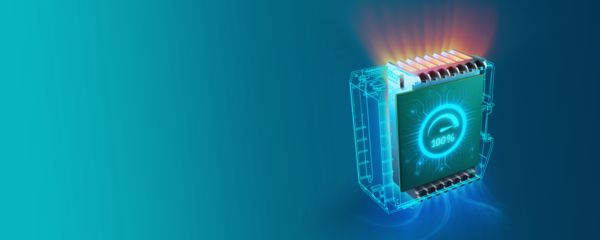

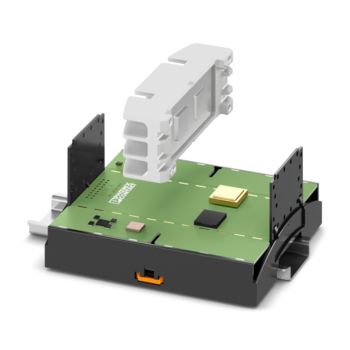

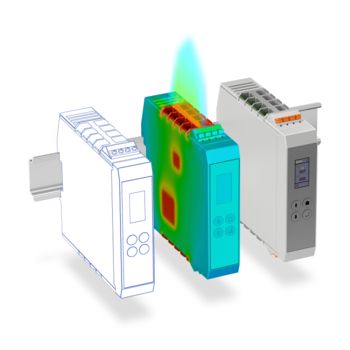

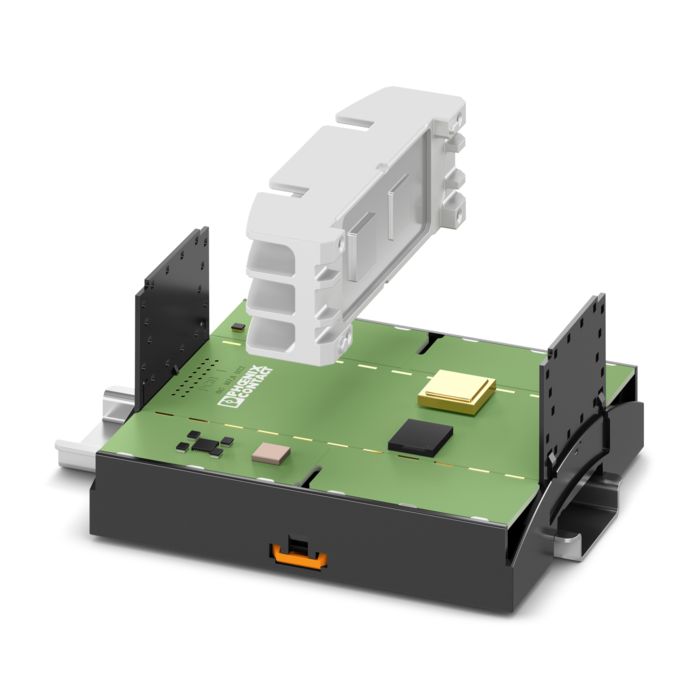

