TB 240 I BU

-

Feed-through terminal block

3251205

Feed-through terminal block, nom. voltage: 1000 V, nominal current: 415 A, number of connections: 2, connection method: Screw connection, Rated cross section: 240 mm2, cross section: 70 mm2 - 240 mm2, mounting type: NS 35/15, NS 32, color: blue

Product details

| Number of connections | 2 |

| Number of rows | 1 |

| Potentials | 1 |

| Insulation characteristics | |

| Overvoltage category | III |

| Degree of pollution | 3 |

| Rated surge voltage | 8 kV |

| Maximum power dissipation for nominal condition | 13.78 W |

| Number of connections per level | 2 |

| Nominal cross section | 240 mm² |

| Rated cross section AWG | 3/0 |

| Connection method | Screw connection |

| Screw thread | M10 |

| Note | Screws with hexagonal socket |

| Tightening torque | 25 ... 30 Nm |

| Stripping length | 40 mm |

| Internal cylindrical gage | B15 |

| Connection in acc. with standard | IEC 60947-7-1 |

| Conductor cross-section rigid | 70 mm² ... 240 mm² |

| Cross section AWG | 3/0 ... 250 kcmil (converted acc. to IEC) |

| Conductor cross-section flexible | 70 mm² ... 240 mm² |

| Conductor cross-section, flexible [AWG] | 3/0 ... 350 kcmil (converted acc. to IEC) |

| Conductor cross-section flexible (ferrule without plastic sleeve) | 70 mm² ... 185 mm² |

| Flexible conductor cross-section (ferrule with plastic sleeve) | 70 mm² ... 185 mm² |

| Cross-section with insertion bridge, rigid | 240 mm² |

| Cross-section with insertion bridge, flexible | 185 mm² |

| 2 conductors with same cross section, solid | 35 mm² ... 95 mm² |

| 2 conductors with same cross section, flexible | 50 mm² ... 95 mm² |

| 2 conductors with same cross section, flexible, with ferrule without plastic sleeve | 35 mm² ... 50 mm² |

