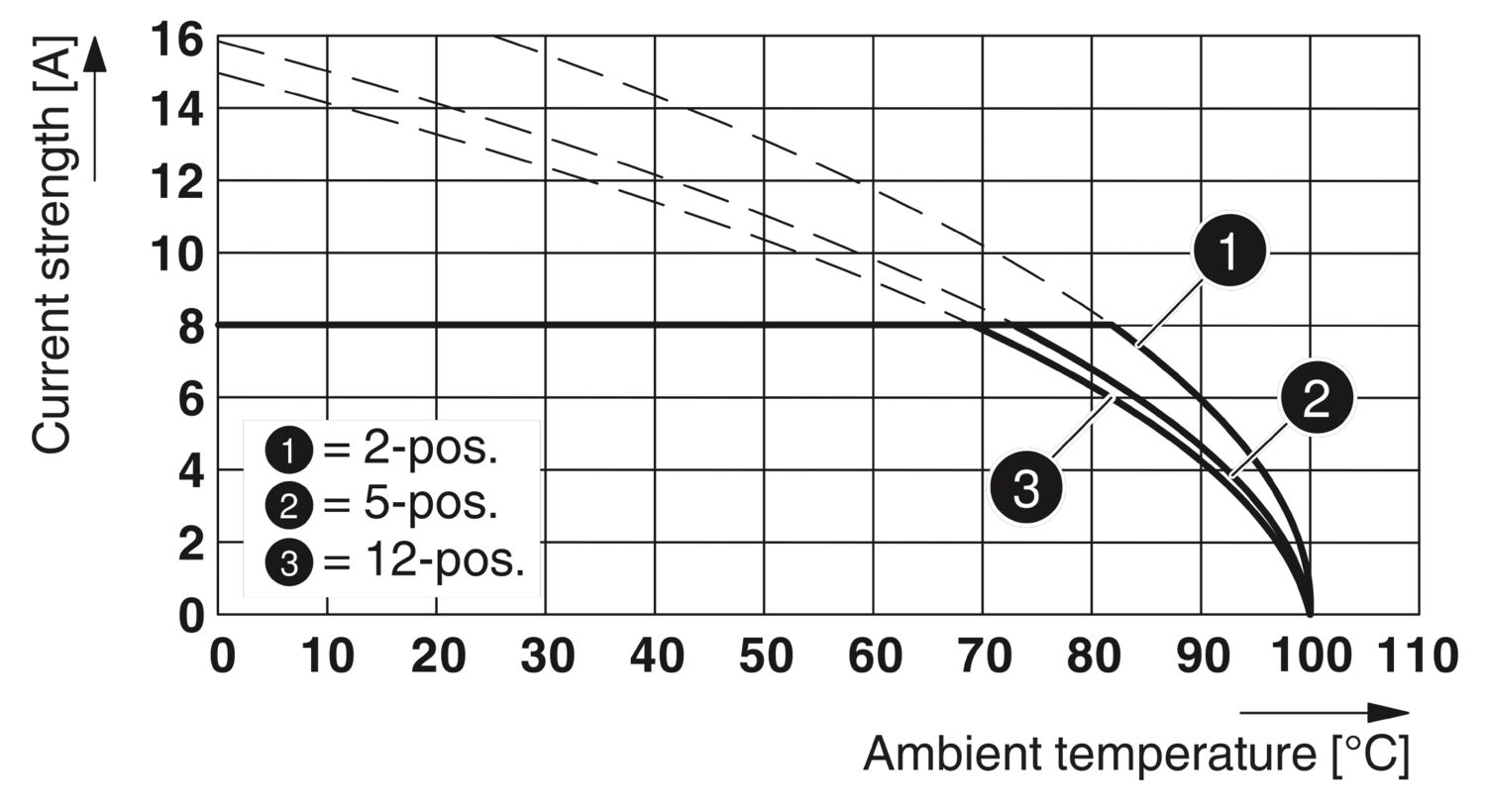

cross section 1.5 mm2

mounting type THR soldering

type of packaging packed in cardboard

