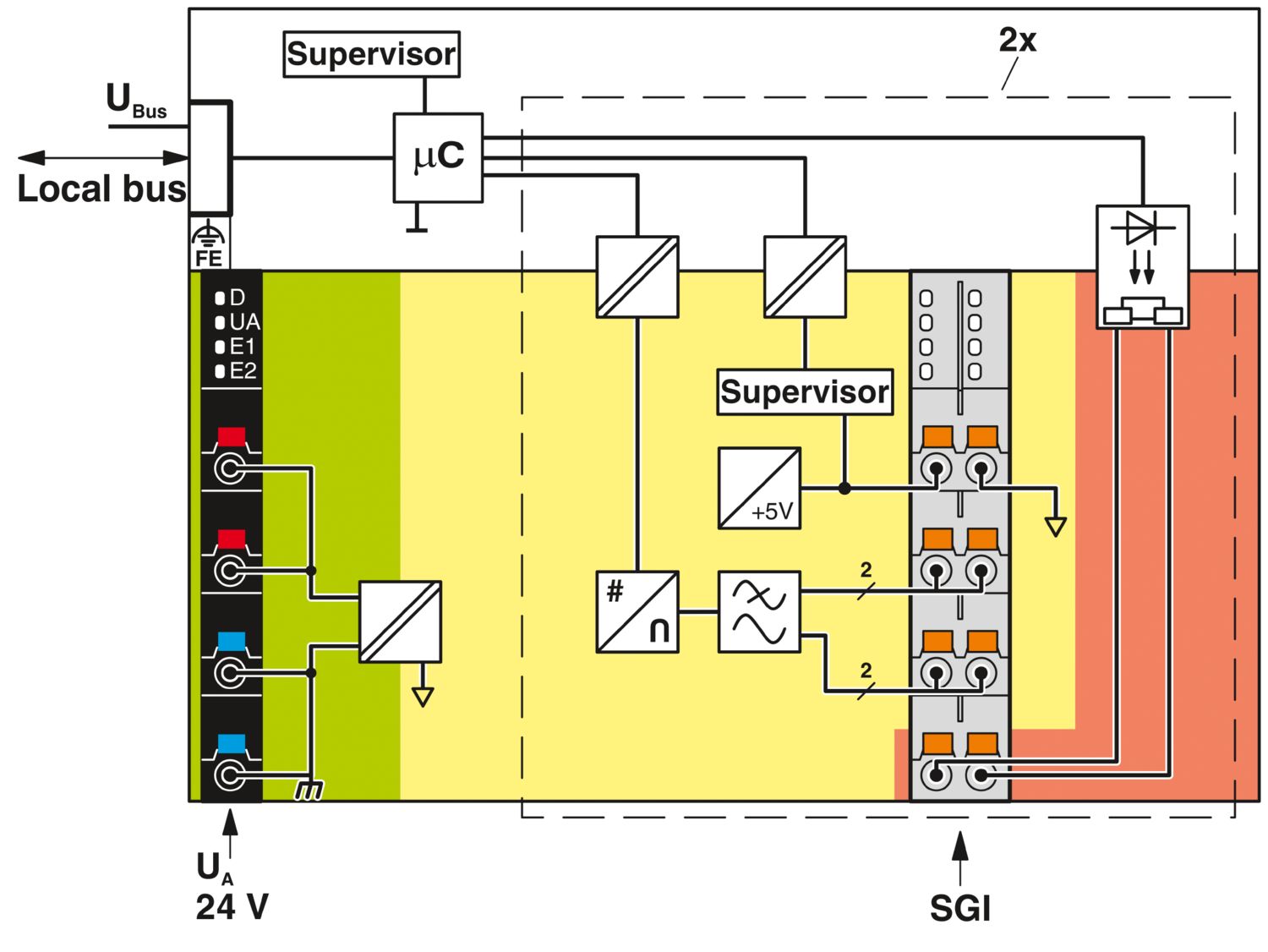

The module is designed for use within an Axioline F station. Used to evaluate strain gauges that may be located in weighing cells or load cells, for example. You can connect the strain gauges using 6- or 4-conductor technology.

