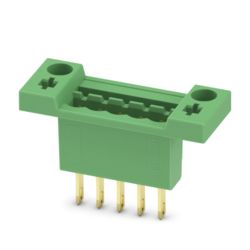

FRONT-MSTB 2,5/ 5-ST AU

-

PCB connector

1921926

PCB connector, nominal cross section: 2.5 mm2, color: green, nominal current: 12 A, rated voltage (III/2): 320 V, contact surface: Au, contact connection type: Socket, number of potentials: 5, number of rows: 1, number of positions: 5, number of connections: 5, product range: FRONT-MSTB 2,5/..-ST, pitch: 5 mm, connection method: Front screw connection, screw head form: L Slotted, conductor/PCB connection direction: 0 °, locking clip: - Locking clip, plug-in system: COMBICON MSTB 2,5, locking: without, mounting method: no, type of packaging: packed in cardboard

Product details

| Product type | PCB connector |

| Product family | FRONT-MSTB 2,5/..-ST |

| Product line | COMBICON Connectors M |

| Number of positions | 5 |

| Pitch | 5 mm |

| Number of connections | 5 |

| Number of rows | 1 |

| Number of potentials | 5 |

| Mounting type | without |

| Properties | |

| Nominal current IN | 12 A |

| Nominal voltage UN | 320 V |

| Contact resistance | 2.9 mΩ |

| Rated voltage (III/3) | 250 V |

| Rated surge voltage (III/3) | 4 kV |

| Rated voltage (III/2) | 320 V |

| Rated surge voltage (III/2) | 4 kV |

| Rated voltage (II/2) | 630 V |

| Rated surge voltage (II/2) | 4 kV |

| Connection technology | |

| Type | Standard |

| Connector system | COMBICON MSTB 2,5 |

| Nominal cross section | 2.5 mm² |

| Contact connection type | Socket |

| Interlock | |

| Locking type | without |

| Mounting type | no |

| Conductor connection | |

| Connection method | Front screw connection |

| Conductor/PCB connection direction | 0 ° |

| Conductor cross-section rigid | 0.34 mm² ... 2.5 mm² |

| Conductor cross-section flexible | 0.2 mm² ... 2.5 mm² |

| Conductor cross-section AWG | 24 ... 12 |

| Conductor cross-section flexible, with ferrule without plastic sleeve | 0.25 mm² ... 2.5 mm² |

| Conductor cross-section, flexible, with ferrule, with plastic sleeve | 0.25 mm² ... 2.5 mm² |

| 2 conductors with same cross section, solid | 0.2 mm² ... 1.5 mm² |

| 2 conductors with same cross section, flexible | 0.2 mm² ... 1.5 mm² |

| 2 conductors with same cross section, flexible, with ferrule without plastic sleeve | 0.25 mm² ... 1 mm² |

| 2 conductors with the same cross section, flexible, with TWIN ferrule with plastic sleeve | 0.5 mm² ... 1 mm² |

| Cylindrical gauge a x b / diameter | 2.8 mm x 2.0 mm / 2.4 mm |

| Stripping length | 10 mm |

| Drive form screw head | Slotted (L) |

| Tightening torque | 0.5 Nm ... 0.6 Nm |

| Specifications for ferrules without insulating collar | |

| recommended crimping tool | 1212034 CRIMPFOX 6 |

| Specifications for ferrules with insulating collar | |

| recommended crimping tool | 1212034 CRIMPFOX 6 |

| Material data - contact | |

| Note | WEEE/RoHS-compliant, free of whiskers according to IEC 60068-2-82/JEDEC JESD 201 |

