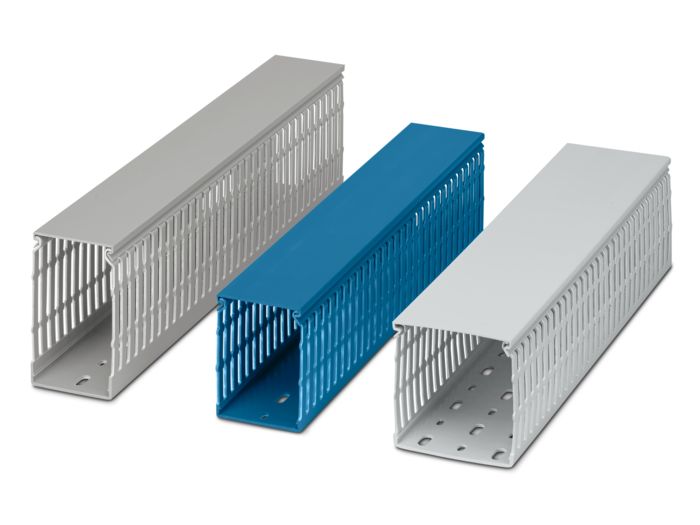

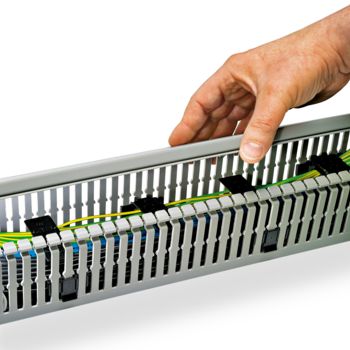

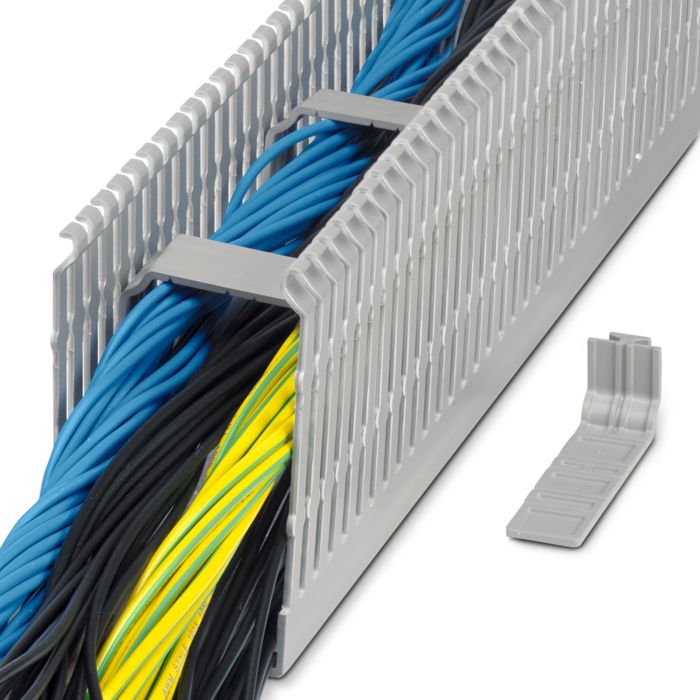

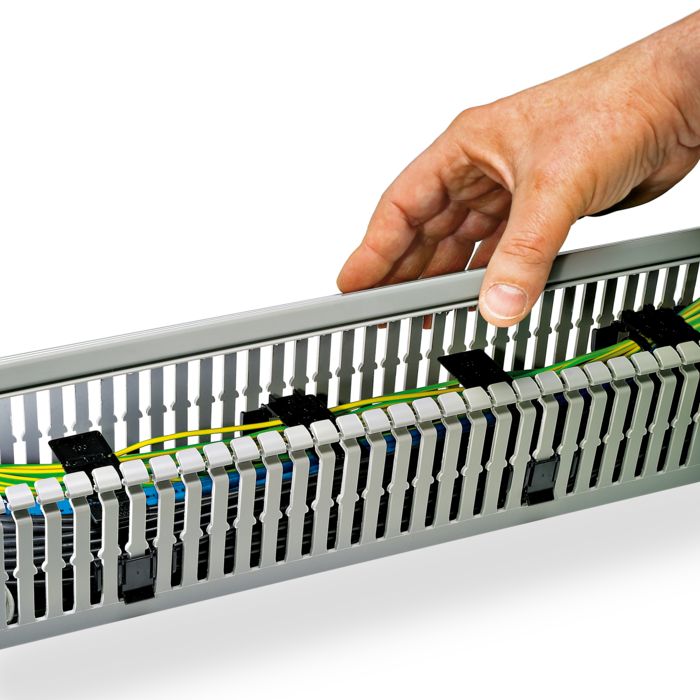

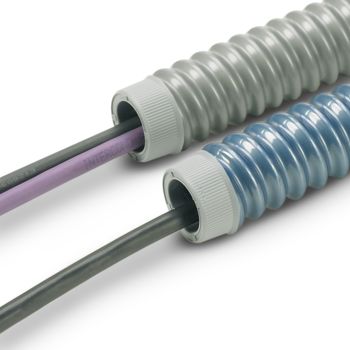

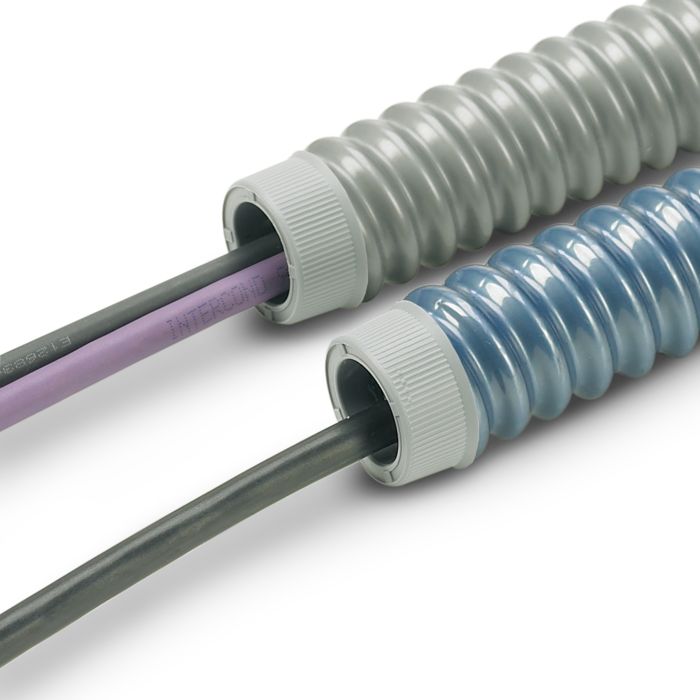

