CSA

Approval ID: 13631cULus Recognized

Approval ID: E60425| Nominal voltage UN | Nominal current IN | Cross section AWG | Cross section mm2 | |

|---|---|---|---|---|

| B | ||||

| 300 V | 20 A | 24 - 8 | ||

| PE connection | 24 - 8 | |||

| D | ||||

| 300 V | 10 A | 24 - 8 | ||

| PE connection | 24 - 8 | |||

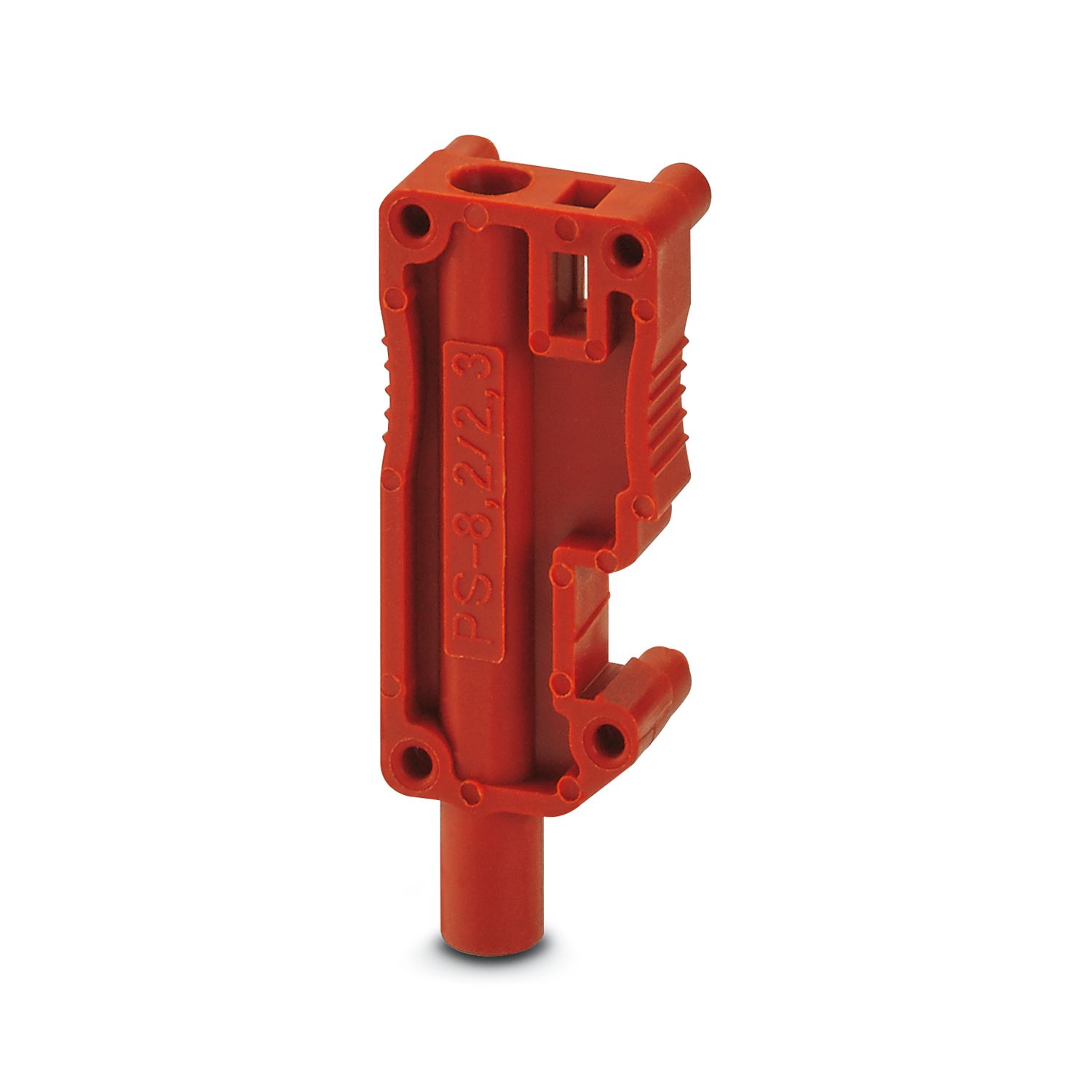

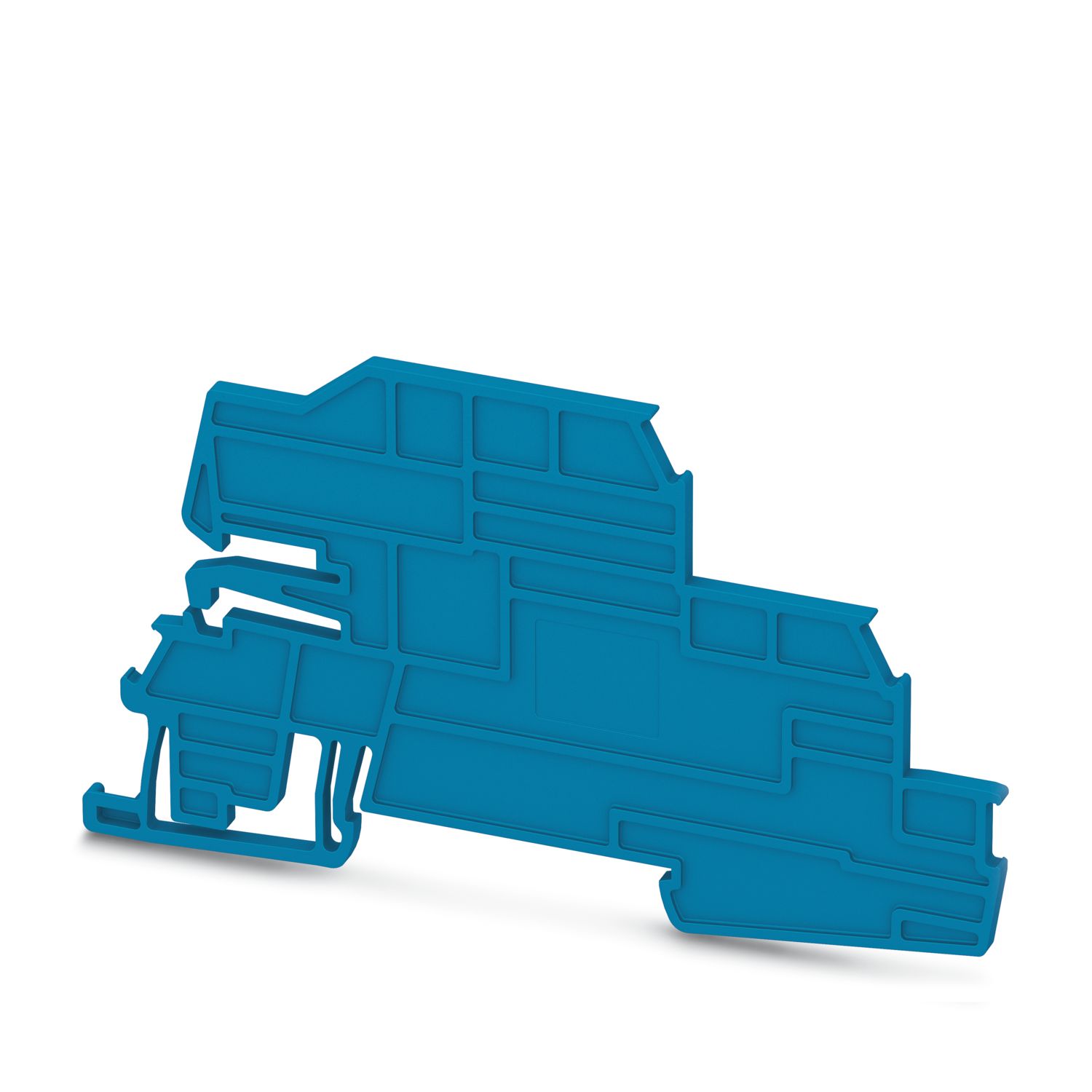

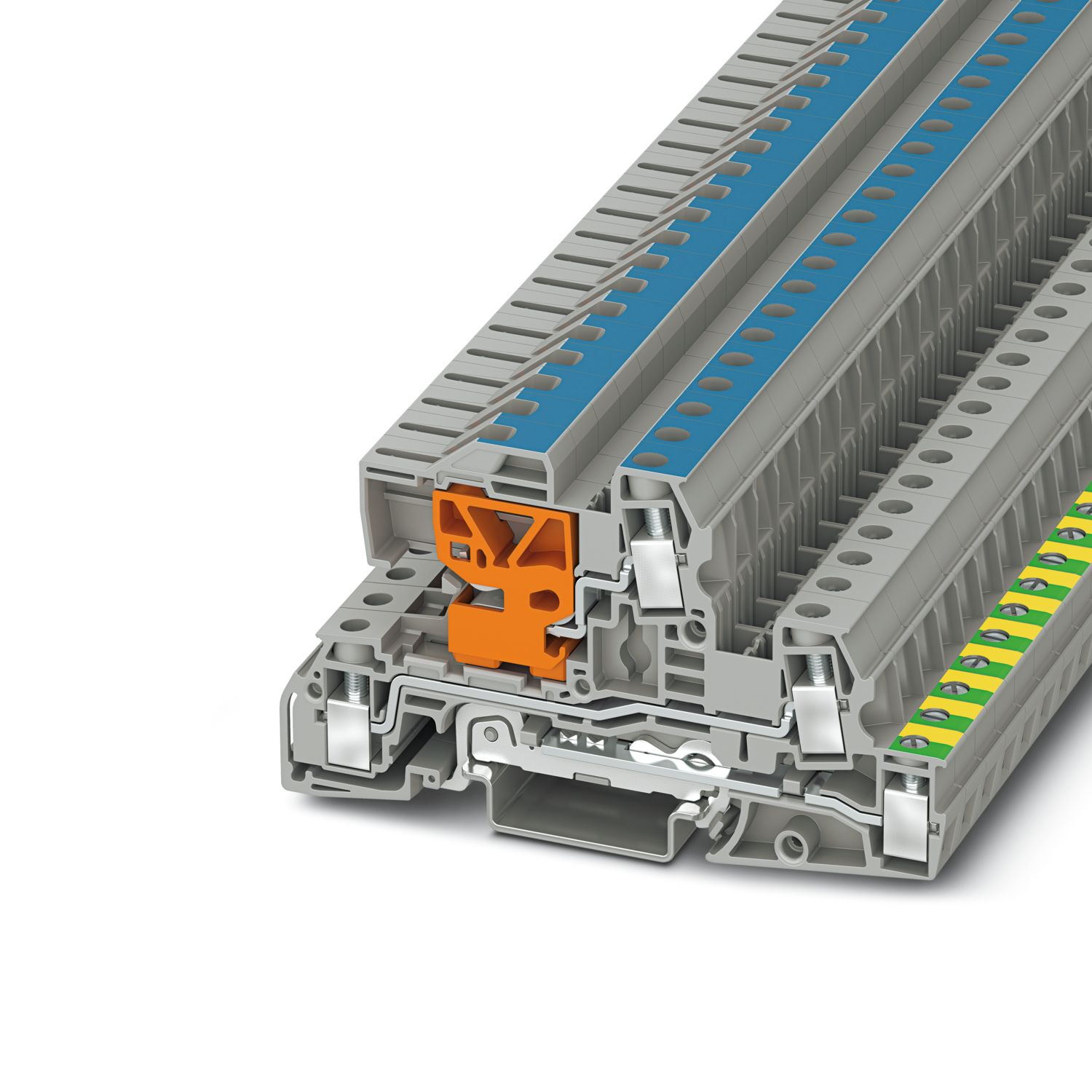

Installation protective conductor terminal block, Assembly instruction:

