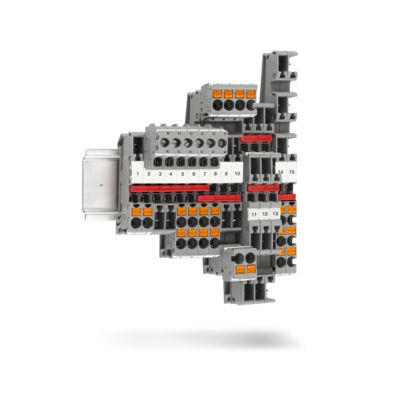

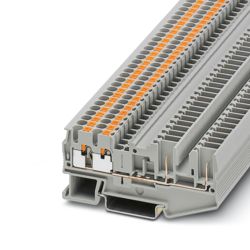

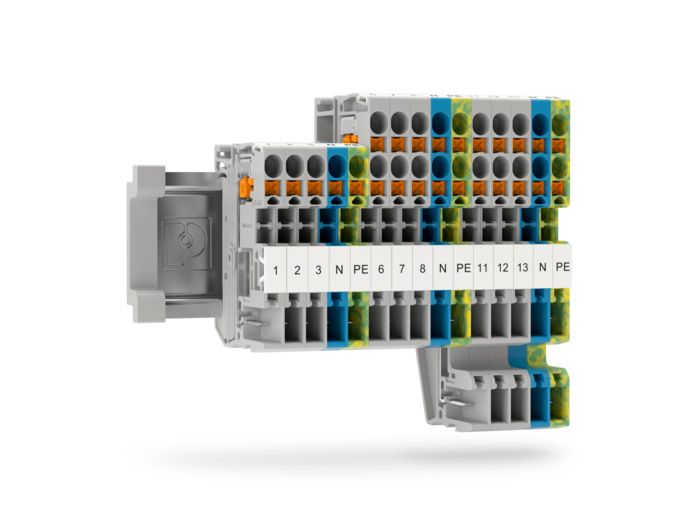

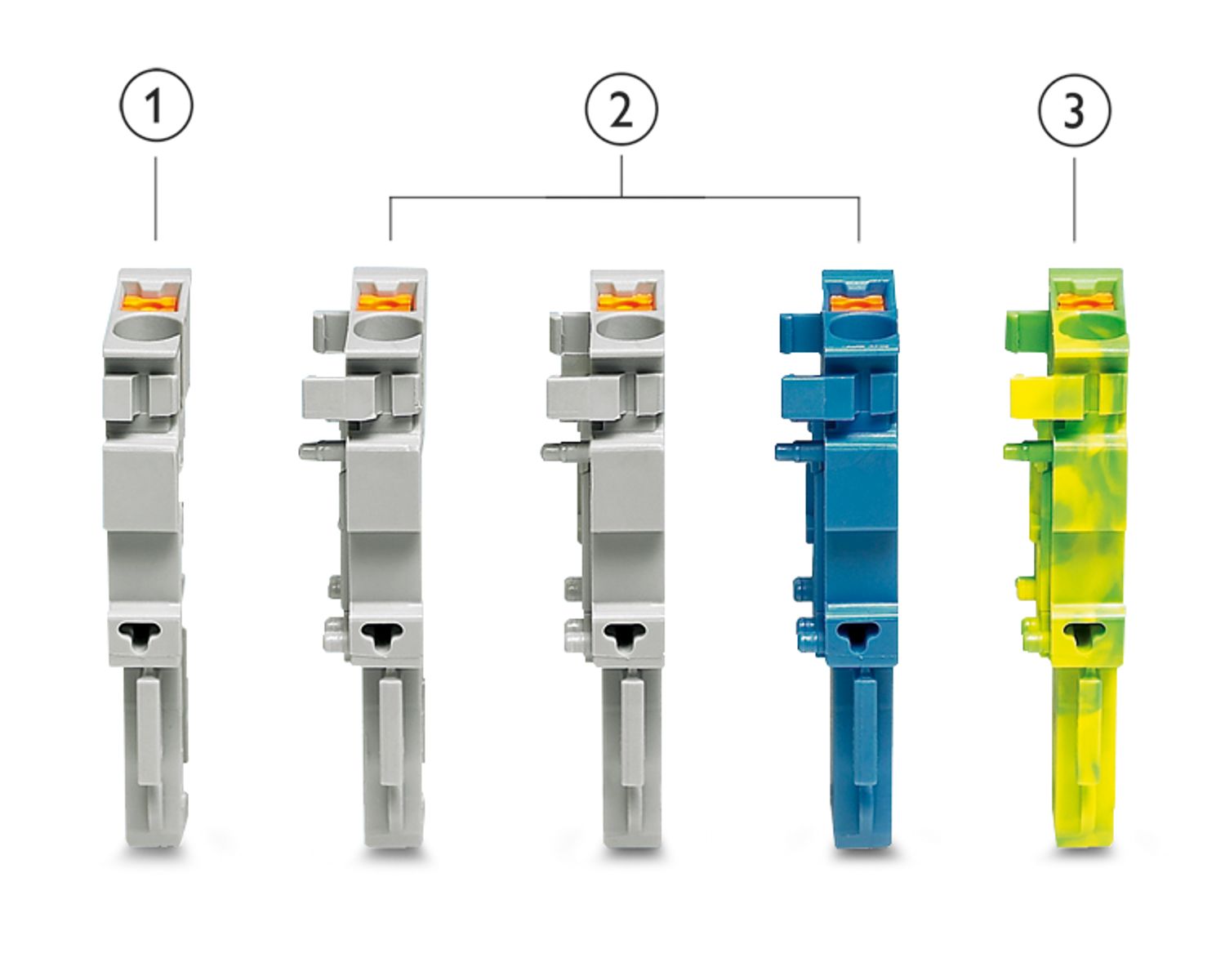

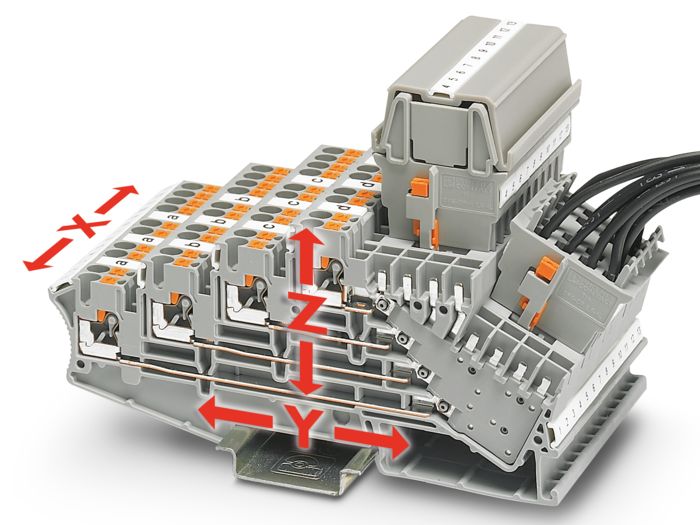

Feed-through terminal block, nom. voltage: 500 V, nominal current: 24 A, number of connections: 3, number of positions: 1, connection method: Push-in / plug connection, Rated cross section: 2.5 mm2, cross section: 0.14 mm2 - 4 mm2, mounting type: NS 35/7,5, NS 35/15, color: gray