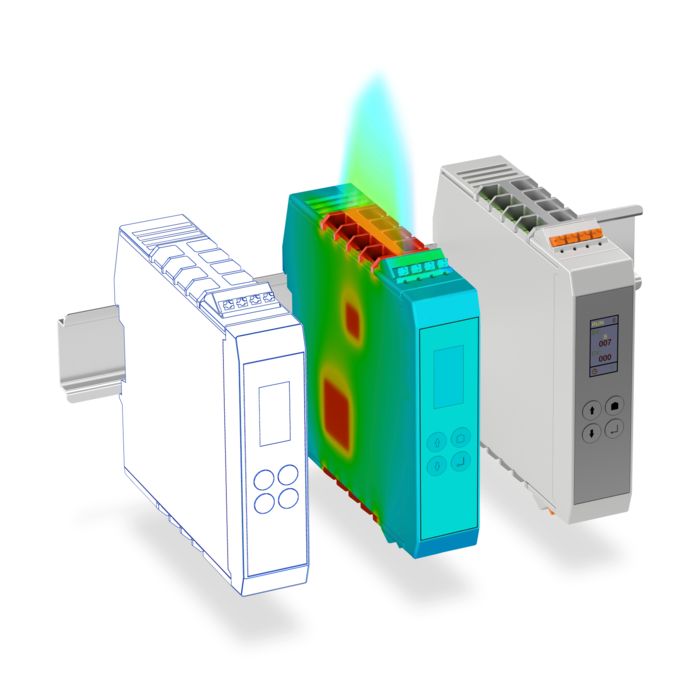

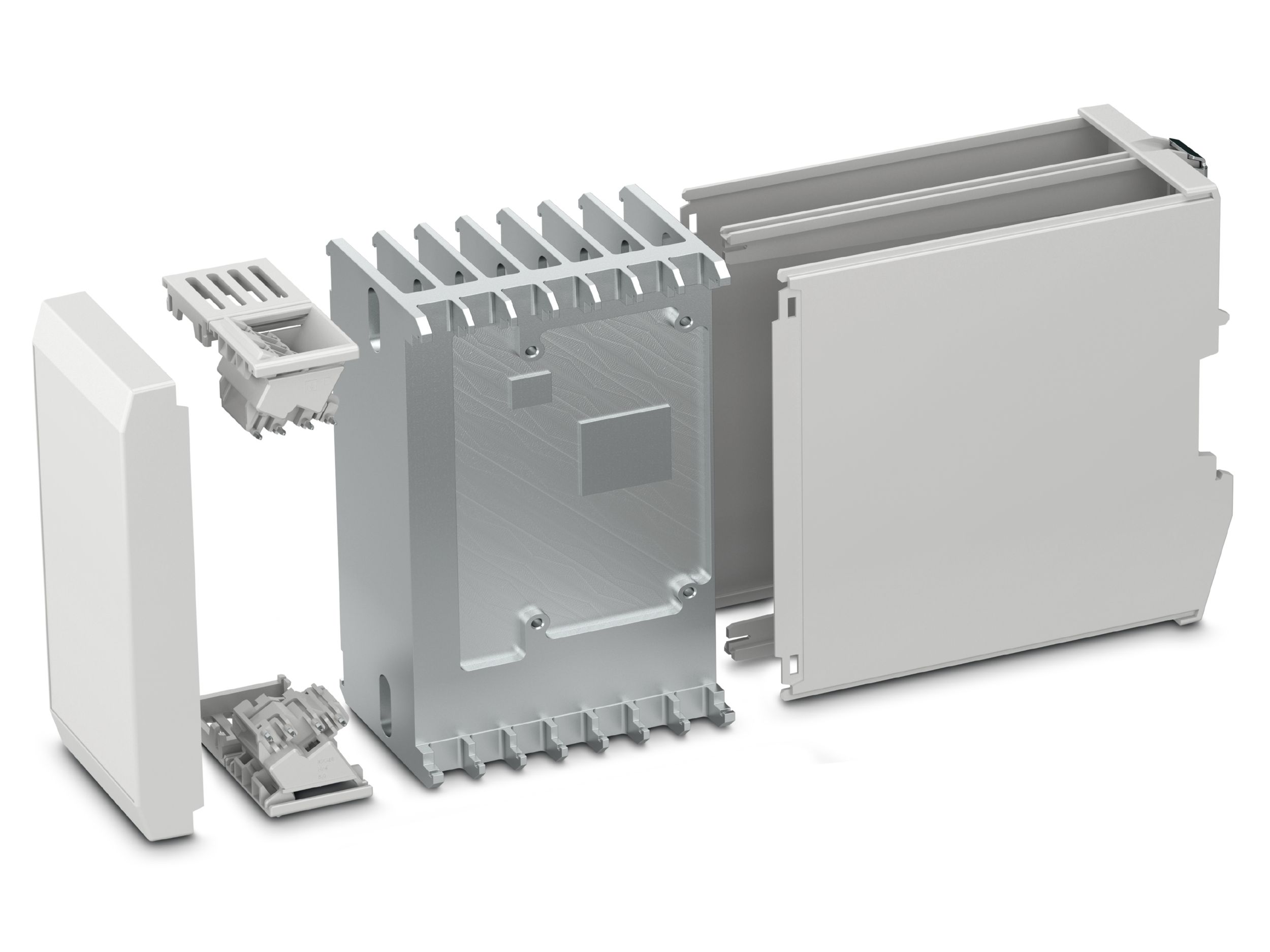

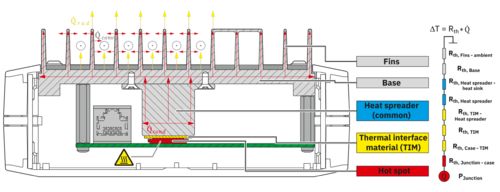

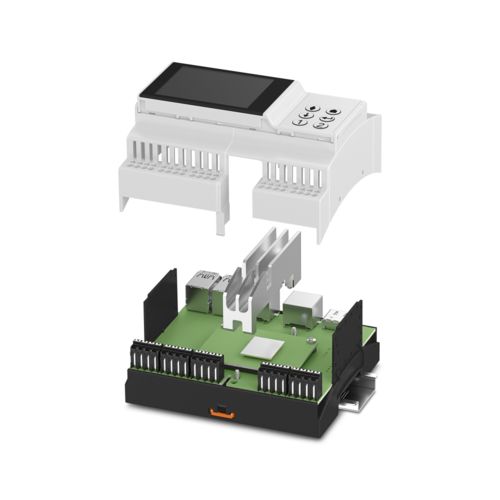