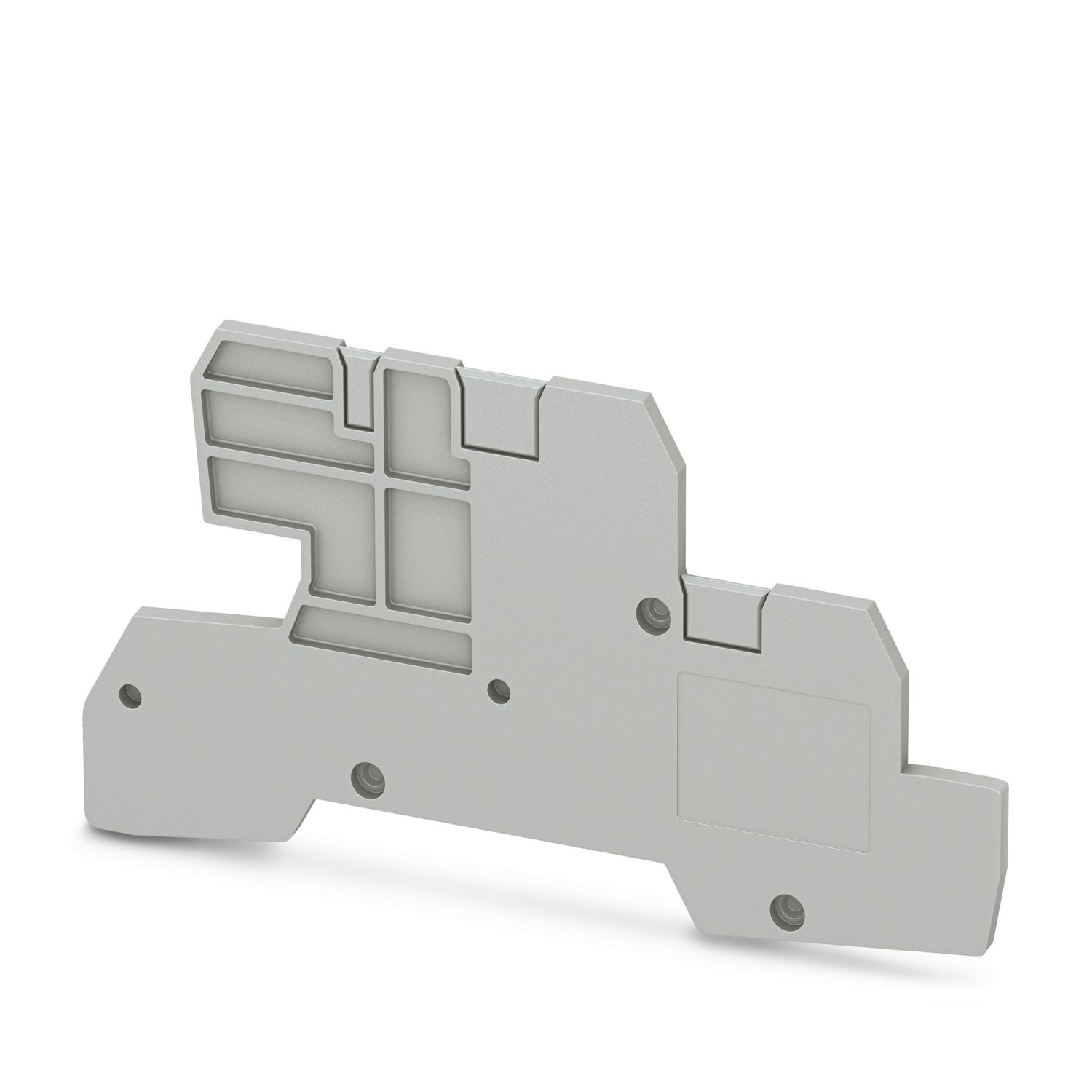

In order to securely fix the neutral busbar in place, support brackets must be placed at the beginning and end of each terminal strip as well as every 20 cm on longer terminal strips.

The corresponding support brackets can be found at phoenixcontact.com/products, nom. voltage: 400 V, nominal current: 38 A, Screw connection, 1 level, Rated cross section: 6 mm2, cross section: 0.2 mm2 - 10 mm2, mounting type: NS 35/7,5, NS 35/15, color: gray

| General | Assembly instruction: In order to securely fix the neutral busbar in place, support brackets must be placed at the beginning and end of each terminal strip as well as every 20 cm on longer terminal strips. The corresponding support brackets can be found at phoenixcontact.com/products |