| Contact material | Cu alloy |

| Surface characteristics | Completely gold-plated |

| Metal surface terminal point (top layer) | Gold (0.8 - 1.4 µm Au) |

| Metal surface terminal point (middle layer) | Nickel (2 - 3 µm Ni) |

| Metal surface contact area (top layer) | Gold (0.8 - 1.4 µm Au) |

| Metal surface contact area (middle layer) | Nickel (2 - 3 µm Ni) |

| Material data - housing | |

| Color (Housing) | green (6021) |

| Insulating material | PA |

| Insulating material group | I |

| CTI according to IEC 60112 | 600 |

| Flammability rating according to UL 94 | V0 |

| Glow wire flammability index GWFI according to EN 60695-2-12 | 850 |

| Glow wire ignition temperature GWIT according to EN 60695-2-13 | 775 |

| Temperature for the ball pressure test according to EN 60695-10-2 | 125 °C |

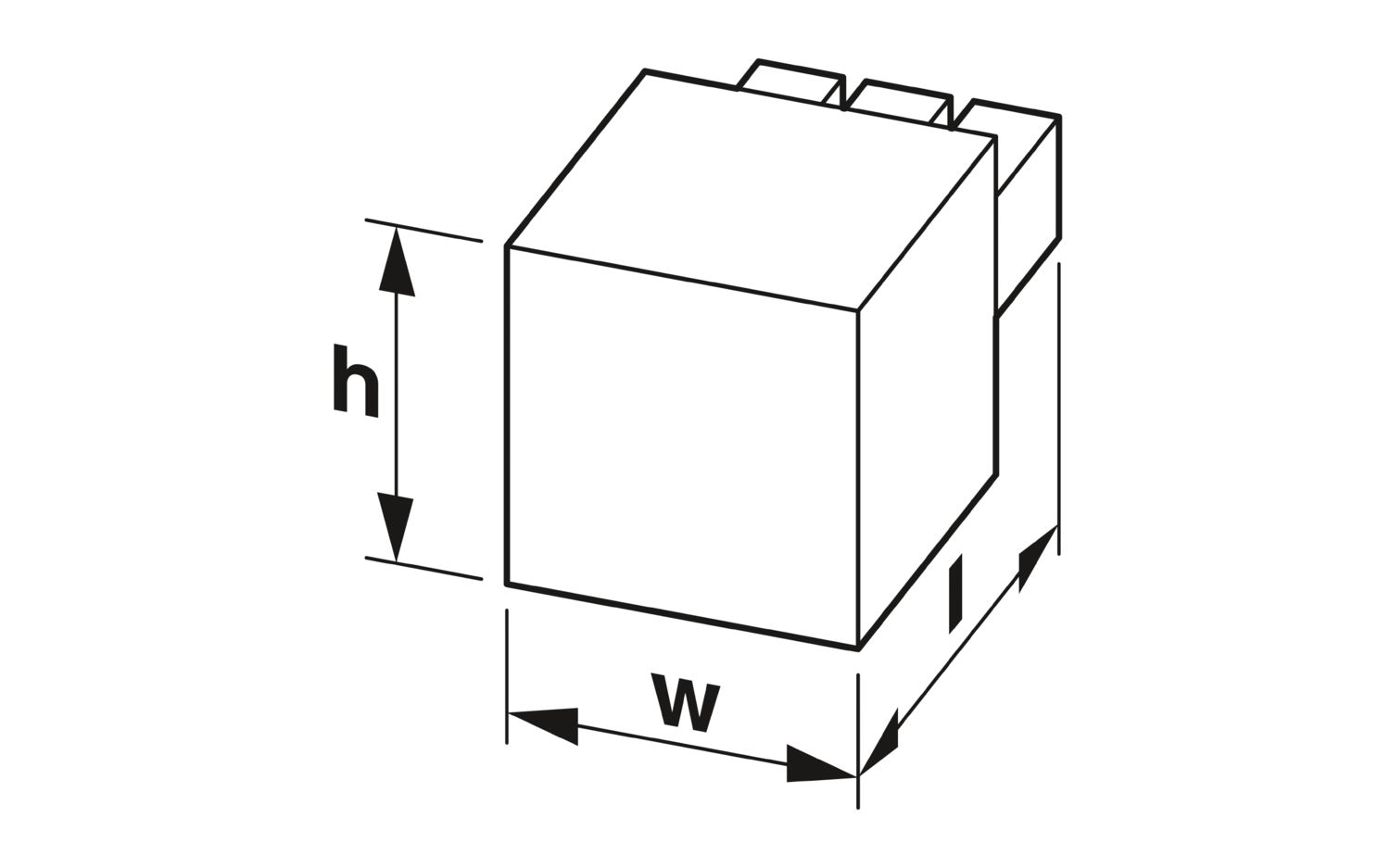

| Dimensional drawing |

|

| Pitch | 5 mm |

| Width [w] | 25 mm |

| Height [h] | 15 mm |

| Length [l] | 27.2 mm |

| Notes on operation | In accordance with IEC 61984, COMBICON connectors have no switching power (COC). During designated use, they must not be plugged in or disconnected when carrying voltage or under load. |

