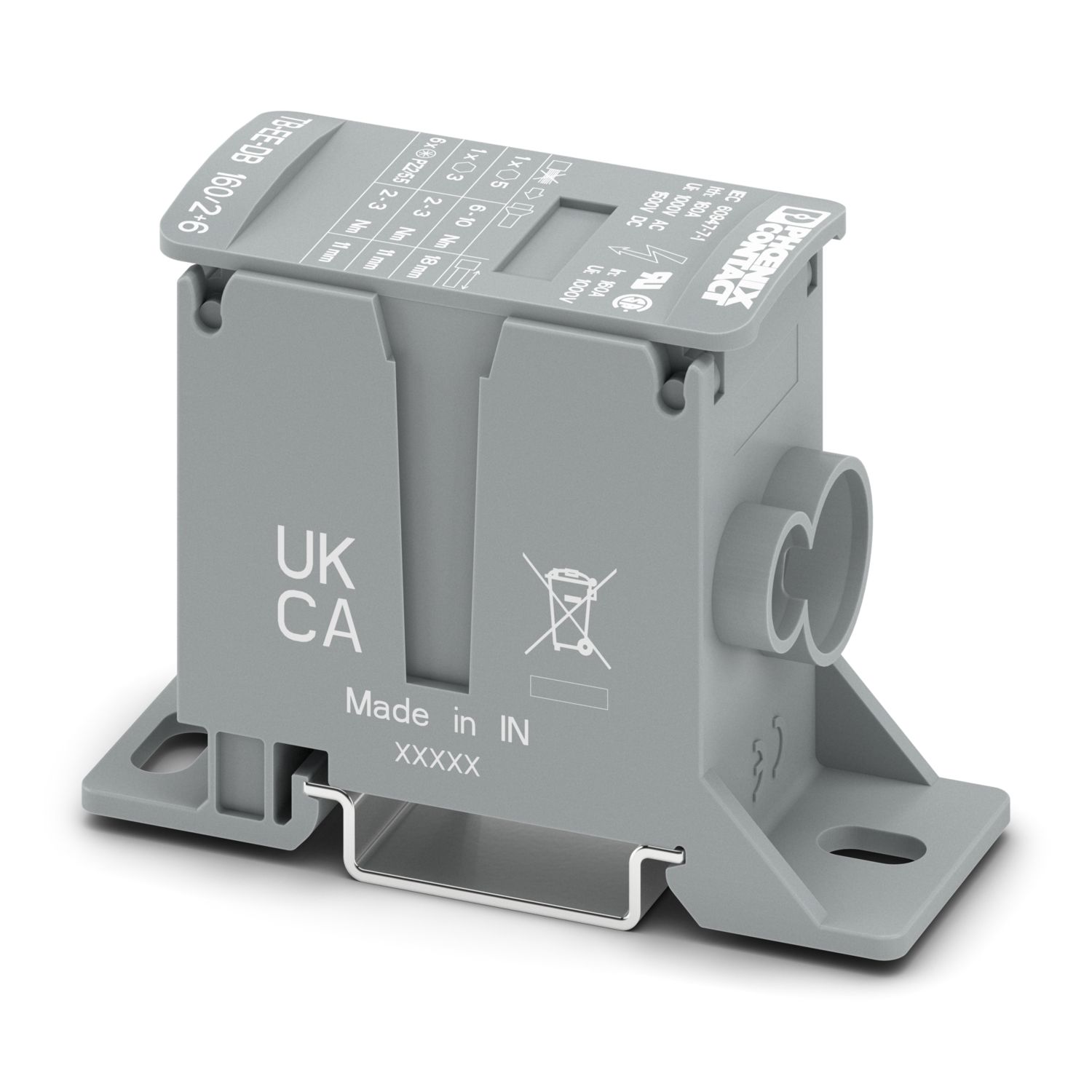

TB-EE-DB 160/2+6

-

Distribution block

1725166

Distribution block, nom. voltage: 1000 V, nominal current: 150 A, Thermal continuous current Ith: 160 A, number of connections: 8, number of positions: 1, connection method: Screw connection, Rated cross section: 50 mm2, Line contact, cross section: 16 mm2 - 70 mm2, Screw connection, Load contact, cross section: 2.5 mm2 - 16 mm2, mounting type: NS 35/7,5, NS 35/15, Direct mounting, color: dark gray

