As a company, you can benefit from legal subsidies, benefits, and tax incentives by providing evidence of a certified energy management system.

Companies today are faced with the challenge of reducing their energy consumption and the cost of energy in order to remain profitable. Numerous legislative changes have been made in recent years. Aspects of climate protection and sustainability are also becoming more and more central to society. Implementing an energy management system helps you respond to growing governmental and social pressures and act in a way that is both sustainable and forward thinking.

The term “energy management” consists of the words "energy" and "management". In this context, management refers to directing and controlling operational processes to achieve the company’s goals. This also includes implementing the company’s policy with regard to improving energy performance. In this context, the term “energy performance”, in turn, stands for the three parameters of energy consumption, energy efficiency, and energy use. Energy use means switching from conventional energy to renewable energy, for example. It’s a change in the energy that is used.

As a company, you can benefit from legal subsidies, benefits, and tax incentives by providing evidence of a certified energy management system.

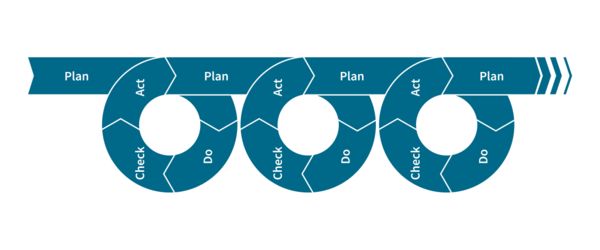

Reduce your costs through targeted, continuous energy consumption reduction, energy efficiency improvement, and energy use changes using the PDCA (Plan, Do, Check, Act) cycle as part of energy management.

Take the first steps toward a more sustainable economy and actively contribute to climate protection. As a result, you also promote your corporate image.

The basis for all modern management systems is the PDCA cycle. PDCA stands for the individual phases of the iterative, systematic approach: Plan, Do, Check, and Act.

The core element of the Plan phase is to identify significant energy use (SEU) areas. This is based on significant energy consumption or high potential for improving energy-related performance.

Here you can ask yourself questions about your own energy consumption, such as on possible energy wastage and the efficiency of individual systems and system networks. Considering activities and processes from operational practice is also part of this point.

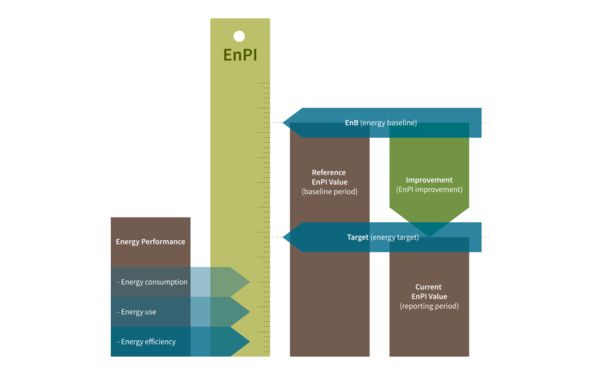

For the measurable evaluation of the individual SEUs, you define energy performance indicators (EnPI) and determine the associated energy baselines (EnB) as reference values.

Based on the recording of the current status and your internal analysis, you ultimately derive measures to optimize energy use and eliminate inefficiencies.

Then you implement the planned measures in the company during the Do phase.

In the Check phase, you must now check whether the measures carried out have actually led to the planned result. For this purpose, the defined EnPIs are used in comparison with the EnBs and the set energy target.

If the review reveals a failure to achieve the planned goal, you must determine appropriate corrective measures.

You carry out these corrective measures in the Act phase in order to still achieve the original goals, as applicable. As a result, you achieve your set energy targets to improve energy-related performance.

After this phase, the cycle starts again, giving you iterative, continuous improvement in energy-related performance and therefore a more sustainable business.

This process is carried out with all energy sources that are essential in your company. Both those you purchase and those you generate yourself.

In most cases, this involves electrical energy that you purchase, such as an external electricity mix, but it also involves the energy that you generate, for example in your own production facilities such as photovoltaic systems or combined heat and power plants.

This also includes thermal energy for heating and cooling, such as from conventional building heating systems and air-conditioning systems as well as combined heat and power plants or steam as a means of process heating. In some companies, this also includes generating pneumatic energy in the form of compressed air by compressors.

If you convert a purchased energy source into another form of energy, the efficiency and effectiveness of the conversion is also relevant: for example, when using electrical energy to generate compressed air, and thus pneumatic energy, by means of a compressor.

The term “key performance indicator” (KPI) originates from business administration. Key performance indicators can be used to quantify various factors that are crucial to the success of a company.

This also applies to the field of energy management with energy performance indicators (EnPI), which you can use to measure, monitor, analyze, and evaluate energy-related performance in the company. The energy performance indicator is the measure of energy-related performance. It is a relative quantity where, for example at the machine level, you set the absolute, consumed electrical energy of the machine in relation to the number of units produced in order to obtain the specific energy consumption.

The energy baseline (EnB), on the other hand, is a quantitative reference value at a specified time period as the basis for comparing energy-related performance. For example, you may have recorded the specific energy consumption of an old machine for a certain period of time, which takes into account seasonal fluctuations, among other factors.

To monitor the success of measures taken, you now compare the current value at the time of reporting with the energy baseline of the energy performance indicator and the previously defined energy target. For example, as a measure, you may have replaced the old machine with a more efficient, modern machine. With the same number of units produced as during the reference period, you can now check whether a reduction in specific energy was achieved through the efficiency measure.

Benchmarking, on the other hand, is basically about comparing similar systems, machines, processes, etc. by means of energy performance indicators. If applicable, you can gain insights to derive optimization measures to increase energy efficiency in the company. Improvements can be achieved in the short term on the basis of identified best practices, or in the medium to long term through a continuous learning process within the company.