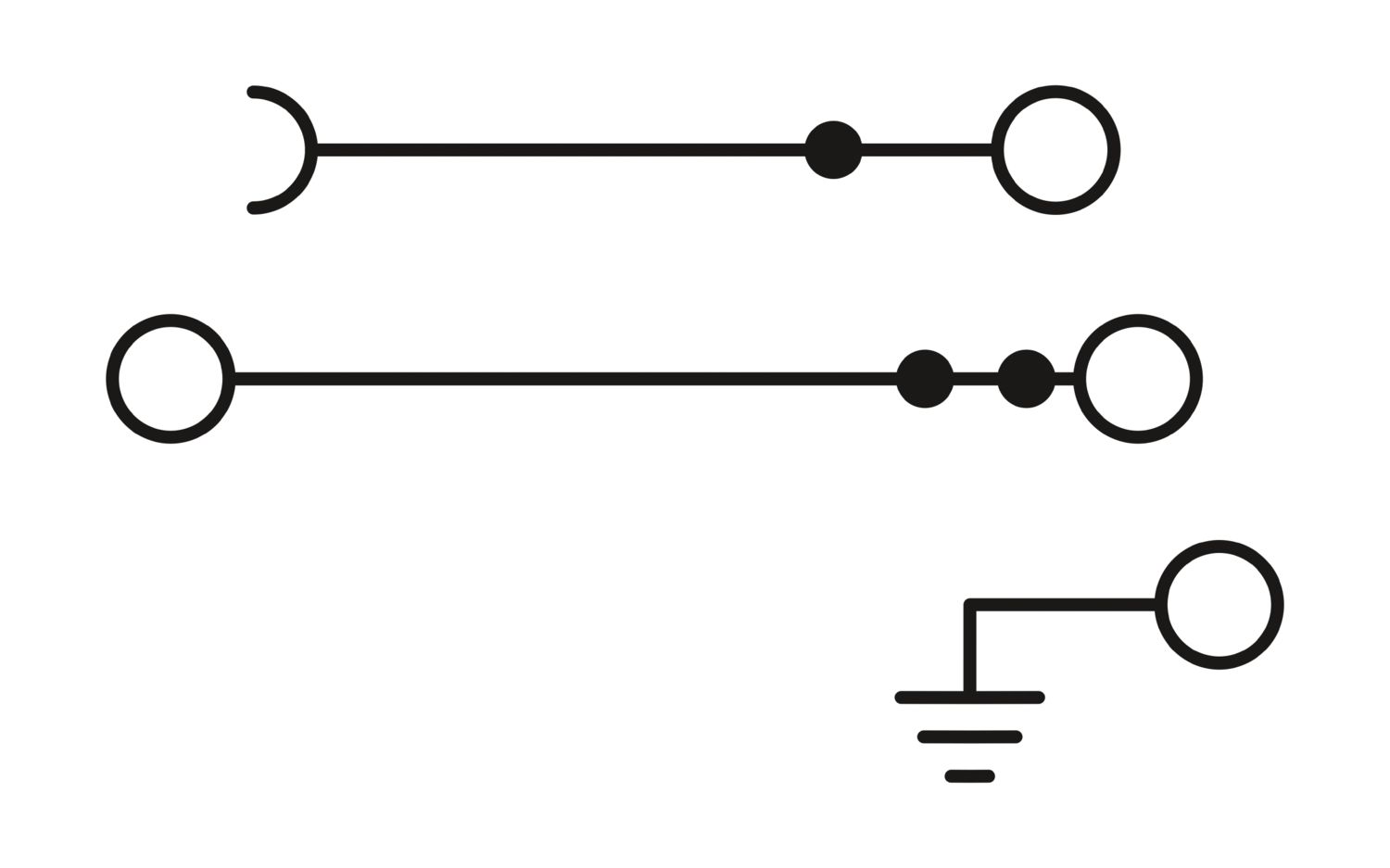

| Number of connections | 4 |

| Number of rows | 3 |

| Potentials | 2 |

| Insulation characteristics | |

| Overvoltage category | III |

| Degree of pollution | 3 |

| Rated surge voltage | 6 kV |

| Maximum power dissipation for nominal condition | 1.31 W |

| Current carrying capacity of the neutral busbar | 140 A |

| Number of connections per level | 2 |

| Nominal cross section | 6 mm² |

| 1 level | |

| Connection method | Screw connection |

| Screw thread | M3 |

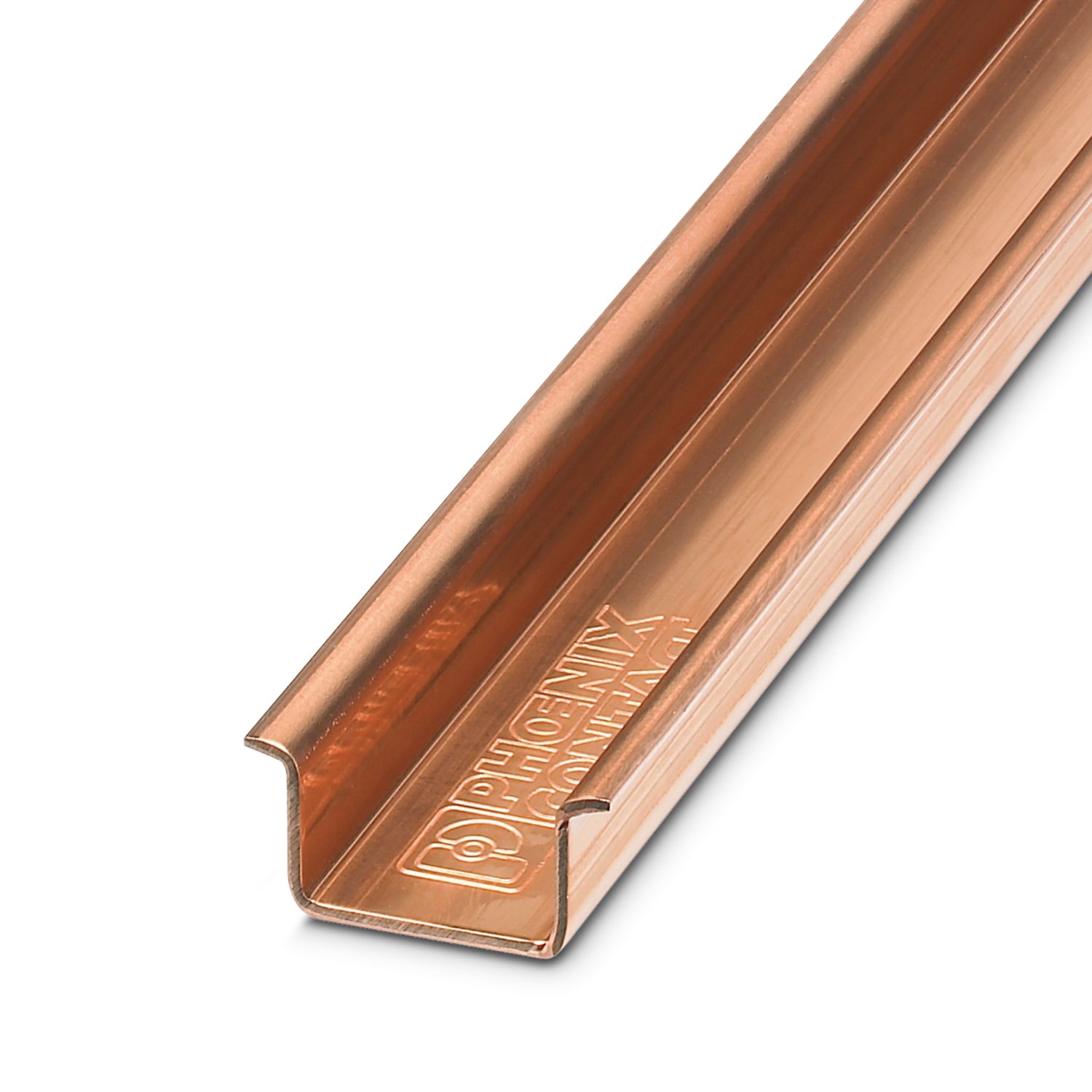

| Note | Please observe the current carrying capacity of the DIN rails. |

| Tightening torque | 0.5 ... 0.6 Nm |

| Stripping length | 9 mm |

| Internal cylindrical gage | A5 |

| Conductor cross-section rigid | 0.2 mm² ... 10 mm² |

| Cross section AWG | 24 ... 8 (converted acc. to IEC) |

| Conductor cross-section flexible | 0.2 mm² ... 10 mm² |

| Conductor cross-section, flexible [AWG] | 24 ... 8 (converted acc. to IEC) |

| Conductor cross-section flexible (ferrule without plastic sleeve) | 0.25 mm² ... 6 mm² |