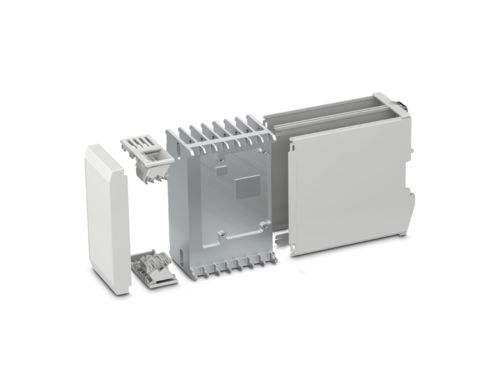

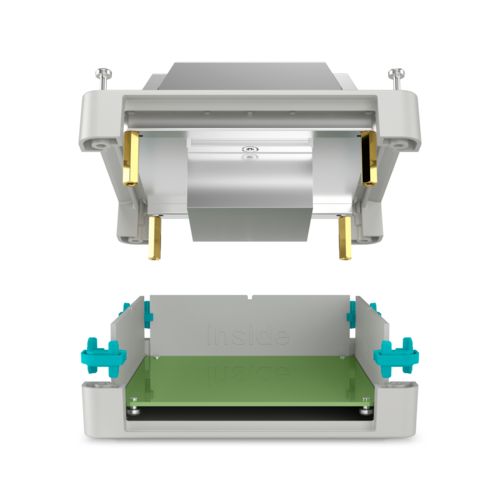

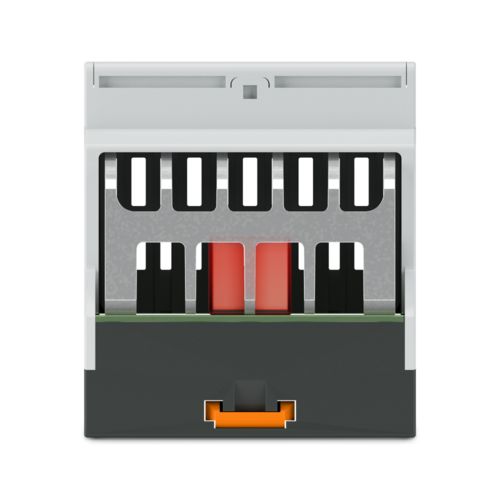

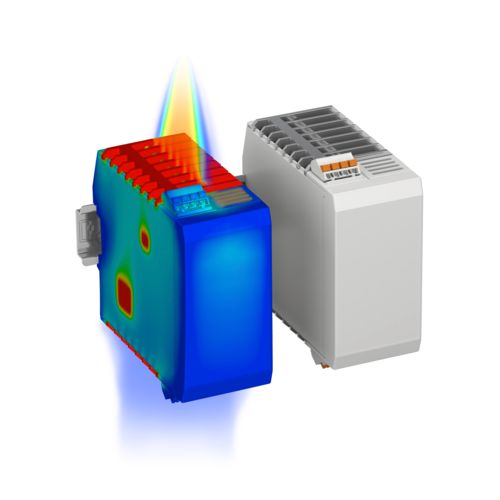

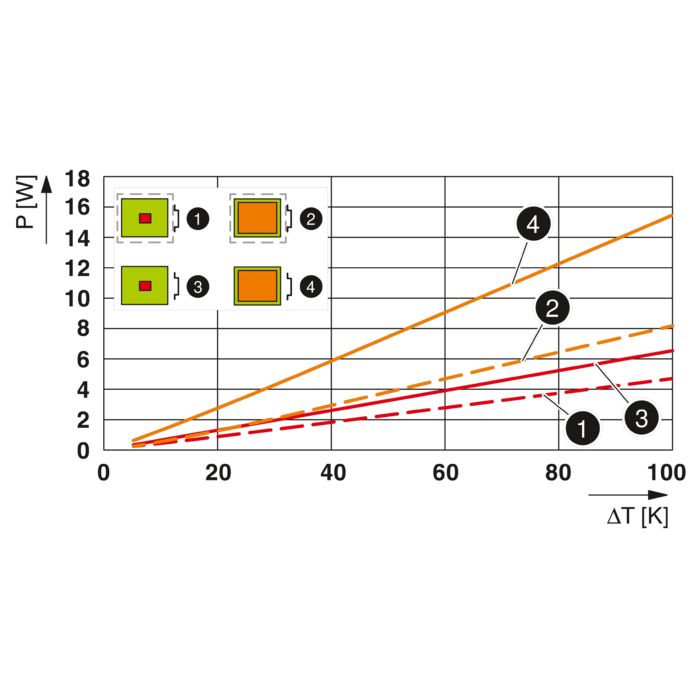