| Nominal current | 415 A |

| Maximum load current | 415 A (with 240 mm² conductor cross-section) |

| Nominal voltage | 1000 V |

| Nominal cross section | 240 mm² |

| Dimensional drawing |

|

| Width | 36 mm |

| Height | 100 mm |

| Depth | 123.6 mm |

| Depth on NS 32 | 129 mm |

| Depth on NS 35/15 | 131.5 mm |

| Color | blue (RAL 5015) |

| Flammability rating according to UL 94 | V0 |

| Insulating material group | I |

| Insulating material | PA |

| Static insulating material application in cold | -60 °C |

| Relative insulation material temperature index (Elec., UL 746 B) | 130 °C |

| Fire protection for rail vehicles (DIN EN 45545-2) R22 | HL 1 - HL 3 |

| Fire protection for rail vehicles (DIN EN 45545-2) R23 | HL 1 - HL 3 |

| Fire protection for rail vehicles (DIN EN 45545-2) R24 | HL 1 - HL 3 |

| Fire protection for rail vehicles (DIN EN 45545-2) R26 | HL 1 - HL 3 |

| Surface flammability NFPA 130 (ASTM E 162) | passed |

| Specific optical density of smoke NFPA 130 (ASTM E 662) | passed |

| Smoke gas toxicity NFPA 130 (SMP 800C) | passed |

| Surge voltage test | |

| Test voltage setpoint | 9.8 kV |

| Result | Test passed |

| Temperature-rise test | |

| Requirement temperature-rise test | Increase in temperature ≤ 45 K |

| Result | Test passed |

| Short-time withstand current 240 mm² | 28.8 kA |

| Result | Test passed |

| Power-frequency withstand voltage | |

| Test voltage setpoint | 2.2 kV |

| Result | Test passed |

| Mechanical data | |

| Open side panel | No |

| Mechanical strength | |

| Result | Test passed |

| Attachment on the carrier | |

| DIN rail/fixing support | NS 32/NS 35 |

| Test force setpoint | 20 N |

| Result | Test passed |

| Test for conductor damage and slackening | |

| Rotation speed | 10 (+/- 2) rpm |

| Revolutions | 135 |

| Conductor cross-section/weight | 70 mm²/10.4 kg |

| 240 mm²/20.0 kg | |

| Result | Test passed |

| Needle-flame test | |

| Time of exposure | 30 s |

| Result | Test passed |

| Oscillation/broadband noise | |

| Specification | DIN EN 50155 (VDE 0115-200):2022-06 |

| Spectrum | Long life test category 2, bogie-mounted |

| Frequency | f1 = 5 Hz to f2 = 250 Hz |

| ASD level | 6.12 (m/s²)²/Hz |

| Acceleration | 3.12g |

| Test duration per axis | 5 h |

| Test directions | X-, Y- and Z-axis |

| Result | Test passed |

| Shocks | |

| Pulse shape | Half-sine |

| Acceleration | 5g |

| Shock duration | 30 ms |

| Number of shocks per direction | 3 |

| Test directions | X-, Y- and Z-axis (pos. and neg.) |

| Result | Test passed |

| Ambient conditions | |

| Ambient temperature (operation) | -60 °C ... 110 °C (Operating temperature range incl. self-heating; for max. short-term operating temperature, see RTI Elec.) |

| Ambient temperature (storage/transport) | -25 °C ... 60 °C (for a short time, not exceeding 24 h, -60 °C to +70 °C) |