| Test for conductor damage and slackening | |

| Specification | IEC 60999-1:1999-11 |

| Result | Test passed |

| Pull-out test | |

| Specification | IEC 60999-1:1999-11 |

| Conductor cross-section/conductor type/tractive force setpoint/actual value | 0.34 mm² / solid / > 15 N |

| 0.2 mm² / flexible / > 10 N | |

| 2.5 mm² / solid / > 50 N | |

| 2.5 mm² / flexible / > 50 N | |

| Insertion and withdrawal forces | |

| Specification | IEC 60512-13-2:2006-02 |

| Result | Test passed |

| No. of cycles | 100 |

| Insertion strength per pos. approx. | 5 N |

| Withdraw strength per pos. approx. | 4 N |

| Torque test | |

| Specification | IEC 60999-1:1999-11 |

| Resistance of inscriptions | |

| Specification | IEC 60068-2-70:1995-12 |

| Result | Test passed |

| Polarization and coding | |

| Specification | IEC 60512-13-5:2006-02 |

| Result | Test passed |

| Visual inspection | |

| Specification | IEC 60512-1-1:2002-02 |

| Result | Test passed |

| Dimension check | |

| Specification | IEC 60512-1-2:2002-02 |

| Result | Test passed |

| Vibration test | |

| Specification | IEC 60068-2-6:2007-12 |

| Frequency | 10 - 500 - 10 Hz |

| Sweep speed | 1 octave/min |

| Amplitude | 0.35 mm (10 Hz ... 60.1 Hz) |

| Acceleration | 5g (60.1 Hz ... 500 Hz) |

| Test duration per axis | 2 h |

| Test directions | X-, Y- and Z-axis |

| Durability test | |

| Specification | IEC 60512-9-1:2010-03 |

| Impulse withstand voltage at sea level | 4.8 kV |

| Contact resistance R1 | 2.9 mΩ |

