Ethernet-APL switches The state-of-the-art Ethernet-APL transmission technology enables the direct two-wire Ethernet connection of sensors and field devices in the Ex zones of process technology applications. The Ethernet-APL switches allow you to integrate APL sensors and field devices into an existing Ethernet network. This allows you to provide direct access to data from the field level.

Your advantages

- Direct access to sensor data from the field level

- Use in potentially explosive areas and for bridging large distances

- Reduced wiring effort, complexity is reduced

- Cost reductions through the use of existing fieldbus cabling

- In addition to the Ethernet-APL functionalities, the managed switches have the proven FL SWITCH 2300 features

Ethernet APL technology

Ethernet-APL technology Direct integration of APL field devices in the process industry

The Ethernet-APL technology enables consistent IP-based communication via just one wire pair in the Ex zones of process technology applications. This enables the direct connection of APL sensors and devices from the field level, without additional gateways or complex subsystems.

The abbreviation APL stands for Advanced Physical Layer and describes a further development of physical data transmission in Ethernet networks. In addition to data transmission via just one wire pair, the technology also enables power supply transmission over the same wire pair as an option. Advanced Physical Layer uses the 10BASE-T1-L standard in accordance with IEEE 802.3cg along with the IEC TS 60079-47, 2021-03 (2-WISE) standard (2-WISE = 2-Wire Intrinsically Safe Ethernet), and supports explosion protection methods including intrinsic safety. Thus Ethernet-APL enables use in potentially explosive areas and the bridging of great distances up to 1,000 m at 10 Mbps.

Product features

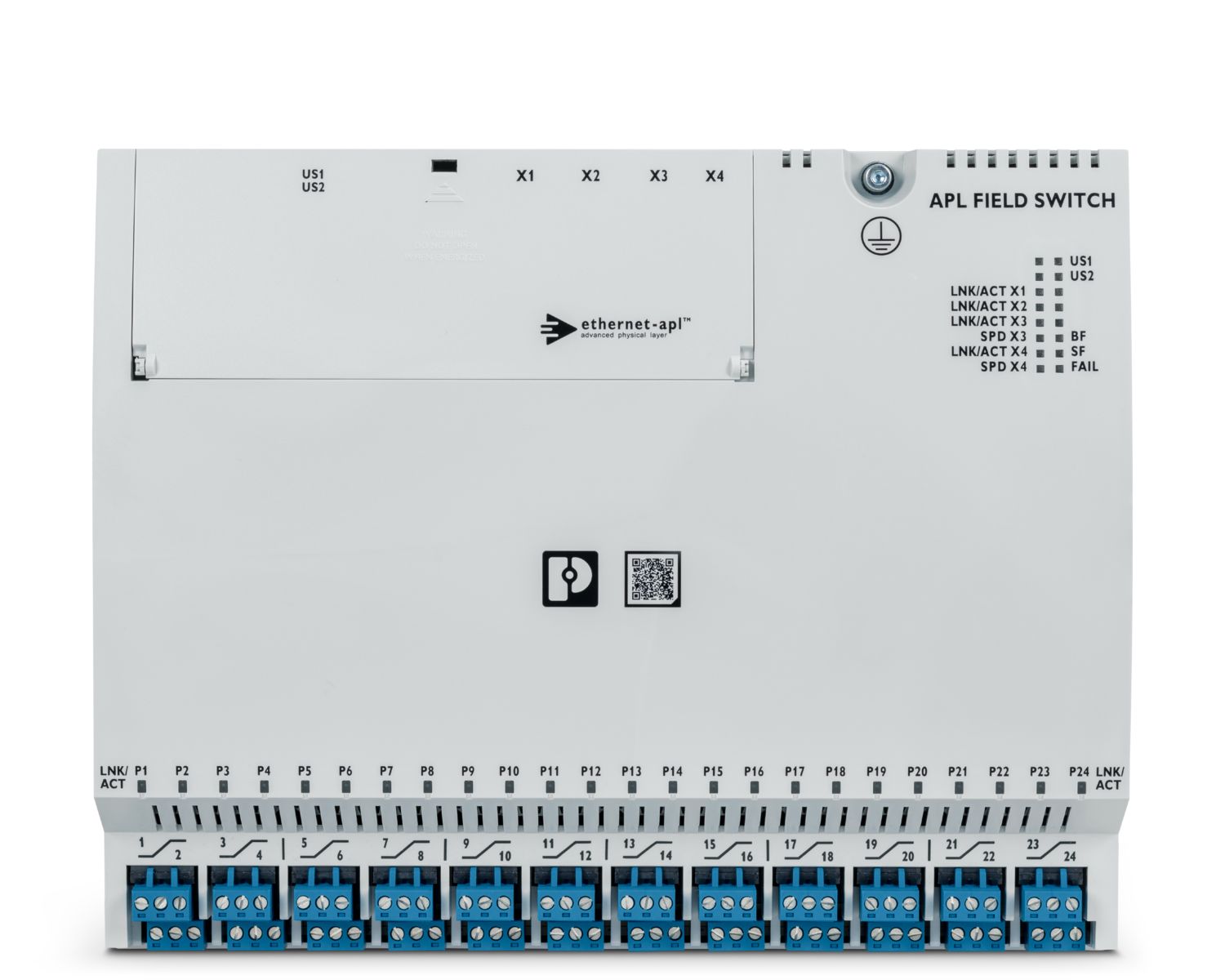

Data transmission via just one wire pair with the APL field switch

Ethernet down to the field level

The APL field switch makes the use of state-of-the-art Ethernet-APL technology simple and efficient. As a managed switch, it ensures secure data transmission with high bandwidth and minimal latency.