| Ambient temperature (assembly) | -5 °C ... 70 °C |

| Ambient temperature (actuation) | -5 °C ... 70 °C |

| Permissible humidity (operation) | 20 % ... 90 % |

| Permissible humidity (storage/transport) | 30 % ... 70 % |

| Connection in acc. with standard | IEC 60947-7-1 |

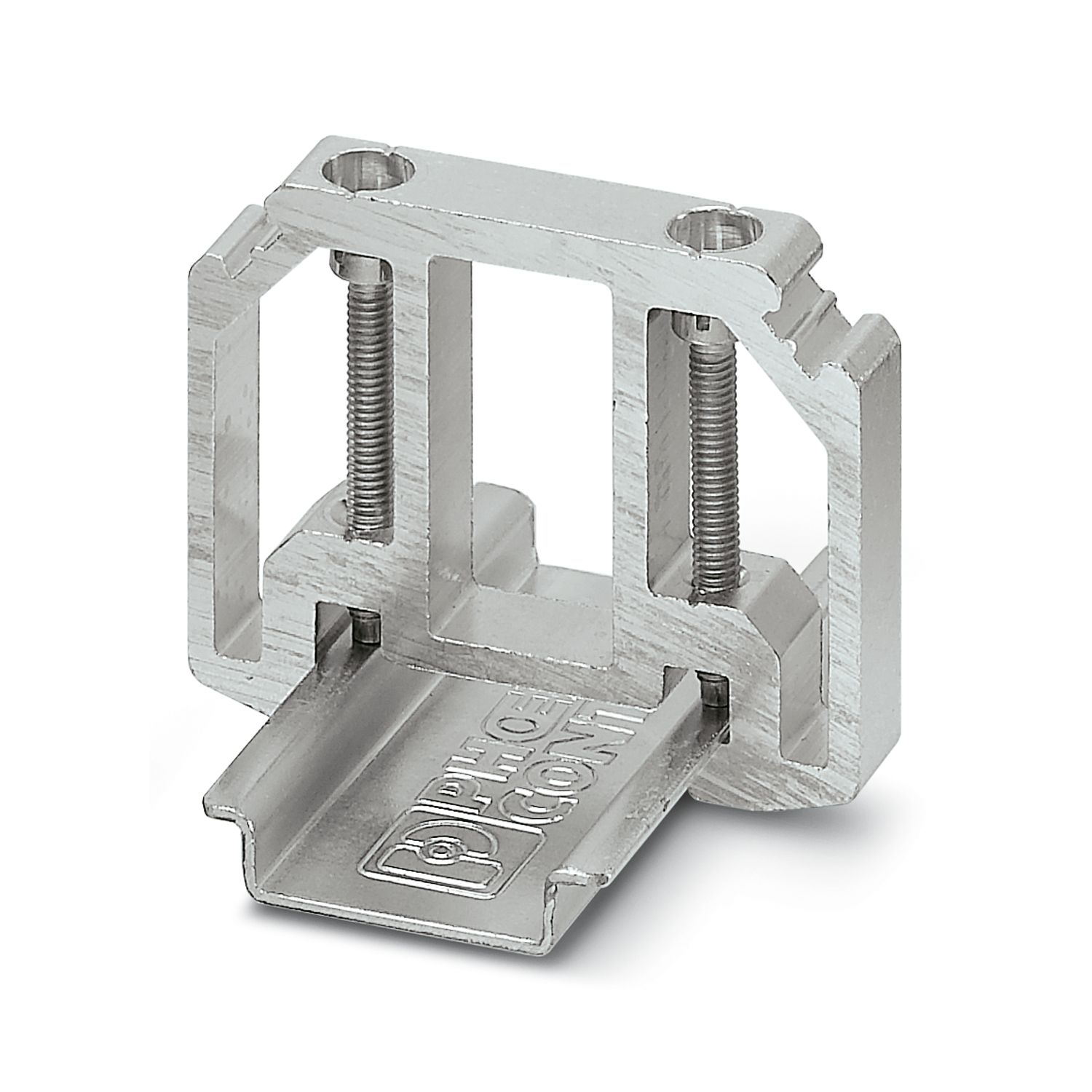

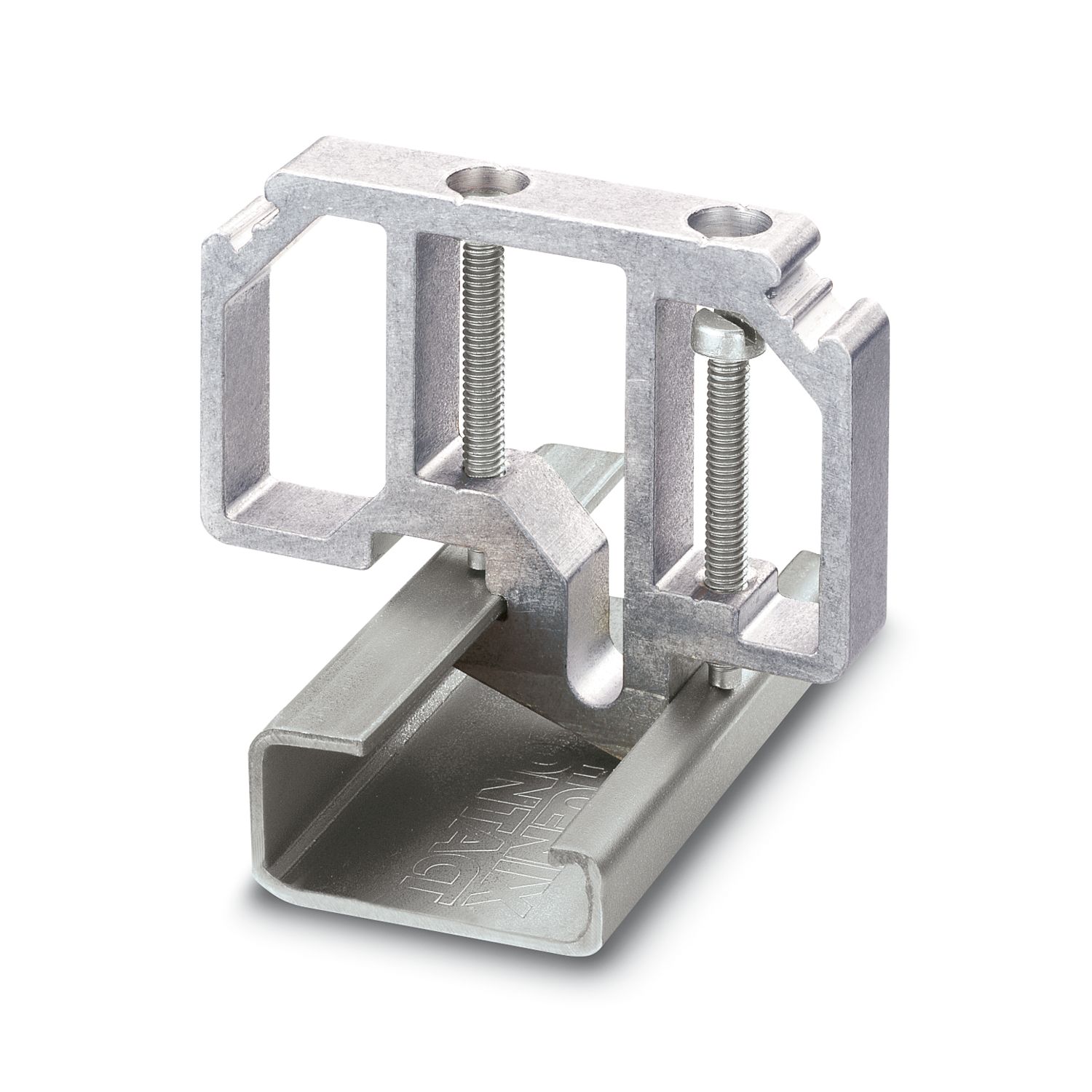

| Mounting type | NS 35/15 |

| NS 32 |

| Item number | 3251205 |

