Ex i NAMUR isolating amplifier, 2-channel. For operating proximity sensors and switches in Ex areas. The signals are transmitted via relay outputs (N/O contact) to the safe area. Line fault detection (LFD), 3-way isolation, SIL 2.

In addition to the standard functions, signal conditioners and measuring transducers for explosion protection guarantee electrical explosion protection for all substance groups and areas in accordance with the relevant standards. Due to the consistent product development and evaluation in accordance with SIL IEC 61508 and PL DIN EN ISO 13849, our signal conditioners and measuring transducers minimize hazards to an acceptable residual risk and ensure the protection of people, machines, and the environment.

Ex i NAMUR isolating amplifier, 2-channel. For operating proximity sensors and switches in Ex areas. The signals are transmitted via relay outputs (N/O contact) to the safe area. Line fault detection (LFD), 3-way isolation, SIL 2.

Ex i NAMUR isolating amplifier for operating proximity sensors and switches in the Ex area. The signals are transmitted via 2 relay outputs (N/O contact) to the safe area. Line fault detection (LFD), 3-way isolation, SIL 2.

Ex i output signal conditioner, HART-transparent. Isolates and transmits 0/4 mA … 20 mA signals with intrinsic safety to a load in the Ex area. 3-way electrical isolation, line fault detection (can be switched off via DIP switch), SIL 2 (SC3) in accordance with IEC 61508, screw connection.

2-channel Ex i NAMUR signal conditioner with wide range power supply for proximity sensors and switches. In terms of signal output, for each channel there is a relay with a changeover contact available. Fault detection (LFD), 3-way isolation, SIL 2.

Ex i repeater power supply and input signal conditioner, HART-transparent. Transmits supplied or active 0/4 … 20 mA signals from the Ex area to a load (active or passive) in the safe area. SIL 2 (1oo1) / SIL 3 (1oo2), wide-range supply.

Ex i solenoid driver for controlling Ex i solenoid valves in hazardous areas, logic input, open-circuit voltage 22.6 V, current limitation at 48 mA, line fault transparency, error message output, up to SIL 3 in accordance with IEC 61508, Push-in connection

Ex i repeater power supply and input signal conditioner, HART-transparent. Transmits supplied or active 0/4 … 20 mA signals from the Ex area to a load (active or passive) in the safe area. SIL 2 (1oo1) / SIL 3 (1oo2), wide-range supply.

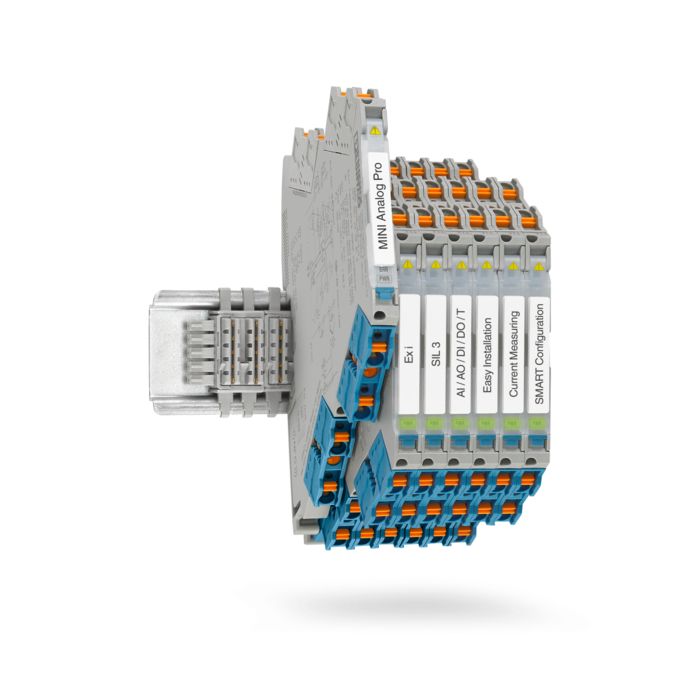

The new Ex i versions in the MINI Analog Pro 6.2 mm signal conditioner family provide explosion protection and functional safety in an unrivaled compact design. With space savings of up to 50 percent compared to current solutions, measurement technology signals are reliably processed while at the same time ensuring the protection of people, the environment, and systems. The products are consistently rated to the highest safety level, SIL 3 one out of one. The operating concept and end-to-end digitalization are particularly user-friendly and future-proof.