APL sensors and devices can be directly integrated from the field level into the existing Ethernet network of the system. This means that process data is available immediately and without any detours. With the two-wire technology, even existing cable infrastructures can continue to be used. This saves time and costs during installation. Complex gateway solutions and additional subsystems, as required in the past, are no longer necessary. The Ethernet-APL switch is the basis for empowering the IIoT in process automation.

Ethernet APL enables large distances to be bridged

Range and speed

The managed APL switches can be used in both compact and wide-ranging systems. The trunk and spur topology is used for long ranges. The 10BASE-T1L standard enables a range of up to 1,000 m (spurs up to 200 m) at 10 Mbps. The bridging of large distances can therefore also be implemented in potentially explosive areas.

Naturally, the network topology can be flexibly designed so that even compact layouts can be realized with the managed switches. It is possible, for example, to do without a trunk by using the APL switches to connect the APL spur ports directly to the standard Ethernet.

Simple planning with standardized power classes

Power classes

Ethernet-APL introduces power classes that significantly simplify the selection and installation of devices in potentially explosive areas. The power class defines the electrical properties of a port, i.e., how much power a device can absorb or provide. This ensures that field devices and switches work together optimally and that intrinsic safety requirements are met.

Power class A and B: For intrinsically safe applications (Ex ia) at the field device level, e.g., in zones 0 and 1.

Power class C: Supports Ex ic applications, typically for zone 2.

Power class 3 and 4: For high-performance trunk segments, for example for long cable runs. These ports are not intrinsically safe.

With the clear classification, it is sufficient to match the power class on the switch and on the field device. Elaborate calculations or complex tables are no longer necessary. This increases safety and speeds up commissioning. This in turn makes the installation of Ethernet-APL solutions simple and reliable, even in demanding environments.

Proven and future-proof in one device

Proven platform with future-proof technology

By integrating Ethernet-APL switches into your industrial network, you can combine proven functions with modern communication technology. In addition to Ethernet-APL technology, the managed switches support all the functions of the well-known FL SWITCH 2300 series. They have comprehensive redundancy and security features, for example, for implementing future-proof networks.

The Ethernet-APL switches make it possible to strengthen the existing network infrastructure and prepare for the high demands of an increasingly networked world.

Ethernet APL switch Click on the hotspots to find out more

Ethernet APL in processing plants

Applications

The Ethernet-APL switches can be used in compact systems such as in the pharmaceuticals and chemicals industries, as well as in large systems in the process industry. The integration of Ethernet-APL switches is a decisive step for increasing efficiency and modernizing existing systems.

The managed switches have been specially developed for use in potentially explosive areas. This means that they meet the high requirements for zone 1 and 2 or division 2 accordingly. The robust design and the use of degrees of protection enable the devices to function reliably even under particularly demanding conditions.

Product overview

The managed APL field switch in detail

|

|

|

|

|

|---|---|---|---|---|

| FL SWITCH APL 2224-4A-213-PA | FL SWITCH APL 2224-4A-211-PA | FL SWITCH APL 2212-4A-211 | FL SWITCH APL 2212-4A-221 | |

| APL ports | 24x 10BASE-T1L | 24x 10BASE-T1L | 12x 10BASE-T1L | 12x 10BASE-T1L |

| Additional ports | 2x RJ45 and 2x SFP | 2x RJ45 and 2x SFP | 2x RJ45 and 2x SFP | 2x RJ45 and 2x SFP |

| Power Class | Power class A and power class B | Power class A | Power class A | Power class A |

| Supply voltage | 22 V DC … 30 V DC | 23 V DC … 30 V DC | 24 V DC … 30 V DC | 25 V DC … 30 V DC |

| Temperature range | -40°C … 70°C | -40°C … 70°C | -40°C … 70°C | -40°C … 70°C |

| Managed switch features | Real-time QoS, redundancy, and security features | Real-time QoS, redundancy, and security features | Real-time QoS, redundancy, and security features | Real-time QoS, redundancy, and security features |

| Management interface | Web, SNMP, CLI, PROFINET device | Web, SNMP, CLI, PROFINET device | Web, SNMP, CLI, PROFINET device | Web, SNMP, CLI, PROFINET device |

| Ex protection | ia | ia | ic | ia |

| Proxy | Yes | Yes | No | No |

| Item No. | 1384244 | 1843743 | 1718555 | 1718554 |

| To the product | To the product | To the product | To the product |