| Packing unit | 2 pc |

| Minimum order quantity | 2 pc |

| Sales key | 02 |

| Product key | BEK311 |

| GTIN | 4046356951111 |

| Weight per piece (including packing) | 485 g |

| Weight per piece (excluding packing) | 485 g |

| Customs tariff number | 85369010 |

| Country of origin | IN |

ECLASS

| ECLASS-13.0 | 27250101 |

| ECLASS-15.0 | 27250101 |

ETIM

| ETIM 9.0 | EC000897 |

UNSPSC

| UNSPSC 21.0 | 39121400 |

| EU RoHS | |

| Fulfills EU RoHS substance requirements | Yes (No exemptions) |

| China RoHS | |

| Environment friendly use period (EFUP) |

EFUP-E

No hazardous substances above the limits

|

| EU REACH SVHC | |

| REACH candidate substance (CAS No.) | No substance above 0.1 wt% |

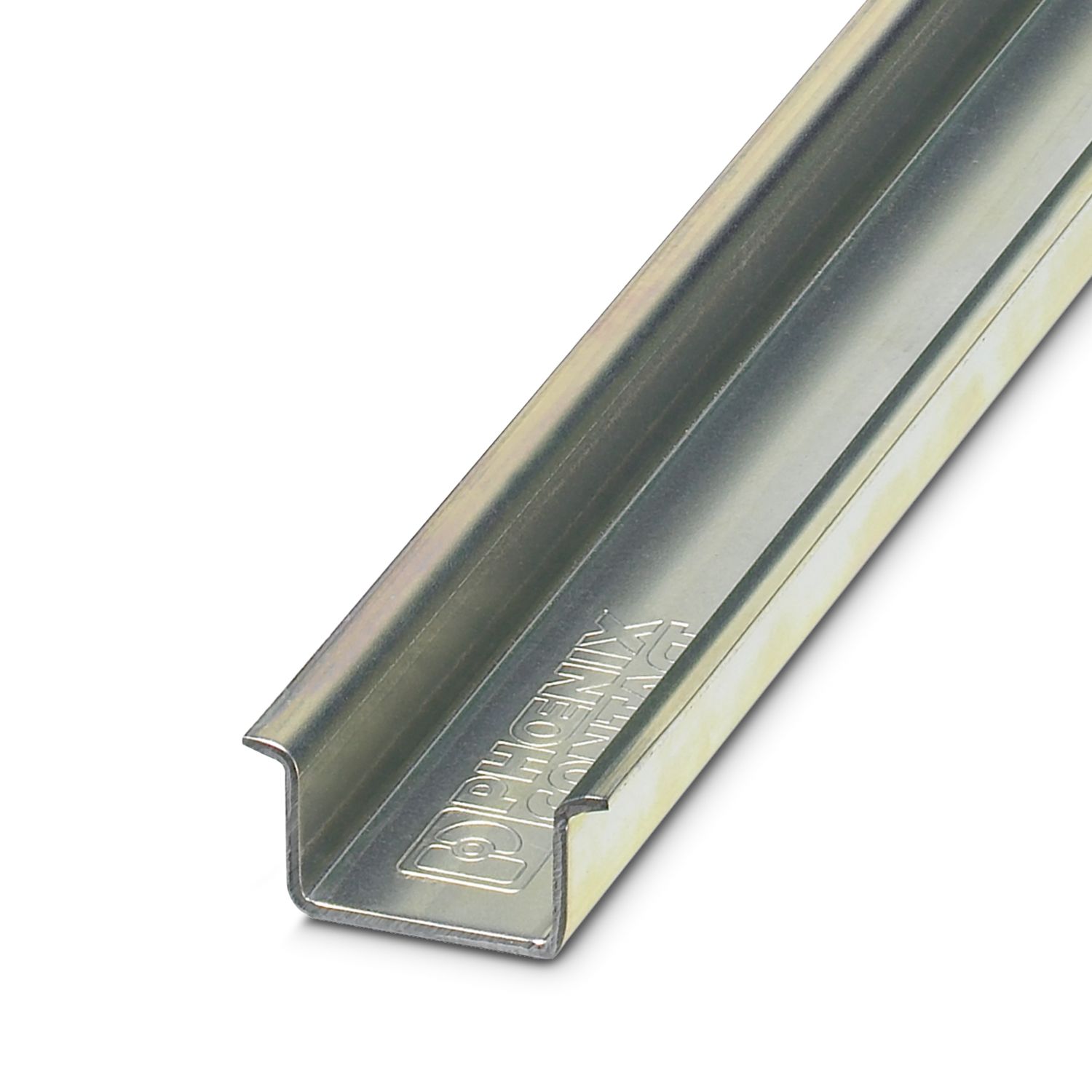

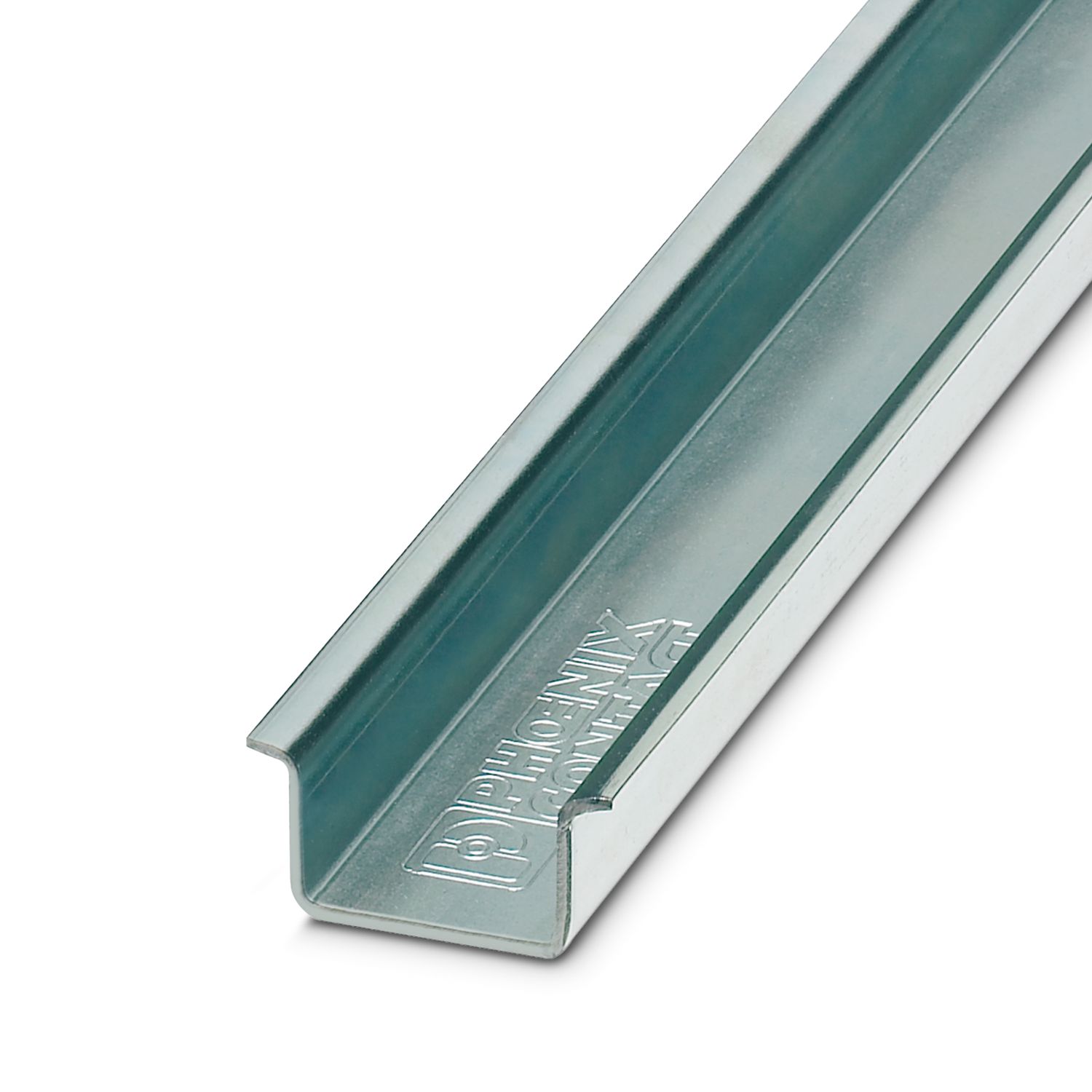

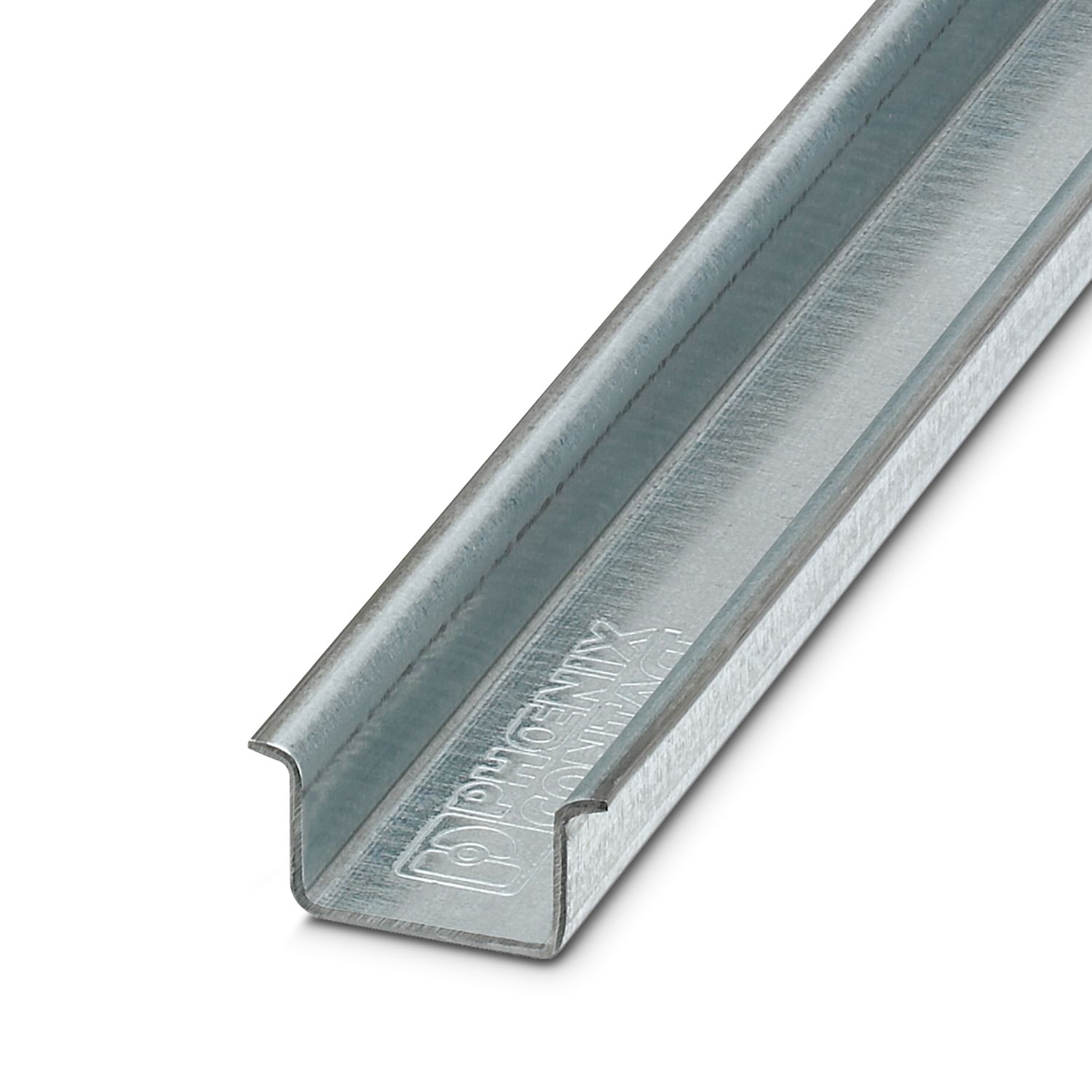

Compatible products

-