Product details

| General | |

| Note | The maximum load current of a single clamping unit must not be exceeded. |

| For power distribution applications, IEC 60364-4-43.2008; modified + corrigendum Okt. 2008 (DIN VDE 0100-430:2010-10) section 433.2 ff must be observed! | |

| Product family | TB |

| Area of application | Machine building |

| Number of positions | 1 |

| Number of connections | 8 |

| Number of rows | 1 |

| Insulation characteristics | |

| Degree of pollution | 3 |

| Rated surge voltage | 8 kV |

| Number of connections per level | 8 |

| Nominal cross section | 50 mm² |

| Rated cross section AWG | 2 |

| Line contact | |

| Connection method | Screw connection |

| Screw thread | M10 |

| Number of connections | 1 |

| Note | Ferrules are mandatory when using flexible conductors |

| Tightening torque | 6 ... 10 Nm |

| Stripping length | 18 mm |

| Connection in acc. with standard | IEC 60947-7-1 |

| Conductor cross-section rigid | 16 mm² ... 70 mm² |

| Cross section AWG | 4 ... 00 (converted acc. to IEC) |

| Flexible conductor cross-section (ferrule with plastic sleeve) | 16 mm² ... 50 mm² |

| Nominal cross section | 50 mm² |

| Thermal continuous current Ith | 160 A |

| Nominal current | 150 A |

| Nominal voltage | 1000 V AC (suitable for 1500 V DC) |

| Load contact | |

| Connection method | Screw connection |

| Screw thread | M5 |

| Number of connections | 6 |

| Note | Ferrules are mandatory when using flexible conductors |

| Tightening torque | 2 ... 3 Nm |

| Stripping length | 11 mm |

| Connection in acc. with standard | IEC 60947-7-1 |

| Conductor cross-section rigid | 2.5 mm² ... 16 mm² |

| Cross section AWG | 12 ... 6 (converted acc. to IEC) |

| Flexible conductor cross-section (ferrule with plastic sleeve) | 2.5 mm² ... 16 mm² |

| Load contact | |

| Connection method | Screw connection |

| Screw thread | M6 |

| Number of connections | 1 |

| Note | Ferrules are mandatory when using flexible conductors |

| Tightening torque | 2 ... 3 Nm |

| Stripping length | 11 mm |

| Connection in acc. with standard | IEC 60947-7-1 |

| Conductor cross-section rigid | 6 mm² ... 16 mm² |

| Cross section AWG | 8 ... 6 (converted acc. to IEC) |

| Flexible conductor cross-section (ferrule with plastic sleeve) | 2.5 mm² ... 16 mm² |