| Flexible conductor cross-section (ferrule with plastic sleeve) | 0.25 mm² ... 4 mm² |

| 2 conductors with same cross section, solid | 0.2 mm² ... 2.5 mm² |

| 2 conductors with same cross section, flexible | 0.2 mm² ... 2.5 mm² |

| 2 conductors with same cross section, flexible, with ferrule without plastic sleeve | 0.25 mm² ... 1.5 mm² |

| Nominal current | 38 A (with 6 mm² conductor cross-section) |

| Maximum load current | 47 A (with 10 mm² conductor cross-section) |

| Nominal voltage | 400 V (phase conductor/phase conductor) |

| 250 V (phase conductor/PE) | |

| 250 V (phase conductor/N) | |

| Nominal cross section | 6 mm² |

| Width | 8.2 mm |

| End cover width | 2.2 mm |

| Height | 95 mm |

| Depth on NS 35/7,5 | 51.5 mm |

| Depth on NS 35/15 | 59 mm |

| Color | gray (RAL 7042) |

| Flammability rating according to UL 94 | V0 |

| Insulating material group | I |

| Insulating material | PA |

| Static insulating material application in cold | -60 °C |

| Relative insulation material temperature index (Elec., UL 746 B) | 130 °C |

| Fire protection for rail vehicles (DIN EN 45545-2) R22 | HL 1 - HL 3 |

| Fire protection for rail vehicles (DIN EN 45545-2) R23 | HL 1 - HL 3 |

| Fire protection for rail vehicles (DIN EN 45545-2) R24 | HL 1 - HL 3 |

| Fire protection for rail vehicles (DIN EN 45545-2) R26 | HL 1 - HL 3 |

| Surface flammability NFPA 130 (ASTM E 162) | passed |

| Specific optical density of smoke NFPA 130 (ASTM E 662) | passed |

| Smoke gas toxicity NFPA 130 (SMP 800C) | passed |

| Surge voltage test | |

| Test voltage setpoint | 4.8 kV |

| Result | Test passed |

| Temperature-rise test | |

| Requirement temperature-rise test | Increase in temperature ≤ 45 K |

| Result | Test passed |

| Short-time withstand current 6 mm² | 0.72 kA |