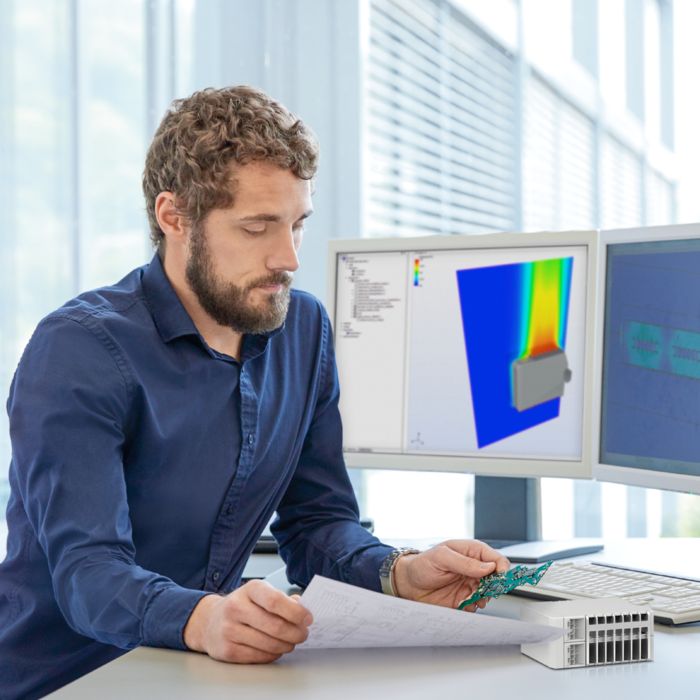

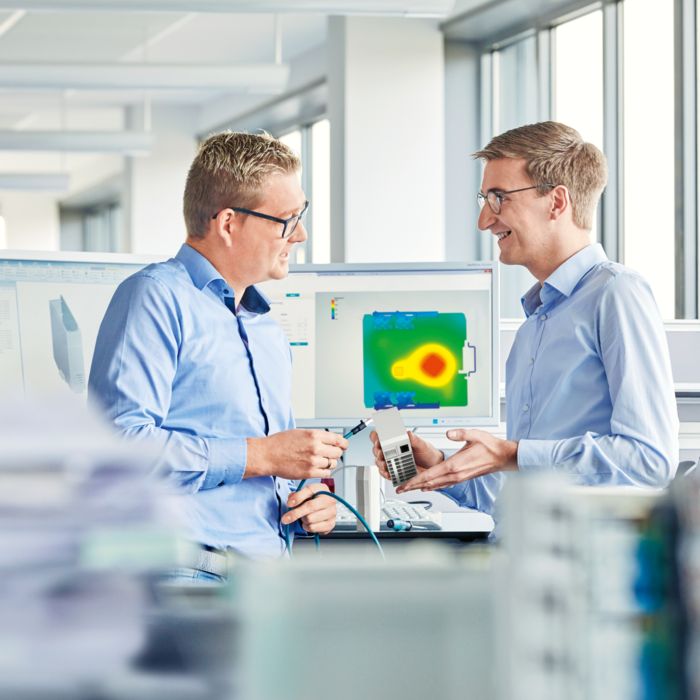

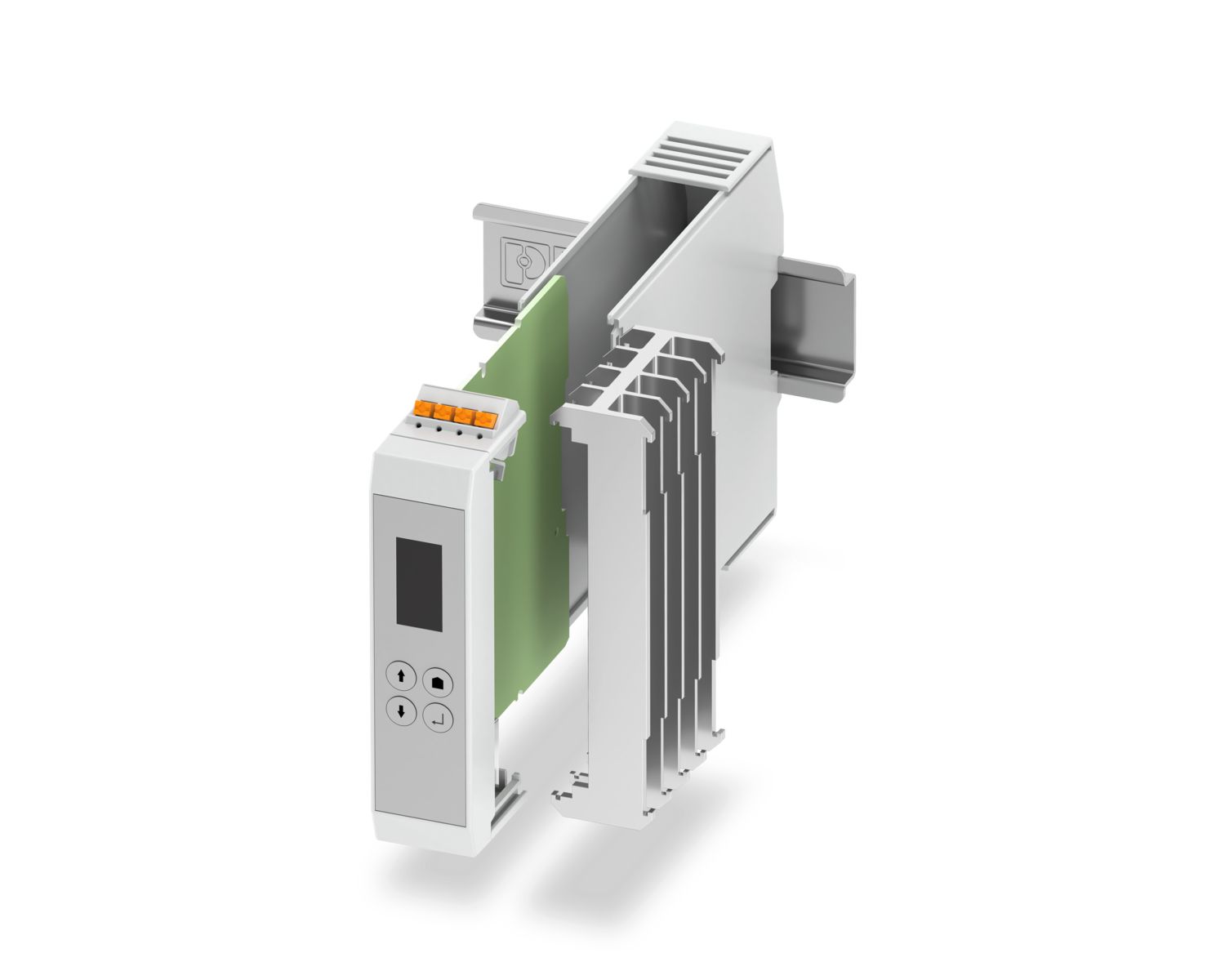

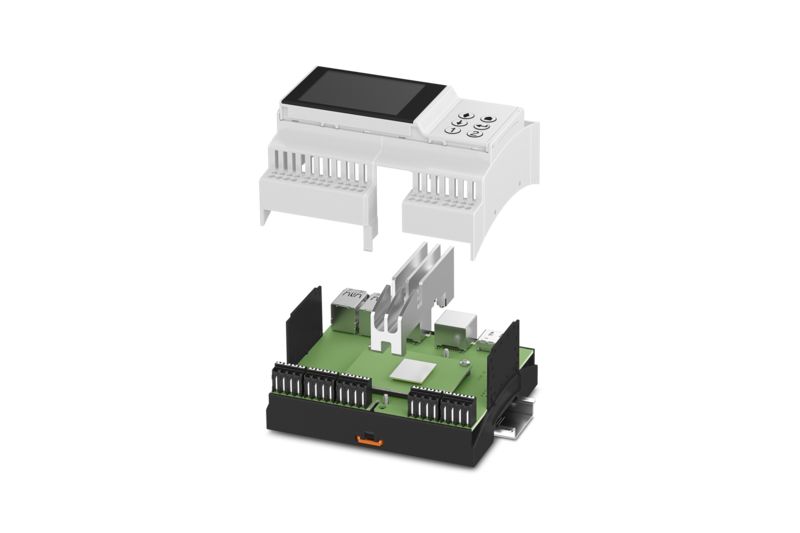

