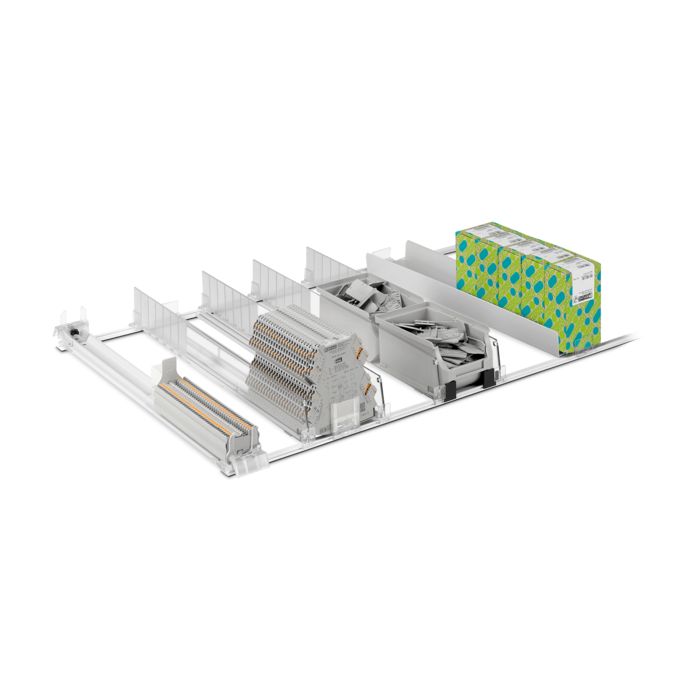

The basic workstation is equipped with a bracket for attaching a terminal board or monitor, for example, and can be positioned flexibly in height. It also has a pull-out drawer below the workbench. The lower area provides space for storing a variety of DIN rails or wiring channels up to a length of 2 m. The brackets already installed on the frame ensure a good hold. Another storage area is also available in the upper part of the workstation.