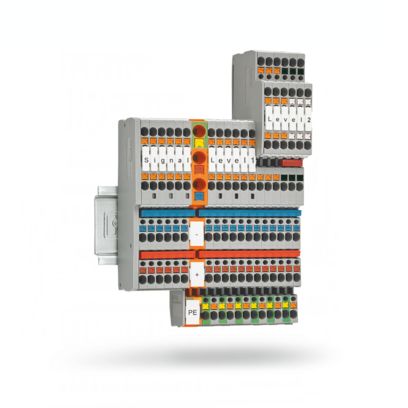

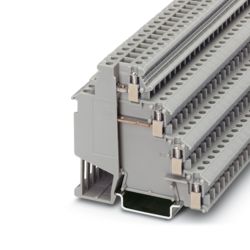

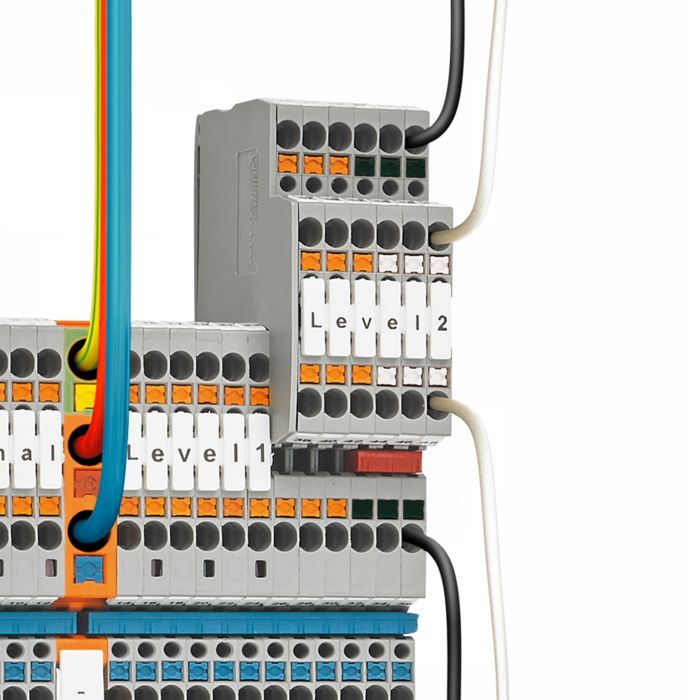

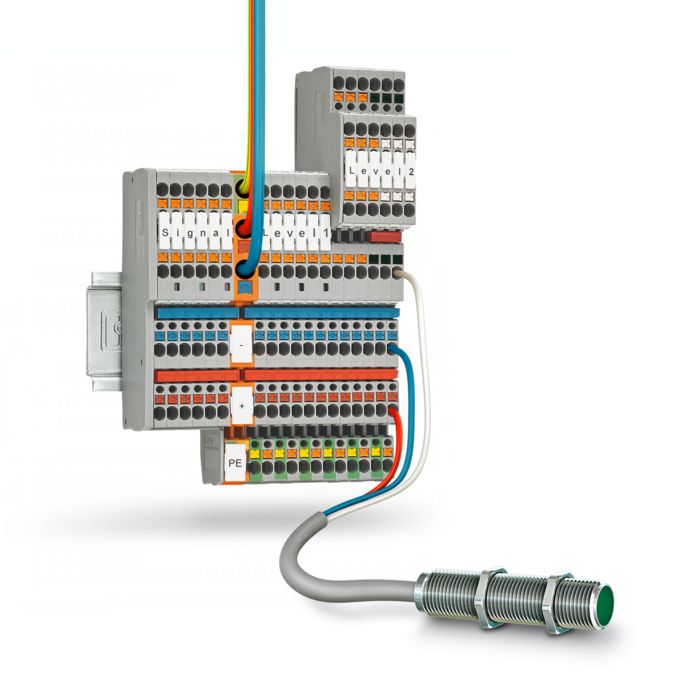

Initiator/actuator terminal block, nom. voltage: 250 V, nominal current: 13.5 A, number of connections: 4, connection method: Push-in connection, Rated cross section: 1.5 mm2, cross section: 0.14 mm2 - 1.5 mm2, mounting type: NS 35/7,5, NS 35/15, color: gray