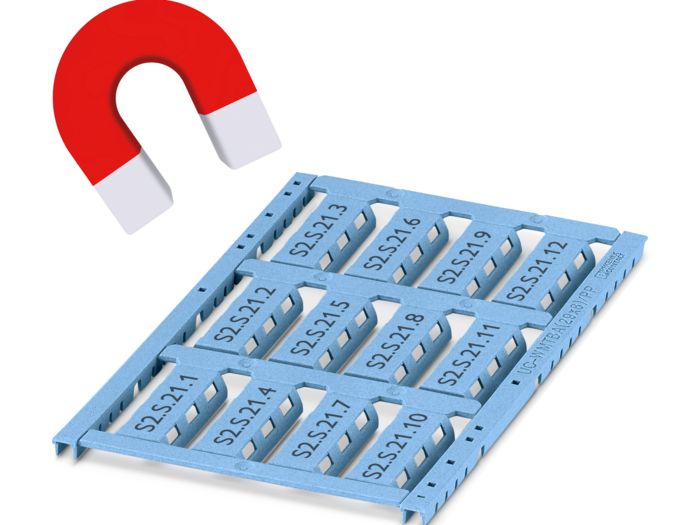

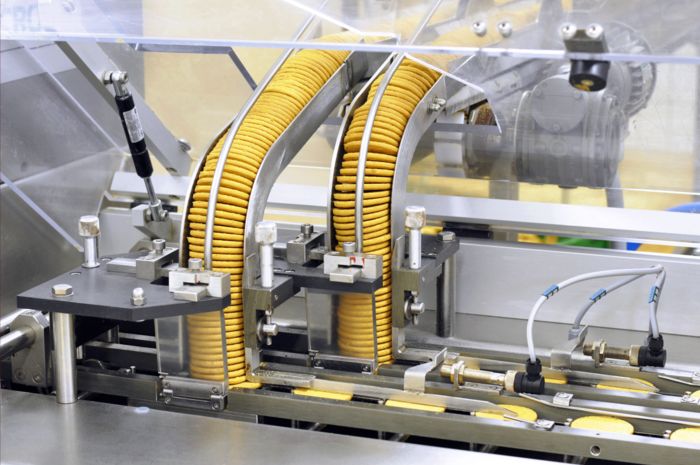

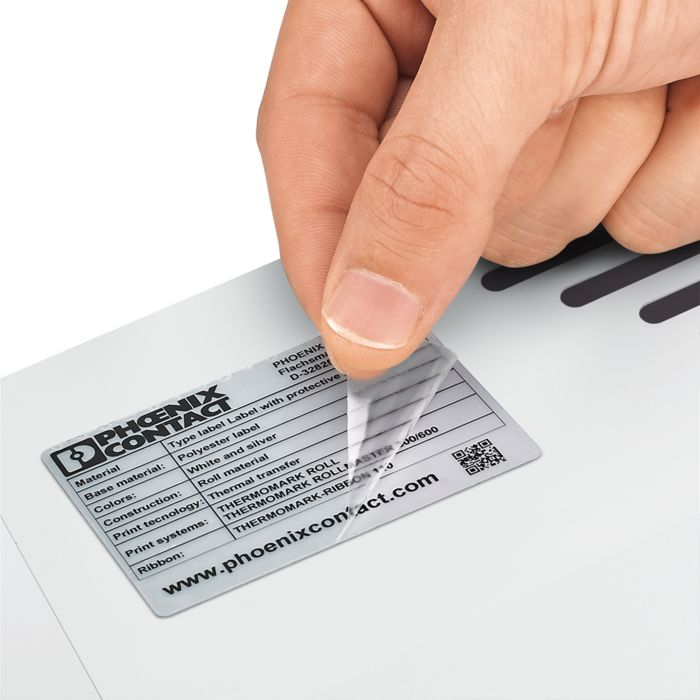

The UC-WMTBA-D... detectable marker is made of polypropylene. The tear-resistant material features outstanding resistance to chemicals and moisture. With this marker and the TOPMARK NEO marking system, you can create a permanent mark. However, if material fatigue should occur, even the smallest fragments of detectable material can be detected during the final inspection.