Flexible signal marshalling for Universal I/O

In the case of I/O signal marshalling for standard I/O systems, the field signals are sorted in large control rooms in accordance with their signal type and then wired to the controller via the interface level in single wires. In contrast, I/O signal marshalling for Universal I/O systems enables a decentral structure with flexible assignment of channels from the field to the controller. VIP I/O marshalling is a controller-independent plug-and-play solution that combines I/O signal marshalling and signal processing in one system.

Challenges

Lack of flexibility, significant wiring effort, and large control rooms

Depending on the size of the plant, several thousand signals must be marshalled between the field and control levels to control a continuous process in process engineering plants.

In classic signal marshalling, the field signals arrive in random order in central control rooms at the marshalling level and are first sorted in accordance with their signal type. From there, they are wired to the interface level. Here, for example, the signals are processed via signal conditioners, measuring transducers, and relays and wired to the IO level via system cables.

In addition to the increased space requirements and wiring effort, these solutions require that the exact signal type must be known at an early stage.

Universal I/O: Flexible – but only with the necessary interface technology

With the Universal I/O approach on the control level, improvements are already achieved compared to the classic signal marshalling. Instead of the 8/16/32/64-channel blocks for each signal type, Universal I/O cards enable software to be used to adapt the individual channels to the necessary function.

However, existing Universal I/O system problems must also be taken into account.

The required interface technology is missing, such as:

- Relays for signal conditioning to the I/Os configured as digital outputs

- Interface modules with intrinsic safety type of protection

- Signal conditioners and measuring transducers for safe signal conditioning, for example, for separating ground loops and preventing signal distortions

Our solution

The flexible I/O marshalling system VIP I/O marshalling

Full flexibility on the interface and marshalling level

The flexible I/O marshalling system VIP I/O-Marshalling has been specially designed for use on Universal I/O systems. The solution offers the same flexibility at the interface and marshalling level as the Universal I/O systems at the I/O level.

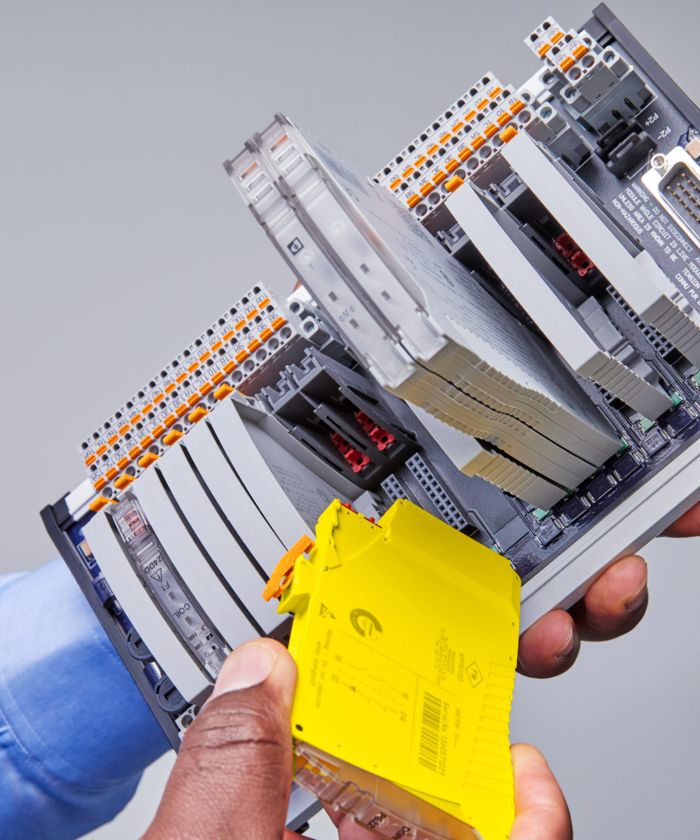

The system is mainly comprised of three blocks:

- The base element is attached to the standard DIN rail, accommodates the field wiring, and provides the connection to the I/O system via connectors.

- The second block is the Input-Output Accessory (IOA) that performs the actual interface function.

- A system cable connects the base element to the Universal I/O system.

Your advantages The design with Universal I/O systems in intelligent decentralized control boxes results in decisive advantages

- A standard product adaptable to all applications

- Pre-tested control boxes with global approval package

- Savings in signal and marshalling cabinets

- Elimination of master cables and cable routes

- Significant reduction in the number of clamping points

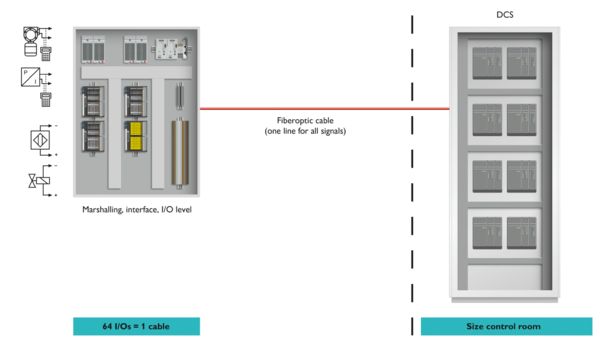

The decentralized control box solution

The Universal I/O approach breaks the mold of the rigid configuration of the marshalling, interface, and I/O level in the central control room. The intelligence is being relocated so it is closer to the process in the field. Universal Remote Cabinets provide a compact and standardized solution for this. The flexible I/O marshalling system handles signal marshalling and processing here.

Decentralized control box solution

Summary

Universal I/O is space-saving and flexible – from the field to the control level

I/O signal marshalling for Universal I/O systems becomes truly universal with VIP I/O marshalling. The flexible I/O signal marshalling system is a controller-independent solution that combines I/O signal marshalling and processing in one system. The flexible plug-in function modules allow you to configure the channels individually and consistently from the field to the control level.

With Universal Remote Cabinets, the need for large marshalling and interface cabinets is eliminated. Adapting a modular design has not only eliminated some components entirely, but has also made the necessary components more compact so they fit in a smaller cabinet.