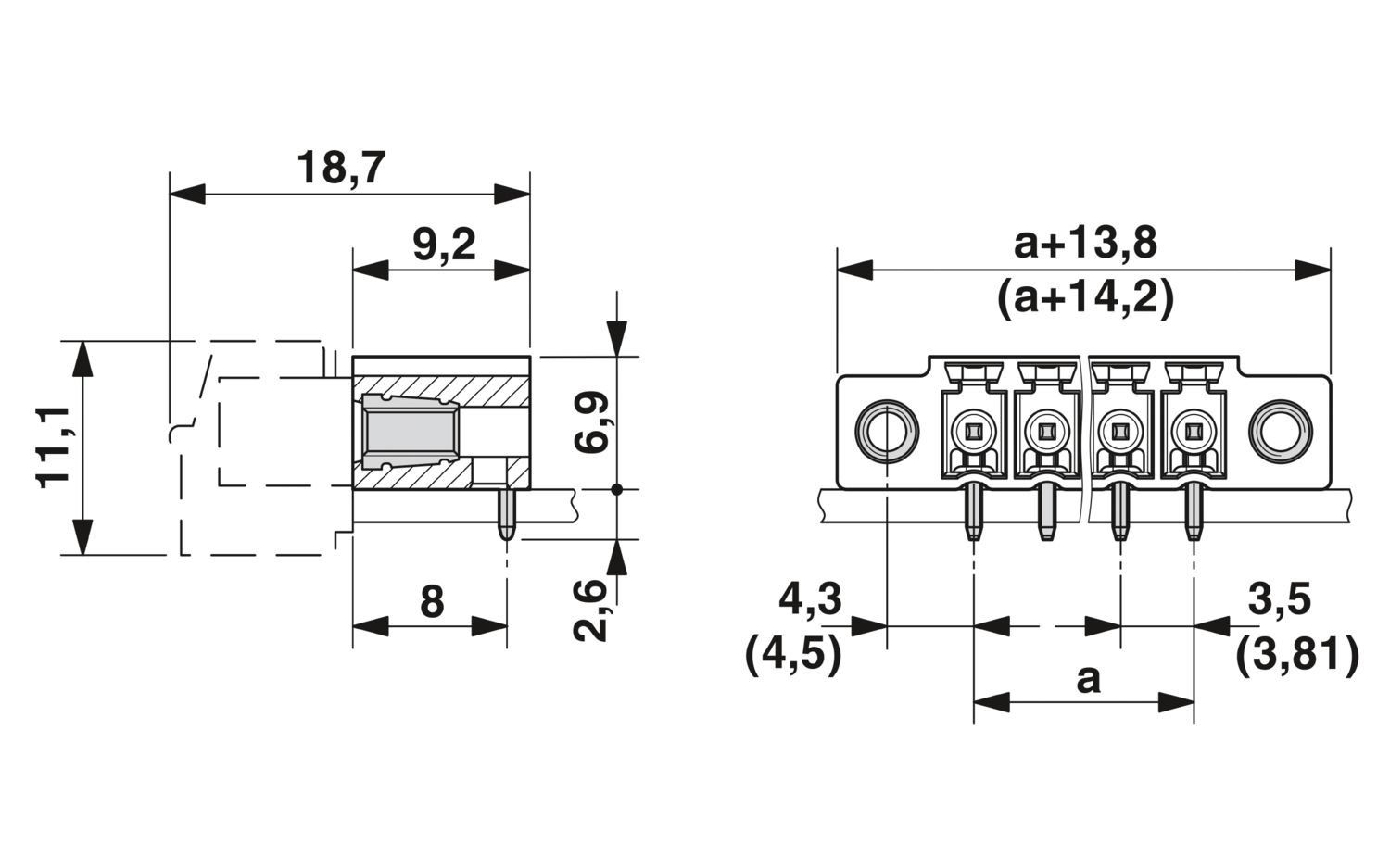

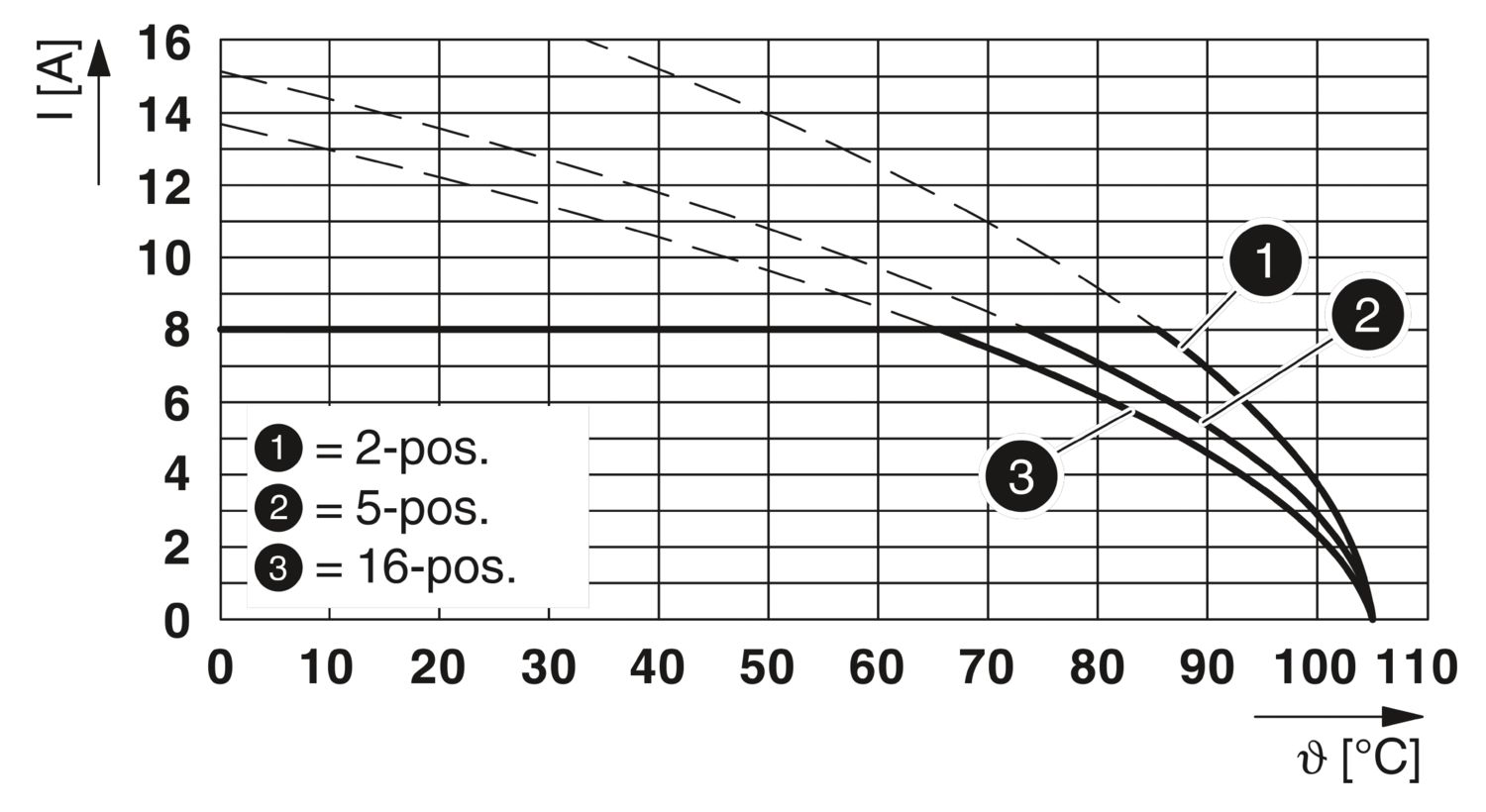

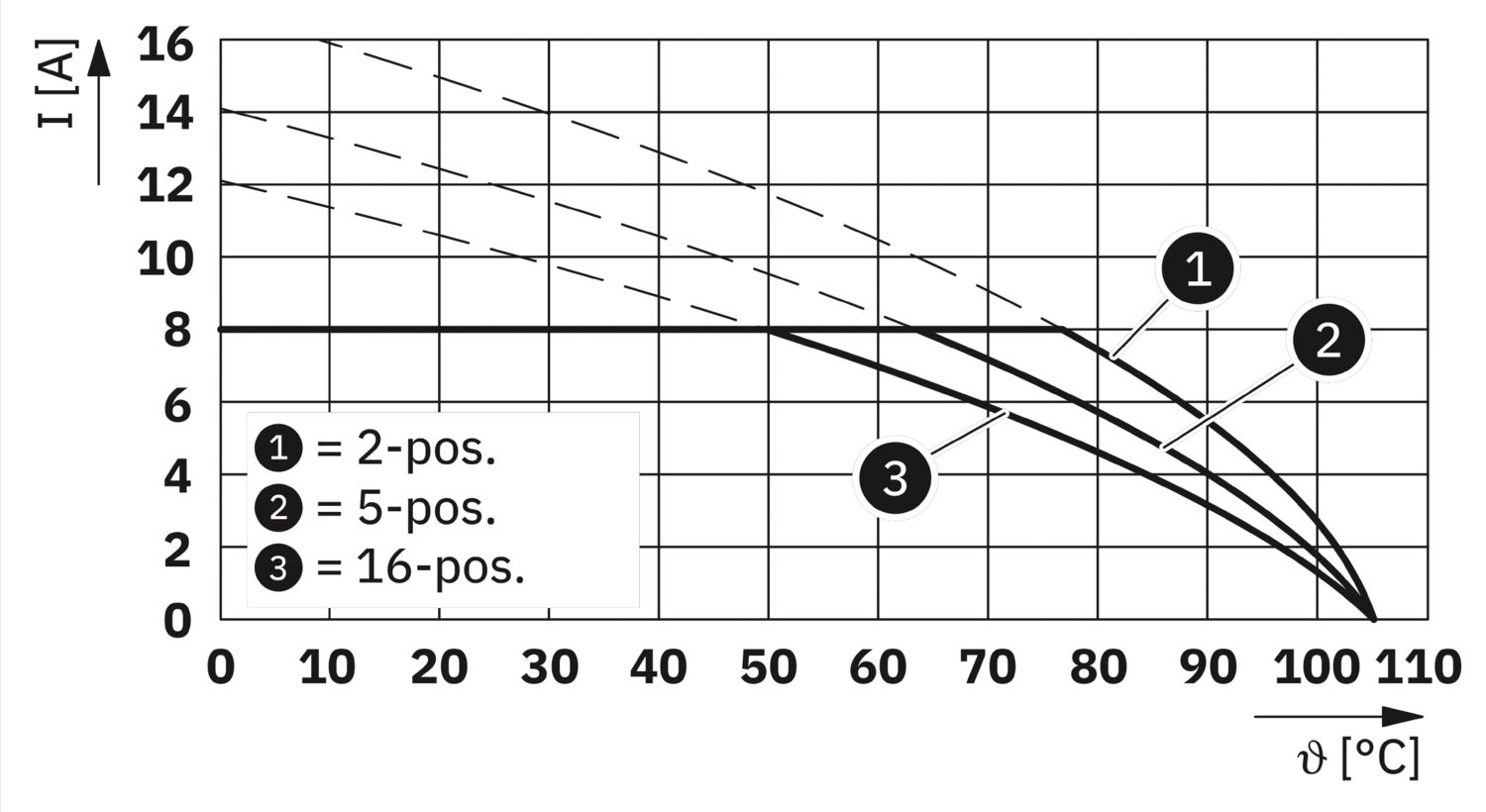

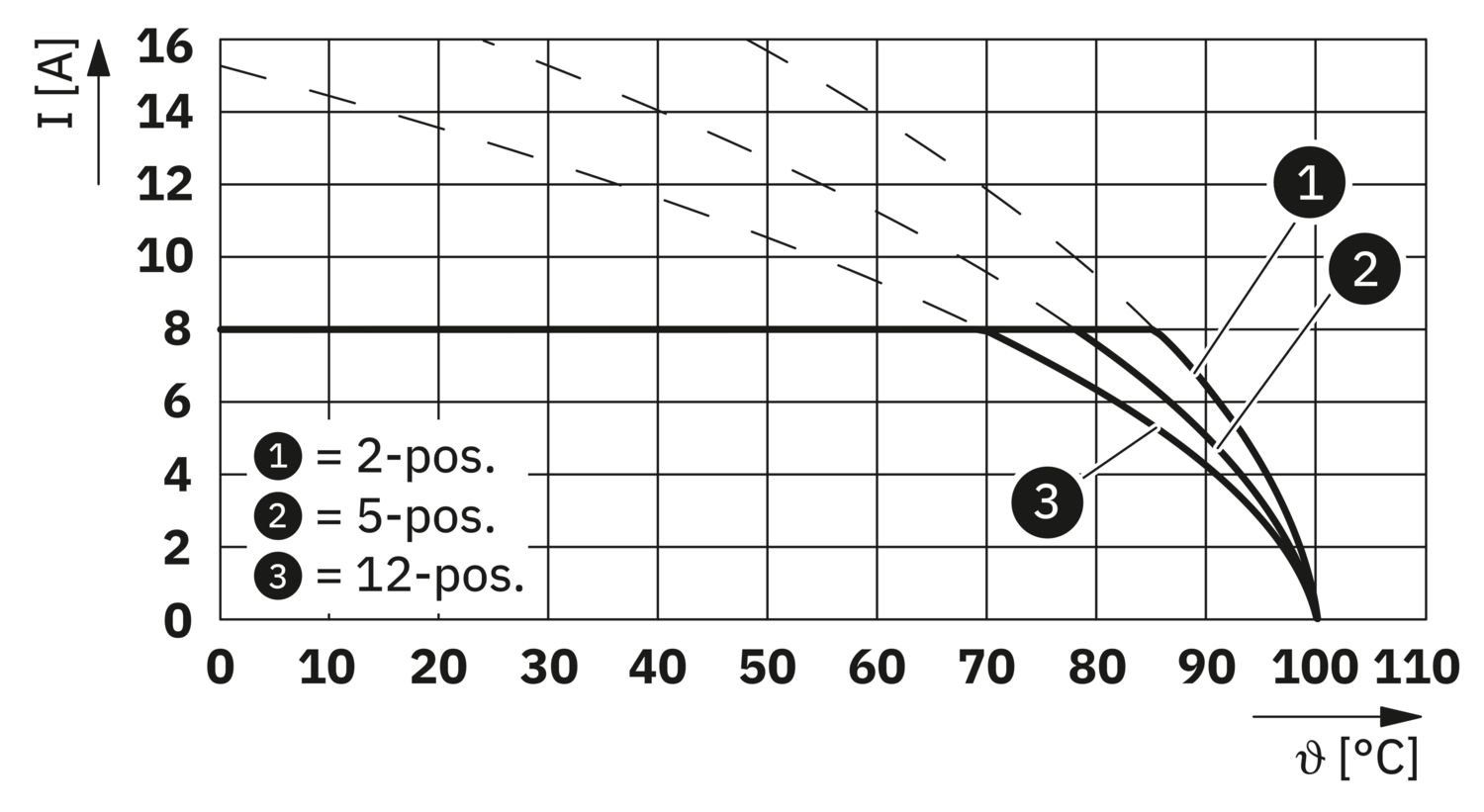