| Short-time withstand current 10 mm² | 1.2 kA |

| Result | Test passed |

| Power-frequency withstand voltage | |

| Test voltage setpoint | 1.5 kV |

| Result | Test passed |

| Mechanical data | |

| Open side panel | Yes |

| Mechanical strength | |

| Result | Test passed |

| Attachment on the carrier | |

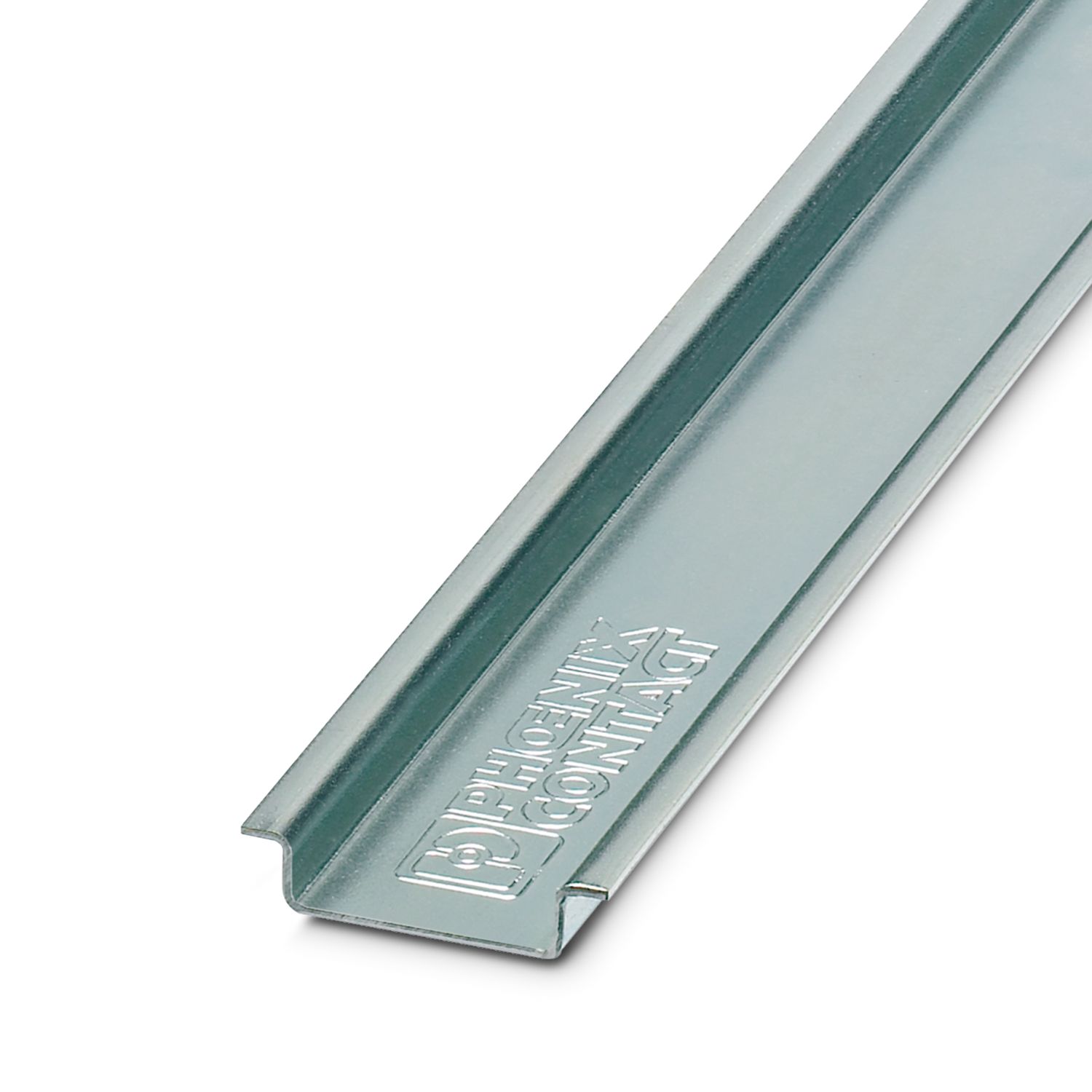

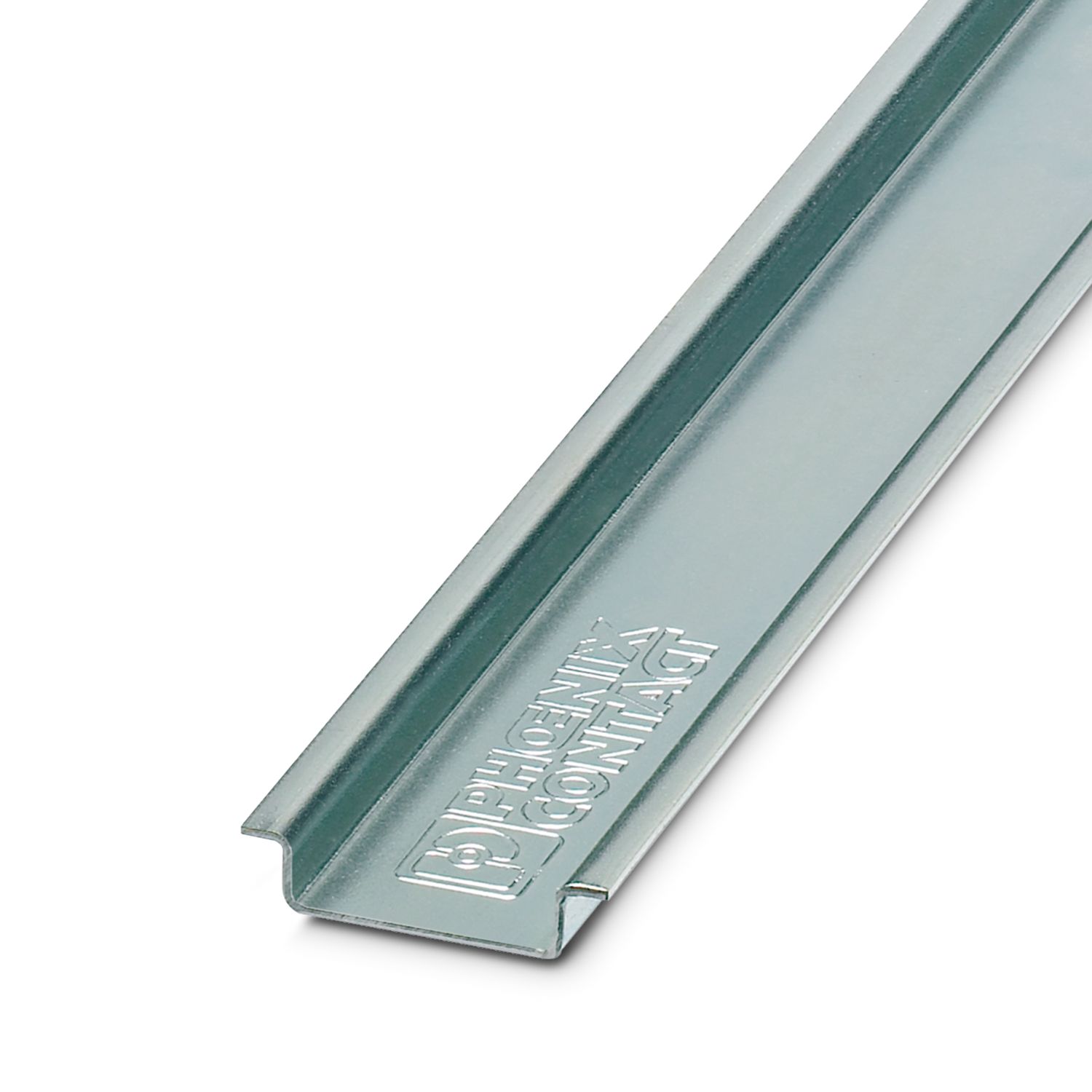

| DIN rail/fixing support | NS 35 |

| Test force setpoint | 5 N |

| Result | Test passed |

| Test for conductor damage and slackening | |

| Rotation speed | 10 rpm |

| Revolutions | 135 |

| Conductor cross-section/weight | 0.2 mm² / 0.2 kg |

| 6 mm² / 1.4 kg | |

| 10 mm² / 2 kg | |

| Result | Test passed |

| Aging | |

| Temperature cycles | 192 |

| Result | Test passed |

| Needle-flame test | |

| Time of exposure | 30 s |

| Result | Test passed |

| Oscillation/broadband noise | |

| Specification | DIN EN 50155 (VDE 0115-200):2008-03 |

| Spectrum | Long life test category 2, bogie-mounted |

| Frequency | f1 = 5 Hz to f2 = 250 Hz |

| ASD level | 6.12 (m/s²)²/Hz |

| Acceleration | 3.12g |

| Test duration per axis | 5 h |

| Test directions | X-, Y- and Z-axis |

| Result | Test passed |

| Shocks | |

| Specification | DIN EN 50155 (VDE 0115-200):2008-03 |

| Pulse shape | Half-sine |

| Acceleration | 30g |

| Shock duration | 18 ms |

| Number of shocks per direction | 3 |

| Test directions | X-, Y- and Z-axis (pos. and neg.) |

| Result | Test passed |

| Ambient conditions | |

| Ambient temperature (operation) | -60 °C ... 110 °C (Operating temperature range incl. self-heating; for max. short-term operating temperature, see RTI Elec.) |

| Ambient temperature (storage/transport) | -25 °C ... 60 °C (for a short time, not exceeding 24 h, -60 °C to +70 °C) |