NS 32 PERF 2000MM-VPE 10 - DIN rail perforated 1201002

-

NS 32 UNPERF 2000MM-VPE 10 - DIN rail, unperforated 1201015

-

NS 35/15 PERF 2000MM - DIN rail perforated 1201730

-

NS 35/15 UNPERF 2000MM - DIN rail, unperforated 1201714

-

NS 35/15 WH PERF 2000MM - DIN rail perforated 0806602

-

NS 35/15 WH UNPERF 2000MM-VPE 10 - DIN rail, unperforated 1204135

-

NS 35/15 AL UNPERF 2000MM - DIN rail, unperforated 1201756

-

NS 35/15 ZN PERF 2000MM - DIN rail perforated 1206599

-

NS 35/15 ZN UNPERF 2000MM - DIN rail, unperforated 1206586

-

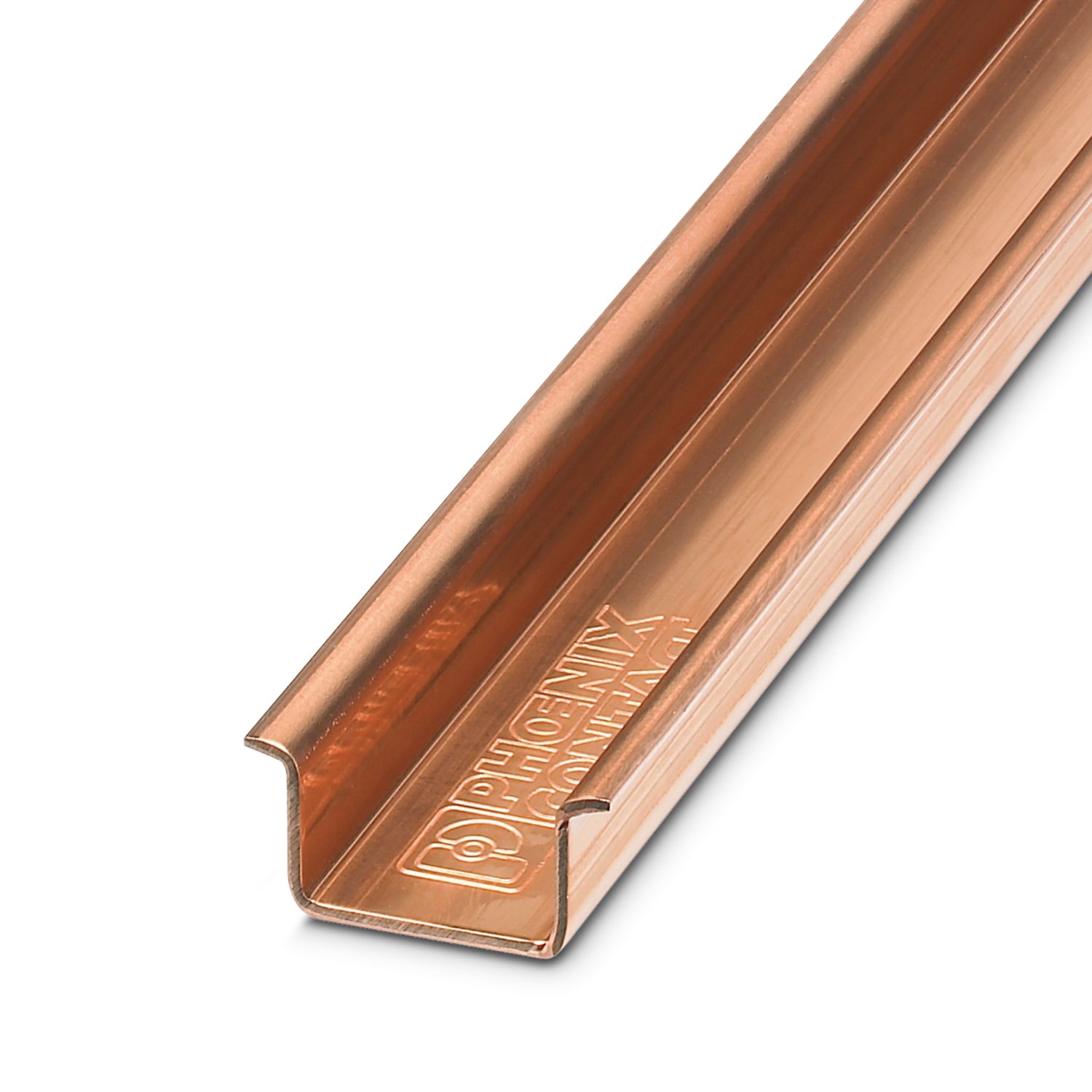

NS 35/15 CU UNPERF 2000MM-VPE 10 - DIN rail, unperforated 1201895

-

NS 35/15 CAP - End cap 1206573

-

ZB 22:UNBEDRUCKT - Zack marker strip 0811862

-

ZB 22 CUS - Zack marker strip 0824949

-

ZB 22,LGS:L1-N,PE - Zack marker strip 0811875

-

E/AL-NS 35 - End bracket 1201662

-

E/AL-NS 32 - End bracket 1201659

-

WS-2K - Warning label 1004513

Your advantages

Reliable cable connection is ensured by three-point centering of the conductor in the prismatic sleeve base

Low contact resistance of the contact surface due to ribbing

Screw locking by means of spring-loaded elements in the clamping part

PHOENIX CONTACT S.A de C.V.

Lago Alberto No. 319 - Piso 9, Colonia Granada, Alcaldía Miguel Hidalgo, México, Ciudad de México, C.P. 11520