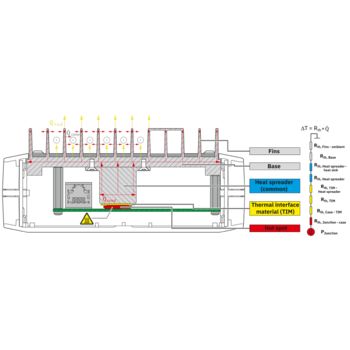

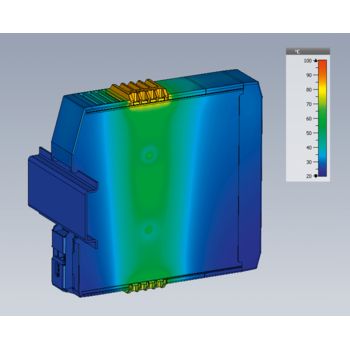

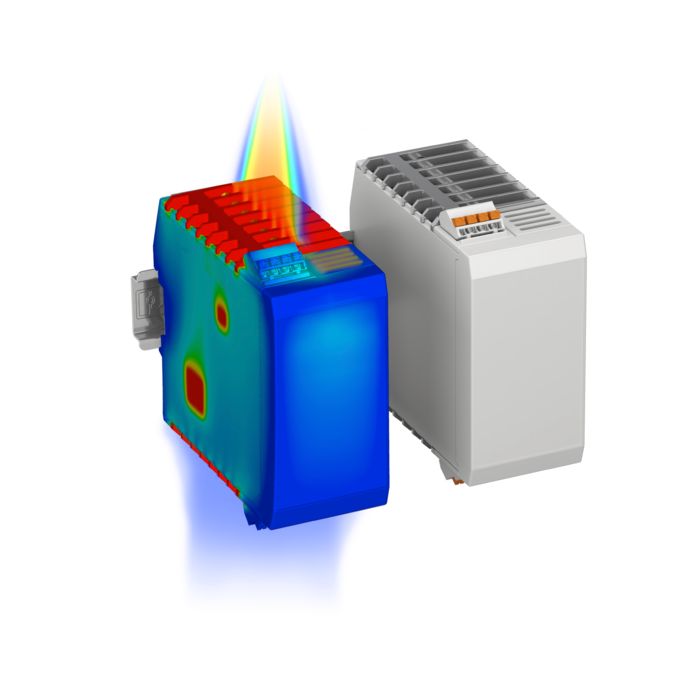

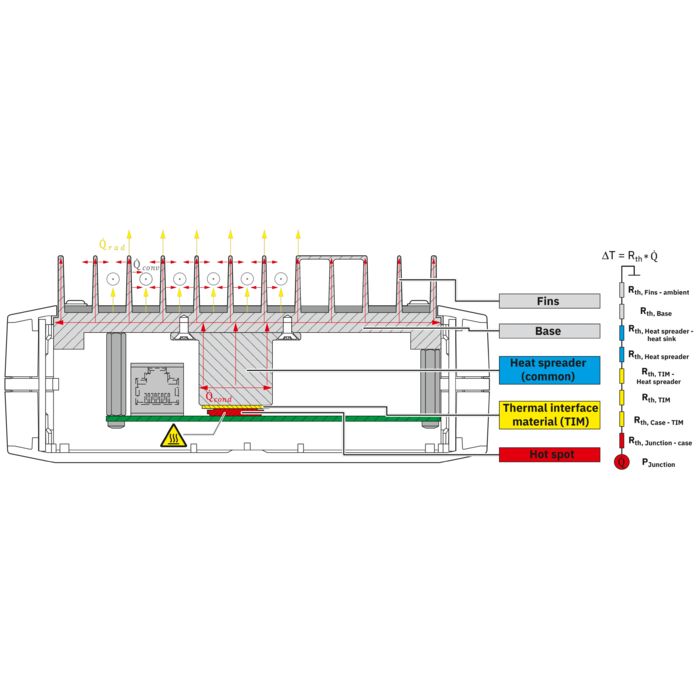