| Contact resistance R2 | 2.9 mΩ |

| Insertion/withdrawal cycles | 100 |

| Insulation resistance, neighboring positions | > 5 MΩ |

| Climatic test | |

| Specification | ISO 6988:1985-02 |

| Corrosive stress | 1.0 dm3 SO2 on 300 dm3/40 °C/1 cycle |

| Thermal stress | 100 °C/168 h |

| Power-frequency withstand voltage | 2.21 kV |

| Ambient conditions | |

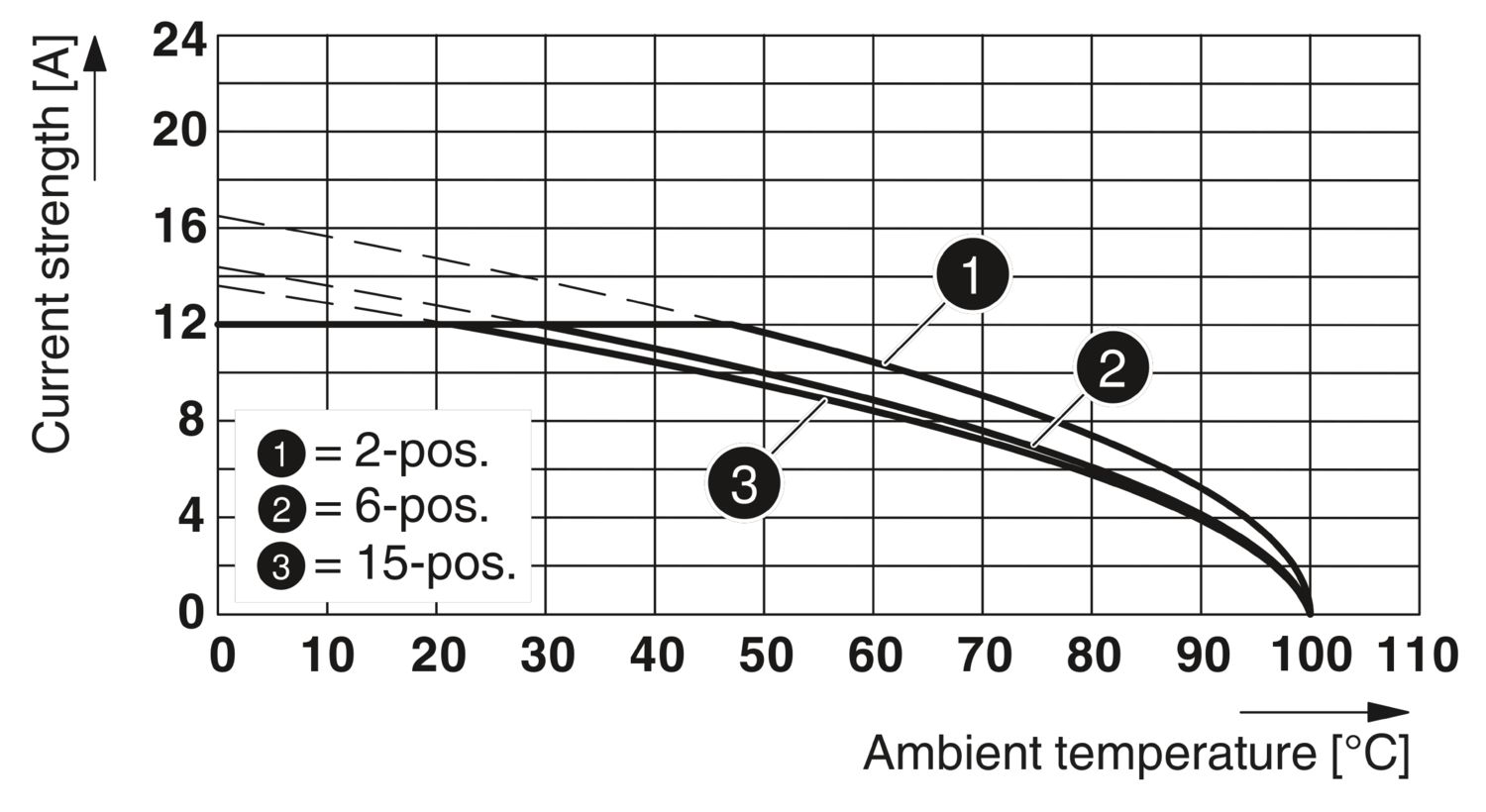

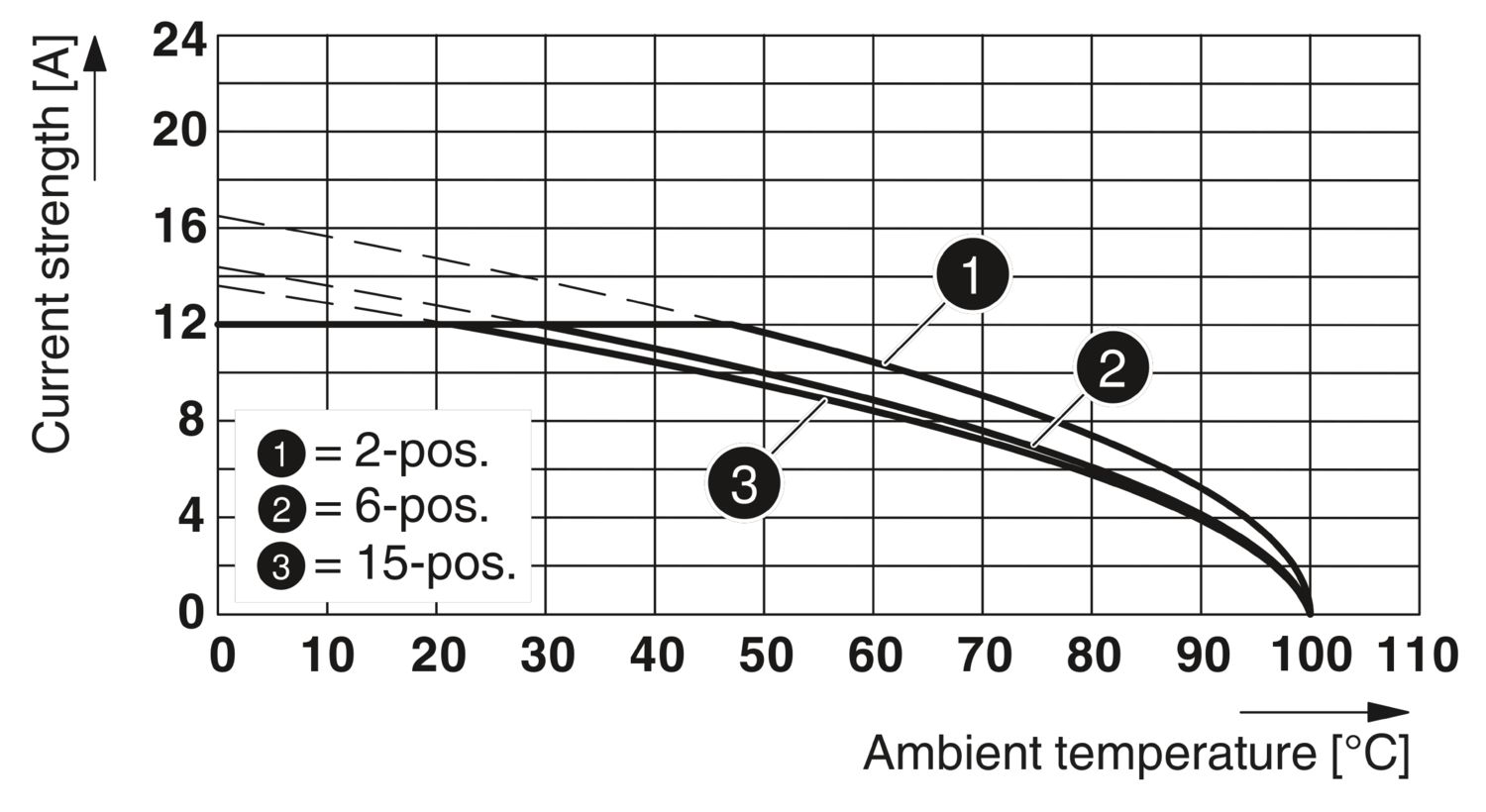

| Ambient temperature (operation) | -40 °C ... 100 °C (dependent on the derating curve) |

| Ambient temperature (storage/transport) | -40 °C ... 70 °C |

| Relative humidity (storage/transport) | 30 % ... 70 % |

| Ambient temperature (assembly) | -5 °C ... 100 °C |

| Thermal test | Test group C | |

| Specification | IEC 60512-5-1:2002-02 |

| Tested number of positions | 15 |

| Insulation resistance | |

| Specification | IEC 60512-3-1:2002-02 |

| Insulation resistance, neighboring positions | > 5 MΩ |

| Air clearances and creepage distances | | |

| Specification | IEC 60664-1:2007-04 |

| Insulating material group | I |

| Comparative tracking index (IEC 60112) | CTI 600 |

| Rated insulation voltage (III/3) | 250 V |

| Rated surge voltage (III/3) | 4 kV |

| minimum clearance value - non-homogenous field (III/3) | 3 mm |

| minimum creepage distance (III/3) | 3.2 mm |

| Rated insulation voltage (III/2) | 320 V |

| Rated surge voltage (III/2) | 4 kV |

| minimum clearance value - non-homogenous field (III/2) | 3 mm |

