Automation technology for Niagara Framework

Find the appropriate PLCs (controllers) and I/Os with IP20 and IP65/IP67 degrees of protection, whether as a system or as a remote I/O station for a wide range of different Ethernet networks. Program in IEC 61131-3 or high-level languages, and ensure your system is secure for the future. For example, with PLCnext Technology you can already implement the latest trends like artificial intelligence or transform sustainable solutions in the solar industry into smart solutions.

The world of automation is changing. The digitalization, networking, and globalization of business and technical systems are generating new market requirements. Manufacturers of future-oriented automation systems must be ready to provide their customers with the ability to meet the standards of modern IoT applications. Phoenix Contact therefore provides future-oriented PLCs, I/O systems, and PLC software. From components through to the complete system, for the control cabinet and field installation. Professional automation for your systems: from decentral water supply to highly complex painting lines in the automotive industry.

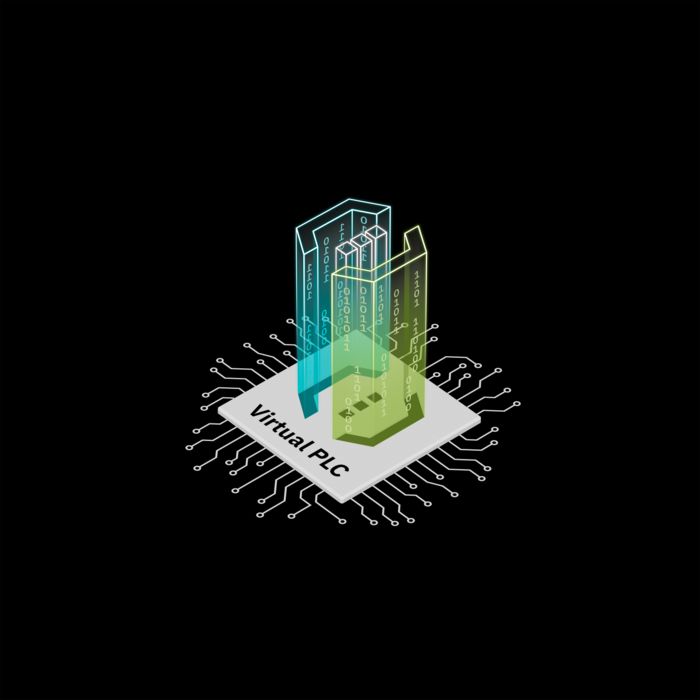

Virtual PLCnext Control offer greater scalability, flexibility, and cost efficiency in automation. As software in an OCI container, they enable seamless integration, combine OT and IT security, and increase the hardware independence of your control solution.

PLCnext Technology – enhance your automation thinking

PLCnext Technology is the ecosystem for industrial automation consisting of open hardware, modular engineering software, a global community, and a digital software marketplace. Digitalization and globalization are placing new demands on industrial automation. The precisely-tailored design of the open automation system is just as important as flexible, modular expansion.

In addition to standard PLC programming in accordance with IEC 61131-3, parallel programming and the combination of programming languages such as C/C++, C#, and MATLAB® Simulink® in real time is also possible with PLCnext Control. Accelerate your application development process with the free basic version of PLCnext Engineer. Or use your familiar programming environment – you decide!

Through simple cloud integration, the option to use open source software, and the constantly growing expertise of the PLCnext Community, you thus benefit from new forms of collaboration. The resulting solutions apps, software modules, runtime systems, and function extensions are available in the PLCnext Store and ensure enormous time and cost savings when creating applications. This makes PLCnext Technology the ideal ecosystem for your modern automation challenge.

PLCs, PLC extensions, I/O systems, and software for PLCnext Technology

Use our broad portfolio of automation technology consisting of PLCs, functional PLC extensions, I/O systems, and software to ready your system for IIoT and Industry 4.0 with PLCnext Technology. The open ecosystem enables the implementation of automation projects without the limits of proprietary systems. Integrate open-source code and apps, or network with PLCnext Control via cloud connections.

PLCnext Technology allows parallel programming based on established software tools. These include Visual Studio, Eclipse, Matlab Simulink, and PLCnext Engineer, as well as the freely selectable integration of existing program code. This enables you, for example, to freely combine functions in accordance with IEC 61131-3 with routines from C/C++, C# or MATLAB® Simulink®, and to merge these functions to create a complete system.

