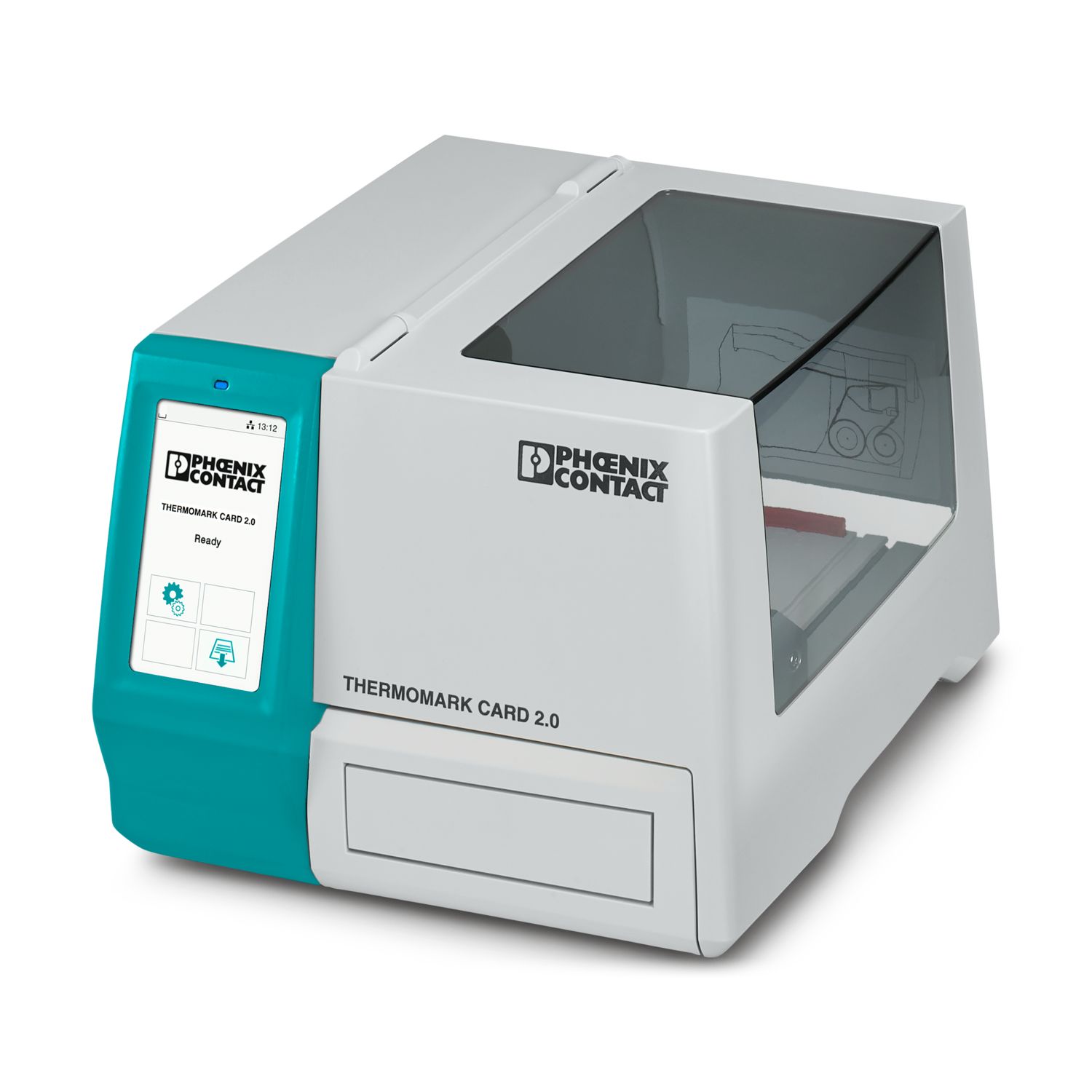

Configure your markers individually according to your needs by selecting the required properties directly. Determine the size of the markers, the shape, and the mounting type for your identification solution. The item is then tailor-made for you using an innovative laser system.