| Ambient temperature (assembly) | -5 °C ... 70 °C |

| Permissible humidity (operation) | 20 % ... 90 % |

| Permissible humidity (storage/transport) | 30 % ... 70 % |

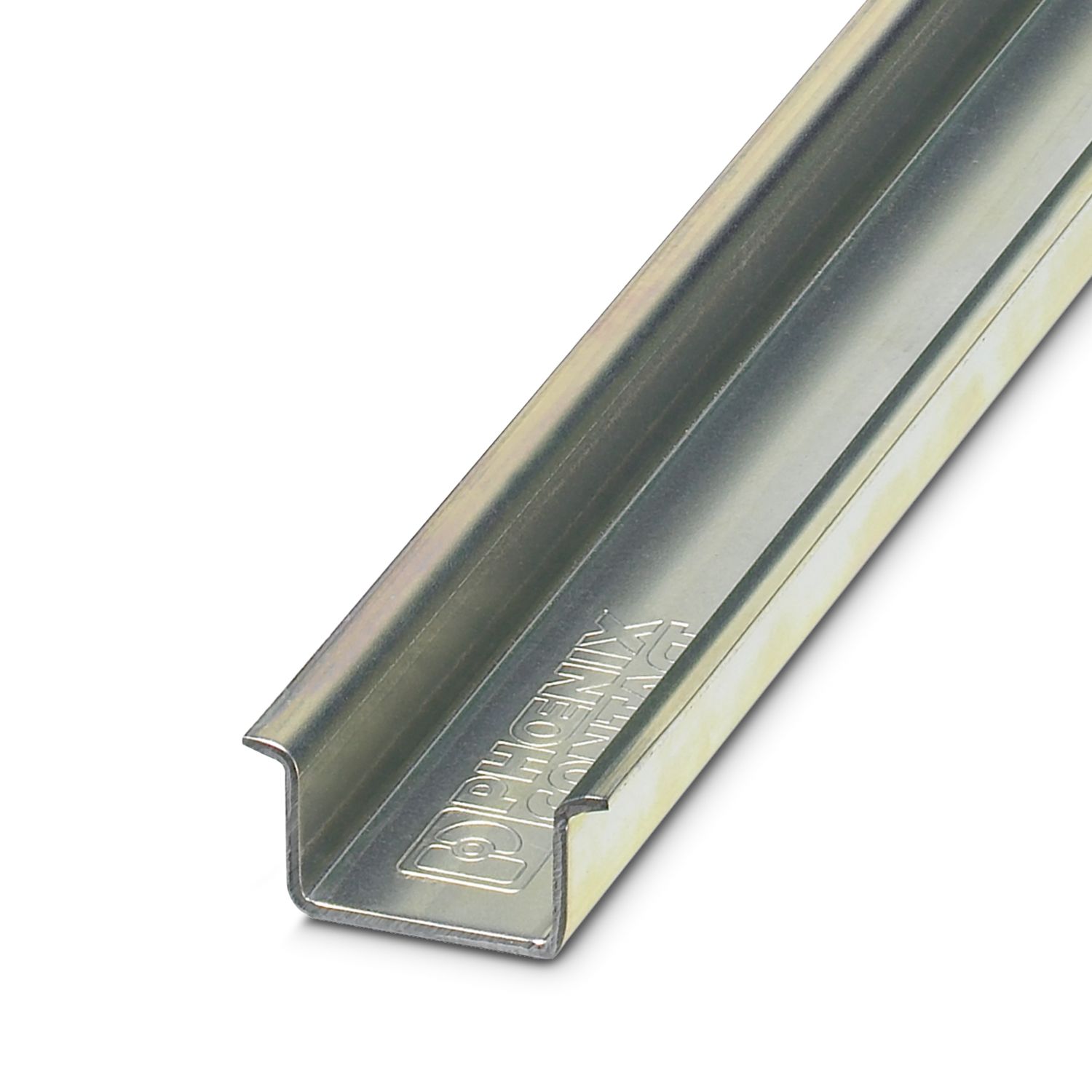

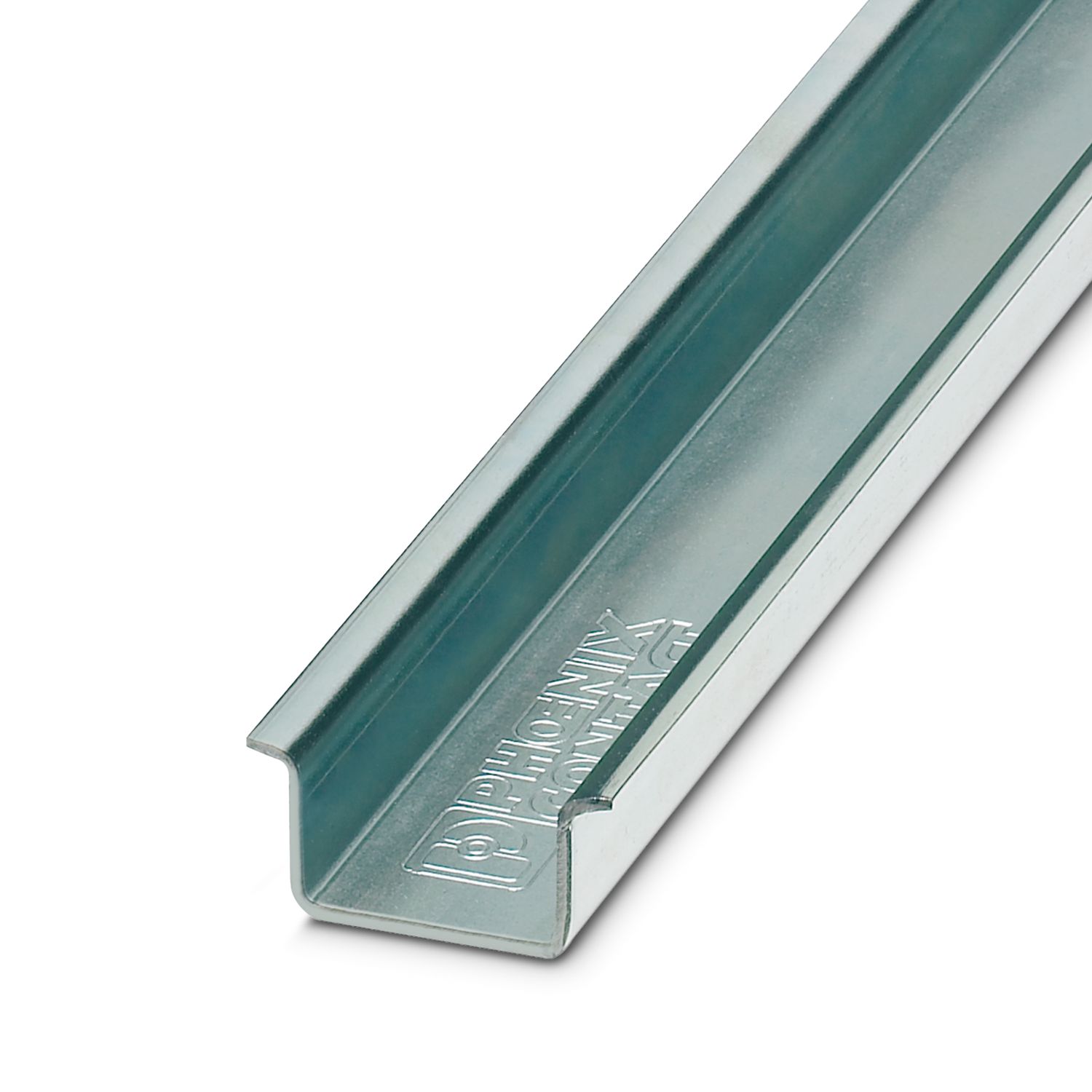

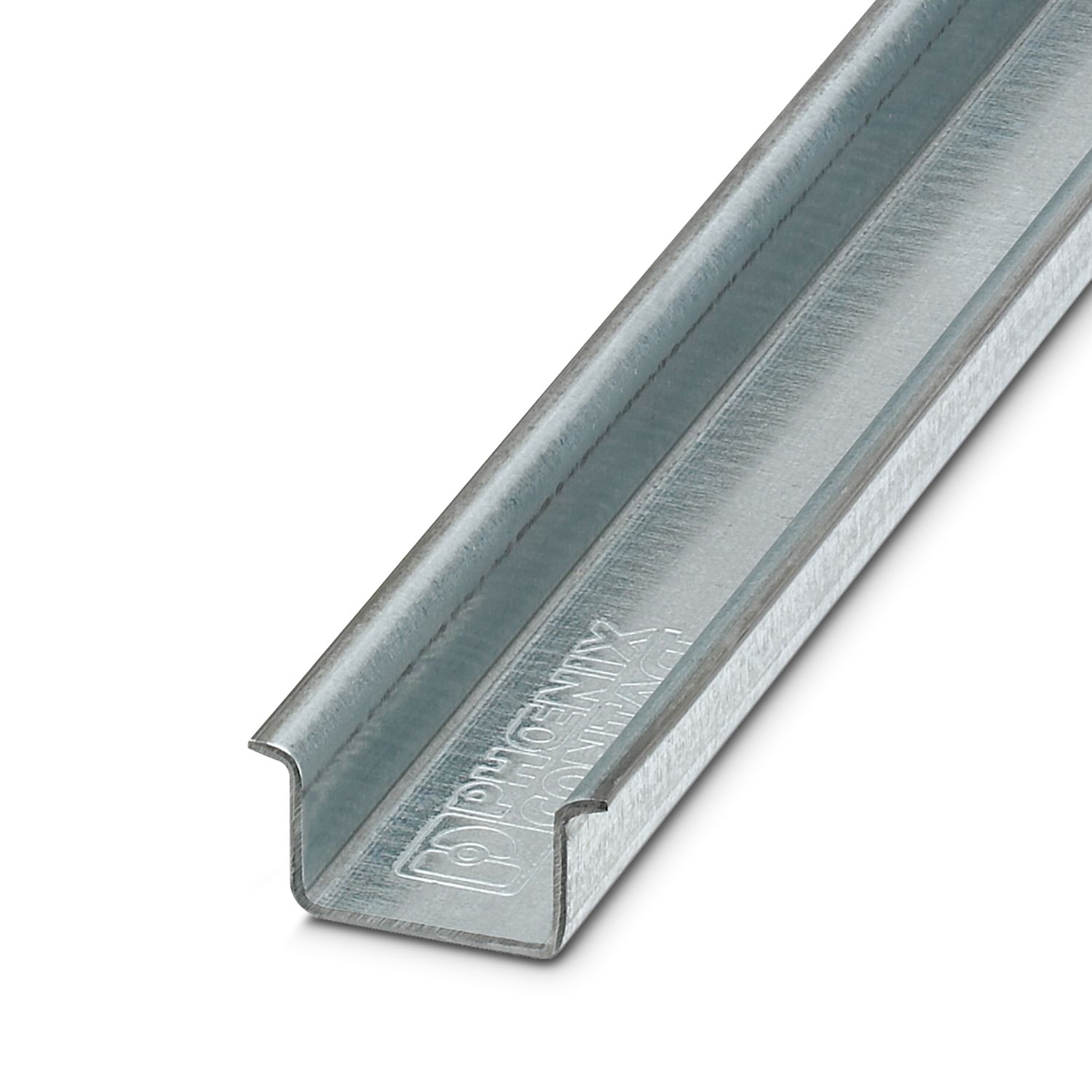

| Mounting type | NS 35/7,5 |

| NS 35/15 |

| Item number | 3076039 |

| Packing unit | 50 pc |

| Minimum order quantity | 50 pc |

| Sales key | 02 |

| Product key | BE1153 |

| GTIN | 4046356817615 |

| Weight per piece (including packing) | 36.42 g |

| Weight per piece (excluding packing) | 36.42 g |

| Country of origin | PL |

| ECLASS-13.0 | 27250110 |

| ECLASS-15.0 | 27250110 |

| ETIM 9.0 | EC001329 |

| UNSPSC 21.0 | 39121400 |

| EU RoHS | |

| Fulfills EU RoHS substance requirements | Yes (No exemptions) |

| China RoHS | |

| Environment friendly use period (EFUP) |

EFUP-E

No hazardous substances above the limits

|

| EU REACH SVHC | |

| REACH candidate substance (CAS No.) | No substance above 0.1 wt% |

| EF3.1 Climate Change | |

| CO2e kg | 0.256 kg CO2e |