| Width | 29.4 mm |

| Height | 75 mm |

| Depth | 50.8 mm |

| Depth on NS 35/7,5 | 52.3 mm |

| Depth on NS 35/15 | 59.8 mm |

| Color | basalt gray (RAL 7012) |

| Flammability rating according to UL 94 | V0 |

| Insulating material group | I |

| Relative insulation material temperature index (Elec., UL 746 B) | 125 °C |

| Surge voltage test | |

| Test voltage setpoint | 9.8 kV |

| Result | Test passed |

| Temperature-rise test | |

| Requirement temperature-rise test | Increase in temperature ≤45 K |

| Result | Test passed |

| Short-time withstand current 50 mm² | 6 kA |

| Result | Test passed |

| Power-frequency withstand voltage | |

| Test voltage setpoint | 3.82 kV |

| Result | Test passed |

| Mechanical data | |

| Open side panel | No |

| Mechanical strength | |

| Result | Test passed |

| Attachment on the carrier | |

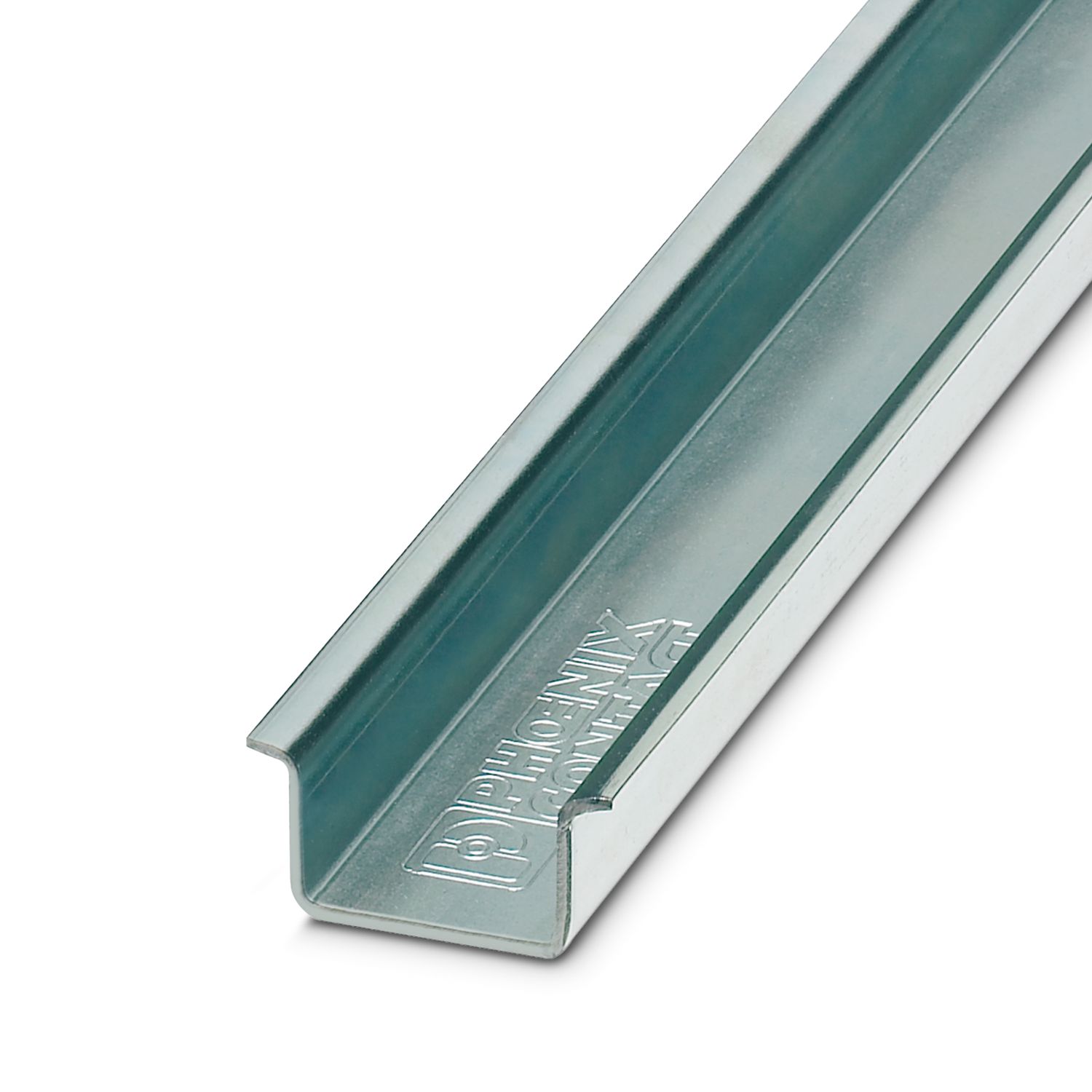

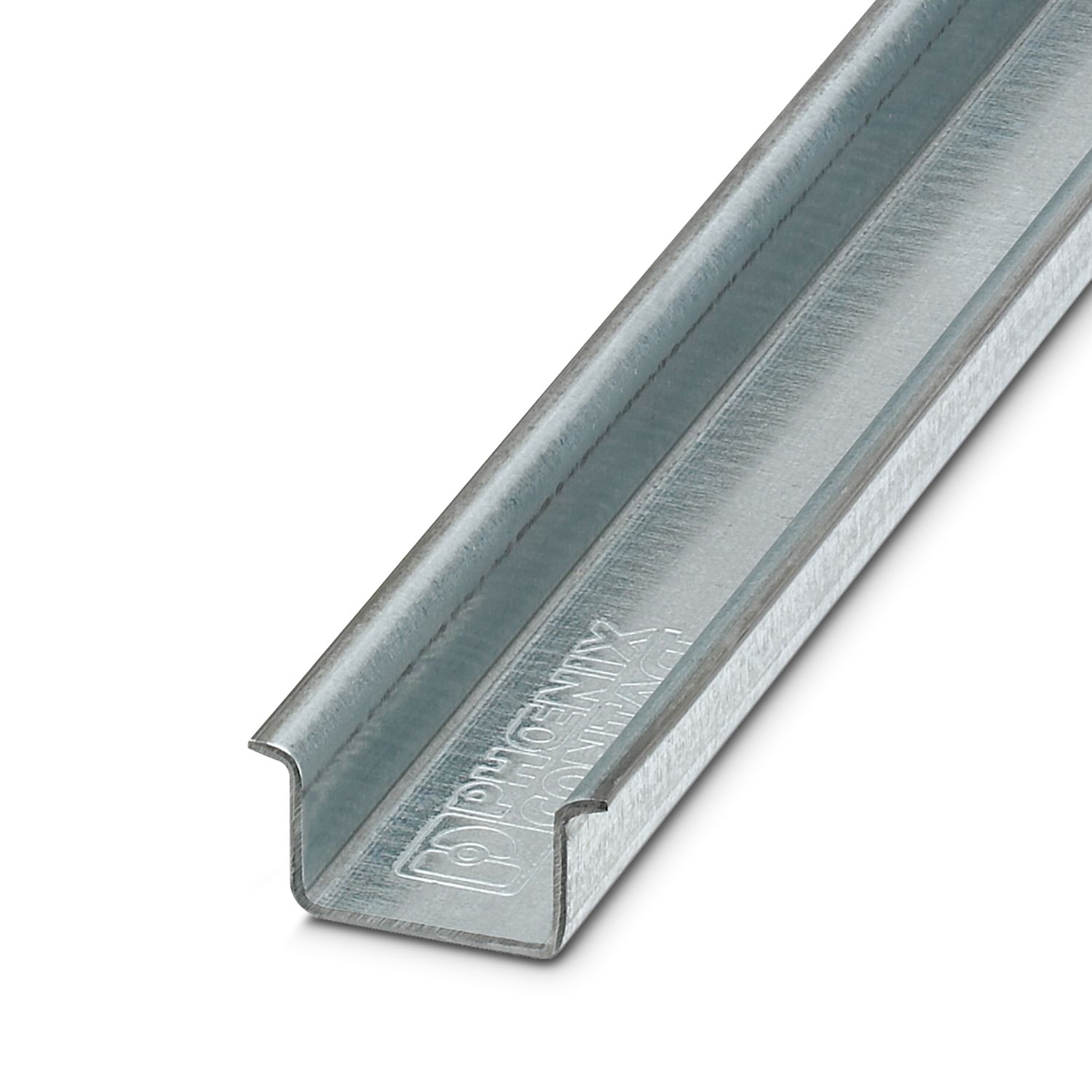

| DIN rail/fixing support | NS 35 |

| Result | Test passed |

| Test for conductor damage and slackening | |

| Rotation speed | 9 rpm |

| Revolutions | 135 |

| Conductor cross-section/weight | 10 mm² / 2 kg |

| 16 mm² / 2.9 kg | |

| 70 mm²/10.4 kg | |

| Result | Test passed |

| Needle-flame test | |

| Time of exposure | 5 s |

| Result | Test passed |

| Ambient conditions | |

| Degree of protection | IP20 |

| Ambient temperature (operation) | -40 °C ... 110 °C (Operating temperature range incl. self-heating; for max. short-term operating temperature, see RTI Elec.) |

