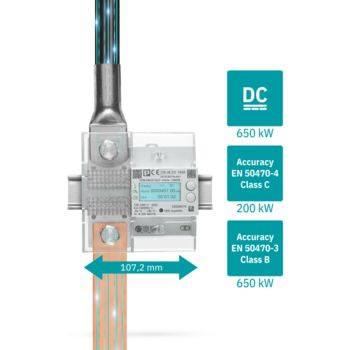

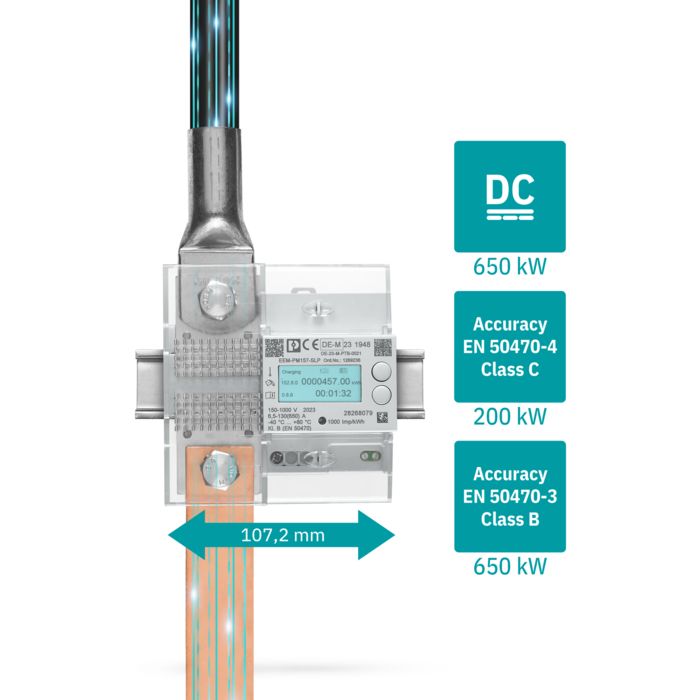

EMpro DC energy meters measure powers up to 200 kW in accordance with accuracy class C (EN 50470-4) and up to 650 kW in accordance with accuracy class B (EN 50470-3).

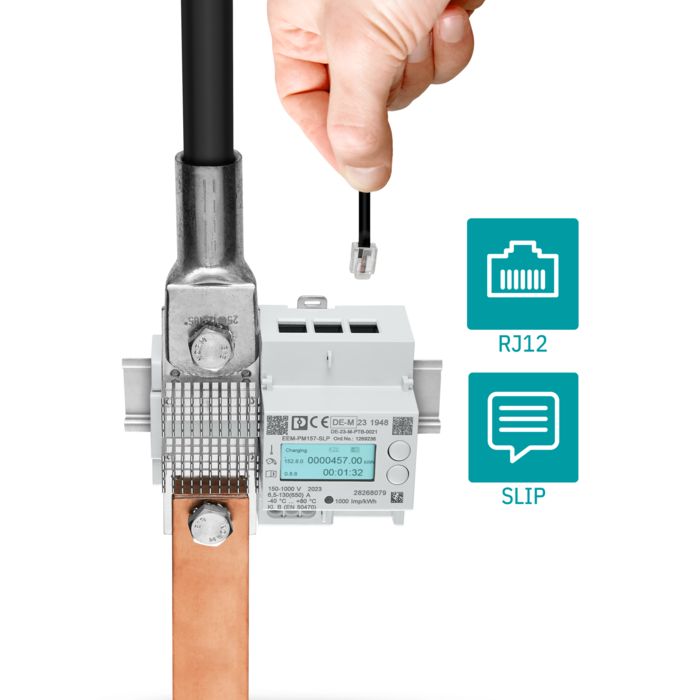

Measurement is performed directly via a shunt, and is also bidirectional depending on the version. The compact dimensions save valuable space in your application.