Push-in connection Push-in connection technology enables the direct and tool-free contacting of conductors from 0.25 mm². The special contact spring enables low insertion forces, high conductor pull-out forces, and impresses with its high contact quality.

Your advantages

- Time-saving conductor connection with tool-free direct-connection technology

- Convenient plugging with lower insertion force

- High conductor pull-out forces due to the spring design

- Vibration-resistant and maintenance-free conductor connection with safe wiring and operation by means of an actuating push button in a contrasting color

- The conductor can be easily released without special tools

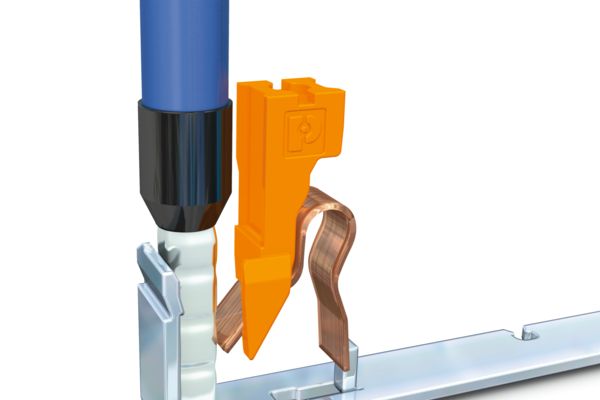

The Push-in connection in detail

Push-in connection technology was developed for direct conductor connection. Rigid conductors and conductors with ferrules can be directly contacted in the conductor connection point without using any tools. The special spring profile of the Push-in connection enables easy insertion. Low insertion force makes wiring significantly easier.

The special contact spring of Push-in connections is made of high-quality spring steel. It opens automatically when the conductor is pushed in and thus ensures the required pressure force against the current bar. The high clamping pressure and the tin layer on the spring pocket or busbar guarantee a reliable electrical connection. When tensile stress is applied, the pull-out force of the conductor is increased because the spring positions itself and locks in the housing. This ensures maximum contact and conductor pull-out forces with a vibration-resistant and gas-tight connection.

The spring is opened by a push button to either release conductors or connect flexible conductors without ferrules - easily and without direct contact with live parts.

The use of pre-treated conductors, e.g. with a ferrule or other splice protection measures, only makes sense if the operating equipment regulations require it or if the conductor must be disconnected and reconnected repeatedly. Untreated conductor ends tend to unbraid over time.

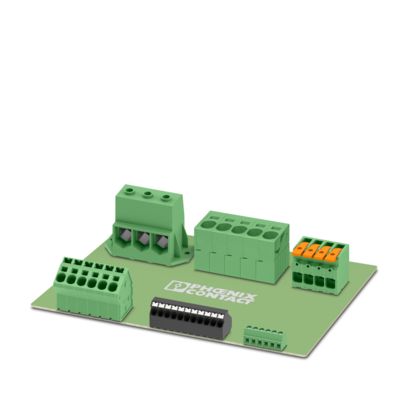

Our portfolio with Push-in connection

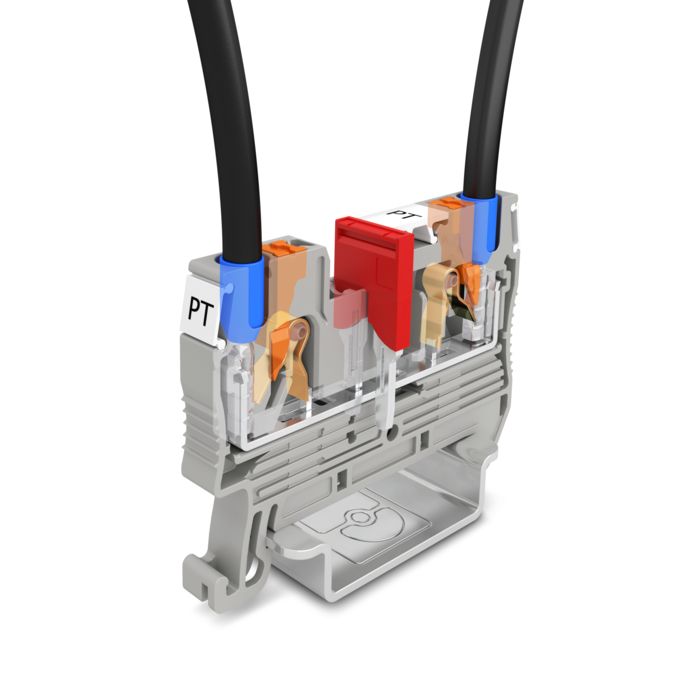

PT 2,5 terminal block

Terminal blocks

With Push-in connection technology, you can easily connect conductors between 0.25 and 25 mm², directly and without tools. The special contact spring enables easy insertion and guarantees a high level of contact quality. During the wiring of small and flexible conductors from 0.14 mm², the pusher must first be actuated before the conductor is inserted into the clamping chamber. Simply press the push button to remove the conductor. While pushed down, the conductor can be easily pulled out of the terminal block.

With Push-in technology, we recommend the use of ferrules, especially for small and flexible conductors.

FKC plugs with Push-in connection

PCB terminal blocks and PCB connectors

With the Push-in connection, you can use push buttons without any disadvantages in construction volume. This is therefore more common, and supports the spring opening if the buckling resistance of the conductor is not adequate. The orange color also has a high recognition value. The Push-in connection is also suitable for compact terminal blocks.

