product line COMBICON Terminals M

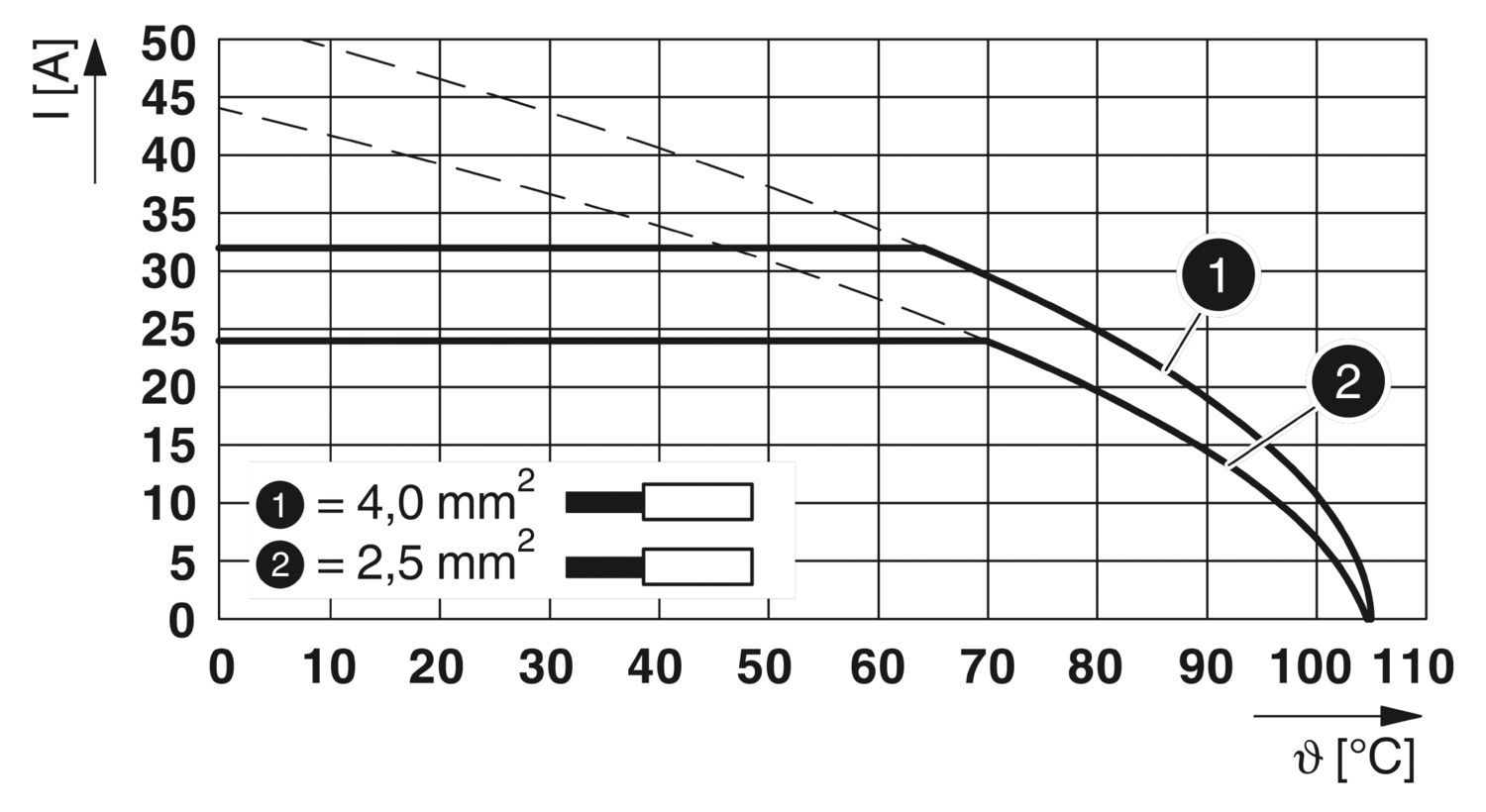

cross section 4 mm2

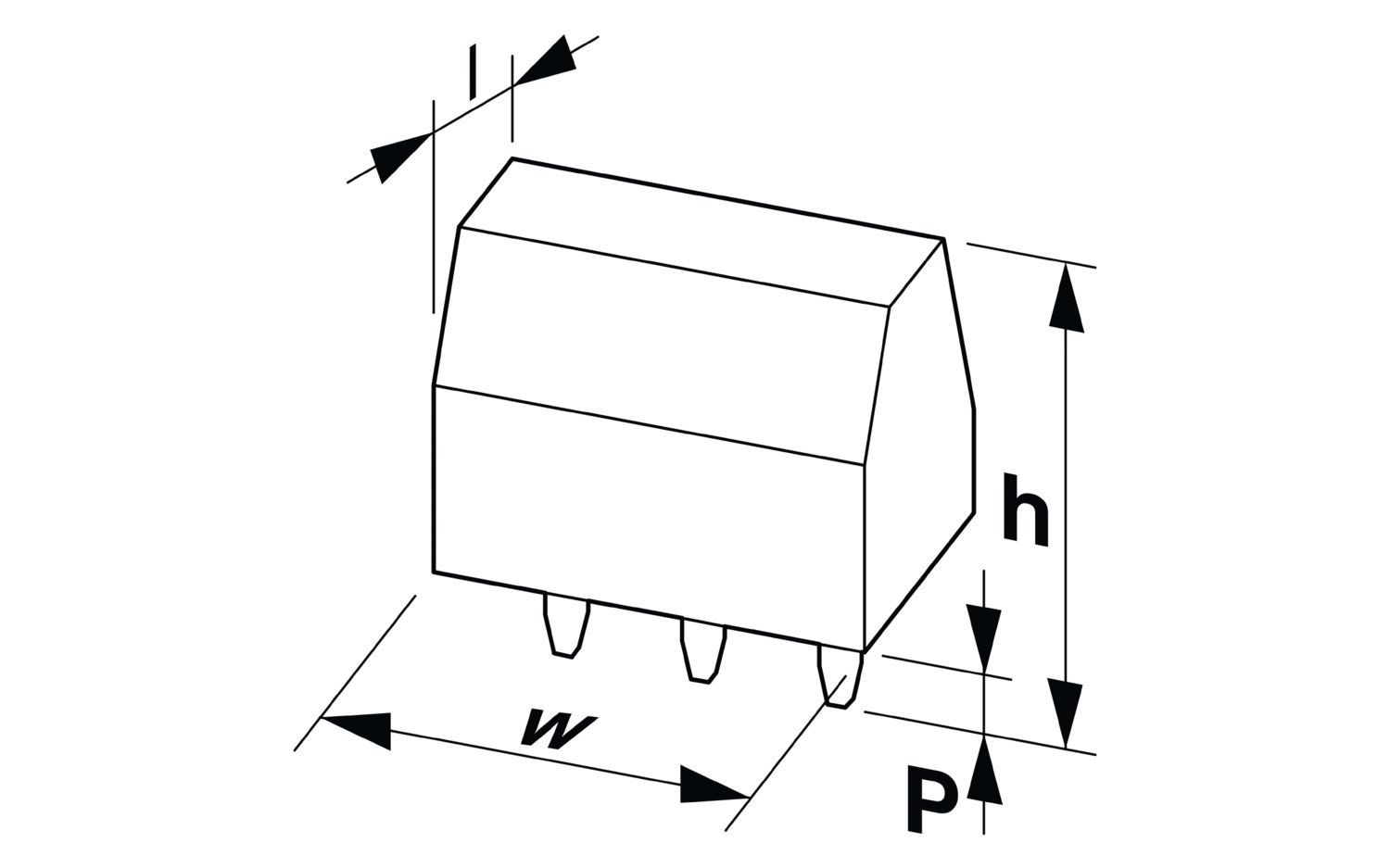

pitch 5 mm

connection method Push-in spring connection

mounting type THR soldering / wave soldering

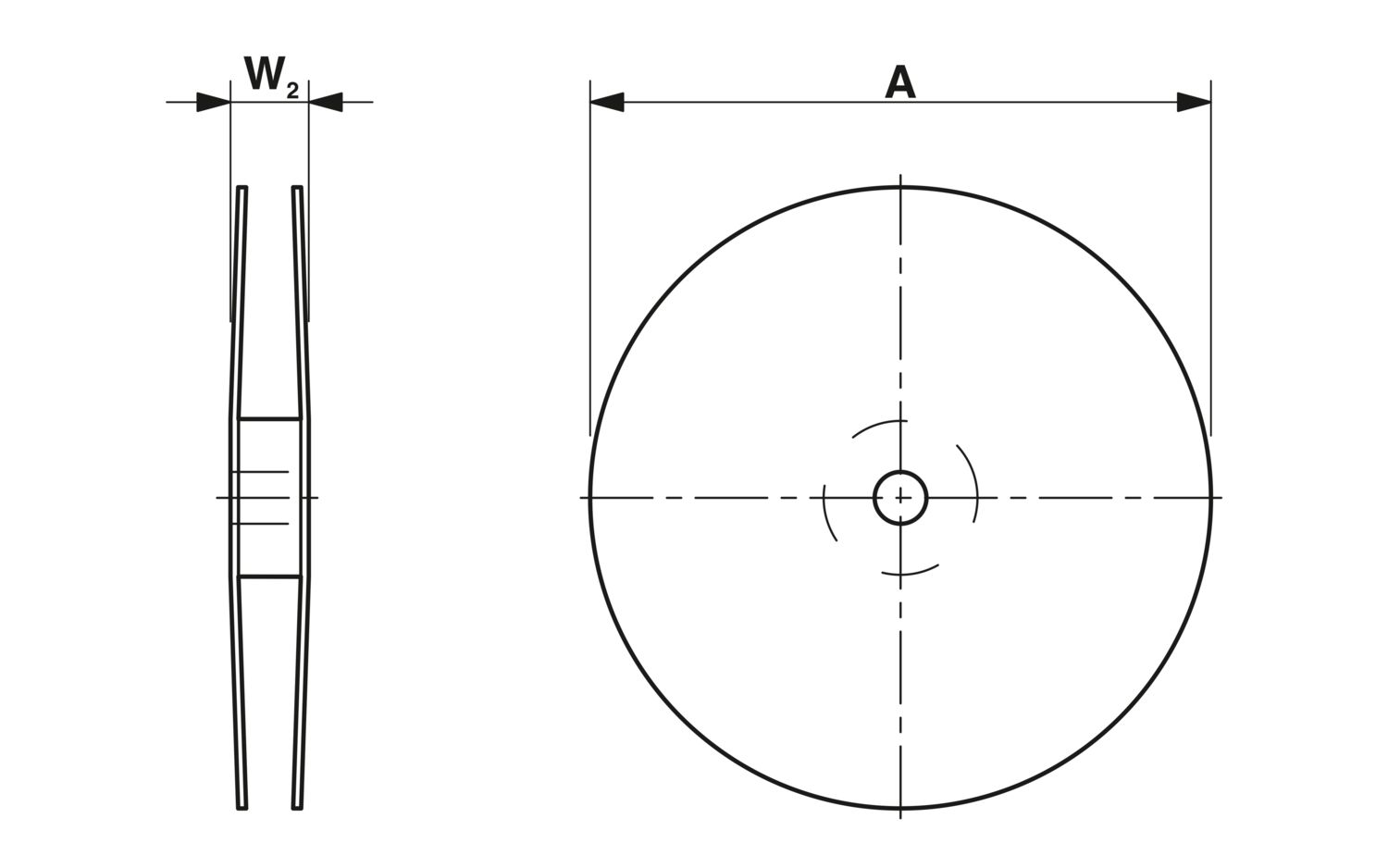

type of packaging 72 mm wide tape

Printed circuit board terminal, nominal current: 32 A, rated voltage (III/2): 400 V, nominal cross section: 4 mm2, number of potentials: 7, number of rows: 1, number of positions per row: 7, product range: SPT 2,5/..-H-THR, pitch: 5 mm, connection method: Push-in spring connection, mounting: THR soldering / wave soldering, conductor/PCB connection direction: 0 °, color: black, Pin layout: Linear pinning, Solder pin [P]: 2 mm, number of solder pins per potential: 2, type of packaging: 72 mm wide tape