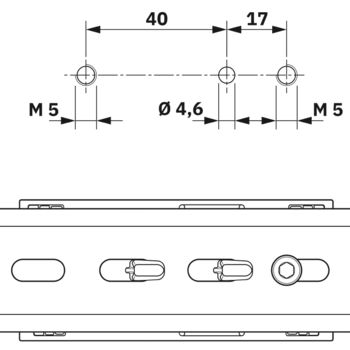

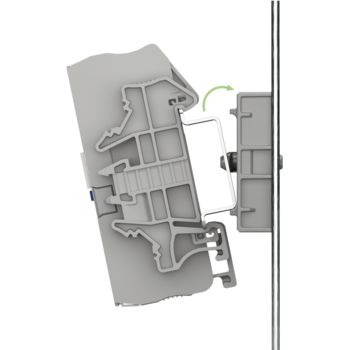

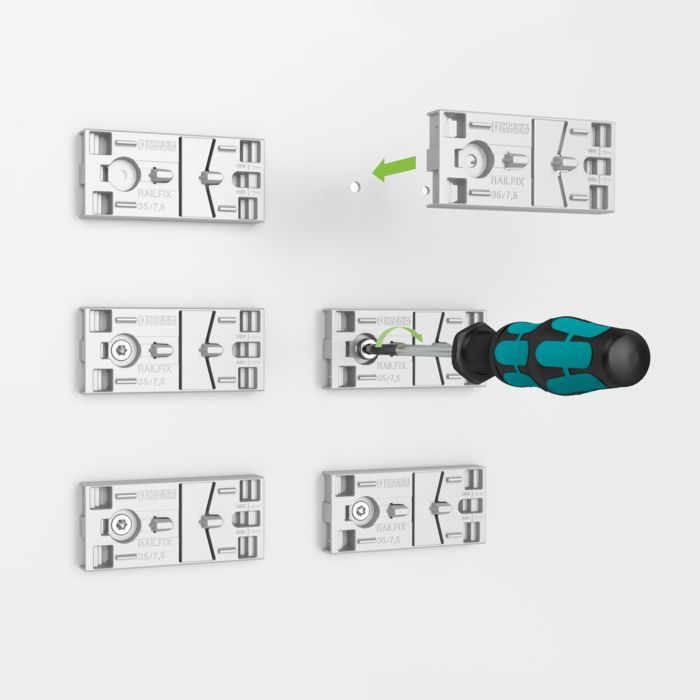

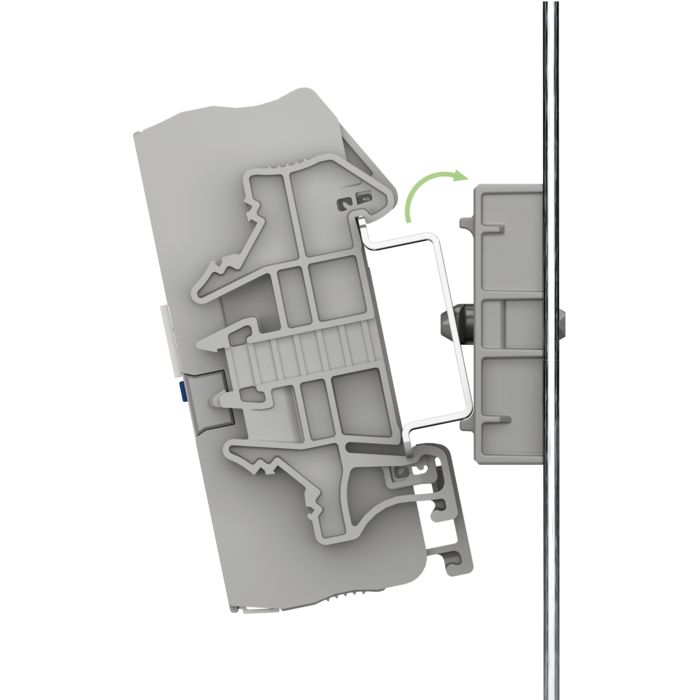

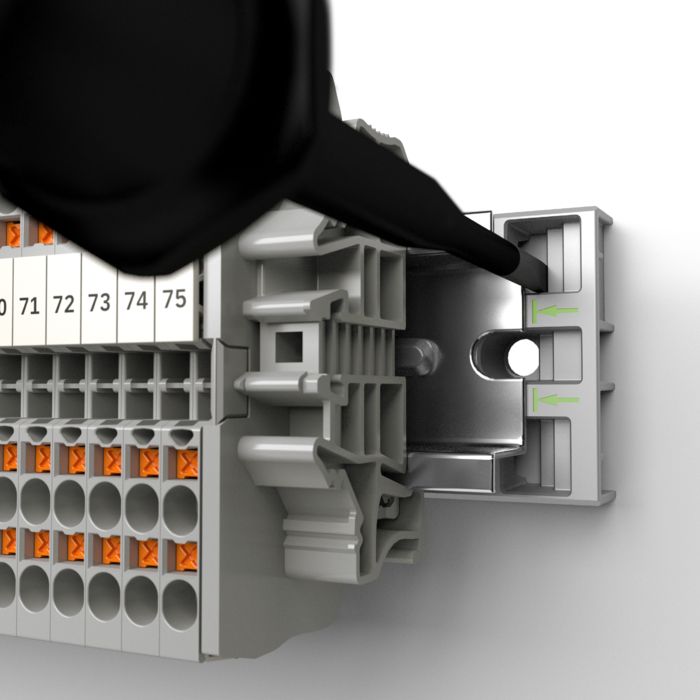

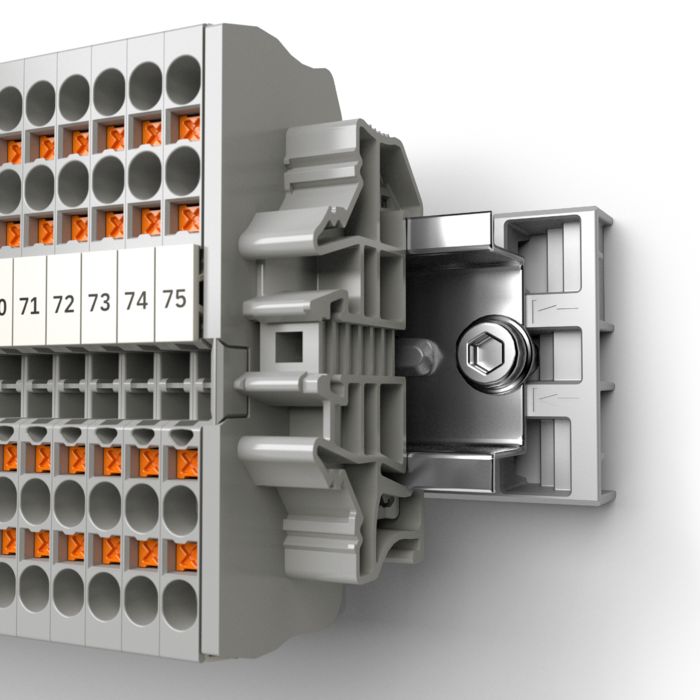

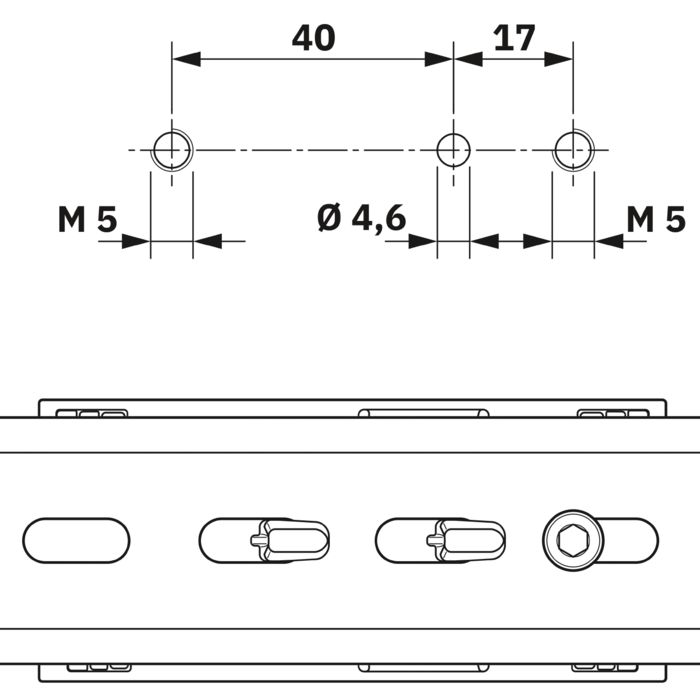

To mount the adapters on the mounting panel of the control cabinet, the through-holes for the securing pins and the threaded holes for the M5 mounting screws must first be drilled. It is important to ensure that the specified distances are strictly observed. To finally secure the fully assembled DIN rail, an additional threaded hole must be drilled for the last adapter.

For correct mounting, an application note is stored in the download area of the adapter.