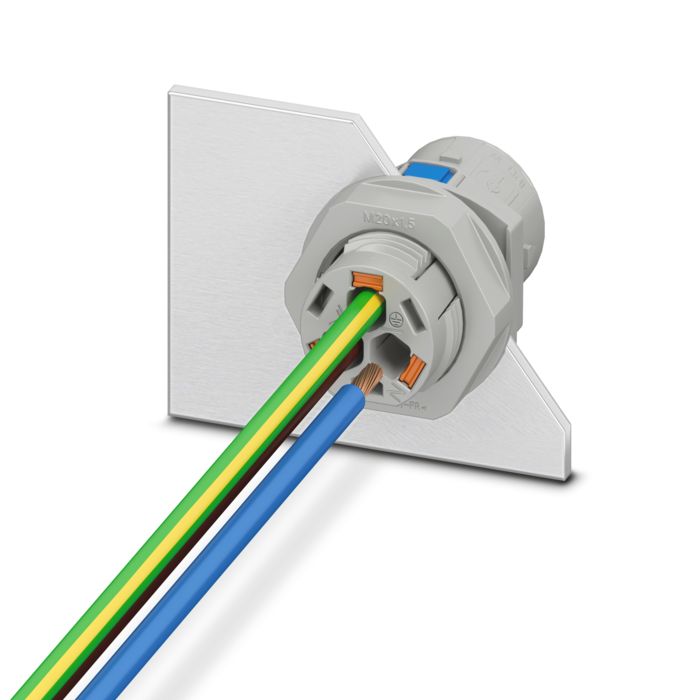

IPD installation system

Experience simple power distribution with the IPD installation system for buildings and infrastructure equipment. The IPD (Installation Power Distribution) system is fully pluggable and ideally suited for your lighting applications.

Push-in technology allows you to connect 3- and 5-position cables up to 2.5 mm² conveniently and without tools, even in difficult-to-access areas. The push button can be used to release already-installed conductors or to connect conductors without ferrules.

Heavy-duty connectors

Fixed-position and modular Push-in contact inserts for heavy-duty connectors enable you to connect conductors easily and without tools. The extensive product range features the right contact insert with Push-in technology for every application. Flexible conductors with ferrules or rigid conductors from 0.25 to 6 mm² can be directly and easily inserted into the connection.

By opening the spring with the help of the push button, you can also connect smaller cross-sections from 0.14 mm² without any problems or disconnect previously connected conductors. The particularly compact terminal chambers of the Push-in contact inserts enable a high packing density, which was previously only possible to realize with traditional crimp connections. With the high-position variants, you can conveniently connect up to 72 signal contacts in one B24 connector. Even the wiring of contact inserts already mounted in the control cabinet is easily realized with Push-in Technology.

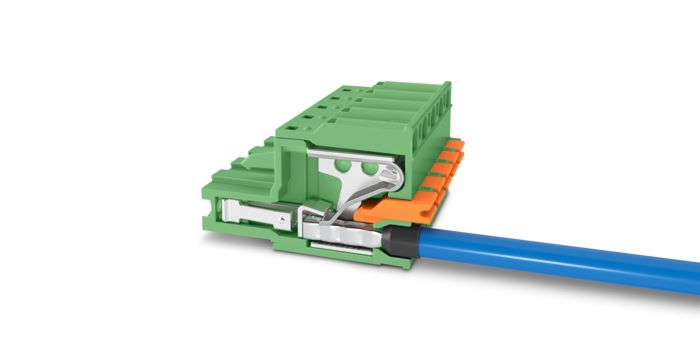

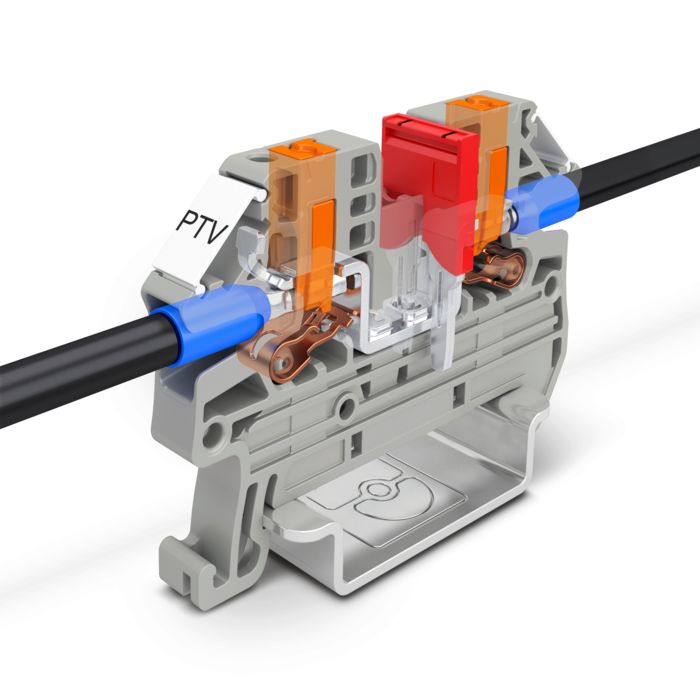

Our portfolio with lateral Push-in connection

PTV 2,5

Terminal blocks

The lateral Push-in technology of the terminal blocks is a modification of the Push-in technology described above. The technologies operate in the same way, but the frontal conductor guide has been changed to a vertical conductor guide. This makes the terminal blocks suitable for flat control cabinets or for easy replacement of existing wiring with lateral conductor routing.

With Push-in technology, we recommend the use of ferrules, especially for small and flexible conductors.

Our portfolio with Push-in connection without pusher

PCB terminal blocks and PCB connectors

The spring is opened for releasing or connecting flexible conductors by screwdriver directly in the actuation shaft. Depending on the application, this prevents unintentional opening without a tool. For the spring-cage connector only, this connection versions also enables convenient two-hand operation when connecting flexible conductors.