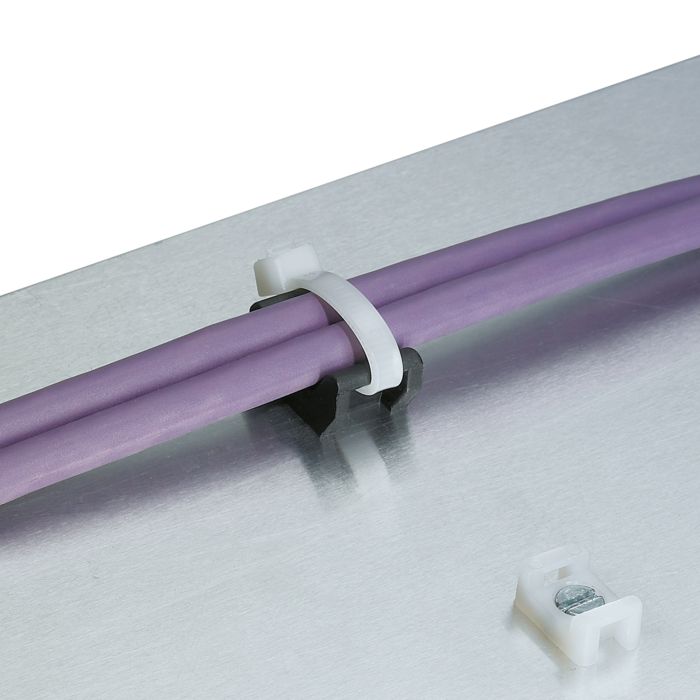

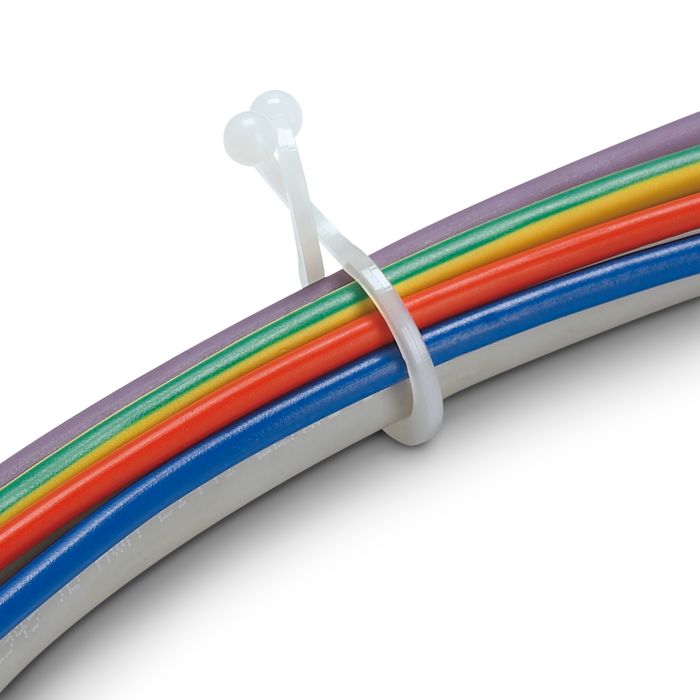

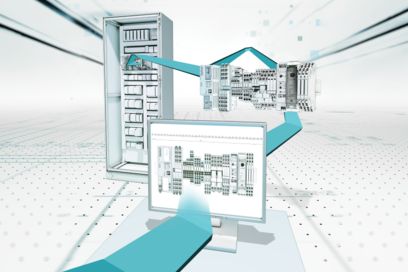

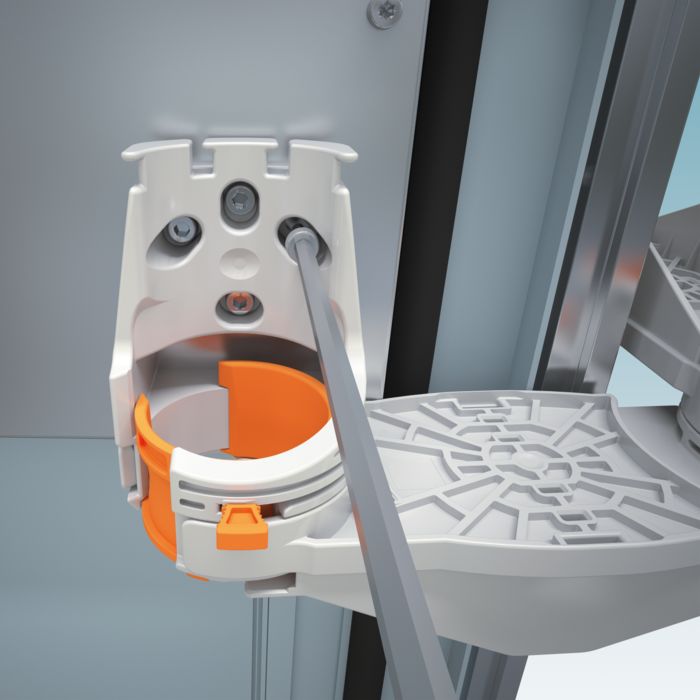

In contrast to cable conduits, the CGS cable guiding system simplifies your design work, because it can be planned and visualized in the CAD system. Cable lengths are therefore predefined and can also be planned. Quick and easy mounting is ensured by integrated flanges with strain relief.