This innovative development resulted in the products being honored as the Winner of the GIT Security Award and winning Gold in the German Innovation Award competition.

The right solution for every application

|

|

|

|---|---|---|

|

MINI Analog Pro

Ex i and SIL 3 in an unrivaled compact design in terms of overall width and installed height |

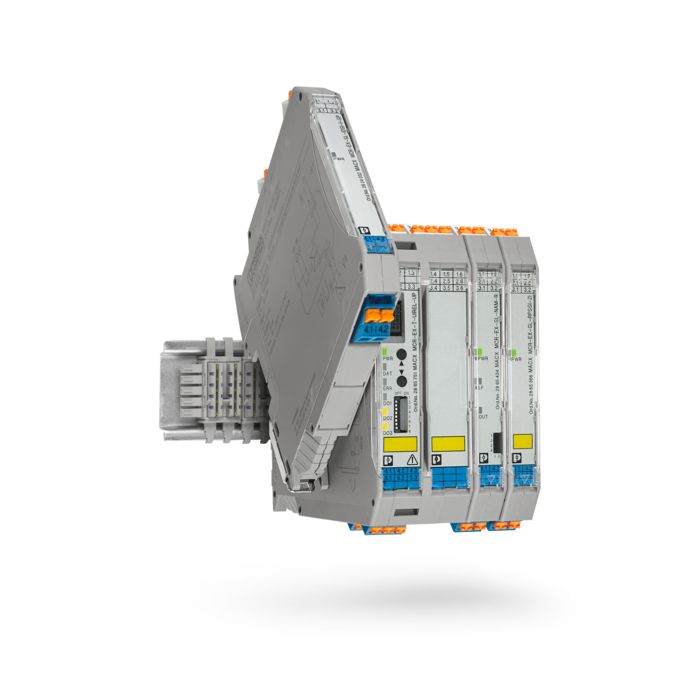

MACX Analog

The proven, comprehensive range of solutions |

|

| Consistent SIL 3 1oo1 functional safety: AI, AO, DI, DO | ||

| SIL 2 SC 3 or SIL 3 functional safety, type-specific: AI, AO, DI, DO | ||

| PL d, PL c functional safety, type-specific | ||

| Two-channel design | ||

| Versions with wide range supply | ||

| Uninterruptible measurement of the current loops | ||

| Ambient temperature range of -40°C ... +70°C without derating | ||

| Gateways for bus and network connection | ||

| Information retrieval via Signal Conditioner App | NFC and QR code | QR code |

The highly compact MINI Analog Pro signal conditioners and measuring transducers combine intrinsic explosion protection and functional safety up to SIL 3 1oo1 in uniquely compact overall width and installed height. In your application, benefit from the particularly user-friendly design and operating concept, the wide range of configuration options, and end-to-end digitalization.

Our MACX Analog-Ex i signal conditioners and measuring transducers offer you a comprehensive range of solutions for safe and reliable signal conditioning. In intrinsically safe circuits, the Ex i versions provide you with explosion protection in all zones and substance groups. The products were consistently developed for safety applications for IEC/EN 61508 and PL EN ISO 13849 to ensure the safety of people, the environment, and the system.

The chemical and petrochemical industries involve industrial processes which produce explosive atmospheres. They are caused, for example, by gases, fumes, or vapors. Explosive atmospheres are also likely to occur in mills, silos, and sugar and fodder factories due to the dust present there. Therefore, electrical devices in potentially explosive areas are subject to special directives, which include the ATEX, IECEx, NEC/CEC, and UL certifications and directives. You will find an overview of the basics of explosion protection here.

As a product-independent service provider, we will help you to minimize safety and liability risks:

Discover other areas of expertise, such as industrial security, CE marking, and occupational safety, on our website or in our “Services for safety and security in the industry” brochure.