Phoenix Contact provides scalable PLCs with the IP20 degree of protection for this purpose. From modular controllers for small applications, through centrally managed high-performance controllers, right through to PC-based edge devices, this product family always provides a suitable solution for your project. The modular controllers give you a high degree of flexibility in the design of your stations. Choose from a wide portfolio of I/Os or extend the functionality of the controller by adding function modules on the left side. You can also integrate new technologies such as OPC UA, TSN, and 5G with the open Linux core. PLCnext Control thus offers the highest level of future-proofing.

The new Virtual PLCnext Control product portfolio offers an innovative solution for modern industrial automation. This technology enables you to abstract control tasks from physical devices and execute them on high-performance computer architectures, providing flexibility, scalability, and cost efficiency. The Virtual PLCnext Control is a software code package in the form of an OCI container, which provides a familiar environment with functions as well as operating and programming options that will also be known to you from hardware-based PLCnext Control. This solution enables seamless integration into existing systems, combines OT and IT security, and optimizes costs by consolidating multiple PLC instances. Easy maintenance and updates, as well as the ability to seamlessly move applications between different hardware platforms, make Virtual PLCnext Control a future-proof and cost-effective solution for industrial automation.

Axioline family remote I/O system for the control cabinet and field installation

Choose from an extensive range of remote I/O systems for the control cabinet, also for particularly fast data communication. Implement safety applications with our PROFIsafe modules, for example, or with no safety controller at all by using SafetyBridge Technology. Our I/O systems can be combined perfectly with all Phoenix Contact programmable logic controllers.

For decentral automation without a control cabinet, you can use I/O modules in a block design with high functionality and a particularly robust design for harsh industrial environments. You can extend the scope of functions of your application by using digital I/Os along with an IO-Link master and the corresponding IO-Link devices.

Classic PLCs in accordance with IEC 61131

Phoenix Contact provides a broad PLC range for any requirement. Choose from programmable logic controller technology with the appropriate I/Os and high-performance PLCs for demanding automation tasks for small to medium-sized systems.

The modular controllers from the Axiocontrol series are designed for maximum performance, easy handling, and use in harsh industrial environments. Their particularly robust housing and excellent EMC properties provide the basis for this.

For high-availability and decentral automation, the high-performance PLC with

IEC 61131 control intelligence, redundancy technology, and network connection is the

ideal solution. The integrated fiber optics-based redundancy function enables an

uninterrupted process in the event of a PLC failure or replacement. RFC controllers are based on PROFINET and establish system redundancy automatically thanks to AutoSync Technology.

Find the right automation technology for monitoring, controlling, and optimizing building functions. Take advantage of our comprehensive portfolio of control units, our building management system, and our analysis software in the cloud.

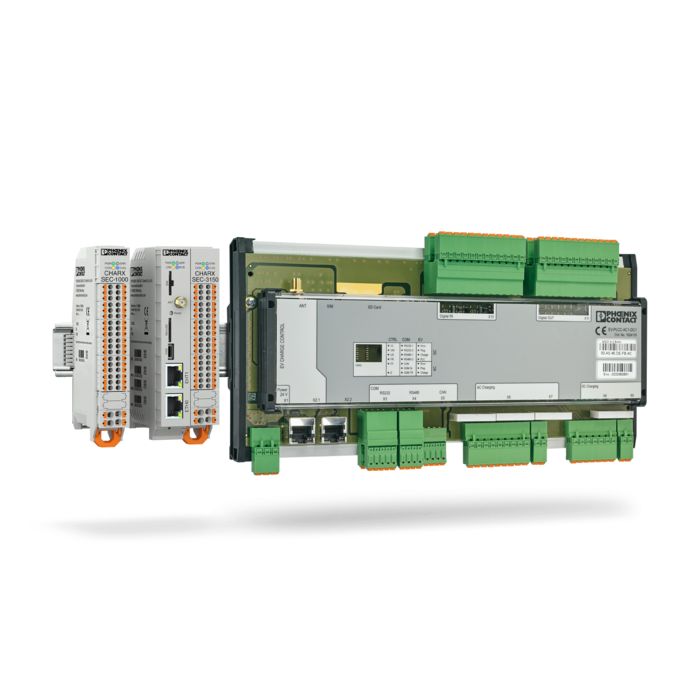

The CHARX control AC and DC charging controllers provide the intelligence for your networked charging stations. Thanks to their scalability, full connectivity, flexible configuration, and integrated load management, they are suitable for private, commercial, and public charging points – ranging from a home charging station to a parking garage.