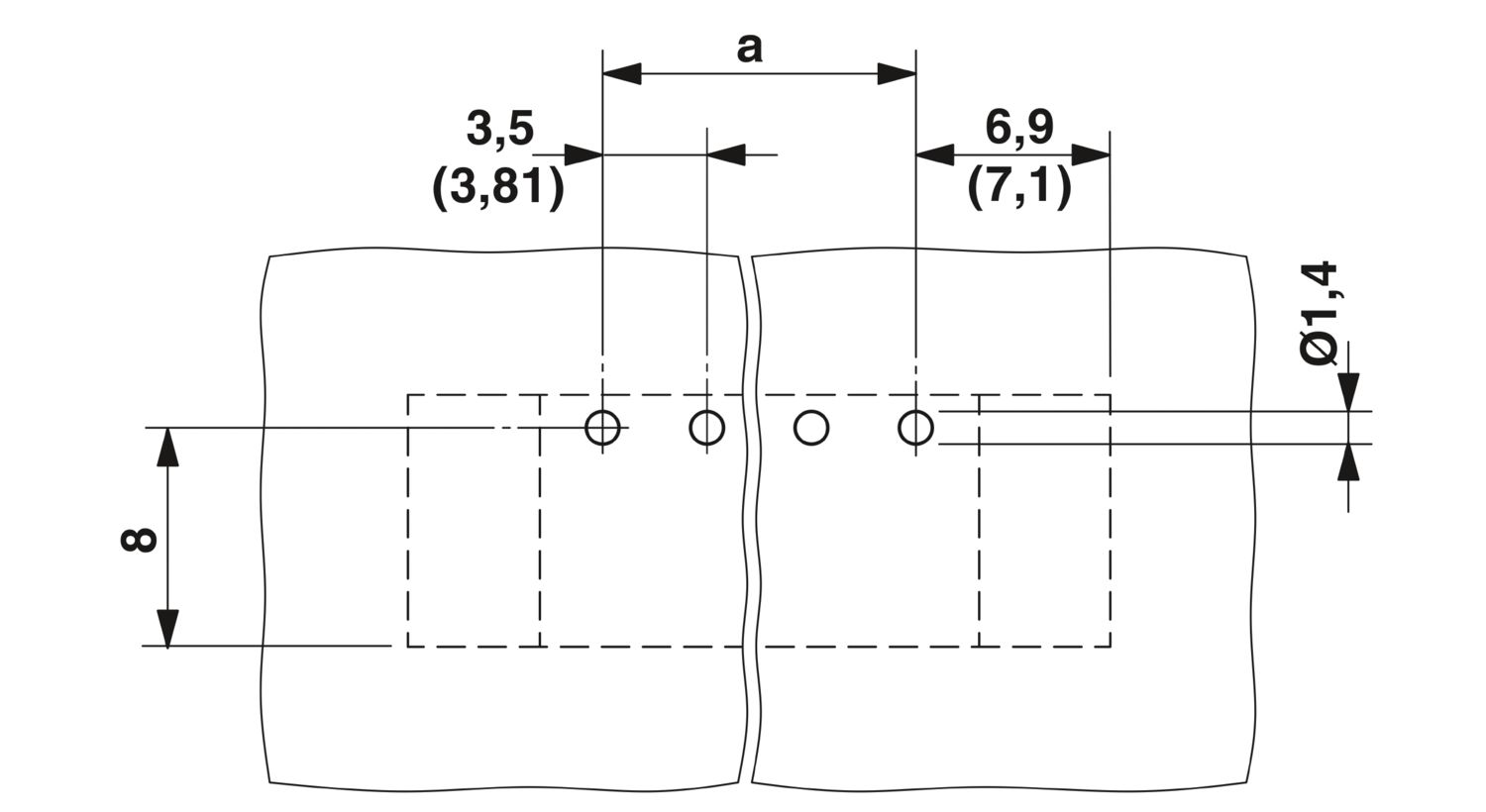

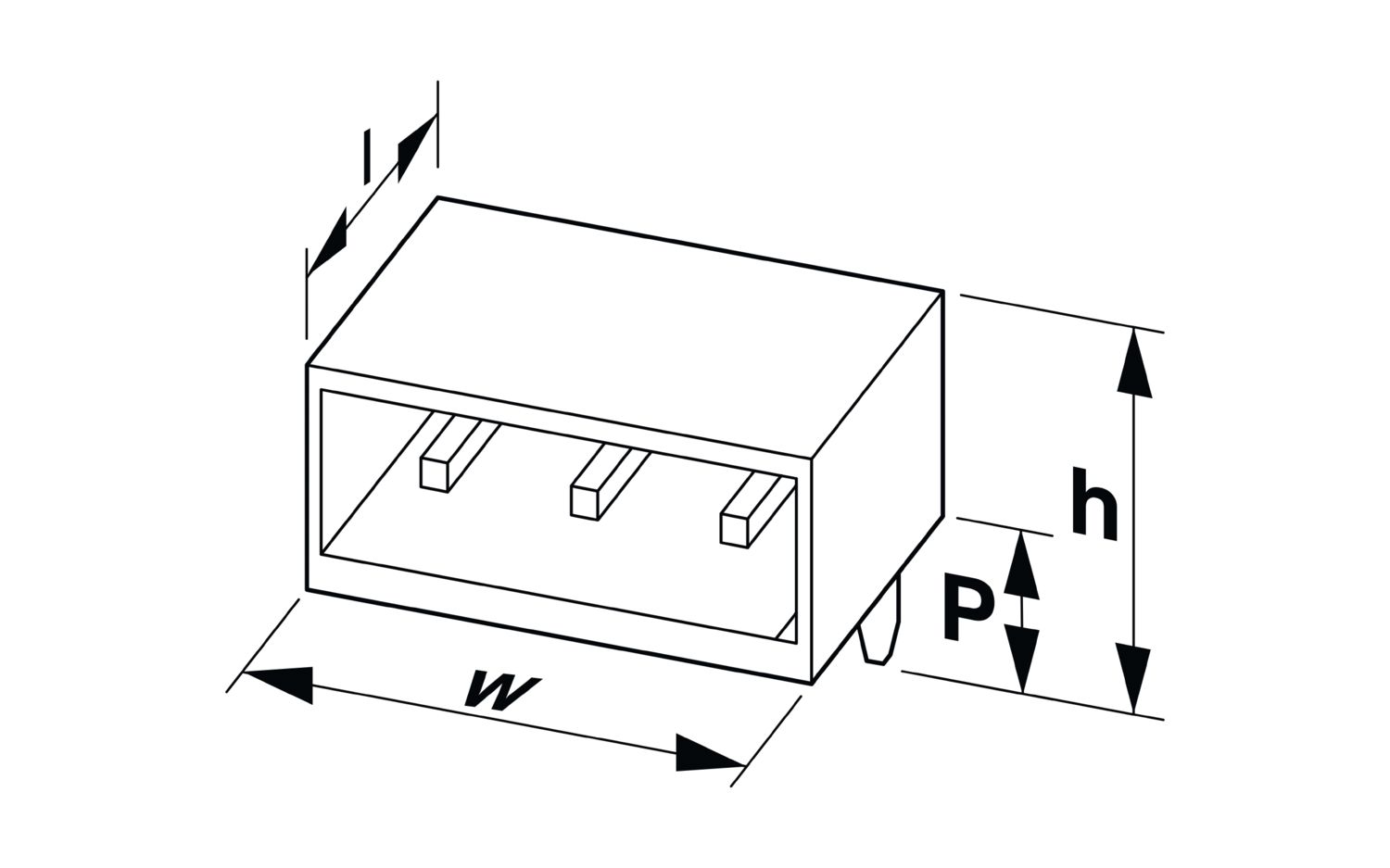

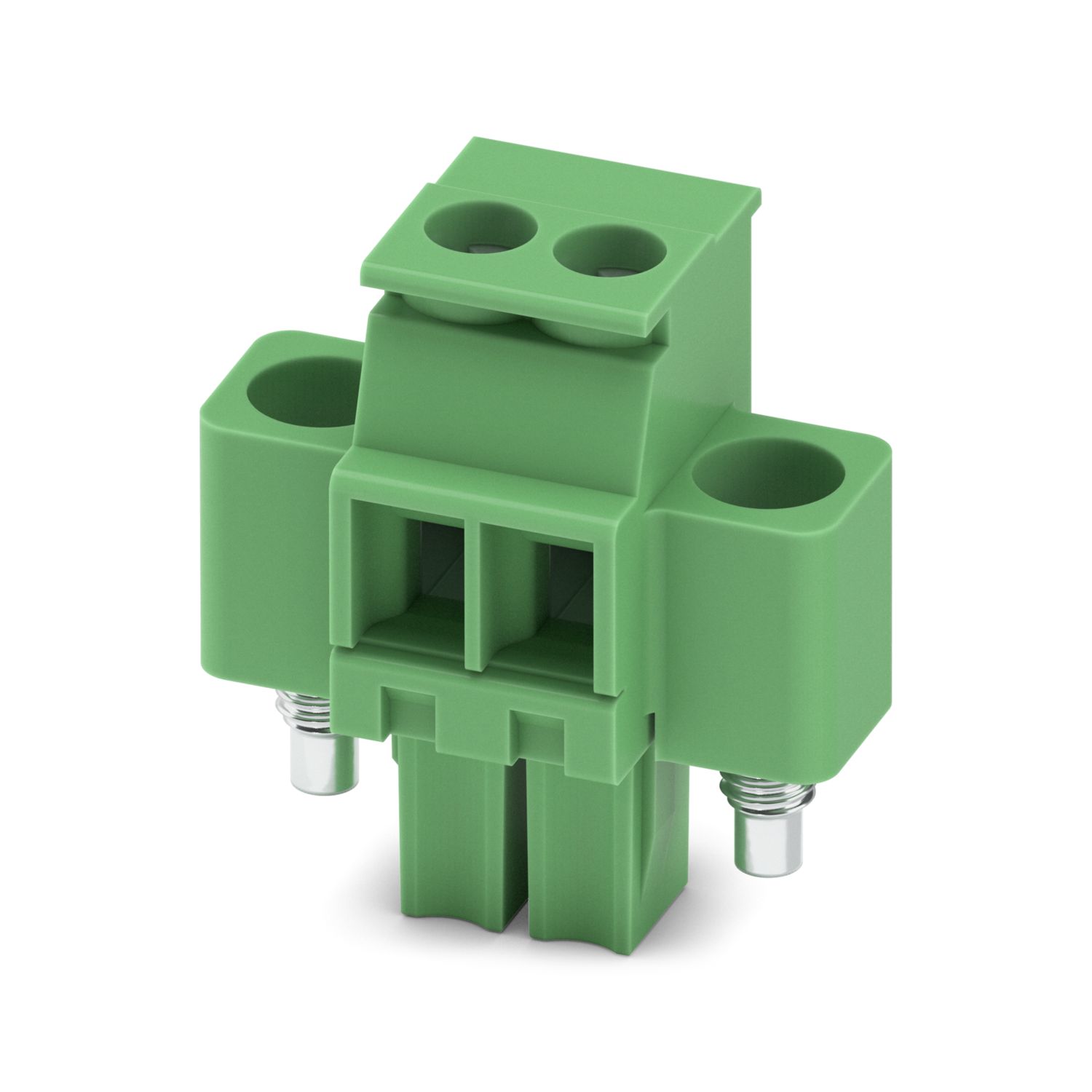