| minimum creepage distance (III/2) | 3 mm |

| Rated insulation voltage (II/2) | 630 V |

| Rated surge voltage (II/2) | 4 kV |

| minimum clearance value - non-homogenous field (II/2) | 3 mm |

| minimum creepage distance (II/2) | 3.2 mm |

| Type of packaging | packed in cardboard |

| Item number | 1921926 |

| Packing unit | 50 pc |

| Minimum order quantity | 50 pc |

| Note | Made to order (non-returnable) |

| Product key | AACAAA |

| GTIN | 4017918204501 |

| Weight per piece (including packing) | 15.459 g |

| Weight per piece (excluding packing) | 14.967 g |

| Country of origin | DE |

ECLASS

| ECLASS-13.0 | 27460202 |

| ECLASS-15.0 | 27460202 |

ETIM

| ETIM 9.0 | EC002638 |

UNSPSC

| UNSPSC 21.0 | 39121400 |

| EU RoHS | |

| Fulfills EU RoHS substance requirements | Yes (No exemptions) |

| China RoHS | |

| Environment friendly use period (EFUP) |

EFUP-E

No hazardous substances above the limits

|

| EU REACH SVHC | |

| REACH candidate substance (CAS No.) | No substance above 0.1 wt% |

Compatible products

Your advantages

Gold-plated contacts ensure transfer quality remains stable over the long term

Well-known connection principle allows worldwide use

Optimized for tight installation situations: operation and conductor connection from one direction

Low temperature rise, thanks to maximum contact force

Allows connection of two conductors

PHOENIX CONTACT S.A de C.V.

Lago Alberto No. 319 - Piso 9, Colonia Granada, Alcaldía Miguel Hidalgo, México, Ciudad de México, C.P. 11520