25 years of CLIPLINE complete

The terminal block system CLIPLINE complete

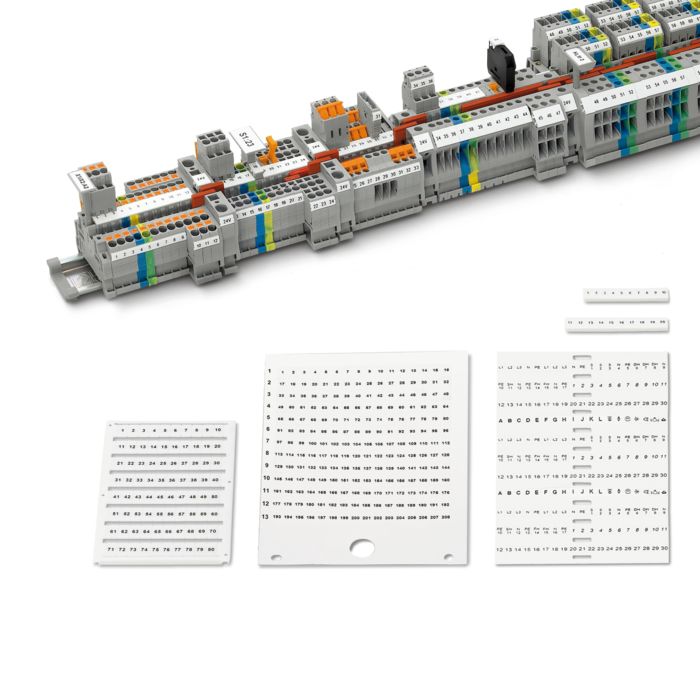

For 25 years, the CLIPLINE complete terminal block system has provided the opportunity to freely and flexibly combine the different terminal blocks. These include feed-through terminal blocks and various function terminals with different connection methods. In addition to the terminal blocks, the system also includes uniform bridge, marking, and test accessories.

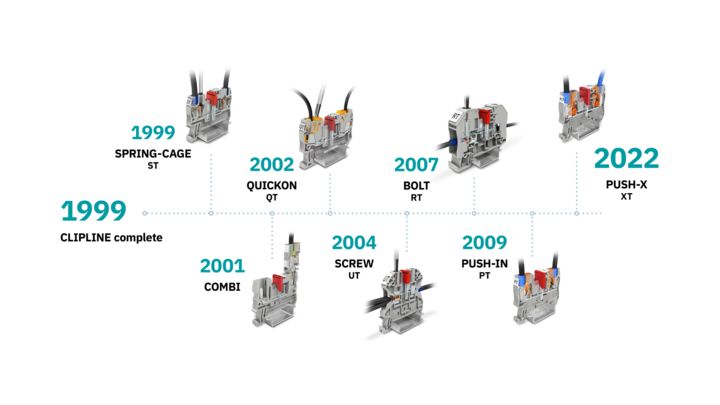

The emergence of the terminal block system The start of CLIPLINE complete

In 1928, we at Phoenix Contact, inspired by RWE, invented the first terminal blocks. In the years that followed, we continued to develop the terminal blocks, which were then still made of ceramic. The ceramic terminal blocks became thermoset terminal blocks in 1953 and were later followed by the first thermoplastic terminal blocks (UK) in 1976. The UK terminal block series was a significant step forward, as the terminal blocks not only met high requirements, but could also be produced in series for the first time. But that was not enough for us. Over time, the cost-effectiveness of products and companies became increasingly important due to internationalization and the initial idea of a comprehensive terminal block system was born. The aim was to be able to combine different terminal block types with identical accessories and thus keep storage and logistics costs to a minimum. In 1999, the ST terminal blocks became the first terminal block series of the CLIPLINE complete system. How has the system evolved? Take a look for yourself and click through the following timeline:

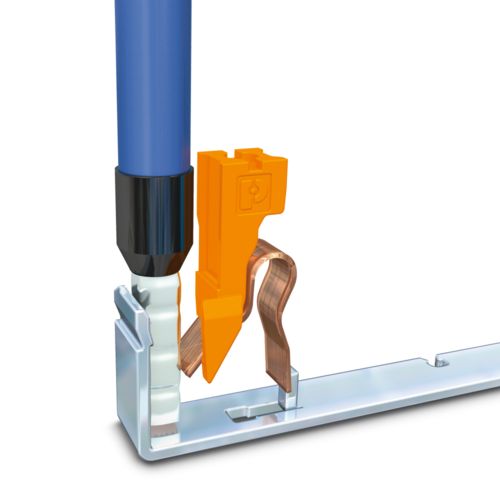

It all started in 1999, when “ST” spring-cage connection technology was introduced, representing the first essential component of CLIPLINE complete.