| Ambient temperature (storage/transport) | -25 °C ... 60 °C (for a short time, not exceeding 24 h, -60 °C to +70 °C) |

| Ambient temperature (assembly) | -5 °C ... 70 °C |

| Ambient temperature (actuation) | -5 °C ... 70 °C |

| Permissible humidity (operation) | 20 % ... 90 % |

| Permissible humidity (storage/transport) | 30 % ... 70 % |

| Connection in acc. with standard | IEC 60947-7-1 |

| IEC 60947-7-1 | |

| IEC 60947-7-1 |

| Mounting type | NS 35/7,5 |

| NS 35/15 | |

| Direct mounting |

| Item number | 1725166 |

| Packing unit | 1 pc |

| Minimum order quantity | 1 pc |

| Sales key | 02 |

| Product key | BEK823 |

| GTIN | 4067923281103 |

| Weight per piece (including packing) | 129.7 g |

| Weight per piece (excluding packing) | 129.7 g |

| Customs tariff number | 85369010 |

| Country of origin | IN |

ECLASS

| ECLASS-13.0 | 27250118 |

| ECLASS-15.0 | 27250118 |

ETIM

| ETIM 9.0 | EC000897 |

UNSPSC

| UNSPSC 21.0 | 39121400 |

| EU RoHS | |

| Fulfills EU RoHS substance requirements | Yes |

| Exemption | 6(c) |

| China RoHS | |

| Environment friendly use period (EFUP) |

EFUP-50

An article-related China RoHS declaration table can be found in the download area for the respective article under "Manufacturer declaration". For all articles with EFUP-E, no China RoHS declaration table issued and required.