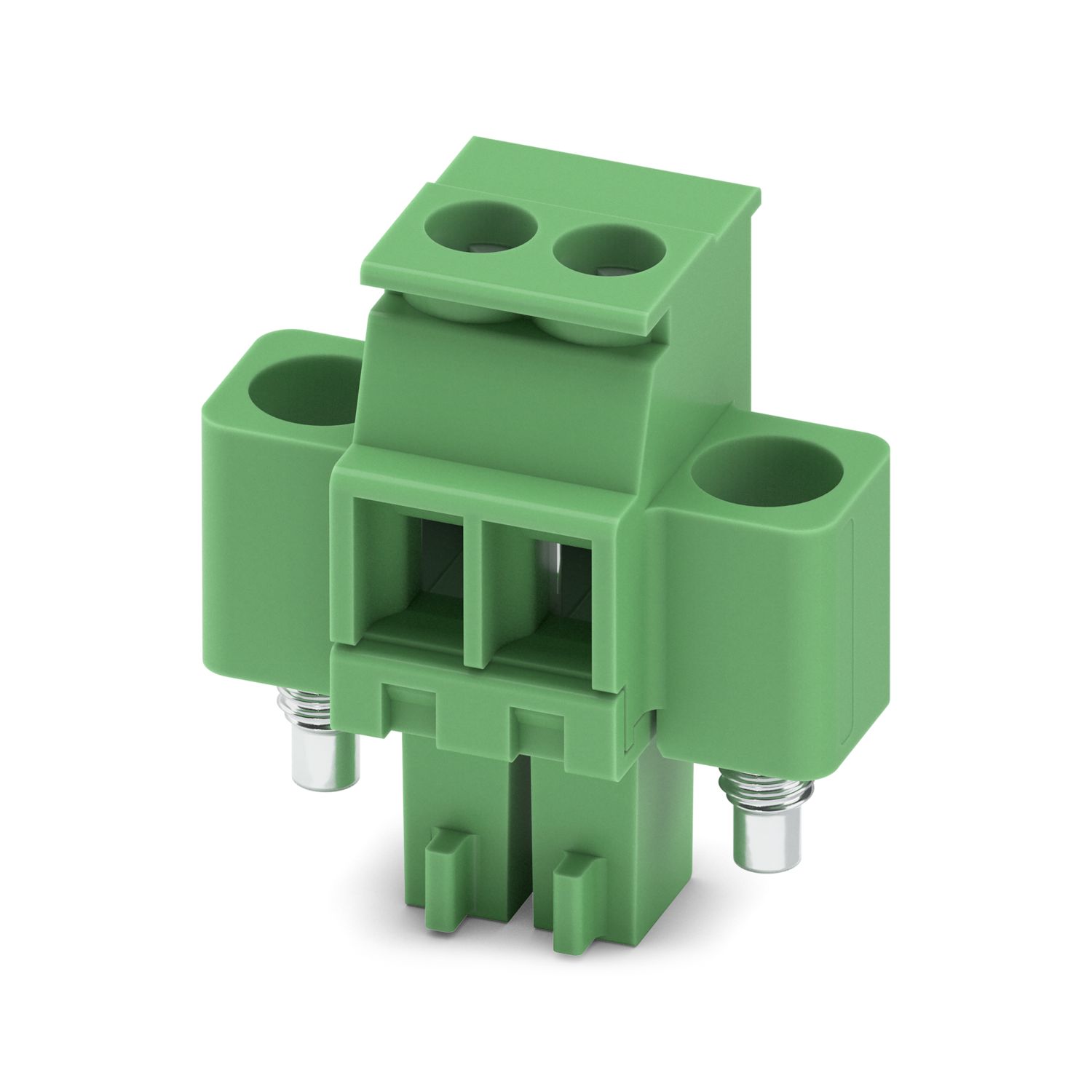

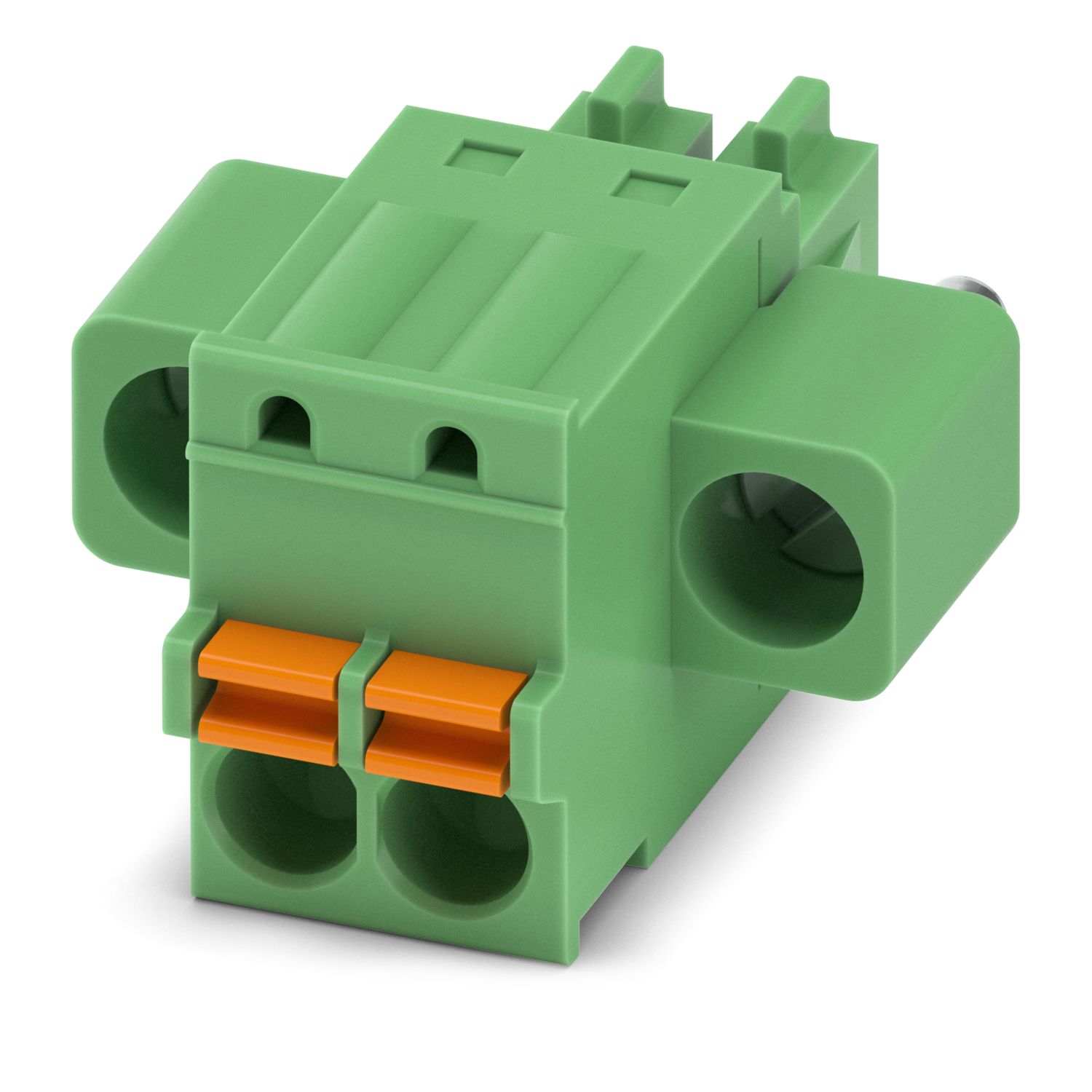

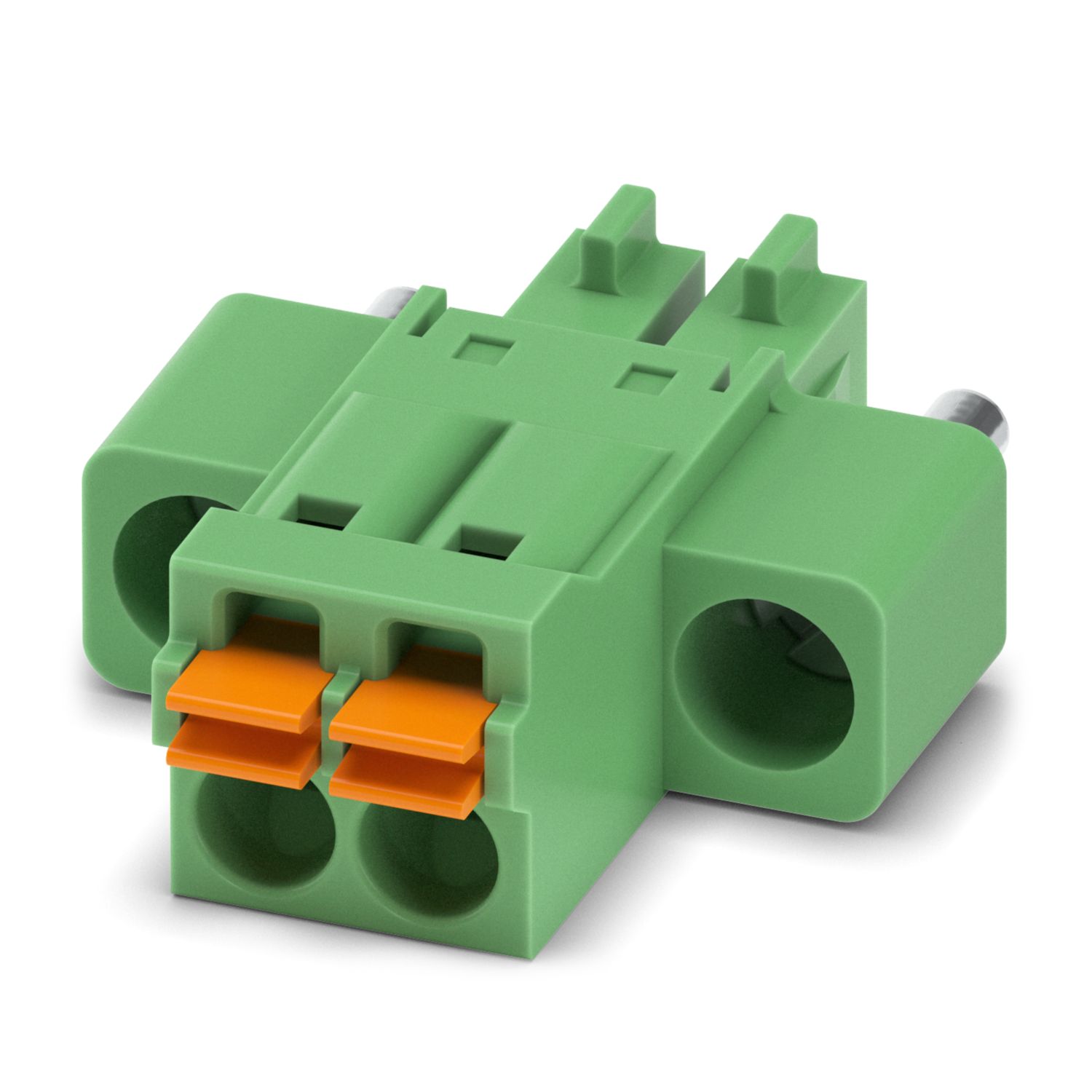

PCB headers, nominal cross section: 1.5 mm2, color: black, nominal current: 8 A, rated voltage (III/2): 160 V, contact surface: Sn, contact connection type: Pin, number of potentials: 2, number of rows: 1, number of positions: 2, number of connections: 2, product range: MC 1,5/..-GF-THR, pitch: 3.5 mm, mounting: THR soldering, pin layout: Linear pinning, solder pin [P]: 2.6 mm, number of solder pins per potential: 1, plug-in system: COMBICON MC 1,5, Pin connector pattern alignment: Standard, locking: Screw locking mechanism, mounting method: Threaded flange, type of packaging: packed in cardboard