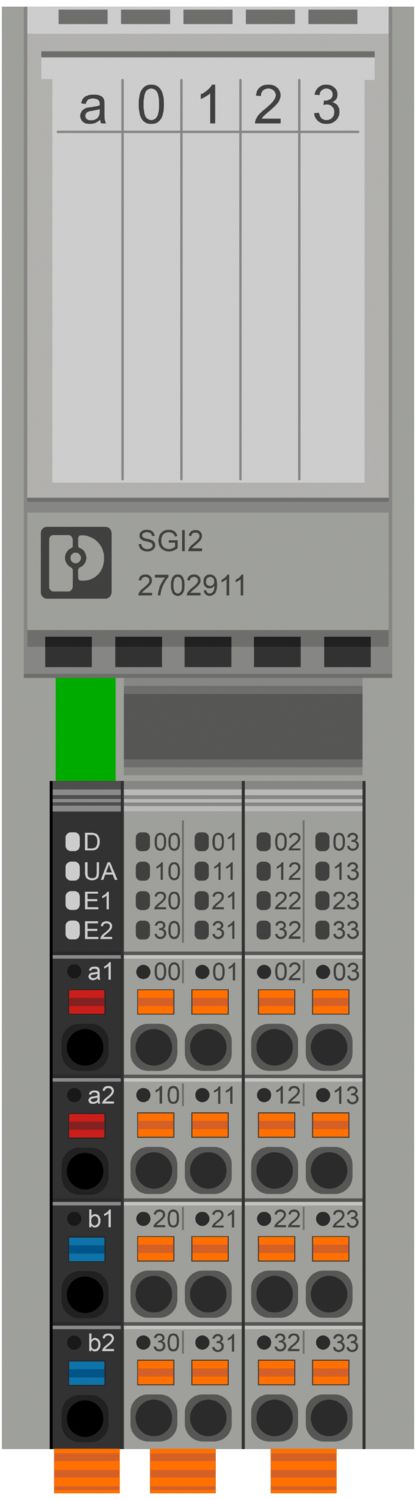

AXL F SGI2 1H

-

Analog module

2702911

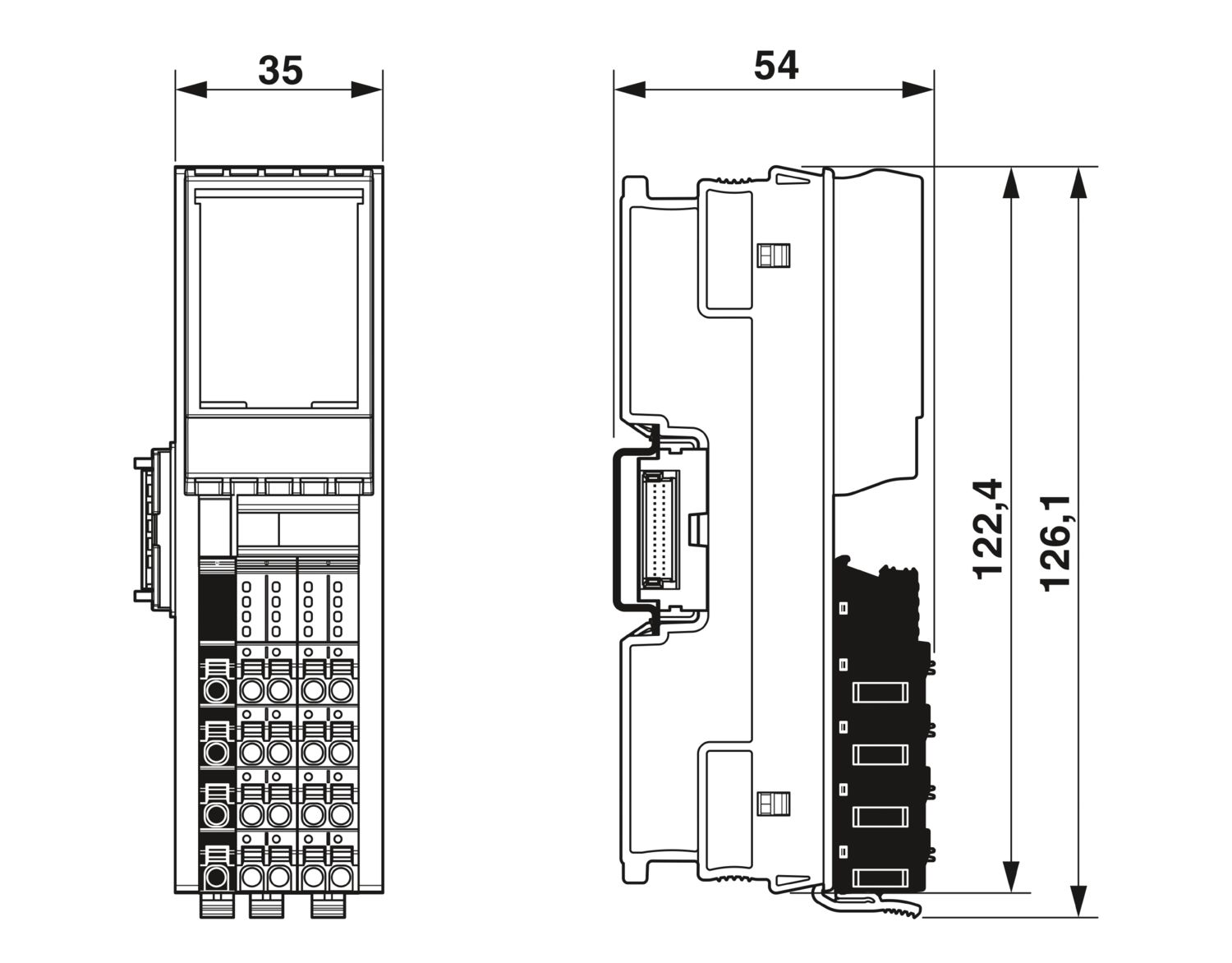

Axioline F, Strain gauge capture module, transmission speed in the local bus: 100 Mbps, degree of protection: IP20, including bus base module and Axioline F connectors

Free download available.

Downloads

Product details

Compatible products

Your advantages

2 high-precision inputs for strain gauges

Measuring ranges adjusted with nominal characteristic values upon delivery

Manual entry of characteristic values

Process data update can be parameterized in increments between 200 µs and 100 ms

Path adjustment in the process environment

2-point adjustment

Connection of strain gauges in 6- and 4-conductor technology

Advanced wire-break detection

Sensor supply of up to 115 mA (8 load cells with 350 Ω per channel)

Per channel: low-resistance, floating N/O contact

The channels are parameterized independently of one another via the bus system

Tara device