|

| EU REACH SVHC | |

| REACH candidate substance (CAS No.) | Lead (CAS: 7439-92-1) |

Compatible products

-

UCT6M-TM 5 - Marker for terminal blocks 0830756

-

UCT6M-TM 5 CUS - Marker for terminal blocks from the SNK series from ABB 0830762

-

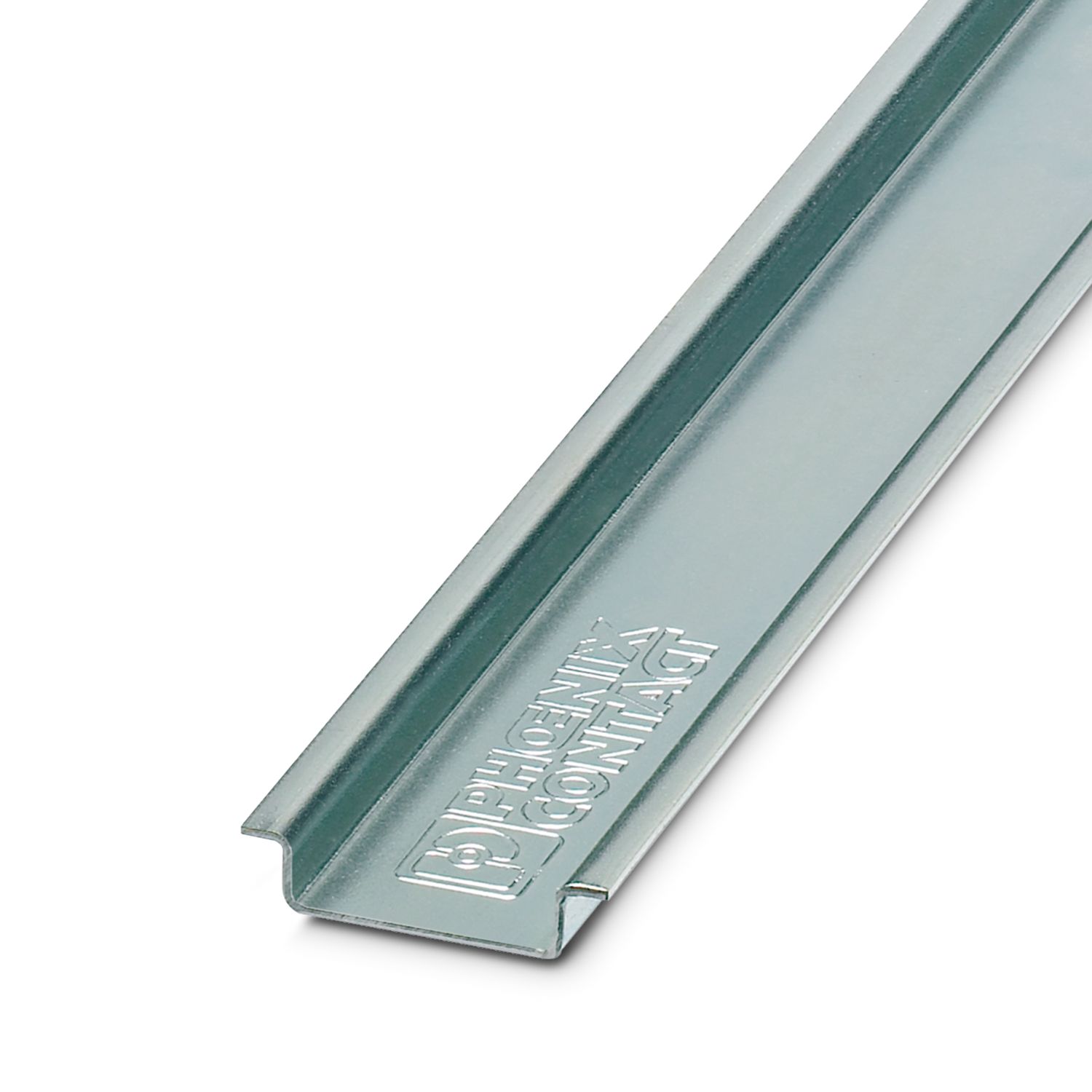

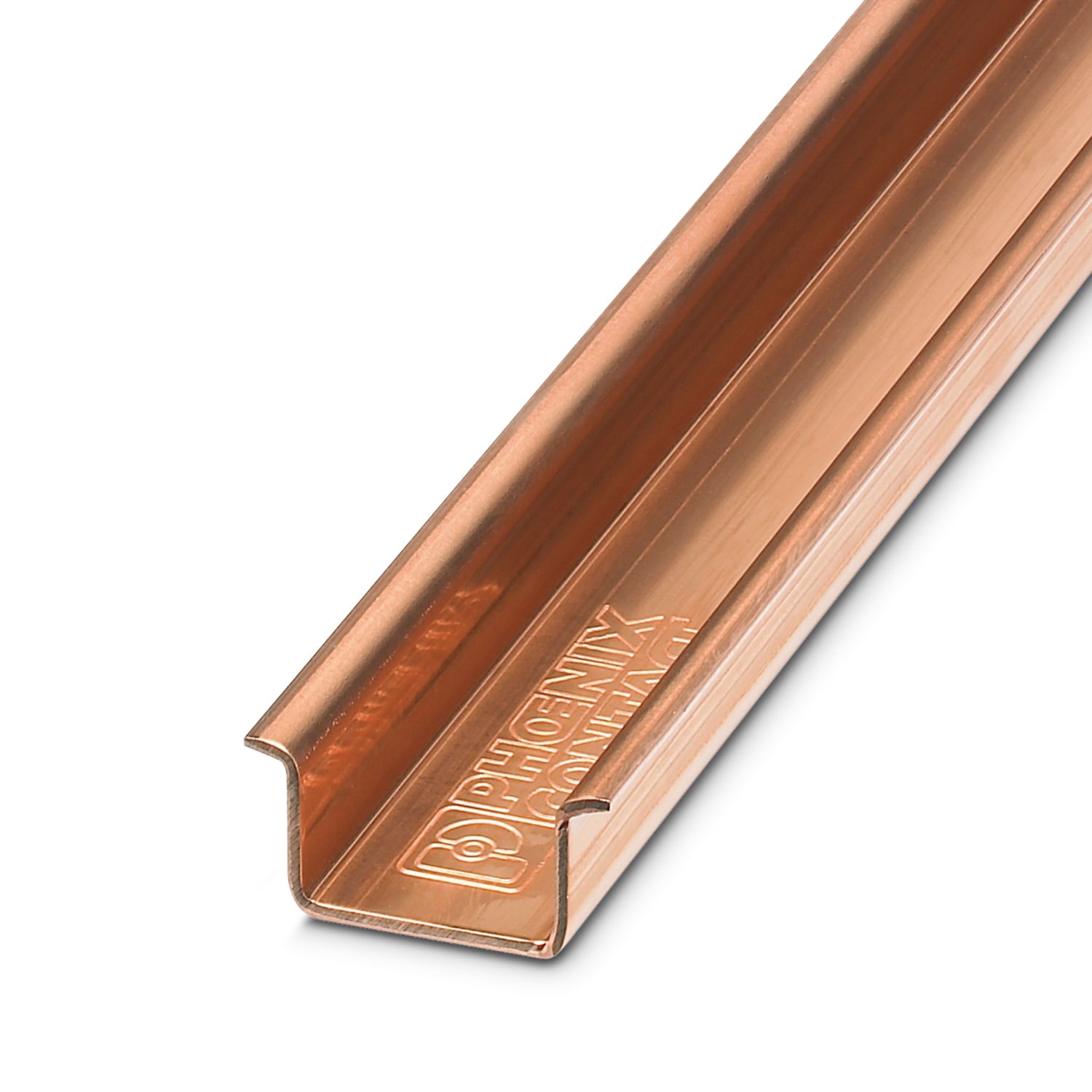

NS 35/ 7,5 PERF 2000MM - DIN rail perforated 0801733

-

NS 35/ 7,5 UNPERF 2000MM - DIN rail, unperforated 0801681

-

NS 35/ 7,5 WH PERF 2000MM - DIN rail perforated 1204119

-

NS 35/ 7,5 WH UNPERF 2000MM-VPE 10 - DIN rail, unperforated 1204122

-

NS 35/ 7,5 AL UNPERF 2000MM - DIN rail, unperforated 0801704

-

