More sustainability through scalability and digitalization:

Around 10% of all production costs can be accounted for by energy costs. In energy-intensive sectors, this can be as high as 40%. Using valuable resources more efficiently not only reduces your costs. It also helps in reducing climate-damaging gas emissions, and increases your company’s sustainability footprint.

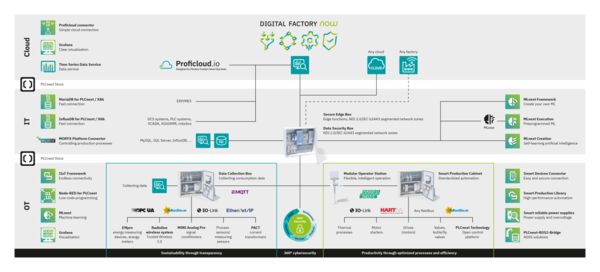

Our Digital Factory now solutions help you to gain transparency regarding all your consumption data.

- Integration and interoperability: Our control cabinet solutions can be seamlessly integrated into existing systems, which is ideal for brownfield applications where existing infrastructures need to be modernized without disrupting ongoing operations.

- Modularity and flexibility: Our modular products feature a high degree of flexibility and adapt to specific requirements, from the terminal block to complex smart services.

- Future-proof through digitalization: Our digitalization and automation solutions as a toolbox enable tailored solutions for every application.