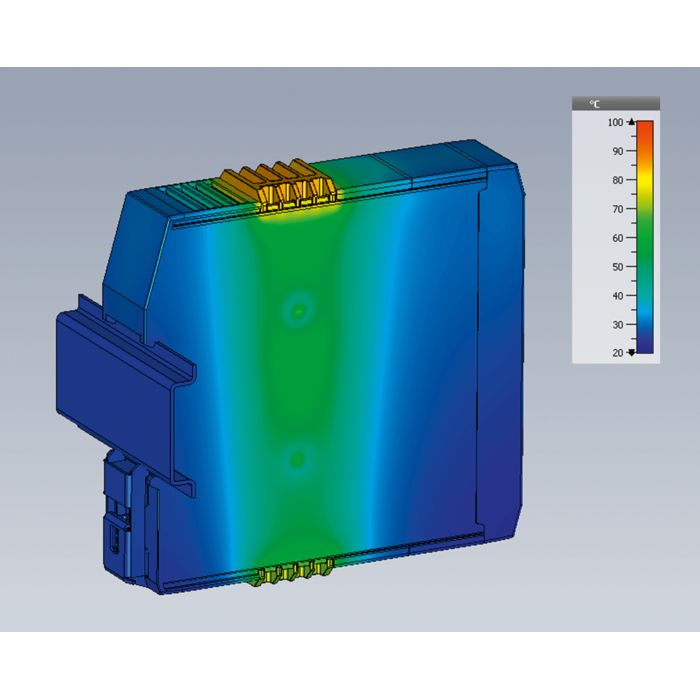

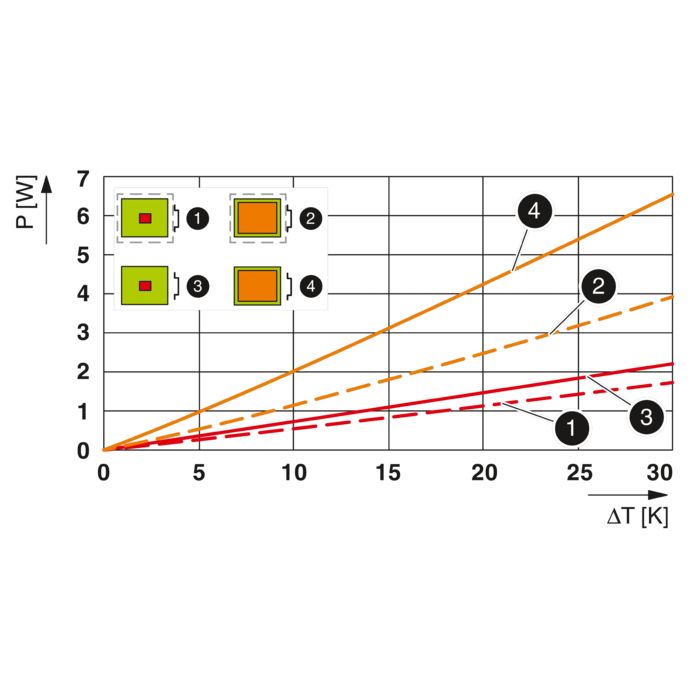

Through the flexible combination of aluminum heatsinks and plastic housings, our hybrid systems provide the ideal solution for the thermal optimization of your devices. The combinable design and coordinated materials enable targeted heat dissipation in various applications.