NS 35/ 7,5 ZN PERF 2000MM - DIN rail perforated 1206421

-

NS 35/ 7,5 ZN UNPERF 2000MM - DIN rail, unperforated 1206434

-

NS 35/ 7,5 CU UNPERF 2000MM-VPE 10 - DIN rail, unperforated 0801762

-

NS 35/ 7,5 CAP - End cap 1206560

-

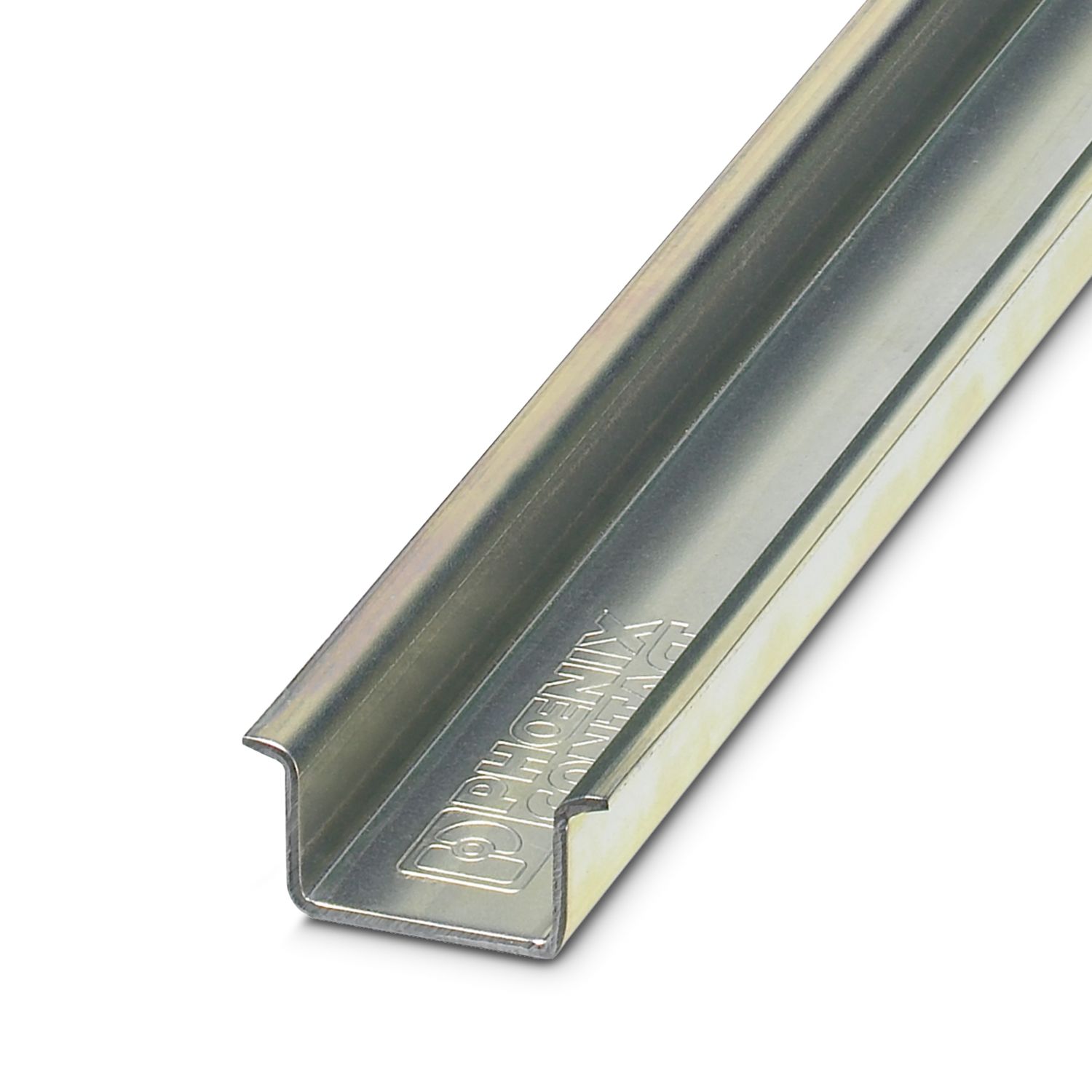

NS 35/15 PERF 2000MM - DIN rail perforated 1201730

-

NS 35/15 UNPERF 2000MM - DIN rail, unperforated 1201714

-

NS 35/15 WH PERF 2000MM - DIN rail perforated 0806602

-

NS 35/15 WH UNPERF 2000MM-VPE 10 - DIN rail, unperforated 1204135

-

NS 35/15 AL UNPERF 2000MM - DIN rail, unperforated 1201756

-

NS 35/15 ZN PERF 2000MM - DIN rail perforated 1206599

-

NS 35/15 ZN UNPERF 2000MM - DIN rail, unperforated 1206586

-

NS 35/15 CU UNPERF 2000MM-VPE 10 - DIN rail, unperforated 1201895

-

NS 35/15 CAP - End cap 1206573

Your advantages

Fast installation via ready-to-connect distributor and collection block

Blocks can be snapped to each other to form function groups

As well as saving space, the compact design enables user-friendly wiring in a small amount of space

Flexible use, thanks to DIN rail and direct mounting

Reversible cover for optimum readability of the technical data

PHOENIX CONTACT S.A de C.V.

Lago Alberto No. 319 - Piso 9, Colonia Granada, Alcaldía Miguel Hidalgo, México, Ciudad de México, C.P. 11520