Machine tool High speeds and perfect processing results are basic requirements for machine tools. In order to meet today’s market requirements, machine concepts must also be flexible and particularly reliable. In addition to modularization as a possible solution, energy efficiency plays an increasingly important role for machine tools and their auxiliary units. We would like to support you in these challenges as a partner and offer you a broad product and service portfolio for the networking, electrification, and automation of your machine tools.

Overview of a machine tool Discover our product and service portfolio for the sustainable automation of your machine tool.

Control cabinet Machine tool subprocess

We provide you with innovative solutions and products for all the functional areas of the control cabinet. In addition to innovative products for the control cabinet, we support you throughout the entire control cabinet building process, from engineering to the finished control cabinet.

-

Comprehensive terminal block portfolio ensures reliable power distribution in the control cabinet. Terminal blocks with different connection technologies can be freely combined

-

Speed starter for reliable and easy drive of motors on the conveyor belt and chip conveyor

-

Remote I/O system with IP20 degree of protection for capturing input and output signals, including I/O link and safety applications

-

Switches ensure reliable data distribution throughout the entire machine network, and security routers protect machine tools against unauthorized access and malware

-

Reliable and communicative 24 V supply systems consisting of surge protection, power supply, and device protection

-

Various relay families as an interface between the controller and machine peripherals to isolate, multiply, and amplify signals

-

Energy measuring devices acquire the energy data of all subprocesses of the machine tool quickly and easily

-

Reliable and robust feed-through of cables directly into the control cabinet with the aid of space-saving cable entry systems

Conveyor belt for finished parts Machine tool subprocess

The conveyor belt features a modular design that enables systems to be designed flexibly and extended cost-effectively. Furthermore, the cost-effective and fail-safe installation of the entire production line is particularly important. These aspects are directly reflected in the electronic components used on the conveyor belt.

-

Robust power supply units with IP67 degree of protection are ideally suited for decentral supply in the field and can be installed directly on the conveyor belt

-

The IPD and QPD installation systems ensure easy and tool-free power distribution directly at the conveyor belt

-

Input and output signals from the conveyor belt are acquired and processed directly with the remote I/O system with IP65/IP67 degree of protection. The fully molded zinc die-cast housing offers a high degree of robustness and the devices are also suitable for I/O link applications

Chip conveyor Machine tool subprocess

When a chip conveyor and the electronic components installed in it are used, special resistance to dust, liquids, and lubricants is required. Furthermore, easy servicing, quick adaptability based on modular systems, and easy integration of mechanical and electrical interfaces are particularly important.

-

Motor starter for safe operation of the chip conveyor

-

Easy power distribution with comprehensive terminal block product portfolio

-

Robust industrial connectors for cabling between chip conveyors and

machining center -

Reliable connection of sensors and actuators, both central and decentral

-

Reliable power supply for IP6X applications directly on the chip conveyor

Raw parts supplied via robot Machine tool subprocess

In order to automate robots in the best possible way, the products used must not only be particularly space-saving and robust against vibration, rotation, dirt, and dust. They must also be integrated into the main process in a communicative and easy way.

-

The inductive NearFi couplers can be used to monitor the tool change directly on the robot head. Power and real-time Ethernet data are transmitted across an air gap of a few centimeters

-

To transmit data, signals, and power between the field and control level, sensor/actuator boxes with the appropriate connectors are installed directly on the robot arm

-

The installation of heavy-duty connectors directly on the base frame of the robot enables the reliable transmission of power, data, and signals between the control cabinet and robot

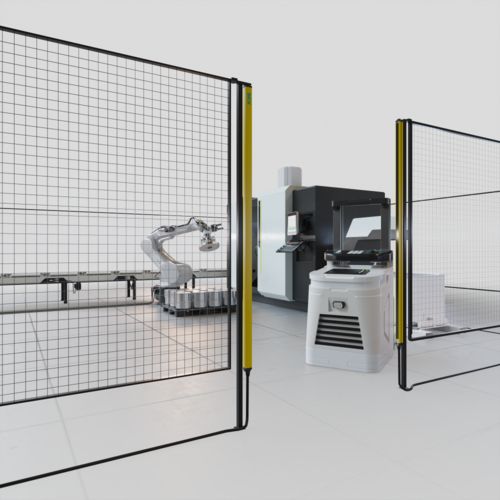

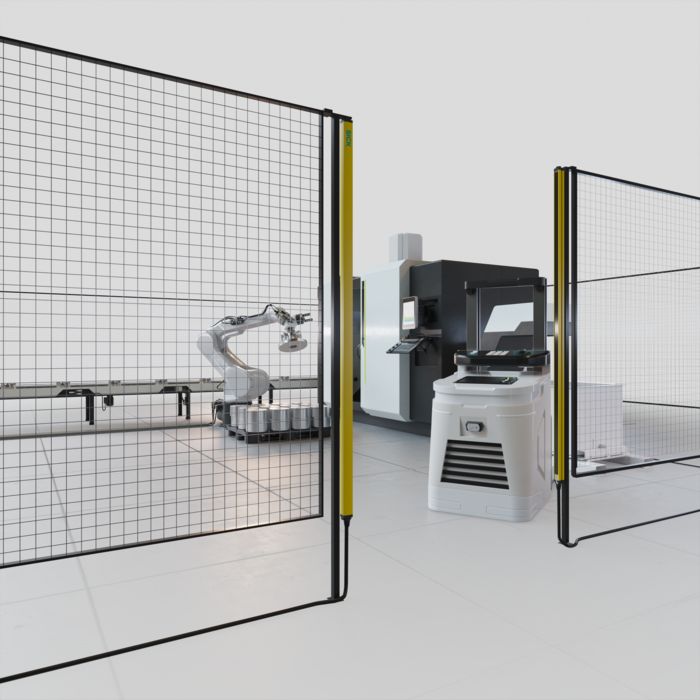

Workspace Machine tool subprocess

The process of several axes operating at high speed, as well as loading semi-finished products and removing the finished workpieces by robot, are major sources of danger for the operating personnel. Safe shutdown and danger-free entry into the workspace are therefore essential.

-

Safety relay for monitoring safety doors, light grids, and other safety-relevant sensors

-

In combination with our safety relays, the non-contact and compact safety switch monitors the safety door to the workspace

-

Robust cables are specified for use in the machine tool workspace. They must be resistant to cooling lubricants and oil, for example

-

Cable feed-through for safe cable installation and robust feed-through between the workspace and control cabinet

-

Machine lights ensure optimum illumination of the workspace

Automated guided vehicle system Machine tool subprocess

Short production times, low inventory levels, and high flexibility are the basis for efficient internal material flow and therefore the prerequisite for increasing productivity. In order to meet these requirements, AGVs are increasingly being used in production and intralogistics.

-

Reliable and secure communication with the AGV via WLAN access point

-

Robust connectors for distributing data and signals

-

Safety is always a top priority in human-machine collaboration:

Our safety product portfolio enables the safe implementation of the necessary application, such as the emergency stop concept, safe motion monitoring, and field switching

Control panel Machine tool subprocess

For use on machine tools, IPCs must be particularly resistant to dust, liquids, and lubricants

-

This fully encapsulated industrial PC with IP65 degree of protection is equipped with Intel® processors, which are used for their balance of processing power, graphics performance, and energy efficiency

-

Easy to service for quick adaptation based on modular systems and easy integration of mechanical and electrical interfaces

-

Use in many different machine tools due to the robust design with VESA, support arm, or stand mounting options and numerous I/O options