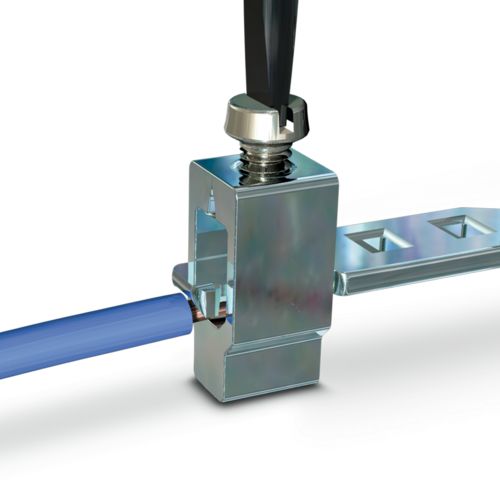

QT was introduced to the market in 2002 and opened the door to the railway industry in France – it still remains the fastest connection technology.

A system requires a high degree of commonality – standardized accessories

Bridge accessories Standardized plug-in bridges – a successful concept

The FBS plug-in bridging system is one of the key factors in the success of the CLIPLINE complete terminal block system. Phoenix Contact thus became the world’s leading terminal block manufacturer. Thanks to the bridging system, various terminal blocks can be connected quickly and easily across cross-sections, functions, and technologies. The standardization of the plug-in bridges also enables customers to reduce storage and logistics costs.

Test accessories Uniform test pick-offs enable fast testing

The test accessories of the CLIPLINE complete system were also standardized and thus contact the current bars in the function shaft across terminal blocks. To test the current flow of an occupied function shaft, the terminal blocks of the CLIPLINE complete system have additional testing options. The spring-cage terminal blocks and QT terminal blocks have a test pick-off for standardized 2 mm test probes, for example, and the screw terminal blocks can be easily tested via the terminal screws.

Marking material for terminal blocks

Marking accessories High degree of clarity for orderly control cabinets

The terminal blocks of the CLIPLINE complete system have standardized marking grooves for holding marking labels. The marking material can therefore be used in the various terminal blocks across technologies, which minimizes both storage and logistics costs. It is only when the cross-section changes and a different horizontal pitch is used that another material is required.

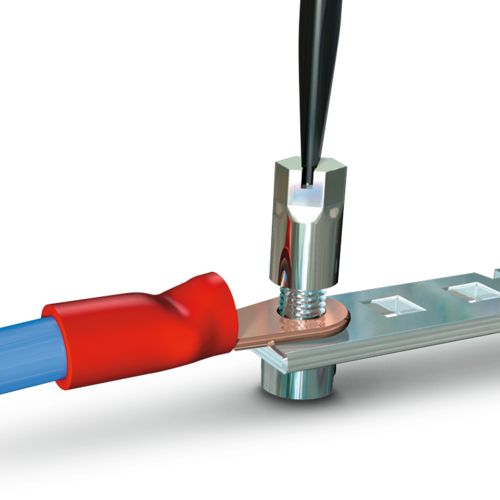

In 2004, the UT family was integrated into the CLIPLINE complete system and revolutionized the already established screw connection technology.

Industries and applications Typical areas of application for the terminal block system

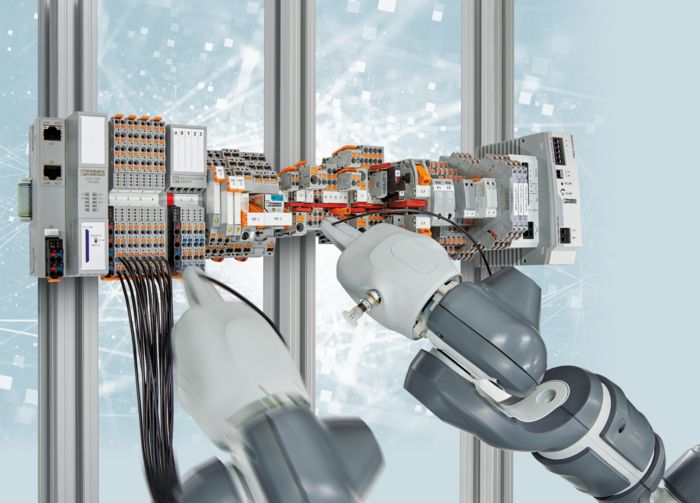

Clever and simple – in 2009, Push-in Technology laid the foundation for tool-free and efficient wiring in control cabinet building.

The future of the terminal block system

Terminal blocks are and will continue to remain an important component of electrification. Of course, certain framework conditions and requirements will change over time, but our products will also continue to evolve. At Phoenix Contact, we research improvements and new technologies every day. We rely on tool-free connection solutions such as Push-in or Push-X technology. We firmly believe that the two spring-cage technologies will be the standard in wiring technology in the future. Why? Both connection technologies offer optimum wiring properties and are suitable for time-saving and effort-saving manual wiring as well as for automated wiring.

In 2022, Push-X became the latest member of the CLIPLINE complete system, thereby shaping the next stage of innovation in control cabinet building.